Izospan A, B, C, D: technical characteristics of insulation and rules of application

The installation of moisture and vapor barriers is a very important stage of construction. One of the best materials used for this purpose is isospan.It belongs to the category of relatively new products used in the protection of structures. The manufacturer offers a wide range of insulating films that differ in purpose.

You will learn everything about the range of membrane films labeled as isospan A, B, C, D from our article. We have described in detail popular insulating materials and provided their technical characteristics. Do-it-yourselfers will find installation manuals and useful tips here.

The content of the article:

Review of existing varieties of isospan

Most isospan is produced in the form of a membrane or film. Both modifications have a vapor barrier function. There are types that are 100% waterproof and unilaterally permeable to moisture. If we consider the types of this material separately, then each is intended for separate tasks.

The term isospan hides four broad groups - A, B, C, D. They are distinguished by individual design features.

Isospan is used when installing attic insulation systems, installation of cold roofs, arrangement of floors, construction of baths, improving the thermal performance of walls as an insulator for enclosing structures.The material is especially effective in protecting insulation systems and wooden elements from putrefactive processes, and metal elements from corrosion.

There is isospan, which is used inside buildings, and other varieties are intended for outdoor use. There is also isospan for universal use. In any case, its use makes it possible to significantly prolong the operating time of the insulation, which, under the influence of moisture, quickly loses its properties.

Vapor-tight isospan is used when performing both internal and external work. Based on the functionality of the material, it is divided into classes.

Insulation material group A

The material marked with the letter “A” belongs to the first group. It is characterized by high density, therefore it is indispensable for insulating attics, walls, and roofs. Fungi and mold do not develop on it.

This diffusion membrane retains water, but steam passes through it unimpeded. Polypropylene is used for production. It strengthens and protects thermal insulation from the influence of outdoor atmospheric moisture or cold air from a room that is not heated.

In order for isospan A to fully reveal its capabilities, it is necessary to strictly follow the technology during installation.Since air streams pass through it only one-sidedly, the sides should not be confused under any circumstances. Otherwise, the insulating layer will get wet due to the accumulation of moisture in it.

Isopan A is produced in rolls 1.6 m wide. The area of the material in the reel is 35.7 m². The optimal temperature limits for operation are -60 - 80⁰. The membrane can be exposed to ultraviolet radiation for three or even four months without loss of characteristics. In the future, these aggressive rays will gradually reduce the UV stability of the material.

Izospan marked with the letter A may contain fire retardant additives. Then another one is added to all its characteristics - fire protection. This brand belongs to the G1 flammability group, and in terms of flame propagation speed - to the RP1 group.

The material can withstand fairly high tensile forces - from 125 longitudinal and from 95 N/5 cm transverse. This is facilitated by special additives that strengthen the structure of the material.

The vapor permeability of the material is at least 3500 g/m² day. Water resistance parameter - 330 - mm. water Art. Based on these characteristics, it is advisable to use isospan A when installing ventilated facades, frame enclosing structures, roofs with double lathing and slopes at an angle of 35⁰.

Unlike the group A membrane, the AM film has a two-layer structure. It has also found application for protecting insulation and roofing elements from condensation and weathering.

These types of insulation have a number of differences:

- AS - the most durable, in addition, it has a fairly significant service life, but the steam transmission rate is only 1000 g/m² per day.

- A - the best type in terms of vapor permeability.

- AD — a strong membrane with a vapor permeability of 1500 g/m² per day.

There are differences in terms of installation. If you choose brand A, an air gap is required, otherwise the steam will be discharged ineffectively. AS and AD membranes are mounted directly on the insulation.

Second group marked B

This vapor barrier has a slightly lower price.

Technical parameters of isospan B are as follows:

- composition - polypropylene;

- minimum breaking load - 130 N/5 cm;

- minimum lateral load - 107N/5 cm;

- application temperatures - -60 - 80⁰;

- water resistance - 1000 mm water. With t. minimum;

- UV resistance - 3 - 4 months;

- minimum vapor permeability - 7 g. per m² per day;

- The structure is two-layer.

It is used as an under-roofing film in frame enclosing structures and in interior partitions. On one side it is smooth, the opposite side is rough, where moisture is retained and evaporates.

With its help, the building is insured against penetration inside insulating layer of the ceiling, walls, systems floor insulation in a private house.

