Panasonic air conditioner errors: identifying the fault by code and repair tips

Panasonic brand air conditioning equipment has powerful intelligent functional content.Among the significant advantages that convince consumers to give preference to these air conditioners is the self-diagnosis system. We will talk about how errors in Panasonic air conditioners are determined using characteristic codes.

From the article we presented, you will learn how, when a malfunction is detected, the control system informs owners about an impending or existing breakdown. You will understand how malfunctions are diagnosed, and then the error code is transmitted to the display of the remote control or indoor module.

Our tips will help you maintain the ideal condition of the unit.

The content of the article:

What is an error code?

Panasonic air conditioners have a good range of functions and many automatically controlled systems. This can be fine air purification, ionization of the atmosphere, destruction of dangerous microorganisms, etc.

Automation turns off the air conditioner when it needs repair or cleaning. New models of Panasonic air conditioners have a developed self-diagnosis system. Based on its results, the control system identifies a malfunction and reports its cause on the control panel.

In the event of a serious breakdown, all operation of the equipment may be blocked. If the fault does not affect system operation, the fault message will continue to flash during operation. If air conditioner or split system detects two or more faults, the fault with high priority is indicated first, then all the others.

However, a working air conditioner with a flashing error is not a reason to continue operating the system. Ignoring the sensor signal will worsen the problem and, as a result, lead to more serious repairs, entailing greater costs.

Therefore, when a flashing signal appears, you need to figure out the causes of the failure as quickly as possible and call a technician for repairs or, if you have the necessary experience and skills, solve the problem yourself.

Also, under the cover hiding the air conditioner buttons there is a Check key, with which you can see all the errors in the system by scrolling with the “Up” and “Down” arrows. To reset critical errors, you need to eliminate them, after which they will disappear from the display on their own. Errors are also reset after a power reset.

Errors on the air conditioner remote control

Different models of air conditioners may implement different methods for reading error codes issued by the system. However, the timer indicator on the indoor unit will always blink. Let's look at how to determine the error code.

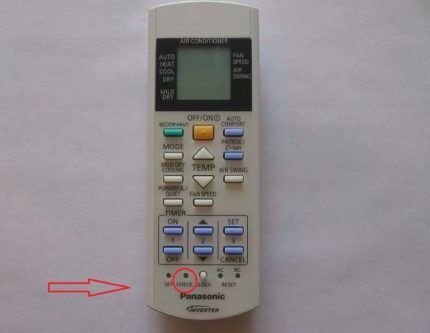

There is a “check” button on the remote control

If there is a “check” button on the control panel, to read errors you need to press it and hold it for about 5 seconds.After this, the display on the screen will change from temperature values to existing error codes.

We point the remote control at the internal module of the air conditioner and use the “up” and “down” buttons to scroll through the error log. At the moment when the desired error is displayed on the display, the air conditioner module will make a sound. You need to flip through the magazine completely from the first code to the last.

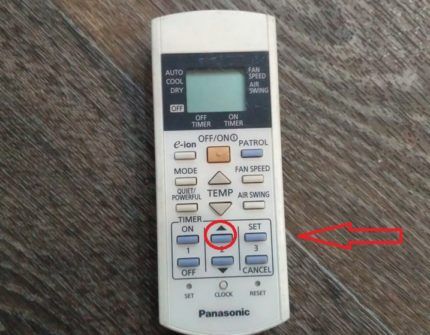

There is no check button on the remote control

If there is no “check” button on the remote control, you must press and hold the “up” timer setting key for 5 seconds. After this, the remote control goes into error code mode.

Next, briefly press the same button and scroll through the errors. At the time of indication, the indoor module will also make a sound. It is necessary to completely scroll through the entire error log, as there may be several of them.

In both cases, after a minute the remote control will return to normal temperature display mode.

On the indicator panel

This is a standard method for finding errors on new air conditioner models. There is an indicator panel on the indoor unit, on which the error code is displayed. The owner of the air conditioner only needs to look at this code and find what it means. In multi-split systems, it is necessary to check for errors on all indoor units.

