What to do if the dishwasher does not drain water and stops: deciphering error codes

You loaded the dishes into the home assistant, set the program, the unit started up, and the normal washing process began.But something went wrong - the dishwasher does not drain the water and stands still, and instead of the usual murmur of water, strange sounds are heard or an incomprehensible silence hangs. The situation is unpleasant, but it is not difficult to cope with. How?

In the article, we examined in detail the probable causes of malfunctions, suggested options for eliminating simple and serious breakdowns, and also described how problems in the drainage system of dishwashers from different manufacturers are signaled.

The content of the article:

Standard error codes for popular models

Many modern dishwashers (dishwashers) have a self-diagnosis option. It is embedded in the software module. The machine, using certain algorithms, identifies the failure and displays it on the screen in the form of a specific code.

The depth of such analysis depends on the manufacturer, model, and generation of the control module.

Error codes for some manufacturers:

If the dishwasher does not have a display, flashing sensors will indicate a breakdown.How exactly this will happen depends on the model; usually the explanation of the light warning is given in the instructions.

Some Bosch modifications do not react in any way to problems in the drainage system and continue to wash dishes in used water. The user learns about the breakdown only after opening the door at the end of the program, when he sees that there is water in the tank.

How to reset error codes? There are two ways. The first is to turn off the PMM for 15-20 minutes so that it restarts. The second is to click on “On.” and hold for some time. This resets the user settings and returns them to factory settings.

The principle of water movement in a dishwasher

If other problems can be dealt with after the fact, without understanding the reasons, then the lack of drainage requires a detailed analysis. And the first thing you need to deal with is operating principle of PMM.

The dishwasher does everything almost like a washing machine, only in the process it moves water twice through its cleaning system.

First, coarse filtration occurs, then fine filtration. Average water consumption is 9-12 liters. Savings are achieved through constant purification of the same water. After the filter, the liquid enters the pump and returns to the rocker arm and sprinklers.

At the end of the program selected by the user, the water goes down, and the drainage pump sends it to the sewer system. This does not happen if some element of the drain system does not work correctly or is completely out of order.

Simple faults and their elimination

When the machine does not drain water, there are two answers to the question of what to do - remove physical obstacles in the drainage system or replace the broken part.

At any PMM operating instructions it is written that you should not neglect a simple rule - clean the dishes from food residues before loading them into the chamber. Debris is the main cause of drainage problems.

#1 - kinked or clogged drain hose

A pinched drain hose is a simple but not the most common problem. Check how it is positioned. The part may be bent or pinched by some object. A blockage may form in the pressed area.

It would also be a good idea to press on all the elastic pipes to liquefy the dirt.

To remove the hose and clean it, you need to:

- Disconnect the machine from the power supply.

- Remove the panel from below the door by removing the screws.

- Disconnect the hose from the sewer using pliers to remove the clamp.

- We lower one end of the tube into a bucket (pan) and turn on the drain mode. If water flows from it, the sewer or siphon is clogged (we will consider this case below). If there is no water, the problem is hidden in the machine itself.

- We knock the garbage out of the hose.

- We pass a powerful pressure of water through the tube, for which a garden hose is ideal. The pressure will dislodge any remaining debris.

- You can clean the hose with a long wire, but be careful. To avoid damaging the tube itself, round the end of the wire with a bend.

When the hose is cleaned or you bought a new one, connect it back, replace the clamp and the bottom panel.The tube should be inclined - go slightly up and down from the machine. If everything is in order, look further.

#2 - food residues in the filtration system

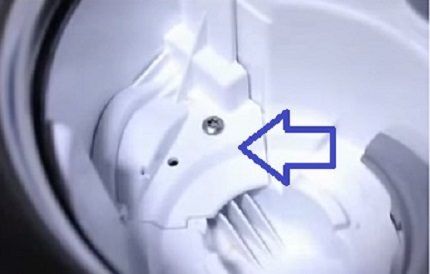

The problem with the drain may be a banal bone that has jammed the filter assembly. If you look into this compartment, on some PMM models you can see a screw, which, when unscrewed, will get to the gear. It gets jammed with small debris. You need to remove everything unnecessary for the gear to start.

Cleaning PMM filters:

- Open the door and take out all the baskets.

- Unscrew the filter cap, which is located at the bottom of the chamber.

- We take out the glass and the mesh.

