Types and characteristics of couplings for polypropylene pipes

Polypropylene pipes are connected to each other with fittings. These are the necessary parts for arranging a functional system.A coupling for polypropylene pipes connects the pipeline into a straight line. This connecting element provides a sealed and reliable joint that can withstand both loads (temperature, pressure) and active exposure to aggressive environments.

The content of the article:

Specifications

Couplings for welding polypropylene pipes are made of the same material as the pipes themselves. That is, made of polypropylene. Therefore, both products have the same technical characteristics.

Basic:

- Density – 0.9 g/cm³.

- Hardness – 40 N/mm².

- Tensile strength – 40 N/mm².

- Elastic modulus – 800 N/mm².

- Kinematic viscosity – 420-500 cm³/g.

- Thermal conductivity – 0.24 W/m C.

Fitting withstands all loads to which the highway may be subjected. Hence the advantages:

- high strength of the product;

- resistance to all active and aggressive environments, which makes it possible to avoid corrosive processes;

- the passage of the fittings is maintained due to the fact that their internal diameter does not decrease during operation due to salt and mud deposits;

- lack of electrical conductivity, which ensures safe operation of both couplings and polypropylene products;

- excellent sound insulation;

- low thermal conductivity, allowing to reduce heat losses of the line;

- withstands temperatures up to +95°C (short-term +110°C), which makes it possible to use fittings in heating systems, hot water supply;

- low specific gravity;

- ease of installation at the connecting joint of two polypropylene pipes;

- service life more than 50 years.

Polypropylene couplings are more expensive than many other connecting elements. But they are cheaper metal analogues. Their quality is high due to the production technology used, which is based on polypropylene extrusion (when molten raw materials are fed into molds under high pressure). Hence not only the quality, but also the exact dimensions. All this makes it possible to use fittings in various engineering networks.

Where are they used?

Polypropylene couplings can be used in the following engineering systems:

- water supply – cold, hot;

- heating – radiator, heated floors;

- conditioning;

- pipelines at industrial facilities through which various liquids move, including aggressive ones;

- melioration and irrigation networks;

- drainage.

Classification

The pipe line is not necessarily elements of the same diameter, made of polypropylene. There are many options when it is necessary to connect products of different materials and diameters into one network.

Today, several types of polypropylene couplings are produced, with the help of which pipe sections with diameters of 20-110 mm are connected.

Classification and features:

- if products of the same diameter are connected - straight couplings;

- for structures of different diameters - transitional;

- installation of pipelines made of various materials, e.g. steel and polypropylene – combined models are suitable.

According to the type of connection, such connecting elements are divided into:

- detachable;

- one-piece.

By connection option:

- welded;

- compression

By functional features:

- repair;

- connecting;

- protective.

To connect the first two options (direct, transition) they use soldering technology, for which they use a special tool - soldering iron. Such couplings can withstand pressures up to 2.5 MPa and temperatures up to +95°C.

The marking must indicate the diameter. If this is a transitional model, then two indicators are noted. For example, MP 40x32. That is, with the help of this element you can connect polypropylene pipes with a diameter of 40 and 32 mm.

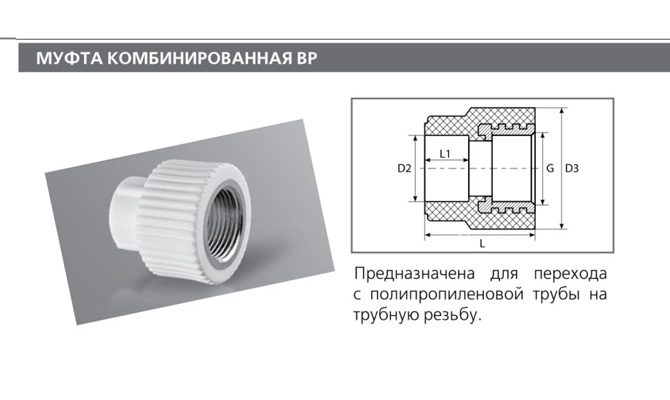

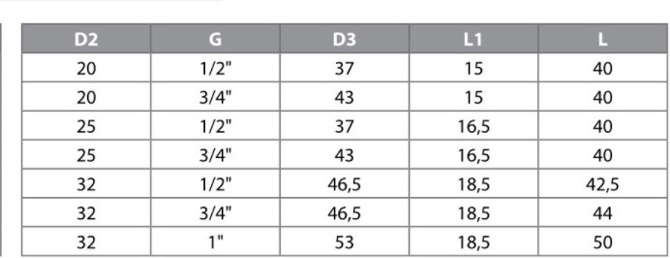

Combined models allow you to connect pipes made of polypropylene and other materials. They are also suitable for joining with shut-off valves. For this purpose, a steel thread is inserted into their design. It can be external or internal.

It is the ability to connect steel and polypropylene elements with each other that is the advantage of combined couplings for polypropylene pipes.

Distinctive features of the “American”

American is a common name for a large number of detachable couplings. These are the elements that can disconnect the pipeline if necessary. Such couplings installed on the connection are used repeatedly, which is their great advantage over other types.