Decoding signals about malfunctions

Let's look at what error codes exist for Panasonic brand air conditioners and how to find a fault using the code.

H00. There are no problems with the operation of the device.

H11. There is no communication between the external and internal modules or the control boards are faulty. If this error appeared immediately after installing the air conditioner, it means there were errors in the wiring of the line. Perhaps there is a break somewhere. For diagnostics, you can check all connections suitable for the boards - it is possible that there is a bad contact somewhere on the line.

If the error appears after several years of operation of the air conditioner, then it’s time to change the board. You need to find out which board has failed - the internal or external unit. If an error occurs, the indoor unit fan may continue to operate.

H12. The total power of the internal modules does not match the power of the external module. This error only appears in multi-splits. The signal appears 1.5 minutes after switching on.

There may be 3 options here:

- the cooling capacity of the indoor units is incorrectly calculated;

- the number of internal modules is incorrectly selected - the external unit cannot cope;

- error H11 appears on one of the units, then H12 appears on the other (incorrect number of internal modules).

H14. Problem with the air sensor - the sensor records the room temperature above +46ºС or below -56ºС. This means there is an open circuit or the sensor has short-circuited.

H15. Problems with the compressor temperature sensor. The same problems as with the temperature sensor - either the circuit is broken in some area or a short circuit has occurred.

H16. Low current consumption by the external module is detected.

A drop in consumption can occur for several reasons:

- not enough freon (low pressure);

- current transformer defect (the board needs to be soldered or replaced);

- failure of the power IPM module.

H17. Similar to H14, but in relation to the external unit - breakdown of the temperature sensor on the suction tube in the compressor. There was either an open circuit or a short circuit on the sensor.

H19. The appearance of an error indicates that the motor of the internal module is jammed: when the actual speed of the module motor does not correspond to the speed that was set by the processor.

There can be several reasons for errors:

- problems directly with the motor of the indoor unit;

- the connectors of the motor wires of the indoor unit have come loose;

- problems with the internal module board.

H21. There were problems with the drain pan float in the indoor module. The signal indicates that the sensor is open. You need to check the sensor logic and look at the resistance on the pump motor windings, which should be about 200 Ohms. The drainage may also become clogged; the drainage needs to be flushed or purged.

H23. Problems with the basic sensor No. 1 of the heat exchanger surface temperature in the indoor module. The processor records the fact of an abnormal heat exchanger temperature above +80ºС or below -40ºС. You need to look for either an open circuit or a short circuit in the sensor.

H24. Problems similar to H23 with the optional heat exchanger surface temperature sensor No. 2 in the indoor module.

H25. There were problems with the ionization unit. The port is on when the E-Ion is off.There may be problems with the E-Ion board or the internal module board.

H26. Practical hint: for some reason the air ionizer has failed.

H27. There were problems with the outside air temperature sensor. The processor records the outdoor temperature above +150ºС or below -40ºС. The cause of the failure may be an open circuit or a short circuit in the sensor.

H28. Problems with sensor No. 1 of the surface temperature of the heat exchanger of the external unit. The processor records the temperature on the surface of the heat exchanger above +110ºС or below -60ºС.

The cause of the malfunction is either a short circuit in the sensor or an open circuit.

H30. Problems with the temperature sensor on the discharge tube in compressor. The processor records temperature readings above +200ºС or below -16ºС. An open circuit in the circuit of this temperature sensor is detected when the condensation temperature is 6 degrees higher than the discharge temperature. The cause may be an open circuit or a short circuit in the sensor.

H33. An interblock connection error appears when there is a voltage mismatch in the data transmission line between the internal and external modules. There are problems with the power supply lines of the external and/or internal units.

H34. An error has occurred in the temperature sensor installed in the power module radiator. The processor records the temperature from the heat exchanger plates of the external unit above +80ºС or below -43ºС. There was either an open circuit or a short circuit in the sensor.

