Stripping wires of insulation: methods and specifics of removing insulation from cables and wires

There is a protective layer on all wires and cables.Called insulation, it separates conductors from the surfaces they come into contact with, as well as from each other.

If you need to connect or install equipment, you need to strip the wires of insulation in separate areas to ensure good contact in the contact groups.

How to perform stripping so as not to damage the current-carrying conductors, we will consider in this article.

The content of the article:

- The nuances of stripping insulation

- Difference between wire and cable

- Types of insulating materials

- How to strip wires correctly?

- Popular methods of removing insulation

- New tools for removing insulation

- Recommendations for quick removal of insulation

- Tips for Safely Stripping Insulation

- Conclusions and useful video on the topic

The nuances of stripping insulation

When choosing a method for removing the insulating coating, it is necessary to take into account its features. Insulation can be single plastic or multilayer. Resins, fabrics, and non-flammable dielectrics are used as the latter.

The procedure involves the use of sharp instruments. They can damage the wire, damage the insulation where it is not needed, and narrow the cross-section. If you use a tool ineptly, you cannot avoid injury.

To reduce all risks to a minimum, special tools and techniques for working with them have been developed.

Difference between wire and cable

When describing electrical wiring, the term “wire” or “cable” is often used as a conductor of current. To a person uninitiated in the intricacies of electrics, it may seem that this is one product. In fact, they are different.

A wire in the traditional sense is a cord with a small cross-section. Such a conductor can be single or multi-core. It may not have insulation at all, or if it does, it is light in the form of a tube. Removing it is not difficult at all.

The cable consists of a certain number of current carriers. They are connected into one unit, but do not touch each other and are enclosed in a shell made of a special material.

For a single-core wire, the cross-section is determined by one core; for a multi-core wire, the cross-sectional area is determined by the sum of the cross-sections of all cores. To improve the performance properties of the cable, a nylon thread is introduced into the middle.

Any conductor should be handled with care, especially aluminum conductors. Compared to copper, they are more fragile. Bending loads reduce the already small margin of safety of aluminum cores.

Some characteristics for comparison:

- density of aluminum - 2.7, copper - 8.9 t/mᶾ;

- multi-wire design is excluded for aluminum, but possible for copper;

- resistivity of aluminum is 0.0294, copper - 0.0175 Ohm x mm²/m.

Damage during stripping of aluminum cores further reduces their performance.

More details about the types of cables and wires can be found in this material.

Types of insulating materials

There are single and double insulation.

For its production, various insulating materials are used:

- Plastics based on organic compounds. These are mainly thermal plastics that soften when heated. When burned, these plastics release various toxins into the environment.

- Thermosetting plastics. They become harder when heated. Insulation made from them is used only in special cases when the requirements for it are increased.

- Natural or artificial rubber of different types. It hardens when heated and supports combustion.

- Fabric based insulation. Withstands a fairly high degree of heating (maximum 400⁰) while maintaining insulating properties.

- Shielding braid. This is not insulation in the literal sense, since the braid does not act as insulation, but it provides protection against mechanical damage.

- Armor braid. Also serves as protection against damage

The choice of tools for removing insulation depends on the material from which it is made.

How to strip wires correctly?

There are some nuances in this process, without knowing which you can make mistakes with irreversible consequences.

The stripped area should not protrude beyond the joint. If a bare wire is left exposed, a person may accidentally touch it and suffer an electrical shock.

The insulation from the core must be removed from all sides. Compressing the remaining insulation will reduce the reliability of the fastening.

Improper stripping will result in short circuits and even fire.

Popular methods of removing insulation

Practical skills play a big role in the process of stripping wire insulation. The main difficulties arise when working with thin wires, when every movement matters. Optimal pressure can only be achieved through practice.

The most commonly used methods for removing insulation are:

- using a knife;

- through side cutters;

- under the influence of high temperature;

- using a stripper.

Each option is preferable in specific circumstances.

Option No. 1 - using a knife to cut insulation

At home, a knife is most often used. When using this simple tool, it is important to choose the correct angle of the blade. The biggest mistake is cutting in a circle while keeping the cutting part perpendicular. In this case, it is difficult to avoid notching the core or breaking the secondary insulation.

The correct position of the knife is when the tool and the wire axis are in the same plane. First, cut the braid along the conductor. Next, separate the insulation, take it to the side and finally cut it off at the base.

