The washing machine does not take in water: causes of failure and possible ways to fix it

Problems with water supply are one of the most common problems that many owners of washing machines are familiar with firsthand.But although modern devices immediately signal their malfunction with symbols on the display or winking indicator lights, finding the culprit of the breakdown can be difficult.

Therefore, we will look in detail at why the washing machine does not fill with water, what problems you can fix yourself, and when you need the help of a specialist. The repair options we proposed in the article will, in some situations, help restore the washer’s functionality without the involvement of specialists.

The content of the article:

Fault signals for popular models

If water does not flow into the machine at all, the essence of the problem is clear. But sometimes the appliance simply does not receive enough water to fully wash or rinse: we see that the drum is not empty and cannot determine the cause of the problem.

In this case, the signals from the machine itself will help, which are displayed on the display immediately or after starting the diagnostics.

Problem codes with water intake for some popular models:

- Asko – Water inlet fault or E01;

- Zanussi and Electrolux – E10 or E11;

- Candy – E02;

- Ariston, Hotpoint Ariston and Indesit – H2O;

- Samsung – E1;

- LG – PE or IE;

- Whirlpool – F01 or FH;

- Bosch – F01 or Aquastop.

If the washing machine is not equipped with a display, the causes of the malfunction will be indicated by flashing lights on the panel. This code is programmed at the factory, so its meaning depends on the specific model, and a decoding table is included in the product instructions.

Simple problems and their solutions

Most often, problems with water intake arise due to improper operation of the washing machine. And some of them can be eliminated even without replacing parts, without resorting to the services of a repair shop.

Problem #1 - water supply interruptions

If the machine signals a lack of water, the first step is to check the presence of pressure in the water supply. Moreover, if there is water in the tap, the supply valve to the washing machine itself, which is installed directly on the pipe leading to the device, may be closed.

The actions in this case are simple: if the valve is closed, it should be opened, if there is no water, postpone the wash until it appears.

If the pressure is insufficient, the machine may start executing the program, but it will take a very long time to fill the drum and constantly fail at the water intake stage. Therefore, it is better to stop the wash and continue it when a normal flow flows from the tap.

Problem #2 - the inlet hose or filter is clogged

Water is supplied from the water supply to the washing machine tank through the inlet hose. Essentially, this is a long flexible tube with nuts and fittings, one end of which is connected to the device, and the other is inserted into the water supply system.

The hose is made of polyvinyl chloride reinforced with synthetic fibers or steel wire so that it can withstand water pressure, but despite its strength, over time the material may fray and require replacement.

But most often the problem lies in a blockage that blocks the narrow lumen of the tube and does not give the machine full access to the water flow.

To check this guess, you need to disconnect the hose from the machine, inspect the inlet filter and inlet pipe.

Cleaning is done like this:

- The water supply to the washing machine is turned off, if provided faucet for machine, or throughout the entire system. The device is de-energized.

- The inlet hose is removed, washed under good water pressure and inspected for kinks and other damage.

- At the point where the tube is connected to the washing machine, a fine mesh mesh will be visible - this is the filter. It needs to be carefully pulled out with pliers, cleaned with a small brush and rinsed with water.

- To check the operation of the filter, put a mesh on the hose, place it over the bathtub and open the water supply. If the water flows under good pressure, everything is in order.

- At the same time, it is worth inspecting the pipe connecting the hose to the water supply system - it may also need cleaning.

Then you need to install the system in the reverse order, connect the machine and check the water supply.

Problem #3 - the hatch does not lock when closing

When the washing machine door closes with difficulty and without a characteristic click, the locking device does not work, without which the control board will not start the selected mode.

There are several possible causes of failure:

- The hatch cannot close tightly due to damage to the plastic guide, which is located under the tab for fixation. Typically, such a breakdown occurs during long-term use of the machine, when the door hinges weaken due to time or frequent use.

- The niche into which the latch tongue fits may become clogged due to residue from soap products.. In this case, you need to clean it from dirt and rinse it. At the same time, inspect the tongue itself - the rod, which serves as a fastener, could fall out of it.

- The most difficult problem is a malfunction of the board or programmer. If the elements responsible for blocking the hatch on the control device have burned out, you will have to resolder the tracks, replace damaged parts or the entire controller.

