Polypropylene transition coupling - selection and installation of fittings

When planning a circuit polypropylene pipelines A situation often arises when it is necessary to join pipes of different diameters or even from different materials. In this case, a polypropylene transition coupling can simplify the solution to the problem. The work can be carried out in the least expensive way. But how to do this and what nuances should you know?

The content of the article:

Where is it used?

The polypropylene transition coupling is a universal additional element that is used in almost any pipeline made of soldered PPR polypropylene. Outwardly, it looks like a round plastic cup with thick walls and no bottom. This shape guarantees the fitting a strong and reliable connection.

Transition couplings for polypropylene pipes are used for:

- permanent soldered connection of two PPR pipes;

- transition from a polypropylene pipe to a steel or metal-plastic one.

This inconspicuous-looking part is a universal tool that can be used to solve small but important problems of water supply or heating.

Entering an apartment or house

The most popular option is the transition from a large diameter to a smaller pipe size. Typically, the water riser in wells of apartment buildings is made with a polypropylene pipe of at least 2". Wiring throughout the apartment is made to a maximum size of 3/4”. Therefore, at the outlet of the water pipe it is necessary to install an adapter coupling with an external thread to connect the water meter.

For home water supply, a polypropylene transition coupling is used:

- for joining polypropylene pipes and steel;

- in places where any metal fittings are inserted - from brass taps to mud filters;

- At the entrance to the house, a polyethylene food line is usually laid along the site, followed by an adapter from polyethylene to metal. The last to be installed is a transitional polypropylene coupling for soldering;

- in caisson well blocks for connecting the water supply to the expansion tank or pumping equipment.

A transition fitting-coupling is often placed at the end of a blind section of a water pipeline. In this case, a polypropylene transition coupling with external thread is used. A flexible liner is screwed onto the threaded section to supply water to a gas water heater, double-circuit boiler or boiler.

Heating systems

Polypropylene fitting couplings are used in the heating circuit to connect a safety group, expansion tanks, and install pressure gauges. Pipes can be used from polypropylene, while all valves and control fittings are only made from brass or stainless steel.

Heating radiators made of aluminum, bimetal or cast iron in heating systems are connected using adapter couplings, but with a union metal nut.

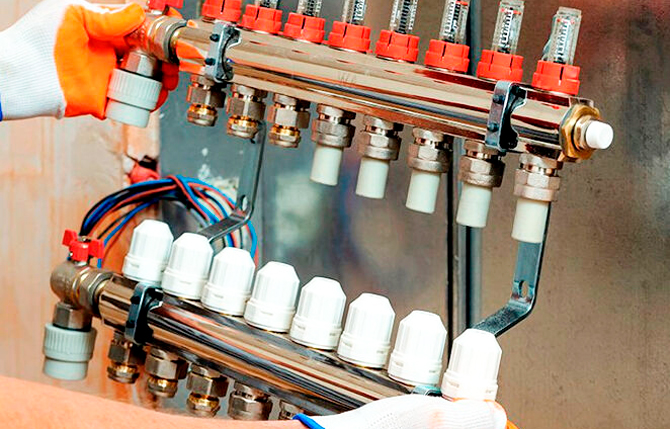

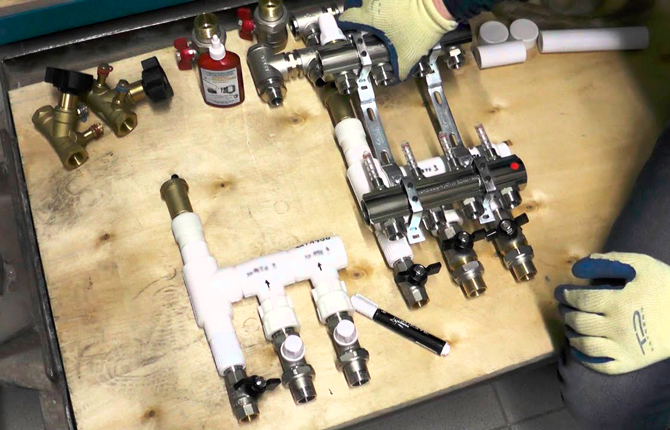

Fitting couplings are placed on the distribution manifold if the house or apartment, in addition to radiators, uses a “warm floor” system.

