Thermal conductivity coefficient of building materials: what does the indicator mean + table of values

Construction involves the use of any suitable materials.The main criteria are safety for life and health, thermal conductivity, and reliability. This is followed by price, aesthetic properties, versatility of use, etc.

Let's consider one of the most important characteristics of building materials - the coefficient of thermal conductivity, since it is on this property that, for example, the level of comfort in the house largely depends.

The content of the article:

What is KTP building material?

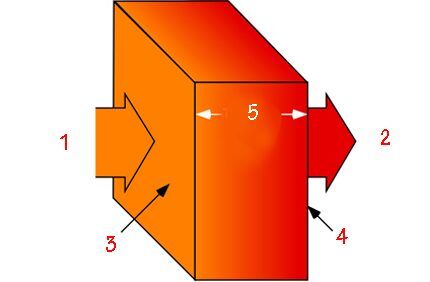

Theoretically, and practically too, building materials, as a rule, create two surfaces - external and internal. From a physics point of view, a warm region always tends towards a cold region.

In relation to building materials, heat will tend from one surface (warmer) to another surface (less warm). In fact, the ability of a material to undergo such a transition is called the thermal conductivity coefficient, or in the abbreviation KTP.

The characteristics of the CTS are usually based on tests, when an experimental specimen measuring 100x100 cm is taken and a thermal effect is applied to it, taking into account the temperature difference of two surfaces of 1 degree. Exposure time 1 hour.

Accordingly, thermal conductivity is measured in Watts per meter per degree (W/m°C).The coefficient is denoted by the Greek symbol λ.

By default, the thermal conductivity of various materials for construction with a value of less than 0.175 W/m°C equates these materials to the category of insulating.

Modern production has mastered technologies for the production of building materials whose CTP level is less than 0.05 W/m°C. Thanks to such products, it is possible to achieve a pronounced economic effect in terms of energy consumption.

Influence of factors on the level of thermal conductivity

Each individual building material has a specific structure and has a unique physical state.

The basis of this are:

- dimension of crystal structure;

- phase state of matter;

- degree of crystallization;

- anisotropy of thermal conductivity of crystals;

- volume of porosity and structure;

- direction of heat flow.

All these are influencing factors. The chemical composition and impurities also have a certain influence on the level of CTP. The amount of impurities, as practice has shown, has a particularly pronounced effect on the level of thermal conductivity of crystalline components.

In turn, the PTS is influenced by the operating conditions of the building material - temperature, pressure, humidity level, etc.

Building materials with minimal package transformer

According to research, dry air has a minimum thermal conductivity value (about 0.023 W/m°C).

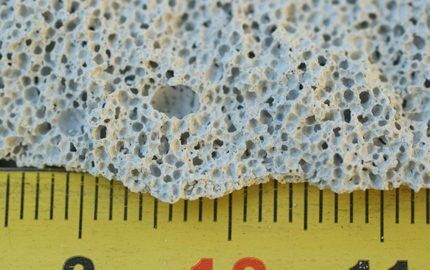

From the point of view of using dry air in the structure of a building material, a structure is needed where dry air resides inside numerous closed spaces of small volume. Structurally, this configuration is represented in the form of numerous pores inside the structure.

Hence the logical conclusion: a building material whose internal structure is a porous formation should have a low level of CFC.

Moreover, depending on the maximum permissible porosity of the material, the thermal conductivity value approaches the value of the thermal conductivity of dry air.

In modern production, several technologies are used to obtain the porosity of a building material.

In particular, the following technologies are used:

- foaming;

- gas formation;

- water sealing;

- swelling;

- introduction of additives;

- creating fiber scaffolds.

It should be noted: the thermal conductivity coefficient is directly related to properties such as density, heat capacity, and temperature conductivity.

The thermal conductivity value can be calculated using the formula:

λ = Q / S *(T1-T2)*t,

Where:

- Q - The amount of heat;

- S – material thickness;

- T1, T2 – temperature on both sides of the material;

- t - time.

The average value of density and thermal conductivity is inversely proportional to the value of porosity. Therefore, based on the density of the structure of the building material, the dependence of thermal conductivity on it can be calculated as follows:

λ = 1.16 √ 0.0196+0.22d2 – 0,16,

Where: d – density value. This is the formula of V.P.Nekrasov, demonstrating the influence of the density of a particular material on the value of its CFC.