The price of this brand is the most affordable. Unlike brand A, this material is not attached to the top of the insulation, but to its lower side. Do this from bottom to top, then overlap. For better capture of water vapor, a 5-centimeter gap above the rough layer is required.

Features of group C material

Regarding resistance to vapor permeation, water resistance, and UV stability, this type of insulation does not differ from the previous material. Isospan grade C has the same temperature range: (-60) - (80⁰). The difference is in the breaking load, here it is greater - longitudinal minimum 197, transverse - 119 N/5 cm.

The two-layer film is characterized by particular strength. Polymer membranes of group C provide hydro- and vapor barrier for protection thermal insulation of attics, attics, roofs with a maximum slope of 35⁰.

It is used as a waterproofing substrate under metal tiles, as it perfectly protects the rafter system from rain and melt water. In addition, it is a good waterproofing for different types of bases. The material is also used in the case of concrete floors in places of high humidity.

Description of brand D products

A distinctive feature of isospan D is its good resistance to UV rays. Tensile strength is also high - longitudinal breaking load is no less than 1068 N/5 cm, 890 - transverse.

Due to its great strength, grade D polypropylene fabric can easily withstand considerable mechanical forces during installation and operation, including the weight of snow. For this reason, it is quite suitable as a non-permanent roof, functioning normally for about 4 months.

The material also performed well as under-roof waterproofing in cold roofs.It saves wooden elements from the destructive influence of moisture penetrating from the outside, as well as wind and snow, which may end up there through leaks in the roof. It is also an effective waterproofing layer in floor insulation systems, basement floors.

Instructions for installing isospan

Steam, moisture and wind protection of a building is a complex undertaking. Using glassine or plastic film is ineffective. Izospan was developed specifically for this purpose and its high qualities have been tested in practice.

For installation, in addition to the isospan itself, you need a supply of tools and fasteners:

- special scissors;

- self-tapping screws;

- construction stapler;

- connecting tape;

- metal profile or wooden slats.

It should be remembered that on the walls the membrane is attached both from the inside of the room and from the outside, and on the roof - only from the inside. The features of a specific type of isospan are reflected in the instructions for use of the material.

Installation of group A membrane

The best use of this thermal insulation, waterproofing, windproof membrane is to protect the frame wall of low-rise buildings from moisture and wind. It is mounted on the outside of the insulation layer under the exterior finishing of the building.

Isospan A is laid in accordance with its technical characteristics on top of the insulation using a special frame.

The technology is simple and does not require special qualifications:

- The roll is unrolled and cut into panels of the required size.

- Alternately, place the membrane pieces on the frame horizontally overlapping with the even side out, starting from the bottom, and moving up.

- Fasten the protection to the frame with an overlap, using a construction stapler or another method. The minimum amount of overlap both horizontally and vertically is 100 mm.

- The material is further strengthened. To do this, the stretched panels are pinned to the rafters with a construction stapler.

- To seal the overlap, the joints of the panels are fastened with 2-sided isospan KL tape.

- Self-adhesive tape is laid in the fastening area.

- Wooden counter-battens are attached on top of the isospan layer vertically in relation to the frame. They are pre-treated with an antiseptic. The size of the slats is 40 x 50 mm. They act as a supporting structure for external cladding - in the form of lining, siding, etc.

A prerequisite is a ventilation gap equal to the thickness of the counter-batten between the isospan layer and the outer skin. The edge of the membrane at the bottom is located so as to divert the flowing moisture into the drain of the building's base.

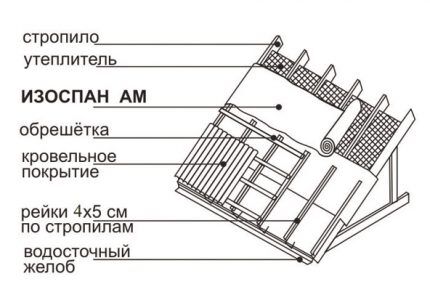

Laying Am and As films in an insulated pitched roof

For this type of roof, experts recommend choosing isospan Am or As.

The membrane is laid without a ventilation gap, so there is no need to install additional sheathing between the insulation layer and the isospan. Secure it taut.

The sequence of operations is as follows:

- The roll is rolled out and cut directly on top of the insulation.

- Lay out the panels horizontally, turning the white side towards the insulation.The beginning of installation is the lower part of the roof. The segments overlap horizontally and vertically by at least 15 cm.

- Strengthen the membrane along the rafters with a stapler.

- The joints are fastened with continuous 2-sided isospan KL tape.

