Beautiful examples of cladding the facade of a house - expert advice

At the final stage of building his own house, the owner is faced with one problem - how to clad the facade of the house.There are many materials for this on the modern market. Each has its own price, performance characteristics and service life.

The content of the article:

What is a building facade

This is the front, or outer, side of the house. Part of it is facade finishing, as well as various architectural elements. The word itself came into the Russian language from Italy, when Italian architects built houses in St. Petersburg. The word “faccia” is translated as “face”. For information, there is a synonym for façade. This is the exterior.

Types of facades:

- Main. It is located on the side of the main entrance.

- Street, aka front. Usually coincides with the main facade. This is the side of the building that is visible from the street (from the roadway).

- Parkovy, also known as a yard worker. This is the back wall of the house. Previously and even today, many courtyards, parks, and flower beds are formed in front of houses. And this part of the facade is located on the opposite side of the main view.

- Side. These are the surfaces of the side walls of the building.

The cladding of a house is an important component of the building.Often it performs not only an aesthetic function, but also a number of others - heat and sound insulation. Therefore, exterior finishing is carried out taking into account the tasks assigned to it.

How to decorate the facade of a house

It is impossible to answer unequivocally that some building material is an ideal option for exterior decoration of a house.

But there are some points to consider:

- the façade of the main house must fit harmoniously into the landscape of the site, plus all other buildings must correspond to it;

- façade materials should be used taking into account energy-saving technologies;

- building materials and building design must complement each other;

- home decoration and national traditions are a good combination, although young owners of private real estate often prefer modern exterior design options.

And, of course, it is important to stay within the budget allocated for external cladding. It depends mainly on the materials that are planned to be used to decorate the facade of a private house. Therefore, it is the building materials that will be dismantled next.

Let's look at the options for exterior decoration of the house and choose the best one.

Natural and artificial stone

A natural variety of this material has been used in construction for a long time. It has not lost its relevance in facade decoration today.

Pros:

- highest strength and durability;

- environmentally friendly material;

- does not burn, does not deform under the influence of temperature and humidity;

- easily withstands atmospheric loads;

- natural beauty makes the facades of houses unusual;

- many types of stone have the property of “breathing” - allowing air to pass through themselves, for example, shell rock, limestone;

- When facing, there is no need to additionally prepare the surface to be finished.

Natural stone is not a cheap pleasure. And this is its big minus. There are other disadvantages:

- the material is heavy, so a solid foundation is laid under the stone finishing of the facade, which leads to an increase in the budget;

- stone is difficult to process;

- The cladding process itself is not easy. Experience with this type of work is required.

To reduce the cost of stone decoration of the facade of a house, manufacturers began to offer an artificial analogue of the natural one. In essence, this is a product based on concrete mortar, which from the front side exactly copies the pattern of natural stone.

The production technology is simple - concrete is poured into prepared forms. In this case, vibration of the molds can be additionally produced, which increases the quality of the products. Today, construction stores sell molds for artificial stone, so making it yourself is not a problem.

As for the characteristics of the artificial analogue, it is in no way inferior to the natural one. But the price is lower, plus - these are ready-made slabs with their own dimensions.

Stone facing materials of both types cannot be called cheap.

Facing brick

Like stone, brick is a powerful cladding of the facade of a house. It is presented on the market in a small classification, which is based on the type of raw material.

There are only four types of finishing materials for facades of this type:

- silicate;

- ceramic;

- clinker;

- hyper-pressed.

Silicate

This type is made from lime mixed with sand. The mixture undergoes semi-dry pressing, after which the semi-finished products are steamed in autoclaves. This technology allows you to achieve good performance characteristics:

- density – 1300-1450 kg/m³;

- frost resistance – 25-75 cycles;

- strength – 10-30 MPa.

But thermal conductivity is 0.3-0.5 W/m K. And this is not the best indicator. Another disadvantage is low water resistance due to the porosity of the structure. At 11% moisture saturation, sand-lime brick is destroyed.

Manufacturers today offer a full-bodied and hollow look with a smooth, textured front surface. The color palette is not the widest, but there is plenty to choose from.

Of all the facing bricks offered, silicate is the cheapest.

