How to build a profile pipe bender with your own hands: a review of the best homemade products

Profile pipes are used as a material no less often than round ones.When performing installation work with them, you also have to cut, bend, sharpen, and cook. Such work cannot be done without the appropriate equipment.

It is not always possible to buy ready-made equipment for a mechanic or plumber; you often have to make the equipment yourself. For example, anyone can make a profile pipe bender with their own hands. We propose to familiarize yourself with the three most popular options and the technology for their construction.

The content of the article:

How to bend a profile pipe without special tools?

The use of a special tool that allows you to easily and simply bend pipes, including profile ones, can already be considered a plumbing tradition. Meanwhile, over the entire period of plumbing practice, a number of simplest ways to obtain bends without using a special tool have been invented.

Take a look - maybe you won’t have to build a pipe bender at all. True, it should be said that this approach is not always ready to fully satisfy the needs for bends. Especially if you need to bend a profile pipe in several places at once and under different radii.

The simplest homemade methods that help you make one or two folds without using any equipment:

- filling the internal cavity of the pipe with sand;

- filling the internal cavity of the pipe with water and then freezing it;

- using a homemade mandrel;

- trimming the profile wall along the internal radius.

When there is a need to bend a profile pipe at one, or maximum two points distant from each other, it is quite reasonable to use simple methods:

- Fill the inner area of the profile pipe with fine river sand.

- Close the end parts tightly.

- Bend the profile with your hands according to the template in the right places.

Work with a pipe filled with water is done in the same way. But in this option, the water must be frozen. Working conditions do not always allow such a procedure.

Another similar method is to use a mandrel - a steel spring slightly smaller than the internal diameter of the pipe itself. The spring is placed inside and then folded.

This way you can bend thin-walled pipes by hand. For profile products with a more powerful configuration, these methods are not suitable.

Thick-walled powerful profiles can be bent at one or two points using a simple method of technological undercuts. The technology involves cutting out small segments of the pipe wall along the internal radius (for example, with a grinder).

Then the profile is bent until the boundaries of the cuts made are connected. The junction points of the undercut boundaries are welded using electric welding.

The best options for homemade pipe benders for profiles

Special tools - pipe benders - provide wider possibilities for bending operations. Working with a pipe bender practically does not limit the needs of designers who use profile pipes in their work.

You can bend products of different sizes, but taking into account various technical characteristics. The diversity of the model range of profile pipe benders allows you to do work of any complexity.

Design #1 - manual pipe bender

In general, the design of the instrument is quite simple, which means it can be performed by an untrained person. They make their own not only small-sized hand-operated mobile structures, but also stationary systems equipped with an electric drive.

For private use, manual models are more relevant. In addition, the manufacture of manual devices is somewhat cheaper.

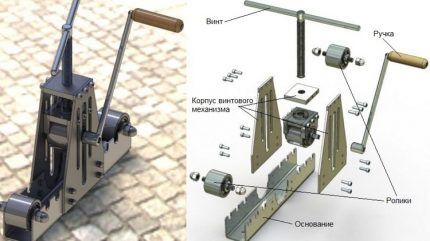

One of the most common hand-held device designs suitable for making a pipe bender is built from the following components:

- road wheels;

- thrust roller;

- chassis parts;

- adjusting screw;

- feed handle.

The tool operates on the principle of a rolling mechanism, like the lion's share of other homemade structures. All parts are made of metal, including support and thrust rollers. Meanwhile, some components (the same rollers) can be made from other materials. For example, there are homemade designs with wooden rollers.

The material of the working elements is an indicator that determines which pipes (based on wall thickness and metal hardness) the pipe bender can work with.

Design #2 - mechanized powerful device

A number of homemade designs are not limited to just hand-operated tools. Craftsmen create homemade pipe benders, which can be compared with industrial equipment. Parts for such systems are easy to find among the junk of technical enterprises or can be bought cheaply on the market.

Reinforced pipe benders for profile pipes are equipped with an electric drive. On such “machines” profiles of different sections with a wall thickness of several millimeters are bent without much difficulty.

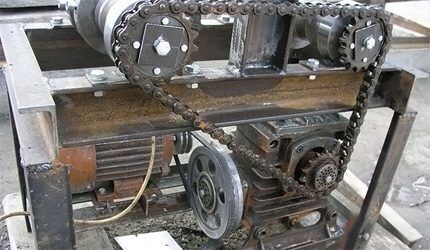

The picture above shows an example of a diagram of a powerful pipe bender, the design of which contains:

- frame welded from channels;

- two metal rolling rollers;

- three transmission gears;

- metal chain;

- gearbox and electric motor with belt drive mechanism.

Rolling rollers are mounted on support bearing units. They receive torque through metal gears connected by a metal chain.

The chain drive receives its main torque from the gearbox, which, in turn, is rotated by the electric motor shaft. The shafts of the electric motor and gearbox are connected through pulleys by a belt.

