Heat accumulator for heating boilers: device, purpose + DIY instructions

How to organize the operation of an autonomous heating system in economical mode? It is necessary to install a heat accumulator for heating boilers.As a result, efficiency will significantly increase while fuel costs will be reduced, and the overall cost of maintaining the property will also be reduced.

We will talk about how the unit works, which allows you to collect and store the heat generated by the boiler. We describe in detail all the device options used in everyday life. The article we presented describes the scope of application of heat accumulators and operating rules.

The content of the article:

- What is a heat accumulator?

- Features of internal and external devices

- The operating principle of a heat-saving product

- Types of heat storage models

- Scope of application of the heat accumulator

- Do-it-yourself energy storage device

- Accumulated resource consumption rate

- Rules for safe operation

- Conclusions and useful video on the topic

What is a heat accumulator?

A heat accumulator is a buffer reservoir designed to accumulate excess heat volumes generated during boiler operation. The saved resource is then used in the heating system in the period between scheduled loads of the main fuel resource.

Connecting a properly selected battery allows you to reduce the cost of purchasing fuel (in some cases up to 50%) and makes it possible to switch to one load per day instead of two.

If you equip the equipment with intelligent regulators and temperature sensors, and automate the heat supply from the storage tank to the heating system, heat transfer will increase significantly, and the number of portions of fuel loaded into the combustion chamber of the heating unit will noticeably decrease.

Features of internal and external devices

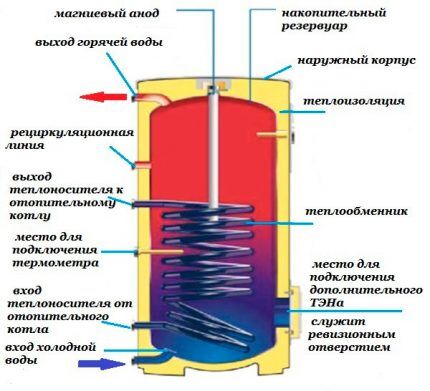

The heat accumulator is a vertical cylinder-shaped tank made of high-strength black or stainless steel sheet.

There is a layer of bakelite varnish on the inner surface of the device. It protects the buffer tank from the aggressive influence of industrial hot water, weak salt solutions and concentrated acids. Powder paint is applied to the outside of the unit, resistant to high thermal loads.

External thermal insulation is made of recycled polyurethane foam. The thickness of the protective layer is about 10 cm. The material has a specific complex weave and an internal polyvinyl chloride coating.

This configuration prevents particles of dirt and small debris from accumulating between the fibers, provides a high level of water resistance and increases the overall wear resistance of the heat insulator.

The surface of the protective layer is covered with a cover made of good quality leatherette.Thanks to these conditions, the water in the buffer tank cools much more slowly, and the level of overall heat loss of the entire system is significantly reduced.

The operating principle of a heat-saving product

The heat accumulator operates according to the simplest scheme. A pipe from a gas, solid fuel or electric boiler is connected to the unit from above.

Hot water flows through it into the storage tank. Cooling down during the process, it falls down to the location of the circular pump and, with its help, is fed back into the main passage to return to the boiler for the next heating.

A boiler of any type, regardless of the type of fuel resource, operates in steps, periodically turning on and off when the optimal temperature of the heating element is reached.

When work stops, the coolant enters the reservoir, and in the system it is replaced by hot liquid that has not cooled due to the presence of a heat accumulator. As a result, even after the boiler is turned off and goes into passive mode until the next fuel supply, the batteries remain hot for some time, and warm water comes out of the tap.

Types of heat storage models

All buffer tanks perform almost the same function, but have some design features.

Manufacturers produce three types of storage units:

- hollow (without internal heat exchangers);

- with one or two coilsensuring more efficient operation of equipment;

- with built-in boiler tanks small diameter, designed for the correct operation of an individual hot water supply complex for a private home.

The heat accumulator is connected to the heating boiler and the communication wiring of the home heating system through threaded holes located in the outer casing of the unit.

How does a hollow unit work?

The device, which has neither a coil nor a built-in boiler inside, is one of the simplest types of equipment and costs less than its more “sophisticated” counterparts.

It is connected to one or more (depending on the needs of the owners) energy sources through central communications, and then through 1 ½ pipes it is routed to points of consumption.

It is planned to install an additional heating element operating on electrical energy. The unit provides high-quality heating of residential property, minimizes the risk of coolant overheating and makes operation of the system completely safe for the consumer.

