Insulating the floor in a wooden house: work procedure + popular insulation materials

In buildings made of wood, the problem of indoor microclimate is especially acute.Due to the drying out of the floor boards and the appearance of cracks through which drafts wander, the rate of heat loss can reach 30%.

Timely insulation of the floor in a wooden house will help reduce thermal costs, especially since it is quite possible to perform thermal insulation without the involvement of specialists. Agree, this approach to solving the issue will save a decent amount and significantly increase the thermal efficiency of the house. Do you doubt your own abilities?

We will help you navigate the variety of insulation methods and provide practical recommendations for choosing a thermal insulation material. In addition, we will describe the technology for performing work using the most popular materials: sawdust, expanded clay and penoplex.

The content of the article:

Methods for carrying out thermal insulation work

Work on laying insulation can be carried out directly in the living room or from the basement. In the first case, it is customary to talk about thermal insulation from above, in the second - about thermal insulation from below. In addition, you can use other methods of floor insulation, which will be discussed in more detail below.

Method No. 1 - installing insulation from above

In this case, the insulation is installed directly in the room. Such work is quite easy to perform, but a number of problems may arise.

Disadvantages of “surface” installation of insulation:

- the height of the walls decreases;

- the lower layers of the structure are not warmed up enough;

- The thermal insulation layer experiences increased load, which is why it is necessary to select a material of increased rigidity.

Due to the difficulties listed above, experts, answering the question of how to properly and easily insulate floors in cottages and wooden houses, recommend using this technology only in special cases.

It is necessary, for example, if there is a shallow underground under the building or the building stands on a monolithic slab.

Work on laying thermal insulation begins with dismantling the baseboards and finished floor, which is necessary to gain access to the joists. After this, the support beams are inspected.

Detected rotten areas must be removed, replacing them with suitable sized fragments of new beams, which are fixed using galvanized metal corners or channels.

A cranial beam is strengthened along the lower edge of each joist. Boards or wooden panels approximately 30 mm thick are laid on the prepared structure without fastenings. The created structure must be treated with an antiseptic.

The length of each fragment should be less than the installation step of the logs by 10-20 mm.

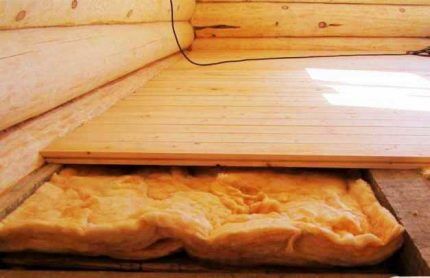

Waterproofing, insulation, a vapor barrier, a counter batten creating a ventilation gap, and finally a finishing floor covering are laid on the assembled subfloor.

Method No. 2 - insulation from the basement

When insulating floors in a private wooden house from below, the installation of a protective coating is carried out between the frame elements and the top finishing layer.

Carrying out work in this case requires more labor than laying insulation on top, but the result provides a number of advantages.

The main advantages include:

- the height of the room remains unchanged;

- the insulation layer is not affected by loads from heavy furniture standing on the floor, which allows the use of any types of materials, regardless of their hardness;

- The heat insulator laid underneath provides protection from freezing not only of the top layer, but also of the entire floor frame - this reduces the risk of moisture penetration, which increases the life of the structure.

This option is well suited for frame buildings installed on pile and pile-screw foundations.

A necessary condition for the use of such technology is the presence of a cellar, basement or other auxiliary room under the house.

The following work order is recommended:

- First of all, it is necessary to dismantle the old rough floor to gain access to the joists.

- Beams should be cleared of debris and their condition inspected, replacing damaged fragments as described above.

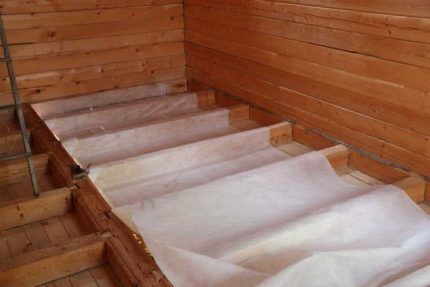

- A vapor barrier, such as a membrane, needs to be laid around the perimeter of the ceiling. If materials are used in rolls, the width of the strips overlapping each other should exceed 10 cm.

- A 30*30 mm cranial beam must be nailed to the side walls of each joist.It will serve as a support for the heat-insulating material and create a ventilation gap between it and the finished floor.

- After this, the insulation is installed, the thickness of which should not be greater than the height of the logs. Depending on the type of thermal insulation, it is strengthened using mounting adhesive, foam or cross-bar.