It is better to use a special electrician’s knife with a straight or curved blade to remove hard insulation from wires. The main thing is that there are no jagged or burrs on it. If the knife is folding, it must be equipped with a lock so that it does not fold spontaneously.

A good blade has a double-sided sharpening at a slight angle and an internal rounding of the cutting edge.Some versions of mechanic's knives have a special blade design - it is short and rounded inward, and there is a “heel” at the end. It limits the depth of cut, which is important if it is necessary to remove the top layer of insulation without damaging the sheath of individual cores.

Option No. 2 - side cutters for stripping insulation

Side cutters are a convenient and safe tool, but only if used correctly. What you need to pay attention to is the direction of the cutting edges and the force applied.

The tool is used in two ways:

- The sheath is cut from different sides, and then removed from the conductor. This method is suitable for working with wires with a large cross-section.

- The braid is fixed and cut through with the cutting edges of a side cutter, and then pulled to the side, making axial movements.

In any case, you need to act extremely carefully, otherwise the conductor will be either damaged or bitten off.

They also produce side cutters with notches for conductors of a certain diameter. This simplifies the use of the tool at home.

Following the recommendations will minimize the risk of biting the core. Also, proper use of the tool will free you from the use of large compressive forces.

Option No. 3 - thermochemical removal method

With very thin conductors, with a cross-section of less than 0.2 mm, removing the insulation from an enamel wire or a wire with PVC insulation mechanically is a big risk. The thermochemical method is more suitable here.

In the first case, the technology is as follows:

- The wire is conveniently laid on a flat surface.Vinyl chloride insulation is placed under it.

- Heat up the soldering iron tip and carefully move it along the shell. When heated, it will disappear under the influence of the released chlorine.

There is another option for removing the enamel insulation from the cable. An aspirin tablet is placed on the wire, heated with a soldering iron and distributed along the entire length. Not only will the insulation be removed, but the wire will also be tinned.

Removing the braid by reflowing ensures the integrity of the conductor. The method works well on old wiring, since the winding here is hard and brittle.

Stripping the insulation of a thin enameled conductor can be done using fine sandpaper. Before removing the insulation layer from the wire, the sheet is bent in half so that the sandpaper is inside. Place the wire in the middle, lightly press it with your fingers and pull. Repeat the action until the enamel is completely cleansed.

Option No. 4 - stripping with a stripper

If the insulation stripping methods under consideration are manual, then some types of strippers allow this work to be partially mechanized. The tool most often consists of special pliers that work with a certain size of wires and cables.

Conventionally, strippers are divided into categories:

- miniature handheld;

- large rack;

- lever

The first ones look like clothespins. It has one or more holes in its spring-loaded jaws. There are small multifunctional strippers in a case-like form. The drop-down body has holes with knives for different sections of wires.

In addition, the device has a knife that cuts the braid longitudinally, a knife that works in the transverse direction or cuts circularly. They are also equipped with a retractable knife for stripping wires.

The next design is a stripper with levers. Visually, the tool is similar to scissors and includes:

- Knives with a wedge-shaped cut;

- Adjusting screw, with its help you set the desired cross-section.

The cable is secured with clamps, then the levers are pulled together and the insulation is removed instantly. The removal length is set manually. The main disadvantage is the need for adjustment when removing insulation from wires of different sections.

If you mistakenly insert a thick wire when setting the jaws to a smaller cross-section, the conductor will be damaged.

In addition to the main functions, most of these hand tools are used for crimping the ends of stranded wires, cutting wires, and cutting bolts. Sometimes they are used like simple pliers.

A tool with sockets in the blades, like the previous one, is universal. When working with it, you must not relax your attention so as not to place the current conductor in a hole that does not correspond to its cross-section.

These disadvantages are not typical for automatic lever strippers. The wire size is set automatically here. The spring-loaded working element begins to operate when the handles are compressed. You can remove not only the insulation from the core, but also the outer braiding from a round or flat wire.

Many models are equipped with a length limiter that allows you to remove the braid to a set length.The required limit is set once, and further withdrawals occur based on the set limit.

Automatic models, like manual ones, may have additional functionality - crimping tips, cutting, etc.

When choosing a stripper model, you need to proceed from where you plan to use it. For normal work at home, a simple hand tool will do.