Thermal accumulator with one or two coils

A heat accumulator equipped with one or two heat exchangers (coils) is a progressive option for equipment with a wide range of applications. The upper coil in the design is responsible for the selection of thermal energy, and the lower one carries out intensive heating of the buffer tank itself.

The presence of heat exchange units in the unit allows you to receive hot water for domestic needs around the clock, heat the tank from the solar collector, warm up house paths and make the most efficient use of useful heat for any other convenient purposes.

Module with internal boiler

A heat accumulator with a built-in boiler is a progressive unit that not only accumulates excess heat generated by the boiler, but also ensures the supply of hot water to the tap for domestic purposes.

The internal boiler tank is made of stainless alloy steel and equipped with a magnesium anode. It reduces the level of water hardness and prevents the formation of scale on the walls.

A unit of this type connects to various energy sources and works correctly with both open and closed systems. Controls the temperature level of the operating coolant and protects the heating complex from overheating of the boiler.

Optimizes fuel consumption and reduces the number and frequency of loading. Compatible with solar collectors of any model and can function as a substitute for a hydraulic boom.

Scope of application of the heat accumulator

The heat accumulator collects and stores the energy generated by the heating system, and then helps to use it as rationally as possible for efficient heating and providing residential premises with hot water.

It works with different types of equipment, but is most often used in conjunction with solar collectors, solid fuel and electric boilers.

Thermal accumulator in a solar system

A solar collector is a modern type of equipment that allows you to use free solar energy for everyday household needs. But without a heat accumulator, the equipment is not able to fully function, since solar energy arrives unevenly. This is due to changes in time of day, weather conditions and seasonality.

If the heating and water supply system is powered only by a single energy source (the sun), at some points residents may have serious problems with the supply of resources and obtaining the usual elements of comfort.

A heat accumulator will help you avoid these unpleasant moments and make the most efficient use of clear, sunny days to accumulate energy. To operate in a solar system, it uses the high heat capacity of water, 1 liter of which, cooling by just one degree, releases thermal potential to heat 1 cubic meter of air by 4 degrees.

During peak solar activity, when solar collector collects the maximum amount of light and energy production significantly exceeds consumption, the heat accumulator accumulates the excess and supplies it to the heating system when the supply of resource from the outside decreases or even stops, for example, at night.

With options and diagrams alternative heating for country property, please read the following article, which we recommend reading.

Buffer tank for solid fuel boiler

Cyclicity is a characteristic feature of work solid fuel boiler. At the first stage, firewood is loaded into the firebox and heating occurs for some time. Maximum power and the highest temperatures are observed at the peak of the bookmark combustion.

Then the heat transfer gradually decreases, and when the wood finally burns out, the process of generating useful heating energy stops. All boilers operate on this principle, including long-burning appliances.

It is not possible to precisely configure the unit to generate thermal energy in relation to the level of consumption required at any given moment. This function is only available in more advanced equipment, for example, in modern gas or electric heating boilers.

Therefore, immediately at the moment of ignition and when reaching actual power, and then during the process of cooling and the forced passive state of the equipment, there may simply not be enough thermal energy for full heating and heating of hot water.

But during peak operation and the active phase of fuel combustion, the amount of energy released will be excessive and most of it will literally “fly down the drain.” As a result, the resource will be spent irrationally, and the owners will have to constantly load new portions of fuel into the boiler.

This problem is solved by installing a heat accumulator, which will accumulate heat in the tank at times of increased activity. Then, when the wood burns out and the boiler goes into passive standby mode, the buffer will transfer the collected energy coolant, which will warm up and begin to circulate through the system, heating the room bypassing the cooled device.

Reservoir for electrical system

Electric heating equipment is a rather expensive option, but it is sometimes installed, and, as a rule, in conjunction with a solid fuel boiler.

Usually electric heating type arranged where other sources of heat are not available due to objective reasons. Of course, with this heating method, electricity bills increase significantly and home comfort costs owners a lot of money.

In order to reduce electricity costs, it is advisable to use the equipment to the maximum during the preferential tariff period, that is, at night and on weekends.

But such an operating mode is possible only if there is a capacious buffer tank, where the energy generated during the grace period will accumulate, which can then be spent on heating and supplying hot water to residential premises.

Do-it-yourself energy storage device

The simplest possible model of a heat accumulator can be made with your own hands from a ready-made steel barrel. If you don’t have one at your disposal, you will have to purchase several sheets of stainless steel with a thickness of at least 2 mm and weld them into a container of a suitable size in the form of a vertical cylindrical tank.

DIY Guide

To heat the water in the buffer, you will need to take a copper tube with a diameter of 2-3 centimeters and a length of 8 to 15 m (depending on the size of the tank). It will have to be bent into a spiral and placed inside the tank.

