What are modern pipeline fittings - how to choose and where to purchase

Not a single modern pipeline system can do without control elements.After all, without pipeline fittings, the flow of liquid or gas becomes uncontrollable. Selecting controls is not so difficult if you have a sketch, diagram or project with characteristics on hand. You cannot buy pipeline fittings by eye.

The content of the article:

What to look for when buying pipeline fittings

The components used in laying plastic pipes are produced for a specific type of pipeline and its characteristics. The body of the polypropylene fittings has landing ring grooves, usually internal, to which the pipe is soldered. The difference between the fitting diameter and the outer size of the pipe blank is clearly regulated by GOST standards.

Similar requirements apply to the landing diameters of pipeline fittings for polyethylene and metal-plastic pipelines. The only difference is that fastening at the joint is carried out by crimping or compression using sealing gaskets. Therefore, when choosing, first of all, we pay attention to compliance with the landing dimensions.

In addition to the diameters, it is necessary to look at such a part of the pipeline fittings as the performance characteristics of the pumped liquid medium:

- Maximum and minimum liquid temperature.The manufacturer sets the upper and lower threshold for heating or cooling of pipeline fittings, at which the part still remains operational. All this is in the product passport.

- Operating pressure. Its value is usually included in the marking of pipes and fittings. Indicate the maximum water pressure (Bar) at room temperature at which the faucet or valve can operate for an almost unlimited time.

In the description of fittings you can also find such parameters as conditional pressure and throughput of the internal cross-section of the pipeline part. For practice they have no special value.

The conditional pressure determines the maximum pressure value during testing of pipeline fittings at room temperature, at which a tap or valve is capable of operating for a specific period of time, usually 1000 hours.

Based on this indicator, one can indirectly judge the theoretical quality of the product. The maximum flow rate is required only for the design of heating systems and high-power water pumps.

The most important criterion that you need to pay attention to when choosing is the ability to repair individual elements with your own hands, preferably without dismantling.

Certain parts of pipeline valves, especially seals, are subject to crushing and abrasion loads, and therefore often fail prematurely. Some models allow you to repair pipeline fittings by replacing a damaged element or at least compensating for production. But many taps, by design, are non-separable - this also needs to be taken into account.

Types of pipeline fittings

The use of additional parts and assemblies on pipes is accepted as a necessary, forced measure. Operation of an air duct, water supply or heating system without pipeline fittings would be more unsafe for human life. In addition, the system must be controlled, often in automatic or semi-automatic mode.

Main functions of pipeline fittings:

- locking or regulating - fittings must be present in cold or hot water supply systems;

- cut-off or safety - the control system is used mainly in steam pipelines and heating circuits;

- separating – used to trap contaminants inside pipeline lines and remove one of the phases of the steam-water mixture.

Regardless of the assigned functions, the elements of pipeline fittings are always made in a housing with ready-made inlets, simplifying the installation and insertion of the unit into a pipe of a certain type. The selected valve model must match the type and material of the pipeline line. Handicraft fastening is not allowed.

Shut-off

This type includes all cranes, ball and valve type, except mixing ones. Shut-off valves also include dampers and gates with a transverse curtain, a rotating membrane-flap, designed for draining water from heating and irrigation tanks.

Also classified as shut-off valves are blocking valves that ensure fluid movement in one direction. Most often, this type of pipeline fittings is used in conjunction with water pumps.

Regulatory

This group includes devices with control functions.Typically these include valves with manual lifting of a poppet valve, ball valves that regulate the flow of coolant through a radiator or heat exchanger.

Heating systems can use pipeline fittings with manually adjustable water flow, as well as semi-automatic valves that regulate flow depending on the water temperature.

A ball valve can only be used as a control valve if the water flow speed does not exceed 30 cm/s. At higher speeds, temperatures and pressures, the ball element is subject to intense wear and quickly fails.

Protective

Pipeline fittings of a protective type include valves for releasing excess water pressure, dirt filters used to trap fibers and solid particles, and magnetic traps. The latter type of fittings is used on steel water pipelines and pipes. They effectively retain rust or scale from cast iron heat exchangers, which allows you to extend the life of pumps and valves several times.

Safety

Typically, the list includes elements of the boiler safety group. These include emergency steam release valves, bimetallic thermostats and hot water cut-offs for shower faucets.

This type of valve is activated when steam appears in the heating system or the safe water temperature is exceeded. The first type can be adjusted by vapor phase pressure. The second type of pipeline protection is triggered and returns to its original state automatically.