H35. Problems with the sump pump or clogged drain. It is necessary to clean/blow out the drainage line.Then check the sensor logic and the resistance in the pump motor windings (should be about 200 Ohms).

H36. There were problems with the temperature sensor in the gas pipe of the external module in heat mode. The processor records temperatures above +149ºС or below -45ºС. You need to check the circuit or sensor for a short circuit.

H37. There were problems with the temperature sensor in the liquid tube in the external unit in cold mode.

Either there is an open circuit or there is a short circuit on the sensor.

H38. Inconsistency between the brand codes of the internal unit and the external one.

H39. The indoor module froze in standby mode. Occurs due to abnormal temperature of the evaporator unit. This indication appears simultaneously on all units except the unit on which the evaporator is frozen. Error code F17 appears on the last block.

The problem occurs because:

- the solenoid valve of the external unit has failed;

- Freon lines and control wires are mixed up.

H41. Incorrect connection of wires and freon lines.

H 50. The fan motor is faulty. Or problems with the internal module board.

H51. The nozzle is clogged.

H52. The limiter switch is faulty. Or problems with the internal module board.

H58. A fault is detected in the PatrolSensor unit.

H64. There is a malfunction in the high pressure sensor installed in the external module. The high pressure switch remains open for one minute when the compressor is stopped.The cause of the failure may be a failure of the sensor itself, damaged/broken wires, or problems with the connectors on the board.

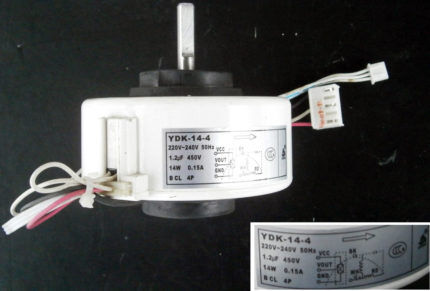

H97. The motor of the external unit is jammed: the actual speed of the motor does not correspond to that set by the processor.

The reason for the failure lies in:

- failure of the external unit motor;

- failure of the internal module board;

- in problems with wire connectors (you need to measure the voltage on them).

H98. The protection of the indoor module against excessively high pressure or overheating of the module in heat mode has tripped. When the temperature of the heat exchanger in the indoor module rises to +52ºС, the protection is activated, and at a temperature of +65ºС the compressor stops completely. The compressor restarts after the temperature drops.

The problem may appear due to:

- insufficient heat removal from the heat exchanger;

- heat exchanger contamination;

- incorrect readings from the sensor installed in the heat exchanger;

- warming up the indoor unit during warm start.

H99. In operating mode, the evaporator of the indoor unit freezes. The speed limitation is activated if the temperature in the indoor module drops to +8ºC. The compressor stops at 0ºC and then restarts when the temperature rises. The restriction is lifted when the temperature rises to +13ºС.

The problem may occur due to:

- refrigerant leak or insufficient refill;

- capillary tube clogged;

- moisture appears in the refrigeration circuit.

F11. This error indicates that the 4-way valve responsible for the cold/heat switching is incorrect.The cause may be defects in its mechanism or in the valve solenoid coil.

F17. Freezing of the indoor module in standby mode is detected. The indicator is triggered exactly on the block on which freezing occurs.

The cause may be a malfunction of the solenoid valve (leaks) in the corresponding circuit of the external unit. An error may also be indicated by incorrect data from the indoor module heat exchanger sensor.

If the error appears immediately after the first start of the system, it means that when air conditioner installation Freon lines and control wires were mixed up.

F90. The error appears when the compressor speed is no longer synchronized with the processor signal.

The signal will appear:

- if the compressor windings break (each winding under normal conditions should have a resistance of about one Ohm);

- if there is a difference in the resistance of the windings;

- if there is a malfunction in the inverter circuit of the outdoor module board.

