How to make a pool with your own hands: step-by-step construction instructions

Sitting near a private house or cottage in the summer heat, you probably imagined how cool it would be to plunge into the cool water of your own pool. You probably immediately drove away the thought of its construction, but it persistently returned and literally haunted you on hot days. Maybe we shouldn't give up on such an excellent idea?

After all, you can build a simple pool with your own hands, investing a minimum of money in the construction. And in this we are happy to provide you with effective assistance by providing full information support. Here you will learn about the types of artificial reservoirs and the features of choosing a location for the bowl.

We have collected for you popular design options and technologies for their construction. The detailed description is supplemented with explanatory diagrams, step-by-step photo instructions and videos.

The content of the article:

Planning and design selection

We should start, of course, with the project. First you need to assess the condition of the site, decide on the location where the pool will be located, select the size of the tank, bowl configuration, etc.

An important point is the level of occurrence of the first groundwater horizon from the surface in the area. If this figure is less than one meter, i.e.groundwater lies high, it is not recommended to build a permanent pool in a pit.

As an alternative, you can consider installing a portable frame or inflatable model.

Choosing a place for building your own pool, the following recommendations from experts should be taken into account:

- The pool should be located at a sufficient distance from a residential building and other buildings, since the close proximity of these structures can have a destructive effect on the integrity of the building’s foundation.

- It is not advisable to locate the pool in close proximity to trees or plant them later, so that the root system, attracted by a large amount of moisture, does not grow and destroy the frame of the structure.

- The presence of a large number of trees near the pool also increases the intensity of its pollution with foreign debris and stimulates the growth of algae.

- Clay soils are best suited for constructing a pool; they serve as an additional barrier to ground moisture; if you have a choice, just such an area should be allocated for the pool.

- Digging a large pit by hand is an extremely labor-intensive task; it is better to choose a place to which construction equipment can be brought: an excavator, a concrete mixer, perhaps a crane, etc.

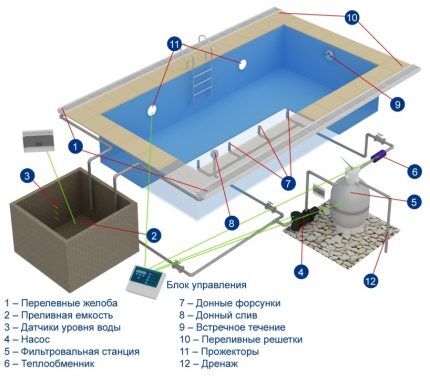

When a place has been chosen, you need to take a sheet of paper and draw the future structure on it. You should select the configuration of the bowl and its depth, and also indicate the location of all communications: the location of the water supply, the ladder for descent, the location of the filter, overflow, lighting, external lighting, etc.

In addition to the main drainage area, it is recommended to provide an emergency water discharge system. Electrical wires must be laid in corrugation.

At this stage, it is necessary to take into account the prevailing wind direction on the site. Debris that falls on the surface of the water will be carried by the wind to a specific side of the pool.

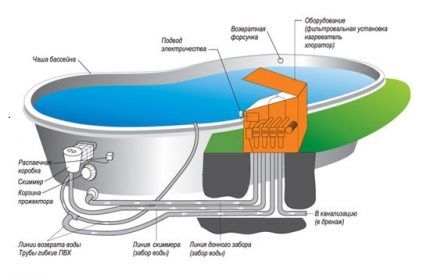

In hardware stores you can find pool equipment kits that include everything needed for installation.

This set may include:

- waterproofing materials;

- materials for the construction of pool bowl walls;

- fittings;

- flanges and nozzles;

- filter, pump, skimmer;

- ladder;

- PVC film for finishing, etc.

The basic set can be supplemented with other elements, depending on the features of the future pool project.

When choosing the size of the structure, you should remember that for one adult a depth of 1.5 m is considered suitable for swimming, and the recommended length of the pool is about 5 m. If you plan to install a diving board or tower, then you should build a pool with a depth of 2.5 m or more.

The deeper the pool, the larger the volume of its bowl, the thicker the walls of the pool should be made, and accordingly, the more materials will be needed to complete the work.

Separately, it is worth discussing the issue of the configuration of the future pool. Here you should remember the following principle: the more complex the shape of the bowl, the more effort will be required to implement the project and subsequent maintenance of the pool.

The easiest way to build a pool is with a rectangular, round or oval bowl shape. If all these points are taken into account in advance and the project is drawn up correctly, much fewer problems will arise during construction.