But the most common breakdown is door misalignment due to hinges weakened when the device is operated at high speeds or mechanical damage. If the hatch does not close completely, tighten the fastenings or completely replace the hinges.

To do this, you need to remove the front clamp from the cuff, bend the rubber band and tighten the nut connecting the hinges with the washer body with a wrench to avoid turning. Then unscrew the bolt and remove the hatch along with the fastener.

The door itself consists of an internal and external decorative flange, between which there is a “porthole” glass.

To disassemble it, you need to unscrew the fastening screws around the perimeter and carefully separate the elements. Now you can pull out the worn out loop and replace it with a new one, then reconnect the halves with the “original” fastenings.

The device itself that blocks the opening of the hatch also breaks down. You can check its performance using a multimeter.

The lock needs to be removed from the machine, switch the toggle switch to test mode, connect one probe to zero, the second to phase, and then also separately check the neutral and common contacts. If 1 or 0 is displayed, the blocker is faulty and requires replacement.

Failure of individual parts

If a visual inspection and cleaning of contaminants do not give a positive result, most likely the machine is signaling the breakdown of certain parts responsible for drawing water to the required level.

In most cases, you can get by with cleaning or restoring them, but sometimes it is necessary to replace failed elements.

No. 1 - malfunction of the water supply valve

Water flows from the water supply into the washer tank due to high pressure, and this pressure is regulated by the inlet (fill) valve. It works like this: a current is supplied to the coil, creating an electromagnetic field, under the influence of which the shutter opens and allows access to the flow from the water supply.

When the tank is filled, the control module sends a signal to stop supplying energy to the valve winding, causing the valve to lower and block the water.

To inspect the valve, you must first remove it. To do this, turn off the power to the device, remove the inlet hose and mesh, and at the same time wash the filter.

Then open the cover of the machine, disconnect the wiring and pipes from the part and, depending on the type of fasteners, bend the latches or unscrew the bolts. All that remains is to turn the valve and pull it out of the machine body.

Detailed information on disassembling washing machines of different models is presented in this article.

Now you can check the functionality of the element. First, connect the inlet hose to the valve, supply water and inspect for leaks - a working valve will not leak. Then measure the resistance on each coil with a multimeter. A value of 2-4 kOhm is considered normal.

You can also verify the correct operation of the valve by applying a voltage of 220 V to each section in turn: the valve should open, and the de-energized valve should close.

Of course, you can try to give a “second life” to the part by replacing the burnt-out winding, but there is no guarantee of the success of such a repair. Therefore, it is much easier to buy a new valve, because it is inexpensive, and it is easy to change - just assemble the structure in the reverse order.

But if the electronics are working properly, the valve may be clogged or a foreign object has entered it and is interfering with normal operation.In this case, you can disassemble the part and clean it.

No. 2 - breakdown of the pressure switch and replacement instructions

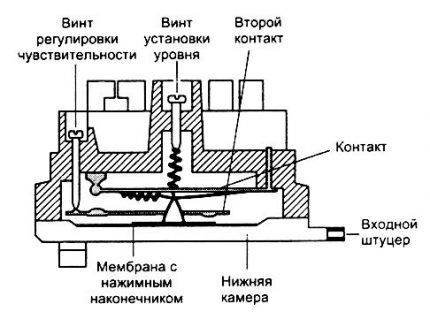

The filling of the tank of the machine is controlled by a water level sensor - a pressure switch. This is a small round-shaped element made of plastic, to which a cable of wires and a tube leading from the high-pressure tank are connected.

It works like this: when filling the tank, pressure is supplied through the tube corresponding to the required water level for each mode, depending on which the relay opens/closes the contacts.

If the pressure switch breaks down, the machine may simply not take in water, refusing to work on the washing and rinsing program, or, on the contrary, constantly drain it without keeping it in the tank.

To check the operation of the pressure switch, unscrew the mounting bolts, disconnect the wires and hose. It is held in place by a clamp, which should either be pressed out with pliers or simply unscrewed.

Then inspect the device itself and its tube for mechanical damage and blockages. If the hose is clogged, it should be removed and washed, and the dirty pressure switch contacts should be cleaned.

