Vacuum solar collector: principle of operation + how to assemble it yourself

Considerable amounts of money are spent on hot water supply and space heating. But there is an alternative energy source - a vacuum solar collector.Have you heard of this? It allows you to significantly reduce the financial costs of maintaining comfort, providing maximum heating effect with minimal heat loss.

This device can be purchased from household equipment manufacturers or assembled yourself at home. To choose the right model, you have to study a lot of information. We will help you decide on the main purchasing criteria.

The article will discuss the operating principle and design of a vacuum manifold. We will talk about the design features of various models, consider the pros and cons of these installations. In addition, we will describe in detail how to make and install a vacuum solar collector yourself.

The material is accompanied by videos from which you will learn about the important features and operating principles of vacuum manifolds.

The content of the article:

- Operating principle of the vacuum unit

- How does a vacuum type manifold work?

- Design nuances and classification

- Comparison of various modifications

- What should the heat collector be like?

- Pros and cons of vacuum type collectors

- Do-it-yourself assembly of the unit

- How to place the device correctly?

- Conclusions and useful video on the topic

Operating principle of the vacuum unit

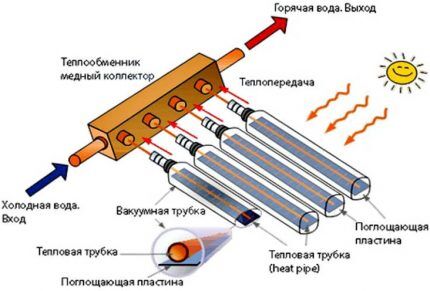

The vacuum solar collector differs from conventional solar systems in the way solar energy processing. A classic battery simply takes light and converts it into electricity. The collector consists of glass tubes with a vacuum created inside. They are combined into a single system through special docking units.

Inside each tube there is a channel of one or two copper rods with coolant. Catching the sun's rays, the active element heats the coolant material, thus ensuring the operation of the collector.

Due to this design, the level of energy efficiency increases significantly, and heat loss is significantly reduced, since the vacuum layer allows you to save about 95% of the captured solar energy.

In addition, the dependence of collector productivity on seasonality, ambient temperature and various weather conditions, such as gusts of wind, partly cloudy, precipitation, etc., is reduced.

How does a vacuum type manifold work?

Modern vacuum devices that provide rooms with heat and hot water using solar energy vary technologically.

Collectors are divided into the following types:

- tubular without glass protective coating;

- module with reduced conversion;

- standard flat version;

- device with transparent thermal insulation;

- air unit;

- flat vacuum manifold.

They all have a common design similarity, so they consist of:

- external transparent pipe, from where the air has been completely pumped out;

- heated pipelocated in a large pipe where liquid or gaseous coolant moves;

- one or two prefabricated distributors, to which larger caliber pipes are connected and a circulation circuit of thin tubes placed inside enters.

The entire design is somewhat reminiscent of a thermos with transparent walls, which maintains an unprecedentedly high level of thermal insulation. Thanks to this feature, the body of the inner tube acquires the ability to warm up efficiently and fully transfer the energy resource to the coolant circulating inside.

Design nuances and classification

Vacuum-type collectors are classified according to the type of glass tubes installed in the structure, or according to the characteristics of the thermal channels. The tubes are usually coaxial and feather type, and the heat channels are U-shaped direct-flow and heat pipe type. .

Characteristics of coaxial tubes

Coaxial tubes are a double glass thermos flask with an artificially created vacuum space between the walls. The inner surface of the tube has a layer of special heat-absorbing coating, so the actual heat transfer occurs directly from the walls of the glass bulb.

As an absorbing element, a copper tube containing an ether composition is soldered into a glass tube. During the heating process, it evaporates, effectively gives up its heat, condenses and flows to the bottom of the tube.The cycle is then repeated, thus creating a continuous heat exchange process.

Features of feather tubes

Vacuum feather tubes have greater wall thickness than coaxial ones, and consist not of two, but of one flask. The internal copper absorption element is equipped along its entire length with a durable amplifier - a corrugated plate with a high-level energy-absorbing coating.

Thanks to this design feature, the vacuum is located directly in the thermal channel, part of which, together with the absorbent, is integrated directly into the flask.

Collectors made from feather vacuum tubes are considered the most efficient in their class, perform well and provide reliable service for many years.

Operating principle of the heat pipe

Heat pipes consist of closed tubes containing an easily evaporating liquid composition. Under the influence of sunlight, it warms up, moves to the upper region of the channel and is concentrated there in a special heat collector (manifold).

At this moment, the working fluid gives up all the accumulated heat and falls down again to resume the process.