In addition to classic straight fittings, corner models are widely used, in which the inlet and outlet have different diameters, and at the same time are turned at an angle of 90゜ to each other. The outlet may have a metal fitting for a pipe thread.

Under what conditions can it be used?

Transition couplings for polypropylene pipes are capable of operating in extreme conditions.

For example, the material can withstand hot water for a long time:

- working pressure up to 16 At;

- medium temperature up to + 95 ℃.

Neither metal-plastic nor cross-linked polyethylene can compete with polypropylene highways. The coupling connection is obtained with a cast, homogeneous structure; there are no joints, seals, or seams through which hot water or steam could “escape.”

Only polypropylene couplings with a special reinforcing additive in the form of chopped fiberglass can boast of high resistance to steam and hot water. For standard fittings, a temperature limit of 60 ℃ is set at a pressure of up to 20 At.

Due to the cast structure, the transition couplings are not afraid of mechanical stress. Metal-plastic and polyethylene PEX pipes must be additionally secured to the wall in the places where the compression fittings are installed. This is done in order to compensate for the deflection and load at the joints, otherwise the sealing gaskets will quickly fail.

For polypropylene pipes assembled on adapter couplings by hot soldering, this is not required. Craftsmen install clamps and fasten polypropylene pipelines only to improve their appearance. When heated, the PPR hot water supply pipe expands and sags slightly. This does not change the strength and reliability of the adapter coupling.

The only drawback of using a transition coupling may occur during the transition from a large pipe diameter to a small one. If the fitting is welded with slight overheating, and the parts were connected with excessive force, then a circumferential seam will form inside the polypropylene coupling. It practically does not affect the throughput, but due to the acceleration of water flow in a pipe of smaller diameter, it can cause sound vibrations.

Couplings for polypropylene pipes are not afraid of corrosion, even if you have to make a joint with a steel or metal-plastic pipe. Polypropylene contains no substances that provoke the formation of rust or oxidation of aluminum, so there are no problems with the compatibility of polypropylene and metal parts.

How to choose adapters

It is necessary to choose the correct design of the polypropylene fitting. The transition system assumes that pipes of different diameters will be joined in a soldered joint. The more the cross sections at the inlet and outlet differ, the stronger the turbulence of the water flow and the higher the hydraulic losses.

| Name | Smallest diameter, mm | Maximum diameter, mm | Coupling length, mm |

| Transition 50-63-66 | 50 | 63 | 66 |

| Transition 32-40-44 | 32 | 40 | 44 |

| Transition 25-32-44 | 25 | 32 | 44 |

| Transition 40-50-54 | 40 | 50 | 54 |

| Transition 50-75-72 | 50 | 75 | 72 |

| Transition 25-40-49 | 25 | 40 | 49 |

| Transition 40-63-64 | 40 | 63 | 64 |

| Transition 32-50-51 | 32 | 50 | 51 |

| Transition 63-75-71 | 63 | 75 | 71 |

| Transition 20-25-37 | 20 | 25 | 37 |

The resistance increases in proportion to the difference in diameter:

- with a difference of ½”, losses increase by 25%;

- by ¾” – the pressure is lost by 35-40%.

The data given applies only to those highways where the flow velocity in the pipe is more than 3 m/s. For a polypropylene pipe with a cross-section of ¾” this corresponds to a water flow rate for the spout in the range of 0.7-1.0 l/s. In other cases, hydraulic resistance losses in the transition section can be ignored.

If the difference in diameters is large, at a flow rate of more than 3 l/s, several intermediate couplings can be installed. The only trouble may be the accumulation of sediment and rust at the junction of two polypropylene pipes.