- We wash both parts. If you can’t do this simply under running water, a toothbrush and detergent will come in handy.

- We unscrew the drain pump cover and check this place for debris. Be careful, not only food remains can get here, but also broken dishes.

After all the manipulations, close the pump and return the filter to its place.

Are you sure everything is ok? Test the machine.

#3 - garbage in the sewer

If water flows from it when you disconnect the drain hose, the PMM is working properly, and the problems are hidden in the sewer. Causes of blockage: impurities in water, corrosion of pipes, dirt and grease washed off from dishes. Minor debris can be removed with ordinary boiling water - it must be poured into the sewer hole.

Several effective ways sewer cleaning:

- Soda + salt. Add soda and salt to a glass of hot water, dissolve it, pour it down the drain, wait 10 minutes and rinse with a running stream.

- Back blow vacuum cleaner. If the household has a vacuum cleaner with reverse blowing, wrap its pipe with a rag and insert it into the sewer hole and turn it on. The method is suitable for light pollution.

- plunger. We use a plunger if its diameter fits the hole.

- Metal cable. Cleaning the sewer special cableby inserting a flexible metal hose into the pipe and turning it. We take the dirt out and rinse the pipe with water. It is dangerous to use this method for plastic pipes.

- Soda + vinegar. Pour a glass of soda into the drain and pour a glass of vinegar, close the hole with some kind of lid.

To dissolve contaminants, you can also use chemicals from the shop.

Do not forget about protective gloves and general caution when working with them - the products can cause harm to your skin and health.

#4 - pump needs to be cleaned

If the PMM is designed in such a way that you can remove the pump yourself, it is better to clean it. Carefully remove the part, having first unscrewed all fasteners, and remove blockages.

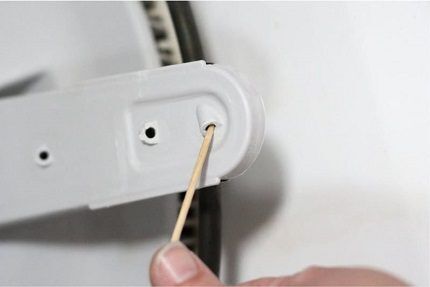

Next you need to check the ease of rotation of the inner impeller.There is no need to do this with your hands; take a handy object - a wooden stick, a pencil, so as not to damage your hands from possible fragments.

If the problem areas are cleaned, we run the machine in test mode. Still problem? Then you should pay attention to a malfunction in the mechanisms of the unit. Let's try to find the type of failure.

Serious situations and ways to solve them

It is important to remember the warranty here. If its period has not yet expired, contact your nearest service center. Almost all manufacturers have representative offices with a hotline. It is better to call and clarify the coordinates of the nearest authorized service center.

Calling a technician to your home is usually free, but they may charge you for replacing the part if the repair is not covered under warranty.

Situation #1 - the pump has failed

The purpose of the drain pump is to remove water from the machine. If it breaks, water will remain in the device until the owner replaces the part. It is easy to determine the malfunction of the mechanism - when the water draining stage starts, the working pump creates a characteristic sound. Silence becomes an indicator of breakdown.

The device has a unique design. The electrical elements of the stator are located outside the boundaries of the impeller and magnet - this way the coils of the device are completely isolated from water. Magnetic induction rotates the rotor with the impeller, due to which the water pumps.

It is advisable to treat the shanks with a heat-resistant lubricant during the process, since the usual composition can be easily washed off with hot water when washing dishes.

How to get to the pump:

- We remove water from the dishwasher manually or by tilting the machine forward.

- We take out the filter.

- We place the unit on the rear panel to remove the tray, which is screwed in with self-tapping screws.

- We unscrew the part itself and remove the hoses.

- Checking the rotation of the impeller. The absence of intermittent rotation is a clear sign that the mechanism needs to be replaced.

- We look at the resistance indicators by connecting the multimeter probes to the contacts on the pump. Normal parameters are within 200 ohms.

When you reassemble the pump housing, replace the gasket or use heat-resistant silicone sealant. Check the wiring leading to the pump as well. If the wiring is in good condition, the pump will have to be replaced.

This part is practically beyond repair. In rare cases, you can get by with lubricating or removing dirt from the impeller. If the pump is completely faulty, we contact the manufacturer’s representative, order a new part and make a replacement - we install a new pump using the reverse disassembly algorithm.