- A layer of waterproofing is applied on top of the heat insulator layer, which can be roofing felt or ordinary polyethylene film.

The final stage is applying the finishing coating: boards, waterproof plywood or other materials.

Method No. 3 - double floor arrangement

To qualitatively reduce heat loss in wooden buildings, double floors are often applied. In this case, the first step is to install the logs. Uncut boards are fixed on them, which form the so-called subfloor.

Next, logs made of thinner timber are installed. The space between them is filled with thermal insulation material. Then a finishing floor made of tongue and groove or edged boards is applied.

If desired, a finishing decorative coating is also used. Between two wooden layers it is convenient to place service communications: corrugated pipes with cables, water supply network.

Instead of laying a subfloor, you can use various types of smooth or embossed floor coverings that have a high degree of thermal insulation. These materials are even preferable because they do not accumulate debris.

This layer is attached with bustylate glue, which is applied to the material in the form of strips with mandatory gluing of all joints.

Read more about the technology of floor insulation using joists in this article.

Method No. 4 - heated floor system

The “warm floor” technology, which also uses traditional insulation, is very popular, which is quite natural. It ensures uniform heating of the entire coating, thereby effectively achieving a comfortable room temperature and reducing its humidity.

There are two options for such systems, in which heating is carried out using water or electric current.

Water floor constructed following the following sequence of actions:

- Prepare the foundation, for which concrete slabs are installed or a cement screed is performed.

- The surface is covered with the selected insulation, the thickness of which can vary from 2 to 10 cm.

- A reinforcing mesh is laid on top, along which a pipeline system is mounted, secured with plastic clamps.

- Next, the surface is filled with a special material, and, if necessary, a substrate is installed.

- The final stage of work arrangement of a water floor can be considered the installation of the finishing coating.

Electric "warm floor" performed similarly to the option described above, however, a cable stretched on a metal mesh is used as a heating element, which is firmly connected to the logs.

The installation technology and connection diagrams for the electric heating system are described in detail Here.

An alternative heating source is infrared film materials, which are laid directly on the thermal insulation layer covering the screed.

The importance of hydro- and thermal insulation

It should be especially emphasized that for proper insulation of floors in wooden houses, one must not forget about laying hydro/thermal insulation layers.

The waterproofing coating is designed to protect the structure from moisture that falls on a warm surface when cold air flows in. Water particles penetrating into wooden elements lead to the development of fungi, mold, and, ultimately, to the destruction of the structure.

The vapor barrier layer is no less important. Electrical equipment operating in the house, as well as people in the rooms, constantly generate heat. Warmed air flows from rooms that pass through the ceilings of structures come into contact with cold air masses.

This leads to condensation, which can result in wood swelling and rotting.

Requirements for thermal insulation materials

There are many types of insulation, ranging from simple natural materials to complex synthetic compounds.

In order to make the right choice, you need to take into account a number of factors, namely:

- Thermal conductivity degree. The higher this indicator, the lower the heat loss will be.

- Term of use. This determines how long it will take to repair and replace the material.

- Insulation weight. Too heavy options are not recommended for use in frame houses.

- Moisture resistance. This factor is especially important if the building is located in a low-lying or swampy area, as well as when constructing houses in a humid climate.

- The presence of an unheated room under the floor. In a cold basement, it is better to give preference to denser thermal insulation.

- Difficulty level of work. Ease of installation can be considered an undeniable advantage.

- Fire resistance. The insulation should not burn or support combustion, and also emit gases hazardous to health when heated.

It is also necessary to take into account the ability of the material to resist mold, fungi and other destructive biofactors.

Finally, an important criterion is the cost of the thermal insulation material. You shouldn’t chase cheapness: expensive products are usually easy to install and have a long service life, which allows you to save on labor costs and repairs.

Popular materials for insulation

Among the most commonly used insulation materials are:

- sawdust;

- expanded clay;

- mineral wool;

- Styrofoam;

- penoplex.

Sawdust are still quite popular for thermal insulation work. This is an environmentally friendly, accessible and inexpensive product, moreover, it is convenient to use in hard-to-reach places.

However, it also has disadvantages: over time, sawdust cakes, which leads to loss of quality; they are also susceptible to microorganisms, fungi, and insects.

Expanded clay - bulk material formed during the firing of clay or shale. This completely environmentally friendly material, shaped like balls, has high thermal insulation rates.

It is resistant to freezing and has good fire resistance. The disadvantages of expanded clay include its relatively large weight; in addition, this material cakes, which leads to shrinkage of the house and a drop in thermal conductivity.