The heat-pipe heat exchanger sleeve is connected to the manifold heat exchanger through a special socket soldered into the 1-pipe heat exchanger itself, or is wrapped around a 2-pipe heat exchanger.

The released energy is taken from the thermal reservoir by the coolant and transferred further through the system, thus ensuring the availability of hot water in taps and radiators. The heat pipe system is easy to install and demonstrates high operating efficiency.

In the event of a breakdown or failure without any difficulties, it is possible to replace the damaged unit with a new one without resorting to reconstruction of the entire system.

Repair work can be easily carried out directly at the location of the collector, without dismantling the unit and without applying unnecessary effort to the work.

Description of U-shaped once-through heat exchanger

The tube of the direct-flow heat exchanger is shaped like the letter U. Water or the working coolant of the heating system circulates inside. One part of the element is intended for cold coolant, and the second correctly removes the already heated one.

When heated, the active composition expands and enters the storage tank, thus creating natural circulation of liquid in the system. A special selective coating applied to the internal walls increases the heat absorption capacity and improves the efficiency of the system as a whole.

U-type tubes demonstrate high performance and provide solid heat transfer, but they have one significant drawback. They form one integral structure with the manifold and are always mounted together with it.

It will not be possible to replace a separate single tube that has failed. For repairs, it will be necessary to dismantle the entire complex and put a new one in its place.

Comparison of various modifications

In the manufacture of solar units, thermal channels and vacuum glass tubes for solar collectors are combined in a variety of combinations.

The most popular among consumers are coaxial models with a heat pipe. Buyers are attracted by the loyal price of the devices and very simple, affordable maintenance throughout the entire service life.

Vacuum devices with heat pipe channels demonstrate high reliability and have no restrictions on use even in high-pressure solar thermal complexes.

Devices with a coaxial flask containing direct-flow U-shaped channels are also included in the list of popular ones. They are characterized by such parameters as low heat loss and efficiency of 70% and above.

The situation is somewhat spoiled by: a complex repair process, specific maintenance during operation and the inability to replace an individual damaged unit. If something happens to the device, it is dismantled and a completely new collector is put in place.

Feather tubes are structurally a single cylinder made of glass with thickened, strong walls (depending on the manufacturer, from 2.5 mm and above). The feather absorbent insert contained inside tightly fits the working channel, made of heat-conducting metal.

Almost perfect insulation is created by the vacuum space inside the glass container. The absorbent transfers absorbed heat without loss and provides the system with an efficiency of up to 77%.

Models with a feather element are somewhat more expensive than coaxial ones, but due to their high efficiency they provide complete comfort in the room and quickly pay for themselves.

The most efficient and productive are feather flasks with internal direct-flow channels. Their actual efficiency sometimes reaches record levels of 80%.

The price of the products is quite high, and when carrying out repairs, it is necessary to drain all the coolant from the system and only then begin troubleshooting.

What should the heat collector be like?

The heat collector is another very important working element of the vacuum manifold. Through this unit, accumulated heat is transferred from the tubes to the coolant.

The heat collector is located at the top of the device. One of its components, a copper core, receives energy and transfers it to the main coolant circulating in a closed tank-collector heat exchanger system.

Correct operation is guaranteed when connected to the system. circulation pump. The automation that controls the heating complex clearly monitors the temperature level in the channels and, if it falls below the permissible critical minimum (for example, at night), stops the pump.

This allows you to avoid backheating, when the coolant begins to take away the heat of the hot water collected in the storage tank.

Pros and cons of vacuum type collectors

The main advantage of the units is the almost complete absence of heat loss during operation. This is provided by a vacuum environment, which is one of the highest quality natural insulators. But the list of advantages does not end there.

The devices have other distinct advantages:

- operating efficiency at low temperatures (down to -30°C);

- ability to accumulate temperatures up to 300°C;

- maximum possible absorption of thermal energy, including the invisible spectrum;

- operational stability;

- low susceptibility to aggressive atmospheric manifestations;

- low windage due to the design features of tubular systems capable of passing air masses of different densities through them;

- high level of efficiency in regions with temperate and cool climates with a small number of clear and sunny days;

- durability subject to basic operating rules;

- accessibility for repair and the ability to change not the entire system, but only one failed fragment.

The disadvantages include the inability of the collectors to self-clean from frost, ice, snow and the high price of the components necessary to assemble the unit at home.

Do-it-yourself assembly of the unit

The process of assembling a vacuum manifold begins with the manufacture of a support frame for the working elements. It is installed immediately in the place allocated for the unit.

The size and dimensions of the frame depend entirely on the model that is planned to be made, and are usually prescribed in the instructions found among the accompanying documents for the components.

I additionally fix the places where the frame meets the roof surface with sealant so that in the future water does not enter the house through the holes. Then the storage tank is delivered to the installation site and secured with screws to the top of the frame.

