Equipment for cutting pipes: types of tools and features of their use

When manufacturing and installing pipe products for various purposes, special equipment for cutting pipes is used. It allows you to cut out a fragment of the required size from the base blank.The design of the device consists of a thrust body and cutting rollers.

The force transmitted through the lever acts on the cutting roller and converts the pressure created on the pipe cutter body into rotational movements. The result is an even, neat cut, making it possible to easily and conveniently connect a separate part of the pipe to the overall system.

We will talk about tools for cutting pipes, types of pipe cutters and the principles of their operation, as well as how to properly cut pipes of various diameters.

The content of the article:

Classification of modern pipe cutters

Tools designed for cutting pipes, first of all, differ from each other in power and ability to work with materials of different densities.

Universal pipe cutters can easily withstand high loads and easily cope with thick-walled steel and cast iron pipes with a diameter of up to 12 mm. This class also includes progressive devices equipped with a clamp latch. Thanks to it, the tool becomes stronger and easily cuts pipes with a diameter of up to 324 mm.

The second group includes equipment designed to work with pipe products made of thinner materials: brass, copper and stainless steel. The same tool is usually used to cut plastic and metal-plastic pipes, especially when it is necessary to maintain the most accurate dimensions and obtain an ideal straight cut at the output.

You can read more about the types of pipe cutters for metal-plastic pipes in in our recommended article.

The third category includes units for processing fragile materials prone to crumbling. They are used for cutting ceramic, concrete and asbestos-cement pipes. The tool provides a neat and smooth cut line and does not knock pieces out of the edge.

For personal purposes, equipment with a mechanical lever drive is more suitable for performing one-time repair and installation work. Electric tools of this class are mainly used for regular mass work (providing services for laying sewerage, gas and water pipes, etc.).

Contact with a cutting electrical unit requires certain skills and professional abilities, so it is used extremely rarely in everyday life.

Design features of cutting equipment

An important distinguishing feature of pipe cutters is the number of cutting rollers. The simplest version has only one sharpened roller and two guides. This tool is suitable for cutting pipes with a diameter of 15-50 mm and requires significant physical effort from the worker.

The cut is not very clear and almost always requires additional processing and removal of external and internal burrs.

The three-roller unit demonstrates high speed and productivity. Easily processes pipe material with a diameter of up to 100 mm. The edge on the cut makes it clear, even and smooth.There is no need to additionally grind the surface or remove errors.

The four-roller pipe cutter easily copes with active work and withstands intense loads. Cuts the pipe quickly and cleanly, leaving behind an almost perfect cut.

The manual model, depending on the manufacturer, is equipped with an additional comfortable handle that allows you to work in pairs and cut large-diameter pipe material.

Technical characteristics and principle of operation

The construction equipment market today offers various types of pipe cutters for use: mechanical manual, electromechanical and electric. Manual units are considered the simplest and cheapest. They are most often used in everyday life for one-time repair and installation work. They function only due to human muscle power.

They have an ergonomic handle that ensures the most efficient conversion of effort into results. They do not require complex maintenance, are highly durable and serve reliably for many years.

Electric pipe cutters are characterized by increased productivity, make a better, even cut and do not force the craftsman to make significant efforts to perform the necessary actions.

How do different types of pipe cutters work?

According to the principle of operation, pipe cutting tools are divided into four subclasses:

- Manual work under the direct influence of human physical strength and do not require any specific skills from the user.

- Electrical have an internal motor that starts the unit into operation.Compact models of low and medium power are suitable for domestic use, while massive ones cope with large-scale tasks and increased loads. Equipped with a roller system for holding and rotating pipe material. The cutting disc, made of high-strength alloy, is fed to the cutting area manually or using a built-in drive.

- Pneumatic They efficiently and quickly cut large-diameter pipes using cutters for contact with materials of different densities, ranging from thin polymer plastic to cast iron. They are mainly used for industrial work, as they are characterized by bulky dimensions and heavy weight. They are transported to the place of work on special trolleys and require qualified service by trained personnel.

- Hydraulic consist of a rod, piston and hydraulic pump. To function fully, they do not require electric current, as they operate on the principle of liquid pressure. The internal pump creates an impact on the piston, which causes the mechanism to operate. When the water pressure drops, the cutters return to their original positions. The device is significantly more powerful than manual models, but inferior to electrically powered equipment.

