How and in what way gas flow is measured: measurement methods + overview of all types of gas flow meters

Flow meter is a device for measuring the volume or mass flow of a substance, including natural gas, flammable, corrosive gases, air separation products. Calculation of flow volumes at industrial enterprises or in everyday life can be performed without the involvement of specialists.

Next, we will tell you how and in what quantities gas is measured, provide a description of the instruments that are used for this purpose, and also consider the main methods for determining gas flow.

The content of the article:

Direct method for measuring gas consumption

The volume of gas is calculated in cubic meters; other units of mass, such as tons or kilograms, are less commonly used, usually for process gases.

The direct method is the only method that provides a direct measurement of the volume of gas passing through.

The weaknesses of instruments that calculate the volumetric or mass flow of a substance include:

- Limited performance of flow meters in contaminated gas conditions.

- There is a high probability of failure due to partial flow obstruction or pneumatic shock.

- High cost of rotary counters compared to other devices.

- Large dimensions of devices.

The numerous advantages of this method outweigh the listed disadvantages, which is why it has become most widespread in terms of the number of installed meters.

These include direct measurement of gas volume, absence of dependence on distortions in the flow rate graph, both at the inlet and outlet, which makes it possible to reduce UUG. The range width is up to 1:100. For this purpose, membrane and rotary type devices are used. They can be used in rooms with installed pulse-type boilers.

Indirect measurement methods

These methods involve calculating, for example, the speed of flow of a substance through a given cross-sectional area. To obtain the most accurate results, it is necessary to equalize the gas speed.

Measuring gas flow by differential pressure

One of the most common and studied gas flow methods, based on the use of a restriction device, has several advantages, including the simplicity of the flow transducer mechanism, the action of which is aimed at measuring the pressure drop of the substance flowing through a local restriction in the gas pipeline. No calculations required flow meter stands.

Despite the presence of a complete scientific and technical base, this measurement method has several significant drawbacks - a small measurement range, which, even taking into account multi-range pressure sensors, does not exceed a value of 1:10.

Hydraulic resistance in gas pipelines increase sensitivity to the schedule of changes inaverage speeds along the depth or width of the flow at the entrance to the diaphragm.The length of the straight sections in front of the narrowing devices must be at least 10 diameters DN of the pipe structure.

High-speed method for determining costs

Turbine type converters are used for this method. These devices have several advantages, including small size and weight, and an affordable price in their category.

These devices are not sensitive to pneumatic shocks. The range of flow measurement values is up to 1:30, which significantly exceeds the same indicator for restriction devices.

Disadvantages include sensitivity, albeit insignificant, to flow distortions at the inlet and outlet of the device, deviation of the measurement results of pulsating gas flows. At low flow rates, in the range from 8 to 10 m3/h, flow meters are inoperative.

Ultrasonic measurement method

The popularity of acoustic flow meters, which measure the amount of gas, especially in commercial accounting, has increased with the development of microelectronics. Acoustic flowmeters have no moving parts or parts protruding into the flow, which significantly increases their reliability.

The measurement is carried out over a wide range of values due to the ability of the device to operate for a long time from the built-in power source. Domestic devices do not meet all the necessary requirements, since in order to avoid the influence of gas flow distortions on the calculation results, it is necessary to use exclusively multi-beam ultrasonic flow meters.

Classification of flow meters by operating principle

Flow meters differ in several parameters, including pressure, type of gas used, and temperature conditions. The device should be selected depending on the conditions of use, as well as the assigned tasks.

Measuring instruments consist of parts such as a transducer responsible for the differential pressure, a connecting element and a pressure gauge.

Type #1 - inkjet self-generator flow meters

This type of flow meter, also designed to measure natural gas flow, has several distinctive characteristics. The device is covered by negative feedback; the frequency of jet connections depends on gas flow.

Meters produced on the basis of jet flow meters are used for commercial accounting without preliminary examination.

Jet flow meter self-generator type is susceptible to clogging; its disadvantages also include instability of the conversion rate.

These devices have similar disadvantages to vortex devices:

- dependence on distortion of the speed graph, provided that it is used in conjunction with narrowing devices;

- massive pressure losses are irreversible;

- the main part of the flow meter has huge dimensions;

- significant instability of the conversion rate.

Advantages self-generator flowmeters are no different from a vortex device, except for the ability to work with contaminated gases.These flow meters have not found widespread practical use in commercial accounting.

Type #2 - vortex flowmeters-counters

There are several strengths of the devices, including the accuracy of the measurements, lack of sensitivity to dirt and pneumatic shocks, ease of operation, and the device also has no moving parts.

There are also known significant disadvantages of using this type of flowmeters - increased sensitivity to mechanical vibrations, pressure loss. Pipe diameter should be in the range of 15-30 cm.