The influence of moisture on the thermal conductivity of building materials

Again, judging by examples of the use of building materials in practice, the negative effect of moisture on the quality of life of a building material is revealed. It has been noticed that the more moisture the building material is exposed to, the higher the CTP value becomes.

It is not difficult to justify this point. The effect of moisture on the structure of a building material is accompanied by humidification of the air in the pores and partial replacement of the air environment.

Considering that the thermal conductivity parameter for water is 0.58 W/m°C, a significant increase in the thermal conductivity of the material becomes clear.

It should also be noted that there is a more negative effect when water entering the porous structure is additionally frozen and turns into ice.

Accordingly, it is easy to calculate an even greater increase in thermal conductivity, taking into account the parameters of the ice thermal conductivity equal to 2.3 W/m°C. An increase of approximately four times in the thermal conductivity parameter of water.

From here, construction requirements regarding the protection of insulating building materials from moisture become obvious. After all, the level of thermal conductivity increases in direct proportion to the quantitative humidity.

Another point seems no less significant - the opposite, when the structure of the building material is subjected to significant heating. Excessively high temperature also provokes an increase in thermal conductivity.

This happens due to an increase in the kinematic energy of the molecules that make up the structural basis of the building material.

True, there is a class of materials whose structure, on the contrary, acquires better thermal conductivity properties in high heating mode. One such material is metal.

Methods for determining the coefficient

Different techniques are used in this direction, but in fact all measurement technologies are united by two groups of methods:

- Stationary measurement mode.

- Non-stationary measurement mode.

The stationary technique involves working with parameters that remain unchanged over time or change to a small extent. This technology, judging by practical applications, allows us to count on more accurate results of CFT.

The stationary method allows for actions aimed at measuring thermal conductivity to be carried out in a wide temperature range - 20 – 700 °C. But at the same time, stationary technology is considered a labor-intensive and complex technique that requires a lot of time to execute.

Another measurement technology, non-stationary, seems to be more simplified, requiring from 10 to 30 minutes to complete the work. However, in this case the temperature range is significantly limited. However, the technique has found wide application in the manufacturing sector.

Table of thermal conductivity of building materials

It makes no sense to measure many existing and widely used building materials.

All these products, as a rule, have been tested repeatedly, on the basis of which a table of thermal conductivity of building materials has been compiled, which includes almost all materials needed at a construction site.

One version of such a table is presented below, where KTP is the thermal conductivity coefficient:

| Material (building material) | Density, m3 | KTP dry, W/mºC | % humidity_1 | % humidity_2 | KTP at humidity_1, W/mºC | KTP at humidity_2, W/mºC | |||