The nature of the transition must be taken into account.If you are installing a transition fitting with an outlet fitting with an external thread, then a model with a short threaded section would be more preferable for hot water. For pressures greater than 10 At we use an extended fitting. In this case, a transition sleeve and a clamping nut are placed on the thread.

Another nuance is the quality of the fittings themselves. The best solution in terms of price-quality criteria are considered to be couplings from the BOREALIS company, although Czech or Turkish transition couplings can be used with equal success.

How to install the coupling

Half of the problems with PPR pipes arise from poor-quality installation coupling fittings.

The process itself is simple:

- cut the pipe blank using trimming shears. Cutting with any other tool is not recommended;

- chamfer the edge along the end;

- We install nozzles on the soldering iron according to the size of the pipe and the corresponding cross-section of the adapter coupling;

- heat it up and quickly, but without haste, insert the workpiece inside the fitting. We settle with a little effort.

After about 5-7 minutes, the welding site has completely cooled down.

If possible, strictly observe the heating time of polypropylene blanks on the soldering iron nozzles. Experienced craftsmen determine the degree of heating from their own experience, and it is better for novice workers to use the table.

Problems with soldering adapter

Most often, welding is performed either overheated, in which case an annular bead is formed inside the workpiece, or underheated, in which case the seam may be weak. If you don’t have practical experience, you can practice on polypropylene scraps.

Usually the transition output is soldered first, the one with a smaller diameter. This makes it easier to make a more complex welding joint on a larger diameter pipe.You must try to put the coupling on exactly along the axis, without allowing deviations from alignment. Otherwise, the weld seam or bead will be of different thicknesses, which means there may be unsoldered areas left.

Another nuance is associated with the installation of corner fittings with external threads. The joint on the side of the polypropylene pipe is soldered first. Preliminarily check the position of the transition elbow relative to the steel section.

The metal fitting is wrapped in a damp cloth and welded onto the polypropylene part. In this form, you need to leave the fitting until it cools completely, do not try to try on the fitting or screw on the coupling or nut. Any careless handling of the hot fitting may cause the polypropylene inside the housing to peel off.

The polypropylene transition coupling is durable and strong. Thanks to the thickened, massive walls, the joint is strong if the selection and installation of the fitting was carried out with high-quality tools using proven technology.

Welding polypropylene pipes of different diameters and types through a transition coupling: video.

Share your experience with transition fittings in the comments. What problems did you encounter? How did you manage to solve them? Save the article to your bookmarks so that you can return to useful information at any time. Share the fuck on social networks.

When choosing, check the outer diameter. The case is very thick, if you place it under the wall, it may not be screwed into the radiator, or it does not coincide with the axis of the steel section.You cannot cut it, although the wall thickness margin is very large. Again, if you need to screw a coupling onto the fitting, then your tailbone may simply not hook into the body.

And I always screw the nut onto the fitting first, and then just solder it. This makes it more convenient to hold when heating on a soldering iron. In addition, by preliminary running the threads on a steel coupling or fitting, I can find defects. And it is much more convenient to pack the threads with FUM before soldering the fitting onto polypropylene.

It doesn’t matter in what sequence to solder, the main thing is that the soldering iron is cool. It is better not to take the one with a relay and a light bulb. Needed with electronic regulator. The more accurately you heat the coupling, the easier it is to solder. Some solder adapters are heated on a gas burner, then they complain that the pipe has leaked at the fittings. I don’t have a cool soldering iron, you can borrow it from friends or at a service center if you want.

Good afternoon Maybe someone can tell me: there are heating batteries with a 3/4 outlet, I had to add radiators and bought them with an outlet. 1/2. I noticed it after the purchase))) After the connection, will there be any undesirable moments?

Good afternoon Maybe someone can tell me: there are heating batteries with a 3/4 outlet, I had to add radiators and bought them with an outlet. 1/2. I noticed it after the purchase))) After the connection, will there be any undesirable moments?