For example, if there is no clear design, after pouring the bowl, you have to additionally drill concrete to make holes for communications.

You will need: How to build an indoor pool with your own hands.

Installation of a concrete pool

Since working with concrete mixture is familiar to most builders, a pool cast from this material is considered the most affordable option for self-production. But you can’t call it simple and easy.

Pit and sand and gravel pad

As mentioned earlier, it is best to use an excavator to dig a pit. If this is not possible, for example, there are no access roads for such bulky special equipment, you can perform this work manually, although this will require much more time.

To prevent the walls of the pit from crumbling, they are given a slight slope during the excavation process. An additional recess is made in the center of the bottom of the bowl to create a separate drainage well. The bottom of the pit should also have a slight slope (5-7%), directed towards the place of water drainage.

Backfilling begins from the drainage well. It is simply filled with crushed stone and compacted flush with the surface of the bottom of the pit. After this, the bottom is covered with a layer of sand and gravel. At the same stage, you should consider the features of installing drain structures, etc.

First, a layer of sand about 20-30 cm thick is placed on the bottom, which is compacted thoroughly and evenly. Then a 10-centimeter cushion of gravel is laid on top, which should also be compacted.

Useful: How to make a pool from a Eurocube with your own hands.

Pool bottom concreting

After installation of communications, you can begin to fill the bottom with concrete.

You can prepare the mixture yourself using the following recipe:

- 625 kg of sand;

- 325 kg of cement;

- 1250 kg of crushed stone;

- 170 liters of water.

Since you will need a lot of concrete, it makes sense to buy, rent, or even make your own concrete mixer. To calculate the required amount of mixture and its components, you can use an online calculator. Such services are available on many websites of suppliers of cement and building materials.

It also makes sense to consider purchasing ready-mixed industrial concrete, especially if special equipment can be brought directly to the construction site. In the recommendations on how to make a concrete pool with your own hands, there are two options for concreting the bottom of the pit.

In the first case, a layer of concrete screed 5 cm thick is first poured. Then a layer of reinforcement is mounted on top, which is filled with another layer of screed.

Some masters recommend reducing time and effort by using the second filling option. In this case, first install the reinforcement, which is installed at some distance from the sand and gravel cushion using supports (pieces of brick will do).

Then concrete solution is poured onto the bottom so that it covers the bottom of the pit and all the reinforcement. To prepare concrete mortar, it is recommended to use cement grade M 400 or higher. The reinforcing mesh can be made from 6-8 mm metal wire.

The recommended cell size is 150-200 mm. The rods can be welded, but it will be easier to simply fix their position with thin wire. Now you need to wait for the concrete screed to dry. From time to time, the surface of the concrete is moistened with water to ensure uniform drying.

Healthy: Re-opening the pool after winter.

Formwork and wall filling

Now you need to make formwork to make the walls of the pool bowl out of concrete. For this you will need a 30 mm board. You should immediately make sure that there are mounting holes in which the pool equipment will be installed.

To improve the adhesion of fresh mortar to an already laid concrete base, the base must be moistened before starting work. For the same purpose, aluminum powder is added to the solution for the first layer of wall filling.

It is not necessary to use new boards for formwork; even old used structures, for example, with traces of old paint, etc., will do. The main thing is that they can withstand the weight of concrete. Moisture-resistant plywood is also suitable for these purposes. It can be bent, so it is more convenient than a board when creating formwork of a non-standard configuration.

The formwork should be additionally reinforced with stiffeners. They are made from 50X50 mm timber. The ribs are installed approximately 500 mm apart. If it is planned to make a stationary staircase made of concrete, then the sheathing for it must be made separately.

The reinforcement that is needed to give the concrete walls of the pool additional strength is also made in advance. Metal rods are installed immediately after the first layer is poured, before the concrete has time to harden.

After this, the concrete is poured in layers, each about 150 mm thick. After about four days, the concrete will be hard enough for the formwork to be removed.

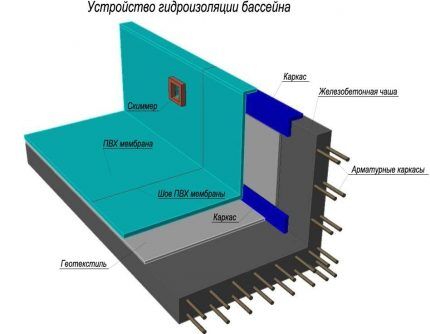

Waterproofing and finishing

After the concrete has completely dried, work can continue. First perform waterproofing works. Some craftsmen consider it necessary to insulate only the so-called cold seams, others advise laying a layer of waterproofing over the entire surface of the pool bowl.