- The traces of fastening with nails or self-tapping screws are covered - glued with a self-adhesive strip along the rafter legs and other elements. This is especially true for roofs with a slight slope - up to 22⁰.

- Antiseptic wooden slats 4 x 5 cm are attached vertically over the tape along the rafters.

- Install the sheathing along the counter-battens. Depending on the type of roof, it can be a continuous deck.

To eliminate under-roof condensation, a condensation gap is created between the front side of the film and the roof covering using slats about 50 mm thick.

When installing isospan over the sheathing, slight sagging is allowed. A membrane without insulation is practically useless.

Application of insulating material B

This type of membrane perfectly performs the functions of a vapor barrier, protecting the insulating layer from water vapor rushing upward from the side of the room, and also protects the space of the rooms from insulation particles getting into them.

It is mounted on the insulation side facing the inside of the room. Installation is carried out using a construction stapler on rafters or rough sheathing. Sometimes galvanized nails are used for this purpose. It is correct when the flat side is closely adjacent to the insulation.

Work starts from the bottom.The vertical and horizontal overlap is the same as when installing other types of isospan - from 150 to 200 mm.

As in the case of isospan Am, the joints are glued with Izospan KL, SL tape. Contact points of the material with structures made of any material are sealed by using a one-sided adhesive strip of isospan ML proff.

The interior trim is attached to the wooden base with a ventilation gap of about 40 mm. If isospan is used as a vapor barrier for a frame wall, it is fixed on the inside of the insulation to the loaded parts of the frame or to the rough sheathing.

A stapler is used as a tool, although it is also possible to use galvanized nails. It is laid on the insulation with the flat side facing it. When finishing walls with plasterboard, galvanized profiles are used, and for clapboard walls, wooden counter-battens are used.

Izospan as a vapor barrier for the attic floor is placed in between the finishing material of the ceiling - the rough ceiling. The smooth surface is turned towards the latter. In this case, a ventilation gap is also required.

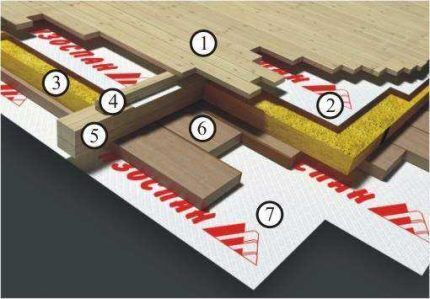

A vapor-permeable membrane of grade B is also a good hydro-vapor barrier for interfloor ceilings. Mounted between the ceiling trim and the rough system. The rough side is turned down. They are secured to the beams with an overlap.

A ventilation gap is created between the insulation layer and the final layer of vapor barrier, between the finished floor and the vapor barrier layer, between the finished ceiling material and the bottom layer of isospan B.

The bottom of the basement floor must be protected with a layer of vapor barrier. This must be done so that moisture does not penetrate from the ground to the insulation and other structural elements. The recommended type of isospan for this purpose is D.

The best option for using brand D

The type of isospan D for cold pitched roofs is an excellent hydro-vapor barrier. By using it, they protect the elements and structures of the attic room, made of wood, from under-roof condensation, snow, wind, and atmospheric moisture.

When starting the installation of a protective barrier for a cold pitched roof, isospan D is spread out and cut out. All this is done directly on the roof rafters. The advantage of the material is that it does not matter which side this isospan is attached to, which is very convenient.

Horizontal sections are installed overlapping, traditionally starting from the bottom of the roof structure.

Conclusions and useful video on the topic

Video #1. How to properly install a vapor barrier in a house:

Video #2. Sequence of work when arranging the interfloor and ceiling:

Video #3. Demonstration of the process of laying vapor barrier film B to protect the roofing pie from household steam:

Laying a hydro- and vapor barrier is an extremely simple process, but the protection they provide to structures is very effective. Protection from atmospheric water and household fumes guarantees a long service life of the materials used in construction.

The key point when choosing a specific type of protection is the specific location and circumstances of its installation.In this regard, when purchasing material, you need to carefully study the acceptable options for its use.

Tell us about how you used Izospan insulating films to decorate an attic at your own dacha or in a country house. Share useful information on the topic of the article that may be useful to site visitors. Please leave comments, post photos, ask questions in the block below.

Good evening! There is no information anywhere about the warranty period of Izospan. It is widely believed that no tests have been carried out on this material and Hexa does not indicate any guarantees.