The gearbox plays a significant role in the machine circuit - the high torque of the electric motor shaft is reduced into a low torque transmitted to the gears of the support rollers. Therefore, there is no need to install a low-speed motor on the device. A standard configuration electric motor of 960 – 1500 rpm is suitable here.

All structural parts are mounted on a metal frame made from channel scraps. The parts are fastened to the frame in a simple way - bolts or welding. There is always a place for installing such a machine on a summer cottage, in the courtyard of a private house, or in a garage for personal vehicles.

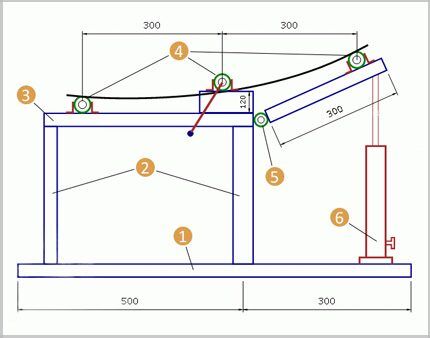

Design #3 - hydraulic version of the pipe bender

The electrically driven unit is a truly powerful machine. But the design equipped with a car jack looks even more powerful.

The schematic is like this hydraulic installation unsurpassed simplicity. But at the same time, the characteristics of the device are impressive. With the help of this machine, profile pipes are bent, which even an electric pipe bender cannot always bend.

Step-by-step instructions for assembling the hydraulic structure of a homemade pipe bender for profile pipes begin with a selection of parts.

The locksmith will need the following:

- three pieces of wide channel;

- three pieces of narrow channel;

- loop lock;

- three rollers mounted on bearing units;

- feed handle with adapter sleeve;

- car jack.

On the channels, all parts are fastened with bolted connections.The two upper channels are connected to one another through a loop lock. In this case, one of the channels is rigidly fixed to the base, and the second is left in a “free” state and is raised or lowered in a horizontal plane by the jack rod.

The support roller axis, emanating from one side of the bearing assembly, is connected to the feed handle through a metal sleeve. The connection is fixed with a pin.

The principle of operation of the design with a jack is somewhat different from the options discussed above in the scheme for adjusting the bend radius.

If in previous installations a lead screw was used for adjustment, moving the support roller along a vertical axis, here the work of the lead screw is performed by a “floating” channel, which is moved by the jack rod. Such a system requires even fewer resources to assemble than an electric drive design.

The following photo selection will introduce you to the process of assembling a simple pipe bender with a jack:

A self-built pipe bender is used when performing various works in the countryside. Most often it is used to make arches from which the greenhouse is assembled.

The owner of a homemade pipe bender can easily make all the structural parts of the greenhouse in one day:

Instruction on the use of pipe benders

Technology bending a profile pipe does not require special skills. But depending on the type of pipe bender used, the bending procedure may be accompanied by certain nuances.

To understand, let’s look at an example of working with a manual pipe bender equipped with a bend radius adjustment screw:

- The profile pipe is cut to the required size.

- The thrust roller of the pipe bender is installed in the starting position.

- The profile is placed in the space between the rollers (thrust at the top of the pipe, supporting at the bottom of the pipe).

- Using the adjusting screw, the thrust roller is pressed against the pipe with some force.

- The feed handle moves the profile pipe back and forth in a short stroke.

The short stroke of the pipe and the clamping with the adjusting screw are carried out until the required bend radius is obtained.

Similar instructions are also applicable for pipe benders of profile pipes, the design of which is based on an electric drive or hydraulics. But in this case, some practical experience in controlling the marked drives is required.

Useful tips for “pioneers”

For those who are encountering flexible profiles for the first time, it is recommended to take into account some features of the processing technology of this type of pipe. For example, experienced craftsmen never sacrifice the quality of the bend to save time.

It is wiser to do a few gentle presses with the adjusting screw and a few passes on the rollers rather than doing everything at once. This approach completely eliminates deformation of the profile pipe and significantly reduces the load on the drives (or on the master’s muscles).

It is recommended to work with rollers of a configuration that matches the pipe profile. So, if there is a correspondence between the size of the roller width and the cross-sectional size of the profile, the bend will be accurate and neat. In addition, the master will not have to periodically correct the pipe, which moves from the center of the support roller to its outer boundary.

Before starting the bending operation of a profile pipe, it is advisable to make a template according to a given bend radius. If it is impossible to make a template for some reason, you can limit yourself to calculating the distance obtained between two control points after bending the pipe. Knowing the calculated figures, the workpiece can be bent with a pipe bender without periodic control measurements, thus reducing work time.

Conclusions and useful video on the topic

From the video you can find out what a homemade pipe bender looks like on a bed.

You have to work with profile-shaped pipes quite often in the context of running a household or country house. Therefore, the presence of a tool called a pipe bender in a home workshop is welcome.

As the practice of self-taught craftsmen shows, this instrument is not difficult to make yourself. And having made such a design, it is easy to master and periodically use.

Please write comments in the block below. Tell us about how you bent a profile pipe with your own hands. Share interesting technological details, ask questions, post photos related to the topic of the article.