Roofing material is quite suitable for the role of waterproofing, the sheets of which are laid with an overlap of approximately 200 mm. You can also use liquid rubber, bitumen, PVC membrane or modern building mixtures with hydrophobic properties. It is important to take into account costs, since the area of the pool bowl is usually large, and such building mixtures are quite expensive.

To improve the quality of waterproofing work, you must first level the walls by sanding. If you use liquid waterproofing that is sprayed onto the walls, you need to apply two layers. In this case, it is recommended to lay a reinforcing mesh between the first and second layers.

After the waterproofing has dried, it is necessary to check its quality. To do this, the pool is filled with water and left for 10-12 days. The water level should be measured at the beginning and end of this period. A small difference between these indicators is quite expected, since water evaporates from the surface.

But if the water decreases at too high a rate, it means that the waterproofing was done incorrectly and the work should be repeated. After this, the surface of the pool can be plastered with a suitable composition to prepare the base for further finishing. A decorative border is made along the top of the pool. It can be cast from concrete or laid out from brick.

All that remains is to install the remaining equipment and then line the pool walls with finishing material. Most often, ceramic tiles are used for this. Due to the pressure of the water layer, the walls of the bowl may be slightly deformed.This does not have a very good effect on the condition of the tiles: they crack or crumble.

To prevent such an unpleasant phenomenon, you need to make a wide seam between the tiles, and use a compound with increased elasticity for grouting. It is quite difficult to lay tiles on uneven surfaces. Owners of swimming pools with complex configurations are better off using mosaics rather than tiles.

After completing the finishing work, you need to wait a little more time so that the glue has time to dry well. After this, you can fill the pool with water to check the quality of its manufacture and the operation of the equipment.

Construction of a swimming pool with a bowl on the surface

An option for organizing a swimming pool at your dacha, which is quite acceptable in terms of price and cost of construction, is to build a frame from a board and lay a waterproofing shell inside it.

Stage #1 - base and frame

To install a structure located entirely on the daytime surface, you need to build a rigid, level base that can withstand the weight of water and swimmers collected in the bowl, and build a frame:

Stage #2 - waterproofing the frame

After the frame has been erected, it should be equipped to connect communications, pumping and control equipment, and be prepared for laying the internal waterproofing coating and installing additional accessories.

Stage #3 - connecting communications

A swimming pool is a hydraulic structure, for the normal operation of which and to provide conditions for swimmers, a number of technical systems are required: a pump, a group of filters, etc.

The technique requires protection from atmospheric influences, which will be provided by a box attached to the narrow wall of the bowl.

Stage #4 - arranging important details

Finally, the pool built on the summer cottage is equipped for ease of operation and maintenance.

Alternative options for constructing a bowl

When figuring out how to build a concrete pool, you should not forget about alternative options for constructing a bowl.

For its construction you can use:

- concrete or expanded clay blocks;

- expanded polystyrene blocks;

- steel sheet;

- finished structure made of fiberglass or plastic.

When using concrete blocks, the bottom of the pool is first poured, but the walls of the bowl are laid out from these same blocks. Every third row of masonry should be reinforced to give the structure additional strength. You can also make a stationary ladder from the blocks, instead of a stepladder, which is not so convenient.

Next, the bowl is processed in the same way as a monolithic structure: waterproofing and finishing work is carried out. A special PVC film can be used as a decorative covering.

It looks very attractive, costs much less than ceramic tiles, and is much easier to install. But the service life of this material is only 5-7 years, then the finish will have to be updated.

Large format polystyrene foam blocks are also laid on a concrete base. They are connected using grooves and ridges provided by the design.

The material is very convenient to work with because it weighs little. If necessary, the blocks are trimmed with a regular hacksaw.

After the masonry is completed, the pool equipment and fittings should be installed. It is placed inside the cavities existing in the blocks.

The space between the communication pipes and polystyrene foam is filled with polyurethane foam. After this, liquid concrete is pumped into the cavity with reinforcement. When the structure is dry, you can begin finishing the finished bowl.

A pool made of steel sheets can be made either on a concrete base or on carefully compacted soil, although the latter option is not as reliable as a screed.Since the steel sheet is supplied in a roll, it is most convenient to make a bowl from it in the form of a circle, oval or figure eight.