Situation #2 - water level sensor is faulty

It is also called a pressure switch. This is an important part in the dishwasher, which measures the water pressure in the PMM and sends a signal to the program unit. This information is needed for every wash cycle. If the data does not arrive on time, the program crashes and the unit begins to work incorrectly.

According to your device water sensor may have a mechanical or electronic device. Its work is based on the principle of communicating vessels. The sensor tube is connected to the tank in such a way that when drawing in, the water in the tube and tank is at the same level.

When the pressure switch is faulty, water accumulates in the pan and does not leave. The defect may also be in the high-pressure reservoir or the tube connected to the sensor. Causes of failures: natural wear of the part, oxidation of contacts, problems with individual elements (puncture or blockage in the tube).

To get to this part, you need to disconnect the machine from all communications, cover the floor with rags, and lay the unit on its side. There are models that require removing the cover on the bottom or back panel.

Now you need to find a pressure switch; a tube leads from it to a large plastic box - a pressure reservoir. The latter is secured with two bolts. Next, use pliers to remove the tube and the tank itself.

We check this part for contamination and clean it. The functionality of the pressure switch can be checked by blowing into the tube - a working part will make a click, but after a couple of seconds.

Additionally, we check the electrical conductivity of the device with a multimeter. If the resistance smoothly decreases to zero, the sensor is working.

A broken part cannot be repaired - after disassembly it is impossible to put it back together, so it needs to be replaced with an original device purchased from official representatives of the brand. To connect a new device, you need to disconnect all sensors, the pressure tube and put the pressure switch in place of the old one.

Situation #3 - the software module is broken

Repairing or replacing the software module is the most difficult problem associated with restoring the operation of the dishwasher. This part is the “brain” of the entire structure, which performs the function of controlling all processes.

He can analyze washing cycles and issue commands to the components: the pump to drain, the heating element to heat, the inlet valve to draw water. A faulty software module either sends tasks incorrectly or is completely silent.

The reasons for this behavior may be a short circuit, natural wear and tear of the device, or errors in the firmware. In this case, you need to reprogram it or completely replace the board.

When the program files in the control unit module are damaged, an adapter for flashing the EPROM will help. This adapter is selected individually for each model.

If after flashing the machine does not work correctly, this indicates a physical breakdown of the control unit. It is not recommended to carry out this procedure yourself, so as not to worsen the situation.

Most often the block is not repaired. There are very few craftsmen who are ready to identify burnt parts on the board and replace them with new ones. Such manipulations require certain skills and experience. It’s easy to spoil a block, and this is one of the most expensive parts of a PMM.

To better imagine the scale of the upcoming work, we suggest watching video instructions on how to troubleshoot various problems if the machine refuses to drain water.

Conclusions and useful video on the topic

How to replace a drain hose - a step-by-step guide using the Beko PMM as an example.

Tips for checking your dishwasher pump.

Simple problems that we discussed in the first part of the article (kinks in the hose, blockages) can be fixed on your own. More serious faults require specialist intervention, especially in cases where the user does not have the proper experience in repairing household appliances and can further aggravate the situation.

Do you have anything to add or have questions about repairing your dishwasher drain system? You can leave comments on the post, participate in discussions, and share your own troubleshooting experiences. The contact form is located in the lower block.

We have a Bosch dishwasher. It worked for 2 years without any complaints, we couldn’t be happier, but it broke down just a month ago. Stopped draining water, as described here. First of all, I checked to see if the drain hose was pinched, but that was fine, then I checked the sewer system. The water was leaving. It turned out that the drain filter was clogged. Somehow I forgot that I needed to clean it from time to time. Now I keep an eye on this all the time.

I got an i20 error on my Electrolux dishwasher. I checked the hose and filter - there are no signs of blockage. Could there be a problem with the pump? I don't hear any sound when draining, but I've never heard it before. Although maybe he just wasn't paying attention.

Hello. Does the error occur again when you reboot the machine?

In general, you did the right thing by checking the blockage. The only thing is that the blockage can be not only on the filter and drain, but also in the pump or pressure switch. The pressure switch could also be faulty; it needs to be checked for functionality.

They connected me to a new one

Candi built-in dishwasher, it does not drain the water completely and does not complete the wash cycle, the panel does not open. It's damp inside, there are drops on the walls, and there's a little water in the pan, what is it?