Heating “Zebra”: principle of operation, features, installation instructions

Convective heating, which is familiar to everyone, turns out to be far from the most effective.This problem is well known to owners of apartments and houses who want to heat their homes productively but economically. To help them, new heating options have been developed, among which Zebra heating occupies one of the leading places.

We will tell you how this heating system works, the action of which is associated with the use of infrared radiation. Let's introduce the advantages and disadvantages of film heaters. For independent home craftsmen, we provide detailed installation instructions.

The content of the article:

Infrared heating: what is it?

School physics talked about the waves around us. We perceive the radiation that our eyes see as a color spectrum, and we know for sure that beyond its boundaries there are ultraviolet and infrared waves. The human body perceives the latter as heat. Scientists have divided the infrared spectrum into three groups: low, medium and high wavelengths.

The higher the temperature of an object emitting infrared radiation, the shorter the wavelength. The shortest ones a person can see are already in the visible spectrum.

For example, a red-hot steel rod emits short-wave radiation. Another regularity is known: short-wave and even medium-wave radiation is not useful, and sometimes even dangerous, for living organisms.

Long infrared spectrum waves have a beneficial effect on a person. However, some are afraid of even the word “radiation” and therefore do not consider infrared heating as a worthy option. This is fundamentally wrong. The Universe is designed in such a way that all heated bodies around us emit infrared waves of various lengths. We ourselves emit them.

The principle of operation of the Zebra system

Infrared heating works similarly. The Zebra film heater is placed on the ceiling of a heated room. After the equipment is turned on, it begins to emit rays whose wavelength matches the length of human infrared radiation.

They rush down and encounter large objects on their way. Most often these are large furniture and floors. The radiation is absorbed and accumulated by them, as a result of which objects begin to slowly heat up and give off the resulting heat.

Thus, the temperature in the room rises and gradually becomes comfortable. And this happens very quickly. Once the room has become warm enough, the heaters automatically turn off and remain inoperative until the room cools down a little.

Doctors note that if we compare convective and infrared heating, the latter is more useful for humans. Traditional convective water system most often based on heating coolant, which, in turn, should heat the air in the room. But it is known that air is a very poor conductor of heat, so it takes too much energy.

The system necessarily contains devices that transfer heat. These are radiators - heating devices, which are heated by the coolant and thereby heat the air. The batteries must be hot to do their job. Thus, they dry out the air in the room, removing moisture from it.

In addition, air masses heated by hot batteries do not remain in place. They rise to the ceiling, and colder ones take their place.

Thus, the floor will always be uncomfortably cold, and at head level there will be unpleasant excessive heat. This temperature distribution is unpleasant and not beneficial for humans.

Infrared heating functions differently. The radiation primarily heats the floor, which becomes pleasantly warm and warms the room.

It turns out that the zone of maximum heat shifts to the lower part of the room, and in its upper part there is a pleasant coolness. According to doctors, this temperature distribution is most beneficial for the body. According to the principle of its operation, radiant IR heating is similar to the natural emitter the Sun. The long waves it produces are beneficial for living organisms.

Design and characteristics of the heater

Film-type IR heaters are produced under the Zebra brand.The system was developed by Russian engineers and is produced at a plant in Chelyabinsk.

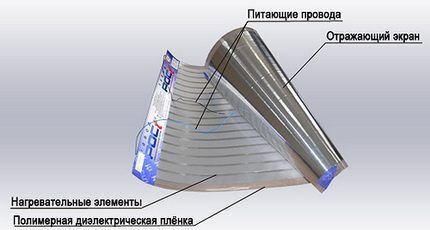

This is a multilayer fabric, where there is a radiating element between the layers of non-conducting films. When an electric current passes, it is the one that is activated and begins to emit infrared rays. To ensure that they move in the desired direction, an aluminum screen is used. The result is a flexible sheet 1 mm thick.