To eliminate the malfunction, you need to measure the resistance and voltage.

F91. The error indicates that the refrigeration circuit is not operating correctly or that low pressure protection is triggered.

A malfunction occurs if:

- no freon;

- The three-way valve on the external unit is faulty.

F93. The signal shows the discrepancy between the actual compressor performance and the controller control signals. In other words, when its rotation speed does not coincide with the controller control signals. In this case, the system stops.

F94. The protection is triggered due to excessively high discharge pressure. It is necessary to check the operation of the refrigeration circuit.

F95. In cooling mode, the high pressure protection of the external module was activated. The problem may occur in the refrigeration circuit or due to overheating of the outdoor module heat exchanger.

F96. Overheating of the power module is detected, and in multi-systems the compressor thermal tablet has opened.

Possible reasons for the error:

- contamination of the external module heat exchanger;

- contamination of the refrigeration circuit;

- power module defect;

- compressor failure.

F97. A high discharge temperature in the compressor is detected and the compressor overheats. The error may clear itself after 20 minutes of uninterrupted operation. One of the signs of an error is frequent stopping of the external module for no apparent reason.

The causes of the problem may be:

- under-fueling;

- compressor discharge tube sensor data error;

- interturn short circuit in the compressor windings;

- failure of the external module fan.

F98. The protection for the total current consumed has tripped. Inadequately high current consumption by the external module in operating mode is detected. The cause of the error must be sought in contamination of the refrigeration circuit or contamination of the heat exchanger of the external module.

The error may appear if there is a strong voltage drop in the power supply when the air conditioner is turned on or during operation.

F99. This is a DC protection error signal. Possible reasons for the error:

- compressor jamming;

- breakdown of the transistor module;

- defective current sensor installed in the outdoor module board;

- the resistance in the compressor windings has dropped below normal. It is necessary to measure the resistance in the compressor windings and in the transistor module.

In order to figure out what this or that error in Panasonic air conditioners shows, you need to download the service manual for a specific model from the Internet and look in the errors section.

Standard Care Requirements

The instructions for air conditioners of this brand necessarily describe the procedures for caring for them. This part of the documentation should be studied especially carefully, since following these instructions will help reduce the number of breakdowns.

Malfunctions in Panasonic air conditioners can require expensive repairs and even the purchase of expensive spare parts to restore the device to functionality. Therefore, regular maintenance in accordance with the manufacturer’s requirements is especially important for equipment.

Most maintenance procedures do not require much knowledge and do not take much time, but some will require disassembling the units, so it is better to seek the help of a technician from a certified service center.

Conclusions and useful video on the topic

You can see how to clean a Panasonic air conditioner in this video:

The following video will clearly demonstrate how to check the internal module for errors:

Intelligent Panasonic air conditioner systems are able to promptly notify the owner of the climate control device about a malfunction that has occurred in the bowels of the unit. Information on decoding can be found in the passport or video review.

Having identified the error code, a person can make a decision - to correct the situation on their own (for example, clean the drainage) or call a specialist for a more complex repair.

Tell us how you identified a malfunction in the Panasonic climate control system using the code. Share the nuances you know about diagnosing and fixing the problem. Please leave comments in the block below, post photos and ask questions about controversial and interesting points.

Error H33, please tell us in more detail or provide a link.

Panasonic CS-XE12JKDW (internal unit) CU-E12JKD (external unit) Operates for 8 years.

It doesn't cool well. Cleaned and refilled. Doesn't matter!

Hello. H 33 indicates an interconnect error.

VRV system external unit U10ME1E81 error on internal unit E 21

Panasonic cs-c7bkp when turned on, the fan picks up speed to maximum, after 30 seconds the speed drops to minimum. On the remote control COOL 16, FAN at maximum.

Hello. H 33 indicates an interconnect error.

Good afternoon, the control panel displays error F32 01, what could this be?

Good afternoon. For an accurate answer as to what exactly the malfunction is, you need to contact a specialist.