Ceramic

The most common version of this brick is red. But the colors vary. It is based on the color of the fired clay. Manufacturers offer white and black ceramic bricks. The first one is made from special clay. The second is fired in an oxygen-free environment.

Characteristics:

- strength – 10-30 MPa;

- frost resistance – 50-100 cycles;

- water absorption – up to 14%;

- density – 1600-1900 kg/m³;

- fire resistance – 10 hours.

Clinker

The production technology for clinker is the same as for ceramic. The raw materials are the same. But there is a difference. This is a firing temperature of +1900 ℃. For ceramics, no more than +1400 ℃.

At such a high temperature, the clay is brought almost to the boiling point. The final result is a molten mass, which after cooling is a monolithic piece. Such a brick, if you knock on it, rings.

Characteristics:

- strength – 25-35 MPa;

- water absorption – 5-6%;

- frost resistance – 200 cycles;

- density – from 1500 kg/m³.

Hyper-pressed

This material can be called a brick only by its size. In all other respects, it is a concrete block, because it is made on the basis of cement and one of the fillers:

- lime;

- marble;

- marl;

- crushed stone screening;

- waste of various ores and others.

No burning. The main process is pressing under high pressure. Hence the characteristics:

- strength – 10-40 MPa;

- frost resistance – 300 cycles;

- thermal conductivity – 0.5-1.0 W/m K;

- water absorption – 3-7%.

Pressing under high pressure makes the brick precise in size and shape, allowing you to obtain a smooth surface on the sides without defects. But the material is quite heavy compared to previous types of facing bricks.

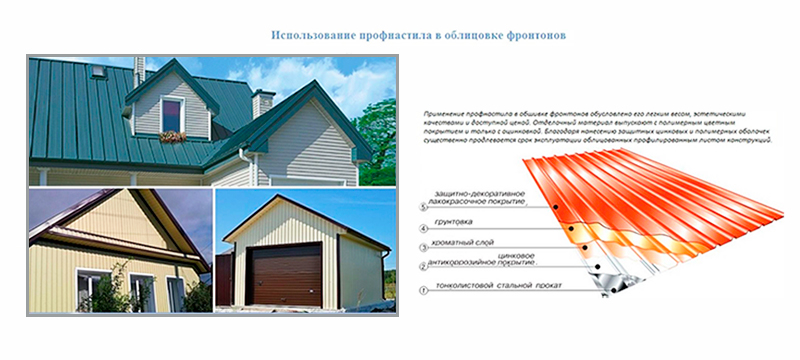

Corrugated sheet

Since the analysis of materials for cladding the facades of houses is being carried out, it would be correct to talk about wall corrugated sheets, the marking of which uses the letter “C”. And other brands of profiled sheets can be laid on the walls of the house. It’s just that the wall one is designed specifically for vertical installation. Its wave height is lower than that of the roofing one. And there are no grooves for water drainage. Made from steel sheet with a maximum thickness of 0.5 mm.

Advantages of facades made of corrugated sheets:

- profiled sheet is a relatively cheap building material, but this does not take into account the frame structure that must be assembled under it;

- service life – up to 50 years;

- withstands changes in humidity and temperature well;

- sufficient strength to indicate the reliability of the protection of the walls of the house;

- easy installation;

- variety of colors;

- there is no need to level the wall surfaces;

- Thermal insulating material is placed under the corrugated sheeting, which makes it possible to reduce the cost of heating the house.

There are few disadvantages to this type of façade cladding:

- the metal heats up in the summer, and if the temperature is high, it is impossible to touch the facade;

- slanting rain or hail can create noise from the impact of drops on a metal sheet;

- Rust may appear on the cuts, so before installation, the edges of the material must be treated with paint.