Zebra goes on sale in the form of a strip divided into segments. Thanks to this, the strip can be easily cut into fragments of the required length - from 60 cm to 6 m.

The width of the heating film panel is 50 cm. One package usually contains 50 such segments. The cutting of the panel is most often done immediately before installation and is done with ordinary scissors or a stationery knife.

Each of the heater segments is a full-fledged heating element with a useful power of 67W. The film IR heater has sufficient flexibility that allows it to be used on profiles of various configurations. The working side of the panel is marked with a branded sticker laminated under film.

From the technical characteristics of the device, we can conclude that it is suitable for use in rooms with high humidity. The heater is marked IP44, which allows it to be installed in saunas, swimming pools, etc. The wave range of the device is from 8.9 to 9.5 microns. A standard 220 V power supply is used for power supply.

Why choose film heaters

Infrared heating has many advantages over other heating systems. Let's look at them in more detail.

Efficiency and economy

An infrared heater is a direct heating device. The coolant is not used, so no energy is required to heat it. Automatic control allows the IR system to operate in the most economical mode.

In addition, it is possible to maintain a minimum temperature in the house during periods of absence of people. Shortly before the owner arrives, the system will warm up the rooms and establish a comfortable microclimate.

Considering that the system operates in economy mode, its energy consumption is low. On average, about 12 kW is consumed per square meter of a heated room. The figures are valid for buildings that meet the requirements of SNiP “Thermal protection of buildings” 02/23/2003.

In this case, the temperature set on the thermostat cannot exceed +20ºС. If these conditions are not met, energy consumption increases accordingly.

Infrared heating is very easy to install. Film system installation can be carried out independently, which saves money on the services of specialists. The cost of the equipment is quite high.

But if we compare the full price of designing, purchasing appliances and installing a gas heating system, for example, and the Zebra system, the latter will cost about a third less.

In addition, during operation, IR heaters do not require any maintenance and no financial costs.Considering that their guaranteed service life is 15 years, and their operational life is more than 50 years, the savings are significant.

IR heating is easy to regulate, which allows you to configure its operation taking into account the use of a multi-tariff meter. The average payback period for an IR system is two years.

Reliability and durability

A film-type heater is essentially a group of conductors laminated with film. The design has no rubbing or moving parts.

Due to this, provided that it is used correctly, it can serve for an unlimited period of time. The manufacturer guarantees 10 years of equipment service life, but in reality it can be many times longer.

Intelligent control capability

Manual controls can be used to control the operation of heaters and regulate room temperature. But this method has long been outdated. It prevents the system from operating as economically and efficiently as possible.

A person is physically unable to respond in a timely manner to all changes occurring in the environment that affect the operation of the system. Therefore, the best choice is automatic control of heaters.

To implement it, you will need to install temperature sensors and a controller that will process the data coming from the detectors and, based on this, turn off/on the entire system. If you wish, you can control such a controller not only while directly next to it, but also remotely, for example, from your phone.

Infrared heating is perfectly integrated into Smart home system. In this case, the main processor will monitor the comfortable temperature.

He will be able to set individual temperature conditions for different rooms and track its strict implementation. In addition, all kinds of problems in the system will be immediately detected and reported to the owner.

Wide possibilities for decoration

Zebra is a film type heater, its thickness is only 1 mm. This means that during installation it does not “eat up” any free space at all. The equipment is mounted on the ceiling, floor or wall.

However, those who urgently require an option with a tension structure can, for protection purposes, install a rough plasterboard ceiling behind the film heater, and then install the stretch ceiling.

Versatility of film placement

This type of IR film can be installed in three ways:

- on the ceiling;

- under the floor covering;

- on the wall.

Each method is good in its own way. Most often, Zebra is mounted on the ceiling. This is considered the best option. In this case, the floor and furniture warm up well over the entire surface located under the heater.

Additional advantages - the heater cannot be accidentally damaged, the film will not fail due to overheating caused by furnishings standing above it. It is possible to move large household appliances and furniture.