| Roofing bitumen | 1400 | 0,27 | 0 | 0 | 0,27 | 0,27 | |||

| Roofing bitumen | 1000 | 0,17 | 0 | 0 | 0,17 | 0,17 | |||

| Roofing slate | 1800 | 0,35 | 2 | 3 | 0,47 | 0,52 | |||

| Roofing slate | 1600 | 0,23 | 2 | 3 | 0,35 | 0,41 | |||

| Roofing bitumen | 1200 | 0,22 | 0 | 0 | 0,22 | 0,22 | |||

| Asbestos cement sheet | 1800 | 0,35 | 2 | 3 | 0,47 | 0,52 | |||

| Asbestos-cement sheet | 1600 | 0,23 | 2 | 3 | 0,35 | 0,41 | |||

| Asphalt concrete | 2100 | 1,05 | 0 | 0 | 1,05 | 1,05 | |||

| Construction roofing felt | 600 | 0,17 | 0 | 0 | 0,17 | 0,17 | |||

| Concrete (on gravel bed) | 1600 | 0,46 | 4 | 6 | 0,46 | 0,55 | |||

| Concrete (on a slag bed) | 1800 | 0,46 | 4 | 6 | 0,56 | 0,67 | |||

| Concrete (on crushed stone) | 2400 | 1,51 | 2 | 3 | 1,74 | 1,86 | |||

| Concrete (on a sand bed) | 1000 | 0,28 | 9 | 13 | 0,35 | 0,41 | |||

| Concrete (porous structure) | 1000 | 0,29 | 10 | 15 | 0,41 | 0,47 | |||

| Concrete (solid structure) | 2500 | 1,89 | 2 | 3 | 1,92 | 2,04 | |||

| Pumice concrete | 1600 | 0,52 | 4 | 6 | 0,62 | 0,68 | |||

| Construction bitumen | 1400 | 0,27 | 0 | 0 | 0,27 | 0,27 | |||

| Construction bitumen | 1200 | 0,22 | 0 | 0 | 0,22 | 0,22 | |||

| Lightweight mineral wool | 50 | 0,048 | 2 | 5 | 0,052 | 0,06 | |||

| Mineral wool is heavy | 125 | 0,056 | 2 | 5 | 0,064 | 0,07 | |||

| Mineral wool | 75 | 0,052 | 2 | 5 | 0,06 | 0,064 | |||

| Vermiculite leaf | 200 | 0,065 | 1 | 3 | 0,08 | 0,095 | |||

| Vermiculite leaf | 150 | 0,060 | 1 | 3 | 0,074 | 0,098 | |||

| Gas-foam-ash concrete | 800 | 0,17 | 15 | 22 | 0,35 | 0,41 | |||

| Gas-foam-ash concrete | 1000 | 0,23 | 15 | 22 | 0,44 | 0,50 | |||

| Gas-foam-ash concrete | 1200 | 0,29 | 15 | 22 | 0,52 | 0,58 | |||

| Gas-foam concrete (foam silicate) | 300 | 0,08 | 8 | 12 | 0,11 | 0,13 | |||

| Gas-foam concrete (foam silicate) | 400 | 0,11 | 8 | 12 | 0,14 | 0,15 | |||

| Gas-foam concrete (foam silicate) | 600 | 0,14 | 8 | 12 | 0,22 | 0,26 | |||

| Gas-foam concrete (foam silicate) | 800 | 0,21 | 10 | 15 | 0,33 | 0,37 | |||

| Gas-foam concrete (foam silicate) | 1000 | 0,29 | 10 | 15 | 0,41 | 0,47 | |||

| Construction gypsum board | 1200 | 0,35 | 4 | 6 | 0,41 | 0,46 | |||

| Expanded clay gravel | 600 | 2,14 | 2 | 3 | 0,21 | 0,23 | |||

| Expanded clay gravel | 800 | 0,18 | 2 | 3 | 0,21 | 0,23 | |||

| Granite (basalt) | 2800 | 3,49 | 0 | 0 | 3,49 | 3,49 | |||

| Expanded clay gravel | 400 | 0,12 | 2 | 3 | 0,13 | 0,14 | |||

| Expanded clay gravel | 300 | 0,108 | 2 | 3 | 0,12 | 0,13 | |||

| Expanded clay gravel | 200 | 0,099 | 2 | 3 | 0,11 | 0,12 | |||

| Shungizite gravel | 800 | 0,16 | 2 | 4 | 0,20 | 0,23 | |||

| Shungizite gravel | 600 | 0,13 | 2 | 4 | 0,16 | 0,20 | |||

| Shungizite gravel | 400 | 0,11 | 2 | 4 | 0,13 | 0,14 | |||

| Pine wood cross grain | 500 | 0,09 | 15 | 20 | 0,14 | 0,18 | |||

| Plywood | 600 | 0,12 | 10 | 13 | 0,15 | 0,18 | |||

| Pine wood along the grain | 500 | 0,18 | 15 | 20 | 0,29 | 0,35 | |||

| Oak wood across the grain | 700 | 0,23 | 10 | 15 | 0,18 | 0,23 | |||

| Metal duralumin | 2600 | 221 | 0 | 0 | 221 | 221 | |||

| Reinforced concrete | 2500 | 1,69 | 2 | 3 | 1,92 | 2,04 | |||

| Tufobeton | 1600 | 0,52 | 7 | 10 | 0,7 | 0,81 | |||