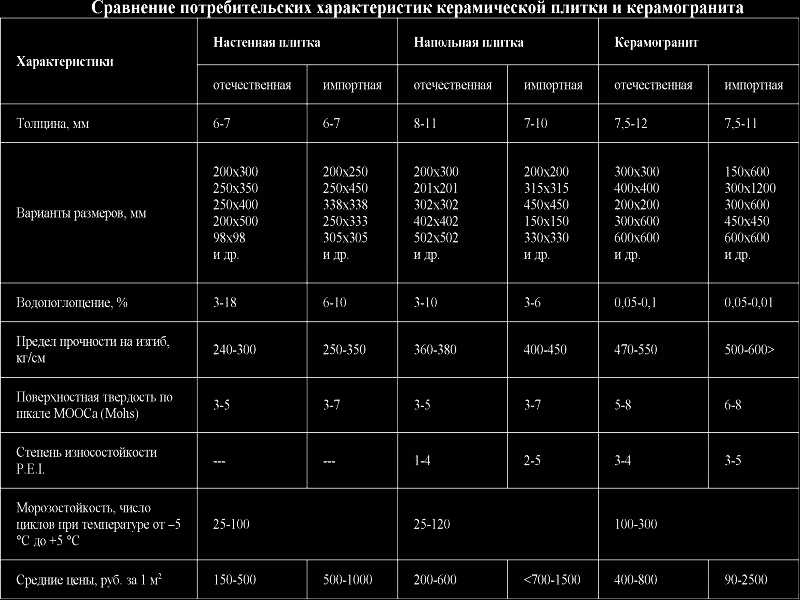

Finishing tiles

Tile materials and facade decoration are two components of success in terms of achieving the external beauty of the house. And there is a lot of this material on the market.

Porcelain tiles

Porcelain tiles are produced using the technology of producing conventional ceramic tiles. This is molding and firing. Only the first stage is carried out under high pressure - 50 MPa, which gives the material high strength by removing air and moisture from the raw material. Firing is carried out at a temperature of 1300 ℃.

Characteristics:

- On the Mohs scale, hardness is 7-8. For comparison, this figure for the hardest material – diamond – is 10;

- water absorption – up to 0.05% (almost zero). For comparison, marble has 0.11%;

- frost resistance – 150 cycles.

There is such an indicator for tiles as wear resistance. It is marked as PEI, and digital values from one to five are added in Roman numerals. For example, PEI V is the most wear-resistant porcelain stoneware.

Since the material is used for finishing the facade of houses, this technical characteristic does not need to be taken into account. Therefore, PEI I is suitable as the cheapest option.

As for the advantages of porcelain stoneware, this is, first of all, the high strength of the material. It is not for nothing that it is compared to granite.

Other advantages and disadvantages:

Installation of porcelain stoneware on the facade can be done in two ways: wet and dry. The first is a standard technology for an adhesive composition, where frost-resistant mixtures are used. The second is frame technology, where clamps are used as fasteners. This option is unique in that there is space between the façade finishing and the walls of the house, which is usually filled with insulation.

Concrete

Concrete tiles are essentially artificial stone, only thinner and produced using a simplified technology - conventional molding without pressure.

In this case, decoration of the material can be done in two ways:

- Throughout the entire body of the tile. The dye is added to the solution when its components are mixed. The finished product is painted throughout.

- Color of the upper facial layer. First, the dye is poured into the mold, and the concrete solution is placed on top of it.

The first option is better. Manufacturers offer both individual tiles and entire panels. The latter are easier to work with. As in the case of porcelain stoneware, this finishing material can be laid on the facades of houses in two ways: wet and frame.

Terracotta

The production uses clinker brick technology. The raw materials are the same. The shape and structure are different.Firstly, these are the panels. Secondly, in order to reduce weight, they are made hollow, thereby increasing their thermal insulation properties.

Characteristics:

- strength – 10 MPa;

- water absorption – up to 5%;

- operating temperature range – from -60 ℃ to +120 ℃;

- frost resistance – from 150 cycles.

Manufacturers offer panels with a thickness of 12-40 mm, a height of 300-600 mm, and a length of 250-1600 mm.

The indicated technical characteristics indicate the serious advantages of the material.

But there are also disadvantages:

- not the cheapest price;

- heavy weight;

- complex installation - it is frame.

Polymer sand

The name of the tile indicates the composition of the material. These are sand and polymers, plus dyes. The second component provides plasticity, which ensures that the tiles will not break during transportation and will not break during cutting.

Manufacturing process:

- mixing components;

- melting the mixture at a temperature of +250 ℃ in the extruder:

- pressure molding.