It is impossible to say which instrument is better and which is worse. Each of the above options has its own advantages and is used depending on the tasks assigned and the type of pipe material used.

Types of mechanical pipe cutters

Mechanical pipe cutters have some design features and distinctive features. Roller models perform cutting by rotating the unit around the pipe.

At this moment, the cutting part removes the metal layer, and the carriage with guide rollers is controlled by a moving screw handle and presses the disk against the pipe being processed with the required force.

Split clamp devices are designed so that they can completely enclose the pipe during the cutting process. The cutting elements are placed in pairs in the pressing and stationary parts of the unit.

Thanks to this design, the load is distributed evenly over the surface and cutting occurs accurately and accurately. Most often, such tools are used for cutting pipes in confined spaces.

Chain models do not have volumetric elements or rotating parts. Working disks, fastened in a loose chain, wrap around the diameter of the pipe.

Mechanics or hydraulics create tension and compress the part in the right place. The metal does not cut, but breaks, and the edge turns out to be quite clear and even.

In mechanical rotary pipe cutters, the cutting parts are located symmetrically in two fragments of a split structure. The ring of such a unit is so large that it allows processing of pipe material with a diameter of up to 1000 mm.

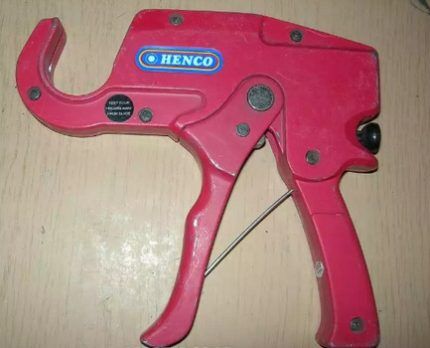

Pistol-type equipment is suitable for cutting pipes made of polymer plastic. The cutting is carried out not by knives, but by sharply sharpened blades made of high-strength, hardened steel.

The edge is smooth and does not require further additional processing with sandpaper or any other grinding tool.

You need to choose the type of tools that is suitable for you depending on the expected volume of work and the density of the material being processed.

The principle of operation of the cutting elements of a pipe cutter

Structurally, pipe cutters differ from each other; all versions of this type of tool cut the pipe differently. Units that perform heat treatment do not so much cut the material as evaporate it and give a very good, smooth, even cut.

Guillotine tools separate the tubular element using extreme pressure concentrated on the sharp tip of the leading cutting part. Grinding units, rather, grind off the layer of the material being processed, while simultaneously leveling and polishing the cut area.

Classic models use a cutting element such as a knife and simply cut off a part of the required size from the main workpiece. Which tool is best to use depends on the type of pipe used to install a particular communication system.

The most efficient pipe cutting machines

Fireless cutting units cope better than others with fast and accurate cutting of pipes made of highly flammable materials. They easily and accurately process any type of polymer, including those that melt at a temperature of 180-200 °C.

On our website there is a detailed article on how to choose a pipe cutter for plastic pipes, read Further.

Classic roller models, both mechanical and electrical, are perfect for cutting durable but ductile copper. The same type of tool is used to cut pipes from more expensive materials (brass, bronze, etc.)

Gas-powered cutting machines cut steel pipes. For cast iron, this processing option is not suitable, since severe overheating occurs in the area of contact of the cutting element with the pipe body. This negatively affects the basic properties of the metal and creates obstacles for even, accurate and high-quality cutting.

We also recommend that you read the review of pipe cutters for steel pipes. More details - go to link.

Various versions of the manual guillotine are ideal for cutting pipe sections made of multi-component materials. They do not damage the thin reinforcing layer of aluminum and do not crush the pliable polymer base.

Pipes made of ceramic or concrete are most often cut with an angle grinder. These materials do not respond to thermal effects, and guillotine-type mechanical devices lead to coloring of the edge and destruction of the integrity of the entire pipe.

In addition to equipment designed exclusively for cutting pipes, other tools are also used for the same purpose, for example, a cutting disc machine, a circular saw, a laser punching machine and a band saw.

However, this is only relevant for one-time work. If cutting pipes of various shapes, diameters and densities is carried out regularly, it is better to acquire a special narrow-profile tool.

Specifics of pipe cutting

In everyday life, when carrying out various repair and installation work, there is often a need to cut pipes of various diameters. Pipe cutters of various modifications or cutters help to accomplish this.