If no blockages are found, you can check the pressure switch using a small piece (10-15 cm will be enough) of a hose of the same diameter as the tube removed from the sensor.

To do this, you need to connect one end of the new hose to the sensor input, and blow or immerse the second input in a container of water - clicks will be heard from a working element.

You can also use a multimeter to check - conductivity readings should change as pressure increases.

If the pressure switch fails, you need to buy a new device suitable for your washing machine model. You can check the markings indicated on the part itself. Then connect the tube, insert the contacts and secure the sensor with bolts, that is, reassemble and check the operation of the machine.

No. 3 - board failure or programmer failure

If there is a problem with the control device, the machine simply does not receive the “order” to draw water. The easiest way to fix an electronics failure is to turn off the power to the device for 10-20 minutes, then plug it in and try to restart the desired program.

Perhaps the controller will reboot and the machine will start working. But take note that such a failure is the first bell indicating what’s to come. washing machine repair in future.

Most often, the electronics of a washing machine fail for the following reasons:

- Increased humidity in the roomwhere the device is installed leads to the contacts becoming damp and coming off. You can try to remove and dry the board (even blow it with a hairdryer at low speed) and subsequently make sure that the humidity level does not exceed 70%.

- Water penetration into the control unit. Here a lot depends on the brand and manufacturer of the machine. In some models, for example, Samsung And LG, the “brain” of the device is completely sealed and protected from such troubles, and at the same time Indesit or Ariston The board may become wet during washing or when carrying the device.

- Power surges or low voltage. For the washing machine, you need to provide a dedicated outlet, and connecting through a stabilizer will help level out the differences.

- Kink in the power cord, old socket or plug with faulty contacts – all these nuances must be eliminated and, if necessary, worn parts must be replaced.

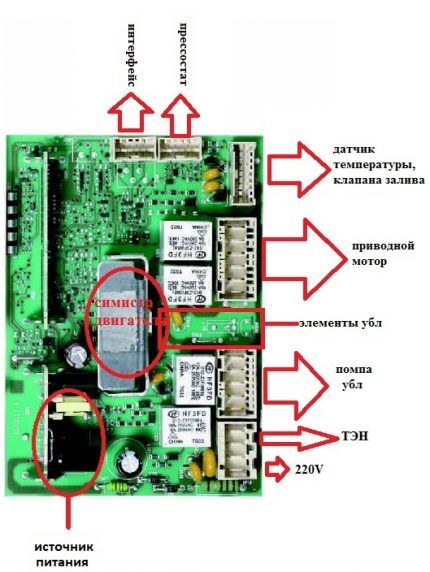

If you suspect a malfunction of the main microcircuit, you need to use a multimeter to ring all the elements that are responsible for controlling the water supply.

The most common problem is the breakdown of the fill valve control triac - the element upon whose signal the machine starts drawing water. But traces and solders can also burn out, and diodes, relays or resistors in the valve control circuit can fail.

A malfunction can be visually identified by the following signs:

- The microcircuit has areas of discoloration, darkened tracks, carbon deposits or marks.

- Burnt varnish coating was found on the damping coils.

- The “legs” of the microcircuit have darkened or marks are visible where the processor is installed.

- The caps of the capacitors have become convex or torn at the cross notch.

If you have experience working with microcircuits, you can try to clean “suspicious” connections using contact cleaning fluid.

If the problem is only carbon deposits or contamination from soap solution, the conductivity of the contacts should be restored.

But if this does not help, you should replace the elements that did not pass the multimeter test, re-solder the burnt tracks and solders, and, if necessary, reflash the board.

Self-repair of electronics is worth undertaking if the warranty period of the device has already expired and you are confident in your skills in working with a soldering iron and multimeter.

But if you have no experience in such “reanimation”, you can completely replace the board with an identical one or contact a service center for help.

Conclusions and useful video on the topic

To get a better idea of the upcoming repair work, we suggest you study step-by-step video instructions about troubleshooting various problems in which the washing machine cannot draw water into the tank.

How to clean the inlet hose filter:

Removing the inlet valve of the washing machine and cleaning it:

Disassembly and repair of the hatch locking device:

Operating principle, performance check and replacement of the pressure switch:

As you can see, most problems with the water intake of a washing machine are quite easy to solve on your own, and components for modern appliances can be easily found on the open market. But if the cause of the breakdown is in electronics, it is better to entrust its repair to an experienced technician.