Type #3 - ultrasonic flow meters

The device, also known as an acoustic device, has several undeniable advantages:

- lack of hydraulic resistance;

- the device has no moving parts, which enhances its reliability;

- increased strength of the mechanism;

- fast action.

This type of flow meter is based on determining the difference in signal travel time.

Ultrasonic sensors, located diagonally relative to each other, perform the functions of a receiver and emitter. The use of multiple channels compensates for the deformation of the flow profile.

Type #4 - drum flow meters

This category of devices is used, as a rule, for laboratory research. The pressure generated during drum rotation causes the sections to be filled with gas and subsequently emptied.

The number of revolutions of the drum is proportional to the cubic units of gas, the indicator is transmitted to the dial of the counting structure. Drum flowmeters have high measurement accuracy.

Type #5 - levitation devices

The moving part of the tachometer device rotates in bearings, the speed is equal to the volumetric gas flow. The speed of circular motion is converted into an electrical signal using a secondary converter, the results are reflected on the indicator.

Levitation The devices are in demand for commercial metering of natural gas consumption, both for domestic and utility purposes.

Type #6 - membrane meters

A patent for the manufacture of one of the most common gas metering devices was issued in the second half of the nineteenth century in England.

The operating principle of a mechanical flow meter is based on changing the position of movable chamber membranes at the moment of gas entry. Alternate movement occurs during the inlet and outlet of the substance.

The counting device is driven by a system of gearboxes and levers. The mechanisms have a wide range of measurement values - up to 1:100.

Type #7 - rotary devices

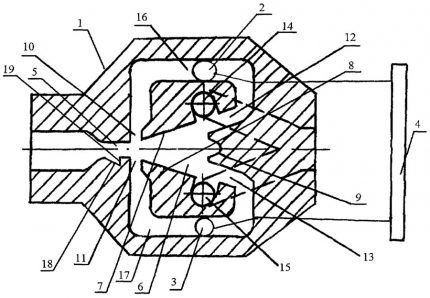

In a mechanical type device, two rotors are located in the measuring chamber, which begin to move under the pressure of the substance.The rotating parts are located at right angles to each other, their initial location is fixed using synchronizer wheels.

The amount of gas is proportional to the number of revolutions of the rotors. With the help of a magnetic coupling and gearbox, the rotation of the rotor is transmitted to a counting device, which is responsible for accumulating the volume of the passed substance.

The main advantages of rotary flow meters include high measurement accuracy, compactness of the device, and a wide range of flow measurements. Among the disadvantages are the noise of the mechanism, its high cost, and sensitivity to external factors, including pollution.

Type #8 - turbine flow meters

The mechanical type device has the shape of a piece of pipe; inside the flow meter there is a turbine with a shaft and moving supports. The power device moves due to the substance passing through the measuring chamber.

The speed of movement of the mechanism is equal to the flow speed and gas consumption. The accumulated volume is reflected on the counting mechanism; transmission to it is carried out mechanically using a gearbox or gear system.

In addition to those listed, there are other devices, but they are used, as a rule, in scientific research. They are practically not involved in the commercial sphere.

We also recommend reading our other article, where we talked in detail about how to choose a gas meter for your home. More details - go to link.

Instruments for measuring gas quantities

Devices for measuring gas flow are divided into several categories based on the calculation method. Velocity ones are used to determine the volumetric number of the medium under study. These devices do not have measuring chambers. The sensitive part is impeller (tangential or axial), which is driven into rotation by the flow of matter.

Volumetric meters are less dependent on the type of product. Their disadvantages include the complexity of the design, high price and impressive dimensions. The device consists of several measuring chambers and has a more complex design. This type of devices is divided into several types - piston, blade, gear.

Another classification of gas quantity meters is known, which includes three types of devices: rotary, drum and valve.

Rotary meters have high throughput. Their action is based on calculating the number of revolutions of the blades inside the device, the indicator corresponds to the volume of gas. Their main advantages include durability, independence from electricity, and increased resistance to short-term overloads.

Drum counters consist of a housing, a counting mechanism and a drum with measuring chambers. The operating principle of the device for measuring gas consumption is to determine the number of revolutions of the drum, which rotates due to the pressure difference. Despite the accuracy of the calculations, this type of instrument has not found widespread use due to its bulky size.

The operating principle of the last type of meters, known as valve meters, is based on the movement of a movable partition, which is acted upon by a pressure difference of a substance. The device consists of several parts - a counting and gas distribution mechanism, as well as a housing. It has large dimensions, so it is mainly used in everyday life.

Conclusions and useful video on the topic

How vortex gas flowmeters work will be discussed in the following video:

Measuring gas flow is one of the key tasks in production. The flow meter market offers a huge number of devices with different designs and operating principles that are also suitable for domestic needs. With their help, you can determine almost any amount of liquid or gas, without the need for a special calibration standard installation.

You can supplement our material with interesting information on the topic of the article, ask questions or participate in the discussion. Leave your comments in the block below.