Distribution and mixing

There are two types of control devices - manual and automatic. Taps on heating radiators are not taken into account, since in this case only the flow of hot water is regulated. There is no mixing or distribution of flows.

An example of a manual device is a mixer tap installed in a shower stall or bathtub, or on a kitchen sink. The simplest models consist of two taps with valve gates, by rotating which you can select the optimal water flow through a common pipe.

Automatic and semi-automatic piping systems are used primarily for underfloor heating. A semi-automatic two-way valve is installed at the outlet of the common manifold. Boiling water and cold water from the return line are supplied at the inlet.

Depending on the position of the valve of the pipeline regulator, the amount of hot and cold water is different. In this way, it is possible to regulate the degree of heating of the heated floor, regardless of the temperature of the heating radiators and hot water for the bathroom or kitchen.

Phase separation

This group includes three types of devices - air separators, water condensate collectors, oil separators. The first option is used in heating systems, for example, the Mayevsky tap.

With its help, most of the air pockets inside the pipes are released. A device similar in function is installed in double-circuit gas heating boilers.

Condensate collectors are used in ventilation or air conditioning systems. Oil separators are used at the outlet of compressor units.

Pipe fittings depending on the type of pipes

The design of shut-off and control devices directly depends on the material and dimensions, and the method of inserting parts into pipeline lines. For modern household water pipelines Polypropylene with copolymers, cross-linked polyethylene, and metal-plastic are predominantly used. Steel or bronze fittings are used only on boilers and high-pressure industrial pipelines.

For polyethylene pipes

There are two types of polyethylene pipelines:

- LDPE – made from a high-pressure polyethylene matrix. For water pipes, pipes are usually black with a blue or blue longitudinal stripe;

- PEX – made of cross-linked low-density polyethylene. Elastic, colored or clear tubes, soft to the touch at room temperature.

For pipeline lines made of LDPE, cast fittings made of high-density polyethylene are used.

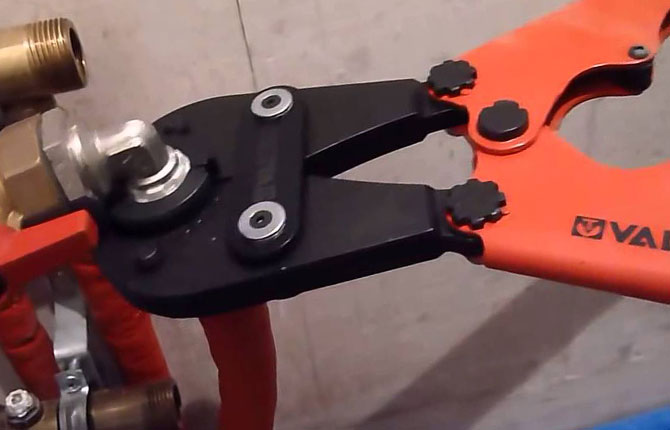

Docking is done by screwing the crimp nut along the thread on top of the ring block and the rubber gasket. According to the same scheme, the connection with the shut-off, outlet, and control valves is carried out. For large pipe diameters, pipeline couplings and valves are made of metal.

All components, including reinforcement units, for PEX pipes are made of metal. The connection is made with metal crimp nuts on a fitting built into the body.

