Insulating a garage floor: types of floor insulation + step-by-step instructions

Organizing proper storage of a car is the key to its long service life and reducing overhead costs for repairs. The temperature in the garage during the cold season should be about +5 °C.Higher values will lead to the formation of condensation and premature corrosion of the metal, while low values will cause difficulties in starting the engine.

As the ground freezes, the floor becomes the main area of heat loss. If it is concrete, the room gets colder many times faster. Insulating the garage floor will help solve the problem. And we will consider in detail how to do this correctly in this material. After studying the information provided below, you will understand the types of insulation, read the step-by-step instructions for carrying out independent work.

The content of the article:

Features of garage floor insulation

The simplest option for insulating the floor of a room is to lay heat-insulating materials during the construction process. The choice of insulation materials and the list of works must be agreed upon at the design stage.

For more information on how to choose a material for a garage floor, read the article “What is the best way to make a garage floor - 10 simple and affordable coating methods».

If the garage is actively used and a decision has been made on additional thermal insulation, it will be somewhat more difficult to implement the plan.

When planning insulation of the garage floor, it is worth considering that difficulties may arise during the work, including:

- Selection of materials. The huge variety of insulation materials on the market provides the opportunity to solve a problem of any complexity. However, making a choice on your own can be difficult. Before purchasing, study the types of insulation and their performance characteristics.

- Work order. Insulating a garage does not require deep specialized knowledge or the presence of expensive professional tools. However, the technology for working with wooden and concrete floors is different.

- Price. At first glance, it seems that insulating a garage will not require major investments. In practice, car owners are not always able to take into account all expenses. To ensure that the work on insulating the garage floor does not stop, you should purchase all the necessary materials before starting.

When planning to start insulating a garage floor, it is important to first study the theoretical material, plan all the stages, buy materials, and only then get down to business.

Types of materials for insulation

The complexity of the work and its cost depend on the choice of material for insulation. In order not to make a mistake when purchasing, it is worth studying their types and performance characteristics.

There are different requirements for materials that should ensure heat preservation in the garage.

The main criteria for choosing insulation for walls and floors in a room include:

- Reliability. The material must not only prevent heat loss, but also be resistant to humidity and temperature changes.

- Safety. The insulation must be resistant to fire, or better yet, not support combustion at all.

- Vapor permeability - involves unimpeded air exchange, which allows you to maintain an optimal level of humidity in the garage.

- Strength. The long service life of the material will allow you to enjoy the results of your labor for many years without the need for repairs.

- Insulation characteristics. High-quality insulation will not only prevent the cold from penetrating, but will also increase sound insulation.

An important selection criterion is ease of installation. When choosing insulation, pay attention to whether you can install it yourself. To choose the right insulating material, study the manufacturers’ proposals and understand their characteristics.

Option #1 - polystyrene foam

This synthetic material is successfully used for thermal insulation of various surfaces, including floors. It is perfect for insulating a wooden or concrete floor in a garage.

If it is necessary to insulate a wooden structure, sheets are laid between the joists and covered with thick sheets of plywood. To insulate concrete, foam plastic is completely laid out on the base and filled with mortar.

The advantages of the material include:

- High strength — the insignificant mass of the insulation sheets does not prevent it from withstanding heavy loads.

- Light weight — low weight ensures ease of transportation and laying of the material.

- Moisture resistance — foam panels are resistant to moisture, they do not absorb it, losing their original properties, and do not rot.

Expanded polystyrene is a budget solution. Its use will allow you to insulate the garage floor at minimal cost.

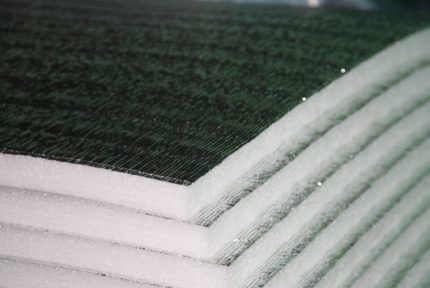

Option #2 - extruded polystyrene foam

Extruded material differs from traditional material in manufacturing technology and the presence of additives in its composition. The result is a material with a foamed structure and improved performance characteristics.

Extruded polystyrene foam can be equipped with foil protection. This option will be an ideal solution for insulating the garage floor. The presence of the film will provide an additional barrier to the cold and protect the material from moisture. Insulation is produced in slabs, rolls, and sheets of different thicknesses.

Using EPS provides additional advantages:

- Hygroscopicity - the foil completely covers the cellular structure of the insulation, so it cannot absorb moisture. This property is relevant when insulating a garage with wooden floors.

- Chemical stability - the level of water and soil pollution is quite high. The use of foil insulation will extend the life of the material even if it comes into contact with acids, alkalis, and other aggressive substances.

- Strength - a special structure, reinforced with a foil layer, allows extruded polystyrene foam to withstand high loads without deformation.

It is easier to lay expanded polystyrene in rolls on a concrete floor. For wood flooring, slabs are the best solution.

Before starting work, we recommend that you familiarize yourself with the features and rules for working with EPS.

Option #3 - penoizol

The material is called liquid foam. It will be a practical solution during construction or reconstruction of a garage.

Thanks to its liquid form, penoizol provides an absolutely airtight coating of the entire surface. Its use eliminates the possibility of cracks forming.