Have you ever repaired a washing machine yourself? Please tell us what was the reason for the poor water intake, and whether you managed to repair the equipment. We are waiting for your comments, questions and advice on repairs - the contact form is located below.

My LG machine did not fill with water. She blocked the door, but that was all. Called the master. I looked and looked and came to the conclusion: there was a problem with the motor. I changed the motor - nothing changed.I checked the filter on the inlet hose, it may be clogged, but everything is fine with it. I replaced the electronic module and everything worked! We fixed the breakdown for just 4 thousand rubles! It’s expensive to buy a new washing machine, and it’s a pity when the old one is only three years old.

Our washing machine is an older model; it is not smart enough to indicate a breakdown. It just stops working, and you can guess for yourself what happened there. When we were faced with the fact that water was not pouring into the tank, we first checked the water inlet hose, it turned out to be clogged. Yesterday the water flowed poorly all day and was full of impurities, so it silted up. In general, we cleaned it, and everything became normal.

Hotpoint Ariston machine, water is poured in, but much less than needed for washing. After 10 minutes of washing, error H20 appears. I checked the simplest thing - the valves are not blocked, the hose and filter are not clogged. Apparently, you'll have to call a professional. Or is there something else I can watch?

Hello. Error H20 is very similar to the water formula in terms of coding, and the manufacturer resorts to this technique deliberately. It indicates that there is a problem with water filling. The reasons may vary. For example:

1. There is no water supply at all.

2. Water pressure is too weak.

3. The mesh filter is clogged.

4. Incorrect connection of the washing machine due to which self-draining occurs.

5. Problem with the control board.

6. The water inlet valve has failed.

7. Malfunction of the pressure switch.

8. Problem with wiring or contacts.

9. The inlet hose is kinked.

Gennady, I have the same nonsense with my washing machine, tell me, have you already fixed your problem? did you find the cause of the problem? If so, please share your advice, I will be very grateful!

So what happened to the machine please tell me

Look at the pressure switch, it is responsible for the water intake level.

The machine does not draw water and does not lock the door... the filter and hose are clean, what is the reason?

Hello. And here the reason is precisely the door, and not the water inlet. If the door is not locked, there will be no water supply. You need to check the lock on the door or the control board, which cannot issue the desired command. That is, either the door does not close due to mechanical damage or the control board cannot close it (damage, something burned out, a control glitch, a program failure, and so on). What needs to be done... Try switching the washing machine to a different mode and turning it on. If the problem persists, call a technician.

Hello! Samsung diamond is old, about 10 years old. Doesn't take up water on main programs. It doesn't even buzz. After 5 minutes it gives the error “no water”. Only spin, rinse and quick wash work. Do you think the problem is in the “brains”?

The washing machine does not draw water, the door is blocked, the programs are running, but it stands still. What's wrong with it?

Hello. Check the water supply system.

Good afternoon, I have the same problem: “The washing machine does not fill with water, the door is blocked, the programs are running, but it stands still. What’s wrong with it?” and the water supply system is also ok. Whirlpool machine

Hello, my Ardo A600X machine does not draw water and the timer does not work, what is the reason?

Electrolux ews 1046. The sunroof is not blocked. After replacing the drain pump, I passed the test, showed 00, everything was fine and immediately followed by E94. And that's it... The test enters, the diodes blink, the error blinks, the test does not allow the test to be carried out, the hatch does not block. The car is 15 years old... Is it worth repairing?

Good afternoon

Washing machine Indesit WIN 100 CSI. Water does not flow, valves do not work (I changed their connection to each other). The pressure switch is operational. The filter is clean. The door closes UBL. My guess is that the valve activation triacs are faulty. Due to the lack of electrical circuit diagrams for the electronic module, it is impossible to identify these semistors. I kindly ask you to advise me regarding my assumption of the cause of the malfunction and, if it is confirmed, to tell me how to find the triacs for turning on the water supply valves on the board. Thank you!

Hello..Indesit machine. It does not fill with water, and blocks water in the main riser. I hear that it is blocked by back pressure. Thank you.