American advantages:

- ease of assembly and disassembly of pipelines;

- high speed of installation work;

- compactness of the connection;

- design versatility - you can connect pipes with both external and internal threads;

- possibility of repeated use;

- when disconnecting there is no need to twist the pipes, cut them;

- the length of the coupling and the thickness of the seal do not complicate the process of connecting and disconnecting, as is usually the case with joints;

- high tightness due to the installed gasket.

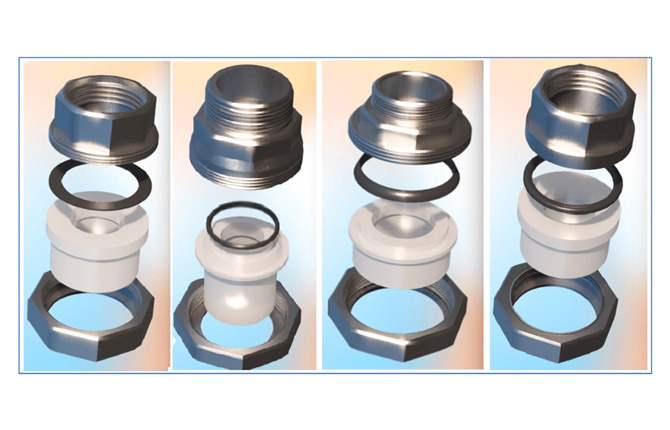

American consists of two fittings that are installed at the two ends of the connected pipes or a pipe and another element of the line, for example, a heating radiator. There is a gasket between them. And also a hex-type clamping nut, which compresses the two fittings, forming a tight and airtight connection.

Types of American women:

- For joining steel pipes to each other or to plumbing and heating equipment. It is completely made of steel. Two threaded fittings. Both threads can be internal or one external, the other internal.

- For connecting polypropylene pipes with other elements. In its design, one of the fittings is provided with a pipe. It is connected to a polypropylene pipe using a direct or transition coupling.

- Cone model. Here, one of the fittings is bored to fit a cone, the second has a straight configuration, but the seat in it is bored to fit an internal cone. This connection creates a 100% tightness, so fittings of this type do not use a sealing gasket.

There is another classification of American women, which is based on the connection configuration. Depending on this factor, they can be straight or angular. The first connect pipes located on the same straight line. Second, if it is necessary to join elements at an angle of 90°.

Installation features

Everything will depend on which coupling is used for joining. The easiest to install are straight and transitional. To use them, you need a soldering iron with tips of different diameters. Usually there are two of these: a drone for pipes, a sleeve for couplings.

The soldering iron is heated to a temperature of +260-270°C, after which the joint elements are inserted into the nozzles. They are heated for 15 seconds, then the coupling is placed on the polypropylene pipe.The joint is strong and airtight.

The free end of the coupling is connected to the second pipe in the same way.

If it is necessary to assemble a water main under cold water temporary type, or in which water will move under a pressure of no more than 1 atm, then compression couplings can be used to connect polypropylene pipes.

Such fittings are a pipe or an angle with union nuts installed on both sides, and cone-shaped gaskets between them. During the installation process, the joints are sealed, and the assembly itself is carried out quickly without the use of tools. The coupling itself is made of low-density polyethylene.

Working with an American one is a little more difficult, because the threaded connection requires good sealing. To do this, use FUM tape or thread, which is wound in the direction of twisting the fitting. Here it is important to accurately select the number of turns of sealant.

Each fitting is connected to the pipeline elements separately. A gasket is inserted between them. Then the nut of one fitting is screwed onto the thread of the other. You cannot press it too hard, so as not to flatten the gasket. Therefore, the clamp is carried out by hand.

An important component of installation is the precise adjustment of polypropylene elements at the area where they are connected. Other features:

- the temperature at which it is best to carry out installation is not lower than +5°C;

- Do not use gas or adjustable wrenches when working with polypropylene pipes;

- do not carry out any aggressive actions with polypropylene - heat, cut threads, bend, etc.;

- The tool used must be in good technical condition and clean.

Couplings for polypropylene pipes are one of the best options for ensuring the most airtight junction of the main line. The presence of detachable structures in the model range makes it possible to simplify repair work on systems of any type.

Have you used similar elements when arranging a pipeline at home? Write in the comments. Share the article on social networks and save it in bookmarks so as not to lose it.

We also recommend watching selected videos on our topic.

What is “American” in plumbing?

Polypropylene pipes: types, fittings, components, pipe soldering.

Sources:

- https://santehstandart.com/poleznye-materialy/mufty-dlya-polipropilenovykh-trub

- https://dispetcherdoma.ru/ustanovka/mufta-dlya-plastikovyh-trub.html

- https://spark-welding.ru/montazh-i-remont/mufty-perehodnye-polipropilenovye-razmery.html

If you connect a PP pipe to a radiator, faucet or other device, then an American pipe is the best option. I unscrewed the nut, removed the radiator, repaired it or bought a new one, and installed it again. Fast. The only downside is that the gasket sometimes starts to leak.

It also begins to leak when the hot water in the system begins to cool. This is especially true for radiators and boilers. You have to twist it to get it tight.

Install a cone, and the problem will be solved once and for all. It's true that it's more expensive.