| Limestone | 2000 | 0,93 | 2 | 3 | 1,16 | 1,28 | |||

| Lime solution with sand | 1700 | 0,52 | 2 | 4 | 0,70 | 0,87 | |||

| Sand for construction work | 1600 | 0,035 | 1 | 2 | 0,47 | 0,58 | |||

| Tufobeton | 1800 | 0,64 | 7 | 10 | 0,87 | 0,99 | |||

| Lined cardboard | 1000 | 0,18 | 5 | 10 | 0,21 | 0,23 | |||

| Multilayer construction cardboard | 650 | 0,13 | 6 | 12 | 0,15 | 0,18 | |||

| Foam rubber | 60-95 | 0,034 | 5 | 15 | 0,04 | 0,054 | |||

| Expanded clay concrete | 1400 | 0,47 | 5 | 10 | 0,56 | 0,65 | |||

| Expanded clay concrete | 1600 | 0,58 | 5 | 10 | 0,67 | 0,78 | |||

| Expanded clay concrete | 1800 | 0,86 | 5 | 10 | 0,80 | 0,92 | |||

| Brick (hollow) | 1400 | 0,41 | 1 | 2 | 0,52 | 0,58 | |||

| Brick (ceramic) | 1600 | 0,47 | 1 | 2 | 0,58 | 0,64 | |||

| Construction tow | 150 | 0,05 | 7 | 12 | 0,06 | 0,07 | |||

| Brick (silicate) | 1500 | 0,64 | 2 | 4 | 0,7 | 0,81 | |||

| Brick (solid) | 1800 | 0,88 | 1 | 2 | 0,7 | 0,81 | |||

| Brick (slag) | 1700 | 0,52 | 1,5 | 3 | 0,64 | 0,76 | |||

| Brick (clay) | 1600 | 0,47 | 2 | 4 | 0,58 | 0,7 | |||

| Brick (triple) | 1200 | 0,35 | 2 | 4 | 0,47 | 0,52 | |||

| Metal copper | 8500 | 407 | 0 | 0 | 407 | 407 | |||

| Dry plaster (sheet) | 1050 | 0,15 | 4 | 6 | 0,34 | 0,36 | |||

| Mineral wool slabs | 350 | 0,091 | 2 | 5 | 0,09 | 0,11 | |||

| Mineral wool slabs | 300 | 0,070 | 2 | 5 | 0,087 | 0,09 | |||

| Mineral wool slabs | 200 | 0,070 | 2 | 5 | 0,076 | 0,08 | |||

| Mineral wool slabs | 100 | 0,056 | 2 | 5 | 0,06 | 0,07 | |||

| Linoleum PVC | 1800 | 0,38 | 0 | 0 | 0,38 | 0,38 | |||

| Foam concrete | 1000 | 0,29 | 8 | 12 | 0,38 | 0,43 | |||

| Foam concrete | 800 | 0,21 | 8 | 12 | 0,33 | 0,37 | |||

| Foam concrete | 600 | 0,14 | 8 | 12 | 0,22 | 0,26 | |||

| Foam concrete | 400 | 0,11 | 6 | 12 | 0,14 | 0,15 | |||

| Foam concrete on limestone | 1000 | 0,31 | 12 | 18 | 0,48 | 0,55 | |||

| Foam concrete on cement | 1200 | 0,37 | 15 | 22 | 0,60 | 0,66 | |||

| Expanded polystyrene (PSB-S25) | 15 — 25 | 0,029 – 0,033 | 2 | 10 | 0,035 – 0,052 | 0,040 – 0,059 | |||

| Expanded polystyrene (PSB-S35) | 25 — 35 | 0,036 – 0,041 | 2 | 20 | 0,034 | 0,039 | |||

| Polyurethane foam sheet | 80 | 0,041 | 2 | 5 | 0,05 | 0,05 | |||

| Polyurethane foam panel | 60 | 0,035 | 2 | 5 | 0,41 | 0,41 | |||

| Lightweight foam glass | 200 | 0,07 | 1 | 2 | 0,08 | 0,09 | |||

| Weighted foam glass | 400 | 0,11 | 1 | 2 | 0,12 | 0,14 | |||

| Glassine | 600 | 0,17 | 0 | 0 | 0,17 | 0,17 | |||

| Perlite | 400 | 0,111 | 1 | 2 | 0,12 | 0,13 | |||

| Perlite cement slab | 200 | 0,041 | 2 | 3 | 0,052 | 0,06 | |||

| Marble | 2800 | 2,91 | 0 | 0 | 2,91 | 2,91 | |||

| Tuff | 2000 | 0,76 | 3 | 5 | 0,93 | 1,05 | |||

| Concrete on ash gravel | 1400 | 0,47 | 5 | 8 | 0,52 | 0,58 | |||

| Fibreboard (chipboard) | 200 | 0,06 | 10 | 12 | 0,07 | 0,08 | |||

| Fibreboard (chipboard) | 400 | 0,08 | 10 | 12 | 0,11 | 0,13 | |||

| Fibreboard (chipboard) | 600 | 0,11 | 10 | 12 | 0,13 | 0,16 | |||

| Fibreboard (chipboard) | 800 | 0,13 | 10 | 12 | 0,19 | 0,23 | |||

| Fibreboard (chipboard) | 1000 | 0,15 | 10 | 12 | 0,23 | 0,29 | |||

| Polystyrene concrete on Portland cement | 600 | 0,14 | 4 | 8 | 0,17 | 0,20 | |||

