How to change the heating element in a water heater: step-by-step instructions for repair work

On the list of irreplaceable devices that people think about purchasing first when moving to a new house, apartment or cottage is a water heater. It makes residents independent of the hot water supply - they can simply turn on the device and take a shower.

But such household appliances require regular maintenance, and some elements even need to be replaced. Therefore, the owner will need knowledge on how to properly carry out preventive maintenance to avoid breakdowns, and how to change the heating element in the water heater if it does break down.

The content of the article:

- Design of a water heating device

- How the device works

- Reasons for replacing the heating element

- Is it worth it to replace it yourself?

- Checking the serviceability of the heating element

- What will be needed for repairs?

- Replacing the water heating element

- How to increase the service life of a heating element?

- Conclusions and useful video on the topic

Design of a water heating device

The boiler is fundamentally no different from the most ordinary electric kettle, which can maintain a certain water temperature. Only the first one acts as a cover safety valve, ensuring the supply of the required amount of liquid for its subsequent heating.

Today the market offers a large selection of boilers. All modern models have different designs, technical characteristics, appearance and, of course, different prices.

Therefore, choose the model that is optimal in terms of parameters, quality and cost. storage water heater Buyers with any income level will be able to.

Regardless of the brand, all boilers consist of the following components:

- frame — it must be insulated, which will reduce heat losses to a minimum;

- a heating element — there are two varieties of it: the first is in direct contact with water, and the second heats the liquid through a special ceramic shell;

- internal tank — its volume varies from 15 to 200 liters, and the tank itself is made of stainless steel, which allows it to be resistant to corrosion;

- thermostat — a sensor that monitors the water temperature, maintaining it at a user-specified level;

- magnesium anode, the main task of which is to protect the device from electrochemical corrosion, but it in no way affects the formation of scale;

- pad heating element attachment point.

The magnesium anode needs to be replaced regularly - this process should be done at least 1-2 times a year. Such maintenance will increase the service life of the boiler and increase its efficiency.

How the device works

The heating device consists of two containers isolated from each other. The first barrel is usually made of high-quality steel coated with an anti-corrosion coating or stainless steel.

Innovative materials are used to organize insulation. Most often this can be polyurethane foam, basalt wool or their analogues.This solution allows you to keep water hot for up to two to three days. If the liquid temperature drops below a user-specified value, an electric current is supplied to the heating element.

At the same time, in order to prevent mixing of hot and cold liquid, the latter is taken from the upper part of the device. In this case, the laws of physics apply. More precisely, cold water simply displaces hot water.

It is recommended to adjust the thermostat to t = 60. In this case, scale formation can be prevented, which will have a beneficial effect on the inner barrel and heating elements. But in any case, every month you need to turn on the device to maximum. This solution will allow you to disinfect the container, killing all harmful bacteria.

Reasons for replacing the heating element

It is necessary to replace the heating element if the old element fails. But how can you determine that the heating device has actually burned out? To do this, you need to plug in the boiler and wait until it reacts.

If the device turns off immediately, then this is a clear sign of a problem. Well, in the case when the equipment continues to operate, there are no malfunctions and, accordingly, there is no need for repairs.

To be completely convinced that a part is faulty, you need to “ring” it, so to speak.Simply put, evaluate the conductive characteristics.

To do this, the following procedure must be followed:

- unplug the equipment from the outlet;

- unscrew the protective cover;

- find the contacts of the heating element;

- check component resistance.

For testing, you can use an ohmmeter or multimeter. If the measuring device shows “infinity,” then the heating element has become unusable (burned out) and needs to be replaced. Well, when the device shows zero or any exact number, then there are no problems.

Is it worth it to replace it yourself?

Water heating equipment has a fairly simple design and operates on a basic principle. Therefore, every home master will be able to cope with replacing the heating element independently, without calling a specialist.

The main disadvantage of hiring a professional is the high cost of repairs. Often this figure can reach $60 and this is only for work, without taking into account the cost of parts. Therefore, by spending a little of your own time, you can save a significant amount.

Checking the serviceability of the heating element

The above testing method using an ohmmeter is not the only method for determining a breakdown. There are two more options that allow you to identify all sorts of problems and correct them in a timely manner, preventing complete failure of the device. Let's look at them in more detail.

Visual inspection of the element

In this case, it is necessary to disconnect the equipment from the electrical network and drain the water from it.Then disassemble it and clean the heating element from scale if it is present on its surface. It is important to inspect the component for coating integrity.

If even small cracks, chips or damage are detected, the part can be safely thrown into the trash. After all, in this case it will no longer be possible to repair it. The only thing left in this situation is to replace the heating element with a new one.

The reason for damage to the coating of an element most often lies in the low quality of the materials used for its production. As a result, after just one or two years of operation, such a heating element is literally torn to shreds and cannot be restored.

Checking with a tester

One of the methods for detecting a heating element malfunction was given above. But if the ohmmeter did not give results, and nothing could be found during a visual inspection, then the last check is to look for a breakdown.

To do this, you need to disconnect one of the terminals of the measuring device and move it along the surface of the water heating element. If the ohmmeter shows the exact resistance value, then there is a problem and the heating element needs to be scrapped.

If everything is in order with the heating element, then you should start checking the thermostat. To do this, you need to connect the terminals of the measuring device to the contacts of the temperature sensor, which are used to supply electrical current.

If the measuring device showed an accurate value or made a bell, then the component is fully operational. Otherwise, the thermostat is broken and needs to be replaced.And you don’t even have to drain the water from the boiler to do this.