The first option provides even cutting and serves the owner for a long time. The second one performs cutting well, but is considered less durable and is intended to be used for several years.

Features of cutting small diameter pipes

For proper cutting, a small-diameter pipe is fixed in the clamp of the pipe cutter and the tool handle is turned clockwise so that the roller element comes into contact with the pipe surface. Then they make a second turn and carefully examine the cut mark. If the circle is closed and has no visible violations, work continues.

The tool handle is shifted half a turn and the roller is pulled towards the pipe. After making sure that the sharp cutting parts have entered the metal, rotate the tool until it copes with the task.

To make the movement more soft and smooth, the treatment area is lubricated with oil. Lubrication seriously reduces the temperature of metal processing and significantly speeds up the cutting process.

To cut plastic pipes, they often use not specialized equipment, but improvised tools available in the arsenal of every owner, for example, large metal scissors. From the profile devices, cutters for polymer are taken, which look very similar to household scissors.

Reputable manufacturers sell pipe cutters for small-diameter products at a fairly high price, however, if the tool is needed for regular use, it will pay for itself and will serve reliably for many years.

When the plans involve some one-time work, the unit can be rented or borrowed from relatives, friends or acquaintances.

You can read more about different pipe cutting methods in this material.

How to cut large diameter pipes?

Regular cutting of medium and large diameter pipes is almost not in demand in everyday life, but is very important for industrial production and enterprises. To work here, reliable and powerful units are required that can provide high cutting speeds and withstand round-the-clock operating loads.

For daily cutting of large volumes of metal pipe material, roller devices are used. The holder, which is part of the structure, makes it possible to carry out cutting while being at a short distance from the epicenter of the process.

To obtain a high-quality and even cut, make translational movements up and down and stop when the pipe is cut. The work is labor-intensive and requires a lot of time.

A tool of this class shows the best results when processing objects made of thin metal. It copes much worse with thick-walled products.

For regular cutting of large-diameter pipes, some enterprises install a hacksaw machine. It is a bulky structure, somewhat similar to a vertical milling machine. But instead of a cutter, a large hacksaw acts as an active element.

This unit is used to cut not only pipes, but also other metal parts.The most obvious disadvantage of this option is the sharp edge remaining after cutting. It seriously complicates further work with the cropped fragment.

In everyday life, they are often used for cutting large-diameter pipes. grinder or any other cutting tool of this kind. For processing, the pipe is rigidly fixed in the holder, and then the required part is cut off.

To ensure that the cutting is done quickly and the worker is not injured, a safety cover is put on the unit and a special disk is installed, designed specifically for cutting metal.

To obtain a perfectly smooth edge in the cutting area, gas plasma cutting is used. The semi-automatic processing mode (fixing the pipe part and activating cutting) is especially successful. When cutting manually, a number of problems arise that the operator often cannot solve and the process is significantly delayed.

The most progressive tool for cutting large-sized pipes is called laser equipment. Such installations almost instantly cut through metal of any thickness and strength and leave a perfect cut without burrs after processing.

The CNC system makes it possible, through a personal computer, to set the machine the necessary program to carry out work of any complexity.

However, there is a limitation on the dimensions of the processed elements. The unit copes with pipes up to 6.5 meters long and with an outer diameter of up to 160 mm.The laser has a high cost and is purchased only by enterprises that are constantly engaged in cutting, not only pipe products, but also other metal parts.

Conclusions and useful video on the topic

Video review of a manual pipe cutter for plastic pipes:

Video instructions for using a pipe cutter. The video shows how to properly process medium-diameter steel products with a pipe cutter:

Once you familiarize yourself with the types and types of pipe cutting equipment, choosing the right tool will not be difficult at all. If doubts remain, consultants from construction and hardware stores will be happy to help and tell you which device is best to purchase.

Do you have any questions about the topic of the article, have you found any shortcomings in the material, or can you provide valuable information? Please leave your comments in the block below.

I have always had a simple hand pipe cutter designed to cut steel and cast iron pipes. Yes, I had to work hard and then clean up the cut, but it suited me. But now pipes are more often made from plastic and polypropylene; a regular pipe cutter can deform them. That's why I'm looking at the electric model. As I understand it, the option with 4 rollers is too much, with 3 it will be just right.

Why, a four-roller pipe cutter is not too much. It’s not always possible to make a full revolution, but here 120 degrees is enough.