When working with a lot of wires and cables, it is better to arm yourself with a semi-automatic or automatic device. This tool is essential for professional electrical installers.

There is an article on our website where we talked in detail about strippers for stripping insulation from wires. Go to link to familiarize yourself with the material.

New tools for removing insulation

Relatively recently, the range stripping tools added four new products:

- plow knife for removing hard insulation;

- stripper for cutting insulation 2.9 - 6.6 mm² in the longitudinal direction;

- tool for working with wire insulation 0.05 – 2.5 mm²;

- tool for cutting wire insulation 0.25 – 6 mm².

All of them are produced by the US company Jonard Tools.

The new case-type stripper is equipped with five grooves with a diameter of 2.9 - 6.8 mm. There are blades on both the top and bottom. Cuts lengthwise wires, optical modules, protective tubes.

The stripper for removing the PVC insulating layer from cables with a diameter of 0.05 - 2.5 mm² is automatically adjusted to the required cross-section. When pressure is applied to the handle, the conductor is grabbed, the blades enter the insulation and tighten it.

The latest model is similar to the previous one, but works with wires of other sections.

Recommendations for quick removal of insulation

There are non-standard situations from which it is difficult even for a specialist to get out. In this case, you have to make creative decisions and use the tools at hand. Let's look at a couple of examples.

Example No. 1 - damage to the wires leading to the plug

The method is used if, upon visual inspection, it is discovered that the charger has faulty thin wires leading to the plug. The main difficulty of the situation is not only the small cross-section, but also the multi-core cable. Another problematic point is that the wires are enclosed in a continuous braid, so the insulation serves not just as protection, but as a two or three-chamber collector.

To quickly remove the insulation in this case, experts use a thin blade taken from a razor cassette. The cable is secured using a clamp from a table lamp or a vice. The cable is divided into cores, and a blade is used to carefully make an incision in the right place, not too deep. Next, part of the layer is pryed off with a fingernail and carefully removed.

Example No. 2 - removing protection from a cable in a busy area

There is a need to remove cable protection in a loaded area of electrical networks.

First, using a tool, the outer sheath is removed by cutting it along the cable. Then, using pliers, the cores are removed one by one. The remaining insulating layer is simply cut off.

Tips for Safely Stripping Insulation

Electrical work is not easy. Therefore, even if you have certain knowledge, you must not forget that the damaged core will eventually fail.

For safety reasons, when removing insulation that is slightly longer than required, the excess must be cut off. Exposed veins are too dangerous.

It is not advisable for a home handyman to purchase expensive tools in order to use them several times while removing insulation. In most cases, simple means at hand are quite suitable.

When working with a tool, you need to be extremely careful and attentive. The insulation should be pressed down slowly to avoid damage to the cores.

Microscopic damage to the conductors is invisible, so it is better to do everything slowly, but correctly, so as not to have big problems later.

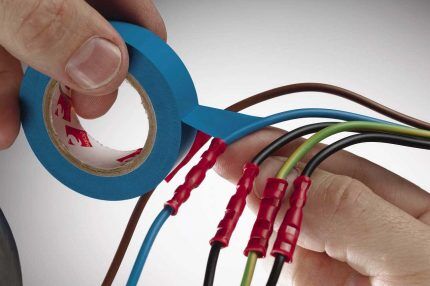

To ensure reliable and safe contact, you need to use special terminal blocks.

Contact when installing a piercing clamp will ensure the insulation is pierced. Sometimes that's enough.

Conclusions and useful video on the topic

An overview of stripping tools - from the cheapest to the most expensive:

Whatever method you use to strip the insulation, you must remember that this work is dangerous.A careful and competent attitude to the tool used will help you avoid problems. Each product must be used in accordance with its intended purpose, with the utmost care.

What method do you use to strip insulation from wires? Please share your own experience with people who are faced with this task for the first time. Leave your comments, share your experience, ask questions in the block below the article.

I don't know much about wires or electronics at all and it was very helpful to start with the very basics. Thanks to the author, I thought they don’t write about such simple things, since everyone already understands.

Anton, you also need to know simple things. You'd be surprised how many people who consider themselves electricians do it wrong.

effective way

UTP 1.0 220V. Thermal wire stripping device Magister 1.0 220V

Well, of course, it’s limited by the cross-section within. But nevertheless, installers use these in production.