Characteristics:

- strength – up to 25 MPa;

- water absorption – 0.15%;

- frost resistance – 300 cycles;

- density – 1600-1800 kg/m³.

For finishing the facades of houses, manufacturers offer both tiles and panels of different textures and colors.

Clinker

The production technology is the same as that of clinker bricks. This is pressure molding and firing at high temperatures. You can form it in two ways:

- pressing;

- extrusion.

Tile differs from brick in thickness - 9-10 mm.

Characteristics:

- frost resistance – 300 cycles;

- water absorption – 3%;

- strength – up to 25 MPa.

Laying is carried out using an adhesive composition using standard technology.

Ceramic

Ceramic tiles, also known as tiles, are a popular material that has long been used both for interior decoration and for cladding the facades of houses. Its characteristics:

- strength – up to 16 MPa;

- frost resistance – 300 cycles;

- water absorption – up to 18%

The advantages include a huge variety of design designs.

Agglomerate

In fact, it is an artificial stone, because it is made from different types of crushed stone, the particles of which are held together either by resins or cement. To give the product a certain appearance in terms of design, the following is added to the mixture:

- pigments;

- steel filings;

- glass granules of different colors, etc.

Hence the technical characteristics of the material, which are exactly the same as those of artificial stone tiles.

Wood finishing materials

Wooden building materials, even in the age of advanced technology, have not lost their relevance. And this also applies to such a process as facade finishing. Manufacturers offer several traditional and new wood products. They are all divided by grade, hence the different prices.

Wooden finishing materials for facades are laid only on the sheathing. The space under them allows for thermal insulation measures at home.

Lining

Covering a house with this material is an old technology. We must immediately make a reservation that there is no lining for facades or for interior work. There are recommendations regarding which type to use where. For example, it is better to lay material made from coniferous trees as finishing for the facades of houses, because the wood contains resins that enhance the protective properties.

Therefore, when choosing, it is better to rely on the types of models;

- American;

- peasant woman;

- standard;

- landhouse and so on.

Eurolining

It's still the same lining, only of higher quality. The prefix “euro” was given to her precisely for this. There is no separate GOST for European materials.

Lining made from high-quality raw materials using the latest technologies, which guarantee the highest quality and exact dimensions of the dies, is called eurolining.

Shingles

These are small boards. But these are not panels. Sheathing a house with shingles is not difficult, because the installation method used here is exactly the same as when installing tiles on the roof. Sometimes shingles are called wood shingles. The thickness of the dies is 3-6 mm.

Block house

This is a type of lining that imitates logs on the facades. Essentially, this is a longitudinal cut of the side of a log, which undergoes serious processing. In the end, a product with a rounded front surface is obtained.

When finishing the facade of a house, the result is a wall that looks like a log house, although it is not one.

Siding board

The word "siding" is American.

It denotes a technology for finishing the walls of houses, which has two objectives:

- wall protection;

- formation of an aesthetic appearance.

The siding category can include lining, block house and other similar wood materials. As for siding, which is made to look like a board, it is called planken. This is a modern type of lining, all sides of which are planed.

There are three types of material on the market:

- all sides are at right angles;

- the ends are located at an angle of 35-70º;

- grooves are made at the ends to connect the panels.

High-quality surface treatment makes planken expensive compared to lining.In all other respects these are identical materials.