The edges of the sheet are connected with a special profile, which avoids welding. After installing the bowl, it is covered with PVC film and filled with water so that the finishing material is pressed tightly against the walls of the bowl. To fix the film along the top of the side, use a fastening profile. After this, the technical equipment of the pool is installed.

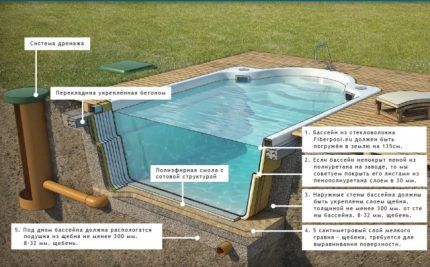

A finished bowl made of fiberglass, plastic or modern composite materials is not a cheap pleasure, even if you choose a standard design rather than a custom-made one.

To deliver and install the bowl, you will have to use a crane and other special equipment. First you should dig a pit of a suitable configuration. Then its bottom is leveled, covered with a layer of crushed stone or gravel and compacted.

After this, you can lower the bowl to the bottom of the pit. The space between the walls of the pit and the bowl is filled with soil and compacted. Such structures usually do not require additional waterproofing and finishing. All that remains is to install the equipment and begin operating the pool.

The weight of such pools is usually relatively low, so owners of areas with high levels of soil freezing should exercise caution. In winter, frozen groundwater can simply push the bowl to the surface.

Useful information can be seen on the topic

The experience of pouring the bowl of a small rectangular concrete pool is clearly demonstrated here:

This video shows in detail the process of finishing a pool with PVC film:

Practical experience in operating a swimming pool and an overview of possible errors, as well as ways to eliminate them, can be seen in the following video:

Arranging your own pool on the site can be done even by a novice master. To do this, you need to correctly design the structure, and then perform all the necessary work, strictly following the technology. With proper care, a homemade pool will last for many years.

Do you want to get your own swimming pool, but haven’t decided which one is best? Maybe you already have experience in construction or have something to recommend to us and site visitors? Please write comments in the block below, express your opinion, ask questions, post photos on the topic of the article.

One day I came up with the idea of making a pond for watering plants and just to decorate the landscape in an interesting way. I dug it without any problems, it served me for 4 years, and then I got tired of it. The idea arose to convert it into a summer pool. I drained it, filled the pit with concrete and waterproofed it, then covered it with tiles and installed cleaning equipment. If you want and have the proper skills, making a pool at your dacha will not be difficult.

We rebuilt the house ourselves, I hope the pool will not be more difficult to design and build. The most difficult thing (for us) is choosing a place. I read something from you about the need to also take into account the characteristics of the soil, the distance from the foundation, etc., and the place that we chose to install the pool is not at all suitable for this.You will have to clean another area for it or even install a prefabricated pool with a good cleaning system. It seems to me that it will be much simpler and more convenient to maintain. First of all, you want clean and warm water.

But there is a question: maybe there are regions where it is forbidden to build swimming pools outdoors? What general temperature (in winter) should it be so as not to damage it? Do I need to dismantle the equipment for the winter?

Ideally, it is better to place the pool in a greenhouse, the effect is amazing - warm water for six months)))

Well, some people actually make a pool in a greenhouse! On the one hand, the idea is great. But on the other hand... at +35 there will be a risk of being boiled alive in such a pool. And as I understand it, if in addition to your own hands you do not have an excavator and a team of workers, then you don’t have to get involved in this adventure.

Spring has started very actively with abnormal heat, I know that for many people it is important to install a mini-pool for children. Many people buy inflatable models, but at a cost of 4-5 thousand rubles, they are short-lived. We built a swimming pool like this on a foundation, it cost a budget, and it has a drain inside. It has been serving well for 8 years now. Pour warm water inside from a children's hose. Immediately, no - no one got hurt or killed on the bricks, the children adore it and practically do not get out of it from the end of May until mid-September on days when it is not possible to take them to the pond.

In the evening, when it gets cool outside and the children go to bed, we pour hot water into it and sit and relax after a hard day. The photo also lacks a mosquito awning; we put it up during the season.As an option for those who, by size or financially, cannot handle a large pool, but at the same time cannot stand the heat - ideal.

Everything is fine with a frame pool except where to get waterproofing of the same shape

What to do if the water in the pool often spoils. turns green. use bleach? How often can you use it?