The disadvantages of a ceiling location include the thermal effect on electronics and household appliances, which can negatively affect operation. In addition, if there are more apartments above the home, there is a risk of flooding, which will lead to failure of the entire system.

The floor-standing arrangement does not have these disadvantages, but in this case the heaters should be especially carefully protected from possible accidental damage.

Film heaters located under the floor covering heat the floor very well: no matter where they are located, on the ceiling or on the floor, the temperature distribution in the room does not change.

The exception is the wall position. Theoretically it is possible, but in practice it is rare. This is due to its low efficiency. The radiation will move only in a straight line, as a result of which a strictly limited area of space will be heated. This option is only good as additional heating.

Zebra IR heater installation technology

The big advantage of an infrared heating system is that you can calculate and install it yourself. Let's look at the main stages of the process.

Preparatory work and calculations

You need to start installing the film, strange as it may sound, by thoroughly insulating your home. The creators of Zebra designed it as a device that almost perfectly maintains a given temperature.

If the room quickly loses heat, the heater will operate in continuous mode. And this is very ruinous for the owner.For this reason, you should start by identifying areas of heat leakage and eliminating them.

Another important point is calculating the amount of film required for installation. To avoid mistakes, you should determine the dimensions of the rooms and draw a ceiling plan.

Then, guided by the size of the panel, you need to try to “place” it on the ceiling in the optimal way. It must be remembered that the heater is divided into segments and can only be cut along the boundary line between them.

After you can outline the location of the film on the sketch, you should count the number of segments and, accordingly, the number of packs of the panel. If planned self-installation of infrared floor or ceiling, it is advisable to additionally purchase a so-called installation kit, which includes heat-shrinkable tubing, eyelets, ZPO clamps, etc.

Installation of the reflective layer

Mandatory for IR film an insulation system is being installed. Despite the aluminum reflector built into the heater, some of the radiation still goes to the base. To prevent this, a reflective screen is attached to the base.

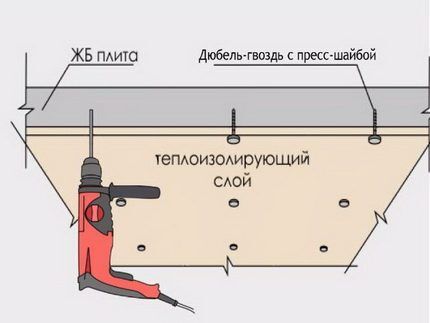

To make it, you should take a material made on the basis of foil. The best option is considered to be Izolon - foil-laminated polyethylene foam. To secure it to the ceiling you will need fasteners. Their type is determined based on the base material.

For example, for concrete floors, dowels with a press washer are used, for wood - a construction stapler or self-tapping screws with a press washer. To begin with, the material is cut out, taking into account that the insulator strips should be joined with a slight overlap. Its dimensions should be specified in the instructions for the material.

The prepared strips are applied to the ceiling. You can't do this alone, so you'll need help. Next, the fasteners are installed. It will be most difficult to work with a concrete base, since you will first need to make a hole and only then put a dowel in it, and then secure the panel with a press washer. By attaching strip to strip, the entire reflective screen is assembled.

Preparing Film Heaters

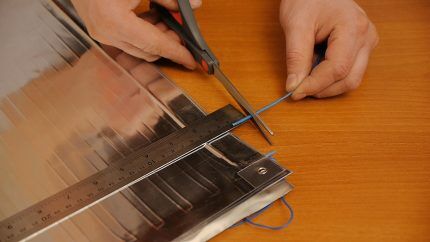

They start by cutting the film. This needs to be done correctly. First, measure out the required number of segments and find the cutting line between them. Next, the film is cut with scissors.

It is important to correctly cut the wires, phase and neutral. About 100-150 mm of wire should remain on one edge, while no more than 10 mm on the other. The latter is considered a dead end and must be insulated with a glue gun or heat shrink tube.