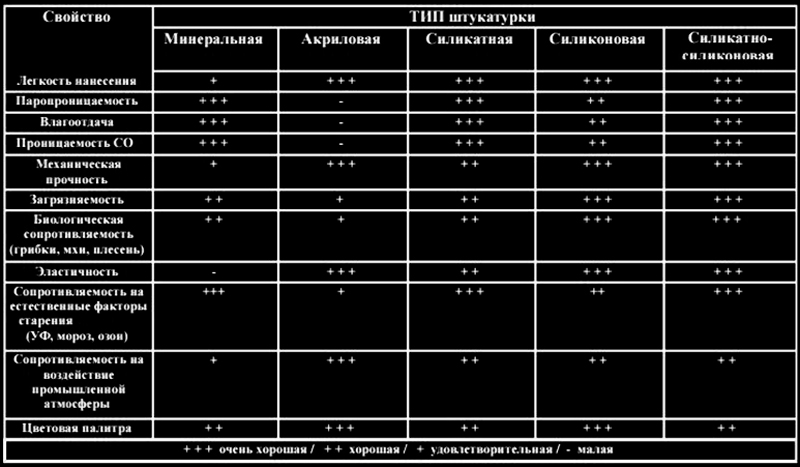

Decorative plaster for facade finishing

This type of finishing, which is also called a wet facade, is an economical option for decorating the walls of houses. This is a practical solution with which you can hide defects in the construction of a house, protect the structure, and give it an aesthetic appearance.

Plastering the outside of a house is not difficult. And that's a plus.

The advantages can be added:

- long-term operation of facades;

- unpretentious further operation;

- variety of textures and colors;

- immunity to atmospheric loads.

It is not worth comparing with the decorative finishing of facades with brick, stone and other durable materials. But the price here is much lower.

There are several types of decorative plasters on the market. They differ from each other mainly in the binding substance.

Acrylic

Here the binder is acrylic resin, into which several additional ingredients are added that make the plaster waterproof, vapor-permeable, durable with minimal application costs. This is a ready-to-use material in the form of a dispersive aqueous solution.

High elasticity is one of the advantages of plaster. Therefore, it is easy to apply to the facades of houses built of brick, concrete, wood and other materials

Other advantages:

- tolerates changes in humidity and temperature well;

- easy to clean;

- good impact resistance;

- dries within 24 hours.

Mineral

The binder here is cement, hence the high strength of the finish. Mineral substances are used as fillers: marble, granite or quartz chips.The layer applied to the facade has good vapor permeability, but at the same time it is as moisture resistant as possible.

Plaster of this type is divided according to the size of the fillers included in the composition:

- rough-textured – granules larger than 5 mm;

- large-textured – 3.5-4.5 mm;

- medium texture – 1.5-3 mm;

- fine-textured – 0.5-1 mm;

- fine-textured - less than 0.5 mm.

The first three are used to decorate the facades of houses.

Silicate

Liquid glass is used as a binder, to which granular fillers, pigment and additives are added to increase the quality of the material.

Silicone

Silicone is a material synthesized from polymers. It is the binder in this type of plaster. Granular fillers, fibers and other substances, special additives are added to it.

Advantages:

- the plaster does not shrink;

- cracks will not appear on its surface due to the high elasticity of the mixture;

- does not allow moisture to pass through;

- its surface is easy to clean;

- Mold and mildew will never appear on such a facade of the house.

Panels

Cladding the facades of houses with panels is considered a fashionable trend. But it is not only high popularity that makes this material in demand. For example, ease of installation makes it possible to make a beautiful façade in just 2-3 days. And the variety of models offered is very large.

Glass panels

An unusual type of facade decoration, which is often used to decorate administrative, commercial and other buildings. But some owners of private houses also decide on such an exterior. Manufacturers offer three types of glass: shock-resistant, vandal-proof and bulletproof.

The facade made of glass panels turns out to be unusual, but with one drawback - the glass quickly becomes dirty.

Alucobond

This is a composite material that is produced specifically for the formation of facades. It consists of two thin aluminum sheets, between which a layer of polymer is laid.

Advantages:

- low specific gravity;

- ease of processing, which makes it possible to make various shapes from the material;

- easy installation;

- one hundred percent moisture resistance;

- do not be afraid of changes in humidity and temperature;

- good strength with good flexibility;

- service life – 50 years.

Two disadvantages:

- low fire resistance;

- maintainability is low - if an area is damaged, several panels will have to be dismantled.

Thermal panels

This is also a composite material consisting of three layers:

- The bottom one is the base. Either OSB board or glass-magnesium sheet is used.

- Medium - insulation, usually polyurethane foam.

- The top one is decorative: porcelain stoneware, tiles, stone, clinker tiles.

This type of façade cladding solves three problems at once:

- Protection of the house from atmospheric loads.

- Decorative design.

- Wall insulation, which reduces heat loss.