Option #4 - expanded clay backfill

The material is relatively inexpensive and easy to handle during installation. The clay raw materials that remain during the operation of pottery and brick factories do not burn, are not afraid of temperature changes, and retain heat well.

Laying expanded clay can be done in two ways. The dry method involves pouring material between the joists of a wooden floor. Wet - adding expanded clay to the concrete solution.

Advantages of the material:

- high sound and heat insulation;

- easy to use;

- does not burn, does not emit acrid smoke;

- not afraid of frost and temperature changes.

Expanded clay is a budget option suitable for most premises. The only negative is the active absorption of moisture, so when arranging the floor it is important to ensure waterproofing.

Option #5 - mineral wool

Classic insulation is versatile, so it’s perfect for garage floors. The material is sold in the form of mats or rolls of various thicknesses, so choosing the optimal solution is not difficult.

Manufacturers offer glass, basalt, stone and slag wool. Materials differ in the type of raw materials used and performance characteristics.

However, the general advantages include the following:

- Low thermal conductivity, the ability to retain heat without giving it away.

- Mineral fibers perfectly absorb sound, providing sound insulation to the room.

- Resistance to damage - the material is recommended for use in wooden structures where mice can live. Rodents do not like this material. In addition, mineral wool is resistant to fungus and mold.

- Excellent air exchange - mineral wool has excellent air permeability.

- Durability - the material does not lose its performance characteristics for a long time, retaining heat for many years.

The ability to choose individual slabs or rolls allows you to simplify the process of insulating your garage floor.

Instructions for floor insulation

There are many options for insulating a garage floor. In most cases, the method you choose depends on the type of floor.

It is recommended to install the insulation in the warm season - the work will be easier, and the screed will be able to harden faster.

The insulation plan depends on various criteria. The main ones are: professional training, available budget, selected materials.

Insulation of a wooden garage floor

The most budget-friendly solution is the use of mineral wool. The material is inexpensive, and installation does not require professional skills or expensive tools.

The work order is as follows:

- level the ground, pour a layer of sand up to 10 cm thick on it;

- pour concrete screed;

- lay a layer of waterproofing using polyethylene, roofing felt;

- install wooden logs so that the distance between them corresponds to the width of the insulation roll;

- place mineral wool in the recesses;

- cover the insulation with a layer of waterproofing;

- lay wood flooring.

Wooden logs can be installed on a base made of expanded clay. Often, instead of mineral wool, polystyrene foam or extruded polystyrene foam is used.

The thickness of the insulating layer or sheets of material should be about 10 cm. If the work is carried out in a finished garage, insulation is reduced to filling the space between the joists with a heat insulator, ensuring its protection from moisture.

Not only do you have a garage, but also have wooden floors in your house? And have you also thought about insulating it? We recommend that you read in more detail technology of work on thermal insulation.

Working with concrete base

A more durable concrete floor is preferred by owners of heavy vehicles. A high-quality screed guarantees long-term use of the surface. If cracks appear or insulation is insufficient, an additional layer of insulating material can be laid on top of the old one, without dismantling.

To create an insulating layer, the same materials are used, only the rules for their installation change. Expanded clay is poured onto a rough base in a layer of 25 cm, covered with a reinforcing mesh, and filled with mortar.

When using polystyrene foam, most of the load will fall on the foam layer.

To ensure the durability of the structure, you must adhere to the recommendations listed below:

- When preparing the base, carefully repair any irregularities that could damage the insulation layer.

- Lay the waterproofing film overlapping, do not forget to go onto walls up to 15 cm high. Secure the joints with tape.

- Lay the foam sheets tightly and secure the joints with glue or foam.

A film is placed on the insulation layer, which will prevent the penetration of moisture from the solution, then a reinforcing mesh. The structure is filled with mortar.

If it is necessary to heat the garage, in some cases it is installed water heated floor. Foiled polystyrene foam is then used as insulation.

The design is additionally integrated pipes, through which the coolant circulates, providing heating.

We looked at the best ways to heat a garage in next article.

When planning insulation of the floor in the garage, it is worth taking into account the inspection hole - its presence facilitates maintenance and repair of the car. However, it becomes a serious heat leakage channel. When working with the floor, do not forget about its thermal insulation.

The complexity of the design of modern machines leads to the fact that owners are less and less likely to carry out various work on their own, so the pits are not used for their intended purpose. As a result, they are closed with homemade plugs, insulated with improvised materials. If there is a difference in the quality of thermal insulation between the floor and the pit, condensation may form at the location of the temperature difference.

Conclusions and useful video on the topic

You can insulate the floor in your garage yourself. A selection of videos will help you understand in detail the procedure for performing the work.

The first video will tell you about insulating a wooden floor in a garage:

The video below describes the procedure for working with a concrete floor and the possibility of installing additional heating:

The latest video, prepared by experts, will tell you about the nuances of floor insulation using extruded polystyrene foam:

In order for the result of floor insulation to ensure the desired temperature regime, it is important to adhere to the technology and rules for laying heat-insulating material, and study the recommendations of professionals. By following installation technology, you can get a high-quality coating that will serve for many years.

If you already have experience insulating your garage floor yourself, share your achievements in the comments. If you have not yet decided on the type of insulation, or don’t know which technology to choose, ask questions in the comments section - let’s discuss together the possible options and their advantages.