For polypropylene pipes

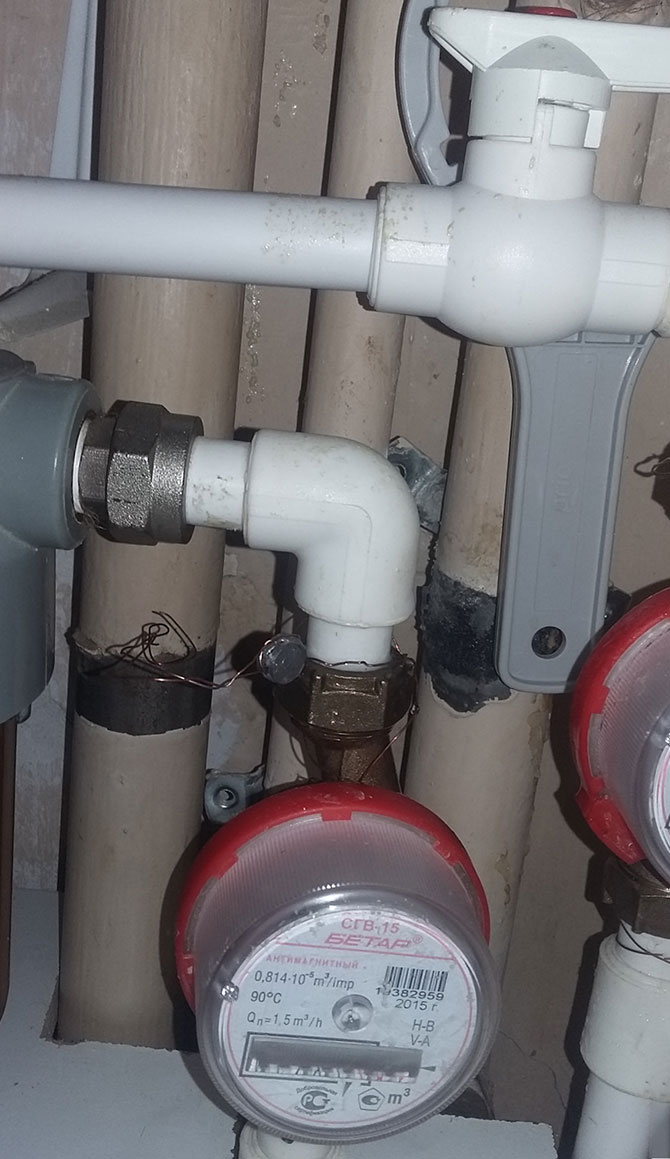

Pipe fittings for water supply systems made of polypropylene are made by hot stamping in the form of a cast body for soldering or with a metal fitting - insert. Such products operate at low pressure or temperature up to 60 ℃.

The most important sections of the heating system are equipped with metal fittings with transition couplings.

For metal-plastic pipes

For metal-plastic pipeline lines, components and fittings made of metal are used. Connection to taps, valves, filters, and safety devices is carried out using a transition thread adapter.

Pay attention to the models of filters, valves, taps designed for insertion into lines of metal-plastic pipes. In appearance and the design of compression fittings, they are similar to products intended for installation of PEX cross-linked polyethylene blanks on pipes.

Despite all the external similarities, fittings for PEX pipes and metal-plastic are not interchangeable, so you need to clarify the information in the product passport and check the markings on the centering rim of the body.

What are pipeline fittings made of?

For polypropylene PPR pipes and polyethylene LDPE pipes, taps, mixer bodies, filters can be made of the same material as the pipeline lines. For large diameter water pipes, as well as for the most critical elements - valves, pressure regulators, exclusively products in a metal case are used.

All pipeline fittings for metal-plastic pipes are made of lead brass CW614N, CW617N, CW602N or the domestic brand LS59.

| Alloy grade | Content Cu,% | Content Sn,% | Content Fe,% | Content Al,% | Content Pb,% | Content Ni,% | Content Zn |

| CW627N | 57-59 | 0,3 | 0,3 | 0,05 | 1,6-2,6 | 0,3 | rest |

| LS59-2 | 57-59 | 0,3 | 0,4 | 0,1 | 1,5-2,5 | 0,4 | rest |

| CW614N | 57-59 | 0,3 | 0,3 | 0,05 | 2,6-3,5 | 0,3 | rest |

| LS58-3 | 57-59 | 0,4 | 0,4 | 0,1 | 2,5-3,5 | 0,5 | rest |

Cheap taps, mixers, and filters are often made from zinc-aluminum alloy TsAM. It is better not to use such products, since their actual service life usually does not exceed one to two years.

Pipeline fittings require increased attention when choosing, since the level of comfort, and often the safety of users, depends on how correctly the part is selected or skillfully installed on the pipe.

Work on installing shut-off valves on a gas pipeline DN300mm: video.

Share your impressions - have you had to install, repair or change water pipeline control parts? What problems did you encounter? Write in the comments. Save the article to bookmarks and share it on social networks.

All parts of the body kit on the pipes, no matter whether they are plastic or metal-plastic, must be made of brass, preferably Italian or Turkish. They don’t rot, you can tighten the nut on the fitting without the fear that it will burst. Don’t take it from TsAM, it lasts for a couple of months, then a crack appears on the body and the water supply system floods the apartment with water.

Don't rush to buy the first thing that comes to hand. When the first polypropylene pipes first appeared, I immediately changed the water supply. Moreover, I also installed a plastic valve at the input. And then the rotating rod of the taps was sealed with a rubber ring without a nut. It’s clear that after a couple of years the rubber dried out and began to wear out. You can't change the faucet, it's soldered in. I had to completely change the axle box. On modern fittings, the stem comes with a clamping nut.