Fiber concrete

The binder is cement. Filler – fine sand or any other similar mineral material. Fiber (usually fiberglass) is added to act as a reinforcing frame.

The panels are durable with a high moisture resistance.The cladding turns out to be non-flammable, does not crack as the house shrinks, and withstands shock loads well.

Siding

The wooden variety was mentioned above. But besides this, there are other types on the market: plastic, concrete, ceramic and metal.

Plastic siding is the cheapest option. It comes in two types: vinyl and acrylic. The first one tolerates low temperatures well. The second, on the contrary, is tall.

Fiber cement siding has the same qualities as fiber-reinforced concrete cladding slabs for facades. Made from the same materials and using the same technology.

Metal siding - there are two types: steel and aluminum. The latter are aluminum panels without additional decoration. The option for the facades of private houses is expensive, so it is rarely used in this area. The first is steel panels coated on the front side with a polymer layer. The latter not only performs protective functions, but also decorative ones.

AMK decorative coating

Cladding the facades of houses is becoming easier. AMK is proof of this. This thin material (only 9 mm) consists of three layers:

- base – fiberglass reinforcing mesh;

- acrylic;

- painted marble chips.

Service life – 60 years. Easy installation - on the prepared surface of the facade wall using an adhesive composition. If the panel fails, it can be easily replaced with a new one. The coating washes well. Light weight.

Sandwich panels

This building material was intended to form the walls of frame structures. Therefore, it was made in the form of a three-layer panel:

- the top and bottom layers are protective;

- medium – insulation.

Sandwich panels are used for cladding facades built from different materials, if the task is to carry out quick and high-quality repairs and create an external thermal insulation layer.

There are three types of panels on the market:

- The protective layers are galvanized steel sheets. The surface can be smooth or corrugated.

- The protective layers are aluminum sheets.

- The same thing, only from wood-polymer boards. Such panels are called SIP.

Mineral wool, polystyrene foam, and polyurethane foam are used as insulation.

Metal cassettes

This option for finishing facades is practically not used in private housing construction. Essentially, these are panels made of metal, in the form of a sheet with edges bent at 90º.

Manufacturers offer four types of metal cassettes:

- made of galvanized steel;

- made of aluminum;

- composite version: aluminum with layers of mineral wool and crumbs;

- from copper.

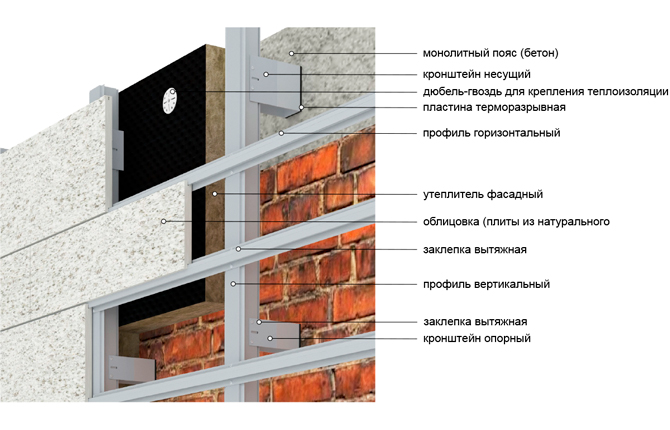

Installation technology - ventilated facade with all the advantages of this design. Thermal insulating material can be easily placed under the cassettes. For installation, a special frame is used, the elements of which are offered by manufacturers as an integral part of the installed facade.

Hanging structures

This group of structures for cladding the facades of houses includes all that fall under the category of ventilated ones - mounted on a frame. And in this case, there is always a space between the cladding and the surfaces of the walls of the building facade.

The list is large:

- porcelain stoneware;

- concrete facade slabs, polymer concrete and fiber cement, including;

- composite panels;

- metal cassettes;

- wooden facade board;

- siding;

- glass panels, etc.

This façade design has many advantages:

- the ability to install insulation on the façade;

- 100% protection of the house from precipitation, wind and sunlight;

- durability – 50 years minimum;

- high maintainability;

- easy installation;

- the structure can be used as lightning protection;

- variety of colors, shapes and materials.