To restore functionality, disconnect the device from electricity, remove the panel, disconnect all wires from the thermostat and connect a new part. Remember that if you do not solve this problem, there is a risk of getting an electric shock if you touch the tank.

What will be needed for repairs?

If the presence of a malfunction is still confirmed, then it’s time to start replacing the heating element. But before you get started, you need to acquire all the necessary tools. The list is small, but without it it’s unlikely that anything will be done.

For repair you will need:

- spanners;

- pliers;

- rags or napkins - they should absorb water well;

- screwdrivers - it is advisable to stock up on Phillips and straight screws;

- phase meter - the tool is a screwdriver with a special indicator built into the handle;

- new heating element.

Armed with everything you need, you can proceed directly to the repair. For everything to be successful, you need to follow a certain order of actions, which will be discussed below.

Read the article: Rating of the best wrenches.

Replacing the water heating element

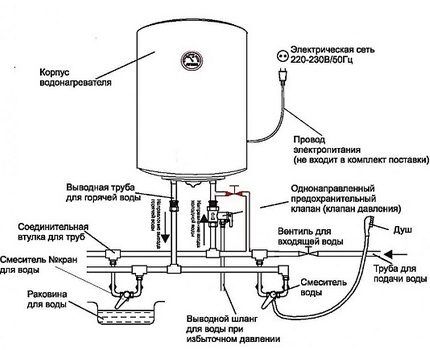

First of all, you need to turn off the water supply. Usually the shut-off valve is located near the boiler. If there is none, you can turn off the water in the entire apartment (from the riser).

Each master can choose any of two methods. The main thing is to stop filling the tank with water. Please note that the DHW supply tap must also be turned off.

Next, you need to perform the following steps:

- drain the water from the boiler;

- disconnect the device from the power supply;

- remove the protective panel, for which a screwdriver is useful;

- using a phase meter, make sure that there is no voltage at the water terminals;

- remove the heating device from its mountings;

- disconnect the wires - before doing this, it is better to photograph the original circuit, which will save you from many problems;

- Unscrew the nuts securing the heating element.

Together with the heating element, the anode that protects the boiler from rust should also be replaced. Next, you can install new parts. In this case, it is necessary to ensure that their contacts are dry. Otherwise, there is a risk of a short circuit.

After all hoses have been connected, the equipment is tested for cold water supply. Please note that the device cannot be plugged into the outlet yet. After all, first you need to check if there is a leak. If there are no problems, then after all the air has escaped through the hot water tap, you can plug in the device.

To make the operation of the boiler as safe as possible, several points need to be checked. First of all, you need to make sure that there is grounding, which must be ensured during boiler installation.

A good addition would be the installation residual current devices, as well as laying a separate power line with its own circuit breaker to protect wiring.

A useful part is the safety valve.It will prevent the pressure in the inner tank from becoming too high. The element is also useful for draining liquid. To preserve boiler components in the event of a water supply interruption, it is recommended to install a check valve in the cold main.

How to increase the service life of a heating element?

In order not to think about the need to replace the water heating element for a long time, you should order it only from trusted suppliers who supply water heating equipment. However, before purchasing, you must carefully study the instructions.

To improve the quality of the water that enters the tank, you need to install purification filters. An even wiser decision would be to organize the purification of the liquid from all kinds of impurities. Multi-stage filtration devices will help to cope with this.

Do not forget to carry out a preventive inspection of your water heater at least once a year. Regular maintenance will allow you to identify problems in a timely manner and solve them without spending a large amount on it.

Conclusions and useful video on the topic

Video #1. Cleaning the water heater heating element from scale:

Video #2. Replacing the boiler heating element:

A water heater is an indispensable device that ensures the operation of an autonomous water supply system. Such equipment will allow you to shower and bathe whenever you want. But in order to enjoy the benefits of civilization, it is necessary to constantly monitor the condition of the boiler, clean it annually and replace worn out parts.

Tell us about how you replaced a tubular electric heater in a boiler with your own hands. Share technological subtleties that may be useful to interested site visitors. Please leave comments in the block below, post photos and ask questions about the topic of the article.

When the old water heater was in place, problems constantly arose with the heating element. Replacements often had to be made. I started looking for information and found a lot of interesting things. It turns out that you cannot turn on the boiler without water. This happened a couple of times by accident. Plus, it was necessary to regularly check the water heating element. Now I have new equipment installed. To avoid problems with the heating element, I decided to install a filter in front of the unit, because the heating element quickly became covered with scale. So far there have been no problems.

Of course, you can’t turn on the boiler without water, this is one of the basic rules. The heating element will burn out very quickly if you do this. Although, in theory, it should not turn on, if the device has a thermal fuse, the foolproof protection should work.

And the old boiler also tormented me with burnt heating elements. Moreover, replacing them is a whole problem. Drain the water and disassemble half of the heater. In short, it was old, and I replaced it with a new one. I bought a new one with dry heating elements and am very happy about it. Changing them is much easier. No need to drain the water. And they fail less often. Scale does not form on them, since there is no direct contact with water. Comfortable.

I’m also thinking about getting a boiler with a dry heating element.Does anyone have experience using such boilers? What kind of problems could they have? Since in a regular boiler it is the heating elements that often fail and the anode must be changed periodically, well, the ouzo can also fly (if it is included, of course). So there’s nothing left to break there anymore. What flies most often in boilers with dry heating elements?