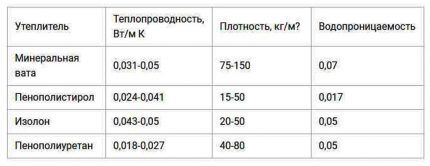

Mineral wool It is considered one of the best insulation materials, since it does not burn and is not destroyed under the influence of biofactors. In addition to good thermal insulation, it also has sound insulation properties.

Among the negative qualities are low mechanical strength and deterioration of insulating qualities when exposed to water or steam, which requires special attention to vapor/waterproofing.

Styrofoam became widespread. It easily retains heat, effectively retains heat loss, has sufficient mechanical strength, and a long service life.

It is necessary to remember, however, about the negative qualities of this material: when burning, foam releases toxic substances, in addition, it is able to absorb water, which leads to a decrease in performance.

Penoplex. A relatively recently appeared material that quickly gained popularity.This type of insulation consists of foamed polystyrene boards, which have excellent thermal insulation characteristics. The easy-to-install slabs do not burn and are not susceptible to bioorganisms.

Other synthetic and natural materials are also used as insulation, including isolon, penofol, ecowool, cork, and fibrovit.

Specifics of working with popular insulation materials

The installation of different types of heat insulators has its own characteristics, which can be seen in the example of three popular materials.

Features of working with sawdust

Sawdust can be used directly by pouring it into the space between the joists, but it is more advisable to use it in the form of a solution. To do this, a mixture is made of five parts sawdust and one part cement or clay, which is diluted with half the amount of water.

It is advisable to add broken glass or special additives to the prepared mixture against the appearance of rodents.

The voids between the joists must be carefully and thoroughly filled with freshly prepared mixture. The layer must be very even, otherwise there will be “holes” in the protective coating, resulting in the floor remaining cold.

Carrying out thermal insulation with expanded clay

An inexpensive type of insulation is expanded clay, working with which also has its own characteristics. In this case, sand is additionally laid. This material is carefully and evenly applied to the base, and then carefully compacted.

As waterproofing, liquid mastic is poured onto the sand layer, after which expanded clay is backfilled, while ensuring maximum evenness of the coating. Next, a vapor barrier is installed, on top of which the finishing is laid.

Expanded clay is a rather heavy material, so it is not recommended for use when insulating buildings on a frame foundation.

Special techniques when working with penoplex

Penoplex is a common insulation option. When using it, precise adjustment of the slabs is required, which creates a barrier to the penetration of cold air. The sheets are laid between the joists, and for maximum adhesion they are attached with mounting adhesive to the floor and to each other.

Easy penoplex insulation is considered the best option for thermal protection of the floor in a frame house. It provides minimal load on the foundation, which avoids shrinkage of the structure.

Conclusions and useful video on the topic

The video below demonstrates the process of insulating a house using joists using mineral wool:

Video review detailing modern types of heat insulators:

In order to perform high-quality thermal insulation of the floor, it is important to carefully select the material, taking into account its features and the specific design of the building. Equally important is compliance with the installation technology recommended for this type of insulation, as well as careful execution of all stages of work.

Do you have experience insulating floors in a wooden house? Please tell readers what thermal insulation material you used and whether you were satisfied with the result. Comment on the post and participate in discussions - the feedback block is located below.

The wife's parents inherited a plot of land with a dilapidated house. It was decided to demolish it and build a new one. Now I’m finishing building a house made of timber, the foundation has been leveled, the beams have been laid, and now it’s time for the floors.

Actually, I consider mineral wool and extruded polystyrene foam as the main options. Floor beams 200 mm high. For now, I’m leaning towards polystyrene foam for reasons of easier installation and no need to bother with film and wind protection. After all, I understand correctly that all this is not needed for EPPS? Because I tried to understand this jungle, but even the experts themselves argue for hundreds of pages on each topic and cannot decide what is best and what is correct.

Good afternoon, Kirill. There really are a lot of disputes. Associated with established technologies over years of practice.

EPPS, unlike most insulation materials, like mineral wool, has zero water absorption. To be precise, 0.2% by volume. This is what causes all the strife.They consider the properties of the material separately from the floor system as a whole, but this is fundamentally wrong.

I can assume: the floor goes on the ground, then according to technology the underground should be ventilated. Accordingly, wind protection is necessary. At a minimum, it will act as protection for wooden beams.

It is necessary to install vents in the foundation for wooden floors, otherwise the ceiling will simply rot quite quickly.

Regarding the vapor barrier, it will also not be superfluous. The wooden floor is quite movable in itself, plus there remains a technological gap between the floor and the wall.

EPPS is superior to mineral wool in many respects: lower heat transfer coefficient, zero water absorption, no “caking” of the material.

Without seeing your project, it’s difficult to give a definitive answer.