Imitation of timber

This is also a type of lining, only thicker and wider. At the same time, the sides of the panels are equipped with a tongue-and-groove locking connection, which allows the boards to be joined together without gaps.

When using this material on the facade, a finish is obtained that imitates a house made of timber. It can be laid on the facade of any building, because the boards are installed on a pre-built frame.

Combined facade finishing options

Different finishing materials are used simultaneously for cladding the facades of houses. There are many combinations. Designers sometimes offer unthinkable ideas that are combined on the façade into a single integrated approach.

The most popular combination options:

- plaster and stone;

- wood and stone;

- paint and stone;

- wooden panels and metal finishing materials;

- tiles and wood, etc.

Combined facade finishing has been used for a long time. And today its popularity has not diminished.

Let's summarize what type of façade finishing our readers liked best.

Requirements for façade cladding materials

There are not many requirements for cladding the outside of a house. Everything is based on the long-term use of the finish and the preservation of its original appearance.

Hence all the nuances of choice:

- strength;

- frost resistance;

- moisture resistance;

- resistance to atmospheric loads;

- preservation of appearance under the influence of the sun (in any case, do not fade for a long time);

- take into account fire safety requirements.

Not least important is the future design of the facade. Therefore, it is necessary to take into account the opinion of experts.

The price requirement is relative. The rule will not necessarily apply here - the more expensive, the better the quality. On the market you can purchase materials in the optimal price-quality ratio.

Facade design styles

Often it is the design of the building that dictates its finishing. But the exterior of the house must be laid out at the design stage.There are many options for designing the facade of a house, even for buildings erected many years ago.

Today, remaking the front side will not be difficult, since the materials and technologies are available. But before you make a choice, you need to understand the types of facades.

Minimalism

Very popular today. There is no pretentiousness here, no unnecessary decorativeness. Everything is based on the important details that stand out first.

Style Features:

- conciseness;

- simple geometry;

- strict forms;

- no bright accents;

- maximum space;

- big windows;

- good lighting;

- stone, wood, glass are the main materials of the facade.

Provence

The style came from France and was named after one of the provinces of this country, where village life was reflected in the design and decoration of houses. Therefore, natural building materials are the basis for the design of facades. Here there is mainly wood and stone, but houses in the Provence style are often plastered.

Modern

Bizarre shapes and ornateness, but at the same time everything should be in moderation. This is the Art Nouveau style, which appeared at the turn of the 19th and 20th centuries. Curved lines of the roof and windows, but no symmetry.

For the facades of houses in the Art Nouveau style today, various building materials are used, even modern ones (made of polymers). But it is porcelain tiles or ceramics that make it different from others. The glaze will highlight this style direction.

Country rustic

The concept of “country” is the most vague. This can include many style trends that originated from village life. For example, Provence is also country. The only thing that unites everyone is the materials used for cladding the facades.They must be natural, natural.

There are no common features in terms of design here. Each has its own traditional shapes, colors, etc. For example, the Russian country style is a wooden hut, the American style is a frame technology with clapboard as cladding. Or chalet-style houses - rough construction, unusual shapes, where raw wood and stone are used as building materials.

Loft

The urban loft style comes from America. The history of its appearance is based on the transfer of factories and factories from the territory of cities to their borders. Old industrial premises were converted into housing, where an industrial atmosphere reigned.

As for the facades, it was the untreated brick wall that became the basis of this style. Brick and clinker are used today to create a loft style. Sometimes it is combined with plaster.

English

Restraint and severity are the main components of the English style. Therefore, the facades of houses in this style are faced with brick. Sometimes a light-colored stone is added. Stone-like ceramic tiles are often used.

Smooth walls, high windows, a small porch, a tiled roof - all this is the English style.

Wright Prairie Style

This direction received its name from its inventor, the American Frank Lloyd Wright. Otherwise often called prairie style.

Distinctive features:

- long horizontal lines;

- A lot of space;

- there are few façade decorations;

- glass galleries;

- The roofs are either flat or hipped.

Only natural building materials are used: stone, brick, wood, paint and plaster.

Scandinavian

The main building material in Scandinavia is wood, which means that the cladding of house facades is made from it. Previously, such finishing was not even painted. Today they are necessarily painted and even in different colors.