| Vermiculite concrete | 800 | 0,21 | 8 | 13 | 0,23 | 0,26 | |||

| Vermiculite concrete | 600 | 0,14 | 8 | 13 | 0,16 | 0,17 | |||

| Vermiculite concrete | 400 | 0,09 | 8 | 13 | 0,11 | 0,13 | |||

| Vermiculite concrete | 300 | 0,08 | 8 | 13 | 0,09 | 0,11 | |||

| Ruberoid | 600 | 0,17 | 0 | 0 | 0,17 | 0,17 | |||

| Fibrolite board | 800 | 0,16 | 10 | 15 | 0,24 | 0,30 | |||

| Metal steel | 7850 | 58 | 0 | 0 | 58 | 58 | |||

| Glass | 2500 | 0,76 | 0 | 0 | 0,76 | 0,76 | |||

| Glass wool | 50 | 0,048 | 2 | 5 | 0,052 | 0,06 | |||

| Fiberglass | 50 | 0,056 | 2 | 5 | 0,06 | 0,064 | |||

| Fibrolite board | 600 | 0,12 | 10 | 15 | 0,18 | 0,23 | |||

| Fibrolite board | 400 | 0,08 | 10 | 15 | 0,13 | 0,16 | |||

| Fibrolite board | 300 | 0,07 | 10 | 15 | 0,09 | 0,14 | |||

| Plywood | 600 | 0,12 | 10 | 13 | 0,15 | 0,18 | |||

| Reed slab | 300 | 0,07 | 10 | 15 | 0,09 | 0,14 | |||

| Cement-sand mortar | 1800 | 0,58 | 2 | 4 | 0,76 | 0,93 | |||

| Metal cast iron | 7200 | 50 | 0 | 0 | 50 | 50 | |||

| Cement-slag mortar | 1400 | 0,41 | 2 | 4 | 0,52 | 0,64 | |||

| Complex sand solution | 1700 | 0,52 | 2 | 4 | 0,70 | 0,87 | |||

| Dry plaster | 800 | 0,15 | 4 | 6 | 0,19 | 0,21 | |||

| Reed slab | 200 | 0,06 | 10 | 15 | 0,07 | 0,09 | |||

| Cement plaster | 1050 | 0,15 | 4 | 6 | 0,34 | 0,36 | |||

| Peat stove | 300 | 0,064 | 15 | 20 | 0,07 | 0,08 | |||

| Peat stove | 200 | 0,052 | 15 | 20 | 0,06 | 0,064 | |||

We also recommend reading our other articles, where we talk about how to choose the right insulation:

- Insulation for attic roofs.

- Materials for insulating a house from the inside.

- Insulation for the ceiling.

- Materials for external thermal insulation.

- Insulation for floors in a wooden house.

Conclusions and useful video on the topic

The video is thematically oriented, explaining in sufficient detail what KTP is and “what it is eaten with.” After familiarizing yourself with the material presented in the video, you have a high chance of becoming a professional builder.

The obvious point is that a potential builder must know about thermal conductivity and its dependence on various factors. This knowledge will help you build not only with high quality, but with a high degree of reliability and durability of the object. Using a coefficient essentially means saving money, for example, on paying for the same utilities.

If you have questions or valuable information on the topic of the article, please leave your comments in the block below.

Wow, what an old slate turns out to be reliable in this regard. I thought cardboard would remove more heat. Still, there is nothing better than concrete, in my opinion. Maximum preservation of warmth and comfort, regardless of humidity and other negative factors. And if concrete + slate, then it’s basically fire :) You’ll just have to worry about changing it, now they make it so dull in quality..

Our roof is covered with slate. It's never hot at home in the summer. It looks unassuming, but better than metal tiles or roofing iron. But we didn’t do this because of the numbers.In construction, you need to use proven methods of work and be able to choose the best on the markets with a small budget. Well, evaluate the operating conditions of the housing. Residents of Sochi do not need to build houses prepared for forty degree frosts. It will be wasted money.