The battery in this model will be the top of the barrel. From there you need to remove the outlet pipe for the hot water outlet, and make the same one from below for the cold water inlet. Each outlet should be equipped with a tap to control the flow of liquid into the accumulation zone.

The next step is to check the container for leaks by filling it with water or lubricating the welds with kerosene. If there is no leak, you can proceed to creating an insulating layer that will allow the liquid inside the tank to remain hot for as long as possible.

How to insulate a homemade unit?

To begin with, the outer surface of the container must be thoroughly cleaned and degreased, and then primed and painted with heat-resistant powder paint, thus protecting it from corrosion.

Then wrap the tank with glass wool insulation or rolled basalt wool 6-8 mm thick and secure it with cords or regular tape. If desired, cover the surface with sheet metal or “wrap” the tank in foil film.

Holes for outlet pipes should be cut in the outer layer and the container should be connected to the boiler and heating system.

The buffer tank must be equipped with a thermometer, internal pressure sensors and an explosion valve. These elements allow you to control potential overheating of the barrel and relieve excess pressure from time to time.

Accumulated resource consumption rate

It is impossible to accurately answer the question of how quickly the heat accumulated in the battery is consumed.

How long will it work heating system on the resource collected in the buffer reservoir directly depends on such items as:

- actual volume of storage capacity;

- level of heat loss in the heated room;

- outside air temperature and current time of year;

- set values of temperature sensors;

- useful area of the house that needs to be heated and supplied with hot water.

Heating of a private house in a passive state of the heating system can be carried out from several hours to several days. At this time, the boiler will “rest” from the load and its working resource will last for a longer period of time.

Rules for safe operation

Heat batteries made at home with your own hands are subject to special safety requirements:

- Hot tank elements must not come into contact with or otherwise come into contact with flammable or explosive materials or substances. Ignoring this point may cause a fire in individual objects and a fire in the boiler room.

- A closed heating system involves constant high pressure of coolant circulating inside. To ensure this point, the tank structure must be completely sealed. Additionally, its body can be reinforced with stiffening ribs, and the lid on the tank can be equipped with durable rubber gaskets that are resistant to intense operating loads and elevated temperatures.

- If the design contains an additional heating element, its contacts must be very carefully insulated, and the tank must be grounded. In this way, it will be possible to avoid electric shock and short circuit, which can damage the system.

If these rules are followed, the operation of a self-made heat accumulator will be completely safe and will not cause any problems or hassle for the owners.

Conclusions and useful video on the topic

How to correctly calculate the capacity of a heat accumulator for a home heating boiler running on solid fuel. All the nuances and details of the necessary calculations.

How to make a large-volume heat accumulator with your own hands with a convenient and practical removable lid. Step-by-step instructions with explanations.

Why is it beneficial to use heat accumulators in a home heating system? A clear example of cost savings while significantly increasing the level of comfort in a residential area.

Installing a heat accumulator for a home heating system is very profitable and economically justified.The presence of this unit reduces labor costs for lighting the boiler and allows you to add a heating resource not twice a day, but only once.

The fuel consumption required for the correct operation of heating equipment is significantly reduced. The heat produced is used optimally and is not wasted. Costs for heating and hot water supply are reduced, and living conditions become more convenient, comfortable and enjoyable.

Tell us about how you installed the heat accumulator on your boiler. Share the technological details of the process and your impressions of the efficiency of the device. Please leave comments in the block below, post photos, and ask questions about controversial issues.

If there is no stainless steel container or there is no money to make a thermal accumulator from the specified material, then this device can be made from a metal barrel with a volume of at least 200 liters. It is better to use mineral wool as insulation, wrapping the outside with thick foil or thin metal. For such a design, one coil made of a copper pipe is enough; in addition, it can be combined with a heating element. Be sure to install two taps that shut off the water at the inlet and outlet.

I had a problem with this buffer. I wanted to save money on buying it, because ready-made ones are expensive, and when you’re building, money is tight.

I decided to weld such a tank myself. I had pieces of iron, I cut them out as best I could for a ton of water, so that I had a spare. True, the heating technician immediately rejected my product, like rectangular is not allowed, pieces of different sizes are also not allowed. Well, I'm stubborn, I cooked it as I thought. We started filling it, but it tore. And this is without pressure, just the weight of water.

I had to order it from the factory, already in the shape of a barrel, then cover it with insulation and make the filling. But still, it turned out to be more profitable than buying a ready-made one for my volume. There is no need for special beauty in the boiler room.