The modern approach to the implementation of Scandinavian design has undergone changes. In addition to wood, stone, brick and siding began to be used. Remains unchanged - two floors, large windows and minimalism throughout the design. In the north, the beauty and thermal insulation properties of houses are important.

Mediterranean

Arched openings, rounded shapes of the house, no symmetry in the design of the building, more often it is a modular structure, where each part is assigned certain functions: kitchen, bedroom, etc. This is a Mediterranean style, where the facades of houses are surrounded by greenery.

But the most important thing is that the Mediterranean is a large number of countries that have their own distinctive features. But everyone has one thing in common - the facade should be light in color, natural materials should be a priority. But more often it is painted plaster.

Chalet

In other words, an alpine house. Despite its apparent simplicity, it is not easy to build.

This building has two floors:

- the lower one is stone;

- the top one is made of wood.

Therefore, the decoration of the facade of such a house is predetermined: stone and wood. Although the stone is often plastered.

High tech

This is a modern style that has become increasingly popular lately.

Its distinctive features:

- modern building materials are used for facades: glass, concrete, plastic, etc.;

- the color scheme is poor – often white and gray;

- no façade decorations;

- large glazing area.

Maximum functionality of the house is the basis of style.

Half-timbered

This is a European style, the distinctive feature of which is the vertical, horizontal and inclined elements of the building frame, visible on the facade. They can be elements of the facade or be located on its surface as decorative non-load-bearing elements. The latter are made of polyurethane foam or other finishing material and are attached to the plastered surface of the facade.

Oriental

The East is a multifaceted and broad matter. But more often this style direction refers to the architecture of China and Japan.

And houses from these countries have clearly defined architectural features:

- pagoda;

- dome additions;

- an open courtyard, along the edges of which columns are installed;

- sharpened arches;

- bright colors;

- stained glass windows are welcome.

Hence the building materials for finishing the facade: wood, stone, brick, plaster and paint.

Building façade lighting

The design of the façade of a private house cannot be approached only from the point of view of finishing. Lighting is an important component.And it should emphasize the architecture of the building and become part of the facade.

For public buildings, there are strict standards for the brightness of façade lighting. They cannot be violated. In private housing construction, everything is much simpler, but at the same time more complicated. There are no norms, but there are customer preferences, his taste, which must be taken into account.

And this is where the difficulty arises. Many people want unusual lighting. But a person spends most of his life in the house. And it is important that the light does not irritate household members, even for the sake of fashion and popularity.

What you need to consider when choosing the type of lighting for the facade of a house:

- building architecture;

- type of facade finishing, what material it is made of;

- type of yard lighting.

Everything should be in a complex. None of the elements should put pressure on the others.

Beautiful examples of house facades

Ordinary plaster and smooth walls can become a beautiful design for the facade of a house. The main thing is to choose the colors correctly and harmoniously.

Stone and modern finishing materials create an amazing design for the facade of a house in a minimalist style.

The block house looks great, which exactly imitates a log house.

The photo shows the facade of a private house in the style of a classic chalet, where the lower floor is stone (brick) and the upper floor is wooden. Everything is concise, all the details emphasize each other.

Expert advice

As indicated above, the main task is to combine the facade design with the architecture of the house. The taste of the owner must be taken into account.

Building materials define the exterior of a building. Architectural details are also an important component of home design. In some style directions they are given special attention. But you shouldn’t put pressure on them.

Landscape design, architecture and facade of neighboring buildings are important.They should highlight the beauty of the house.

Not the last place for lighting, especially at night. With its help, you can emphasize all the advantages of the building or diminish them. Therefore, the hand of a professional is needed here.

Types of house facades: video.

What do you think is the most practical and beautiful façade of a house? Write in the comments. Save the article to bookmarks and share it on social networks.

Stone finishing is a beautiful and reliable thing. In fact, it will last for many decades. But all this is expensive. In addition, you need to think about saving heat. But the stone clearly does not contribute to this.

This can be said about many materials. For example, brick. So why not use them now?

Guys, don't quarrel. Everything is much simpler - insulated plaster. Cheap and cheerful, and of course warm.