When cutting, you need to remember that the neutral and phase wires are not designed for high loads. For this reason, the length of one panel should not exceed 6 m, otherwise serious operational problems may occur.

A grounding wire must be connected to the cut film strips.To do this, a 4 mm bolt is inserted into a hole specially designed for this purpose, onto which the wire is secured.

Installation of radiant heaters

Installation of the prepared heater panels is carried out similarly to insulating strips, but without overlap. The fasteners used are similar. There is one note here.

The fasteners must be installed very carefully - so that they are as far away as possible from the conductive wires laminated in film. Otherwise, the risk of mechanical damage is too great, which will disable the heater segment.

The film is attached to the ceiling with some tension to avoid possible unwanted sagging of the canvas. This is necessary given that the distance from the heater to the subsequently installed finishing cannot exceed 150 mm and should not be less than 10 mm. When installing the panels, the neutral and phase wires are routed strictly to one side.

Connection and wiring

Next, the main cable is laid along the ceiling. It should be located on the side where the wires from the heaters are routed. For installation, a special element is used - a cable channel. Small holes are made in it, located opposite the wires removed from the film.

Through them, each phase and neutral is inserted into the cable channel. Here they must be connected to the main cable. It is optimal to use soldering for this.

Other methods are not as reliable. The wires are carefully soldered in place and must be insulated. After which the main cable, ready for use, is laid in place and closed.

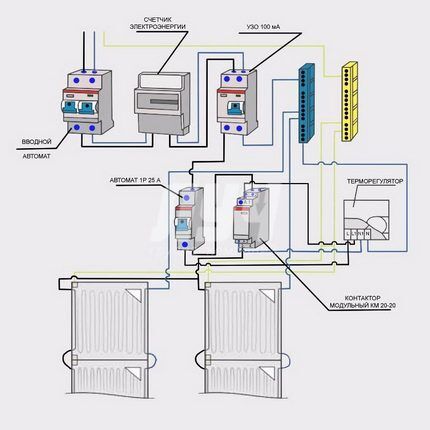

Further installation depends on the system control circuit. For the manual option, a thermostat is connected. If automation is expected, temperature detectors and a controller are added. A very important point: to connect the system to the network, a dedicated line and an RCD must be used.

Conclusions and useful video on the topic

The materials presented in the videos will help you better understand how the heating device works, how it differs from analogues and how it can be quickly installed.

Video #1. Operating principle of infrared heating:

Video #2. Brief overview of the Zebra EVO heating system:

Video #3. How to install the Zebra system:

Infrared heating, and Zebra is precisely this type, is a practical alternative to convective systems. Its effectiveness and cost-effectiveness have been proven by numerous studies and years of practical application.

When deciding to install IR heaters, you need to understand that all their advantages will be fully revealed only if the rooms are thoroughly insulated, otherwise Zebra will only bring disappointment.

Would you like to talk about how you purchased and installed a film heating system in your home? Do you have useful information that will be useful to site visitors? Please write comments, ask questions and publish photographs related to the topic of the article in the block below.

For many years I suffered with conventional types of electric heating; they were uneconomical, did not warm the room well and dried out the air. For this winter season, I decided to change the heating system to Zebra infrared heating. Not only I was satisfied, but also my whole family. The house is much warmer, we no longer use a humidifier, and our monthly heating costs have dropped significantly.

Does it normally warm up your entire room, including the floor? I've heard reviews that it heats normally only up to the middle of the room, and the floor remains cold.

Yes, that’s how it is for me, Zebra PRO (increased power) I feel heat only from the middle of the room, the floor does not warm up (tiles). A fabulous operating principle is proposed, but in fact it does not heat interior items and the floor, at least for me. Moreover, having covered it with the most recommended type of finishing - a suspended ceiling, the efficiency seemed to have dropped compared to there before the ceiling was stretched... It looks like a deception of consumers, the manufacturer is telling fairy tales and making money from it.