At the next stage, the heating element, temperature sensor and automated air vent are assembled. All auxiliary components and related parts are placed on the included softening pads. To attach the temperature sensor, use a socket wrench.

Next, the supply of water supply communications is arranged. For this purpose, pipes are taken from any material that is resistant to low temperatures and can withstand up to 95°C. Well proven polypropylene pipes and fittings.

Having connected the water supply, the storage tank is filled with water and tested for leaks. If leaks are found somewhere within 3-4 hours, they are repaired.

At the end, heating elements are installed. To do this, the copper tube is wrapped in aluminum sheet and placed in a glass vacuum tube. From below, a fixing cup and a boot made of durable, flexible rubber are placed on the flask.

The upper copper tip of the tube is pushed all the way into the brass condenser. Viscous thermal contact grease is not removed from the pipes. Snap the locking mechanism onto the bracket and mount all remaining glass tubes using the same principle.

A mounting block is placed on the structure, a 220-volt power supply is supplied to it, and three auxiliary units are connected to the system - a heating element, an air vent and a temperature sensor.

The last thing to connect is a controller designed to correctly control the complex. The desired operating parameters are entered into the controller menu and the system starts in standard mode.

Step-by-step instructions for constructing a solar collector are given in this article.

How to place the device correctly?

In order for the vacuum collector to work fully and effectively provide the living space with the necessary energy, it is necessary to find the most favorable location for it and correctly orient the device relative to the parts of the world.

For settlements in the northern hemisphere, it is important to place the collector in the southern part of the roof of the house or on the sunny side of the site. It is advisable to ensure a minimum deviation for the plane of the device.

If it is not possible to direct the surface to the south, you should choose the brightest angle in the open space among the west and east.

The solar energy complex should not be covered by chimneys, decorative fragments of roofing, spreading tree branches and tall residential or technical buildings. This will reduce operating efficiency and reduce the level of heating of the operating elements.

If the unit is positioned correctly, it will provide almost the same heat transfer throughout the year, regardless of the season.

If you do not have extensive experience in carrying out complex repair, installation and plumbing work, it is irrational to vacuum tubes at home. This process is very labor-intensive and requires special knowledge and specialized equipment.

In addition, vacuum-type elements made independently have a much lower level of efficiency than factory parts. Therefore, it makes the most sense to purchase products from a specialized manufacturer, and then try to assemble several sections at home.

The website has a selection of articles on arranging a solar heating system, we recommend that you read:

- Solar heating systems: analysis of heating technologies based on solar systems

- Heating a private house with solar panels: diagrams and device

- Flexible solar panels: types, characteristics + connection features

Conclusions and useful video on the topic

A detailed, detailed description of the vacuum tube, the principle of its operation and the features of the functioning of the solar collector as a whole. The author talks about some interesting nuances and shows that the installation can become a real alternative to a gas boiler.

Interesting information about the operation of the solar collector in winter.

How to properly install a vacuum solar collector with your own hands at home. All the nuances of the process, recommendations and useful tips.

Knowing the basic operating principle of a tubular vacuum solar collector, you can assemble the unit yourself. The installation will be fully tailored to your individual requirements and needs.

This is not a very difficult task, but it requires increased attention, scrupulousness and certain skills, otherwise the risk of damaging the integrity of the flask and breaking its tightness increases significantly.

We invite everyone interested in choosing, installing or self-assembling a solar collector to leave comments and ask questions. The contact form is located in the lower block.

A good alternative to adsorption solar panels. Anyway, most of the electricity is spent on heating: heating, hot water. And here everything is very simplified and cheaper - heating occurs directly from the Sun, bypassing the stage of electricity generation, where the greatest efficiency losses occur. In the middle zone (for example, N. Novgorod) it works very effectively.

My husband installed a vacuum solar collector in our house. We bought a ready-made version, but installed it myself, and it didn’t take much time at all. I don’t understand why they asked for such a sum for installation... But we are very happy with the unit, it’s enough even on not the sunny days, it functions without problems in winter at minus 15-20. You just need to clean it periodically.

Anna, where did you buy it?

Where to go for warmth in summer??? How to convert it into electrical energy???)

Dmitry, if the water temperature in summer goes beyond 80 degrees, you can consider the option of dumping excess heat into the pool. If you want it simpler, you can sew strips of fabric 150-160 cm long and a width equal to the circumference of the tube + 2 cm. Sew one piece of Velcro (textile fastener) along the long side on one side, and another on the other.With such a simple cover you can wrap as many pipes for the summer as you need for extra energy. Take it off before fall :)))

Are there such vacuum tubes, but vice versa, to make an air conditioner or a refrigerator without electricity and making fires?