Do-it-yourself greenhouse heating system: the best ways to heat greenhouses in winter

To maintain a certain temperature regime in the greenhouse, different heating systems are used.The choice of heat supply method depends on the size of the building, the climatic conditions of the region, the availability of a particular type of fuel, financial capabilities and other factors.

Some home craftsmen undertake to organize the heating of the greenhouse with their own hands - such a solution will significantly reduce labor costs, don’t you agree? Of course, independently arranging stable heating is not an easy task, but it is quite achievable. The first step is to choose a heat source.

We will tell you what greenhouse heating options exist, what are their specific features, advantages and disadvantages of use. Based on the information presented, you will be able to decide on the type of heating, perform a preliminary calculation of thermal power, and select working units and elements of the system.

The content of the article:

Specifics of maintaining temperature in greenhouses

Heating a greenhouse is necessary to compensate for heat loss that occurs through the walls and ceiling of the structure, as well as due to the entry of outside air. To reduce heating costs, it is first necessary to properly insulate the greenhouse and minimize air exchange with the street.

In addition to the material from which the greenhouse is made, special attention should be paid to the tight fit of the structure to the soil. To do this, it is better to make a shallow foundation insulated from the inside when constructing a greenhouse.

It must reliably hold the structure in strong winds, prevent the formation of cracks and minimize heat exchange with the street through the top layer of soil.

To solve the last problem, even in the conditions of the northern regions, a depth of 30 centimeters is sufficient, since the thermal conductivity of the soil is very low. The intensity of vertical heat exchange between the soil layer inside the greenhouse and the underlying soil layer is very small.

In winter, snow can be used as a natural external insulation along the edges of the greenhouse.

For normal plant growth, it is necessary to maintain the temperature of the air and soil-vegetative layer in a certain range. If the greenhouse operates continuously, the fertile soil will be heated due to heat exchange with the internal air. Moreover, its temperature will be almost the same as under natural conditions in summer.

The soil and ground layers freeze in winter to a depth depending on the geographic latitude of the region and the structure of the rock. To warm the soil and the adjacent top layer before planting, it is necessary to either maintain a positive air temperature for a very long time (up to a month).

An alternative solution is to carry out special actions to transfer heat directly into the soil. This can be done using a system of underground pipes into which coolant is supplied.

The amount of energy spent on heating the greenhouse depends on the following factors:

- Surface area of greenhouse walls and roof. The lower this indicator, the less heat loss. Therefore, to save energy, it is better to use a rectangular or semicircular shape of the structure.

- Thermal conductivity coefficient of the material. The lower this parameter, the better the material retains heat.

- Temperature difference between indoor and outdoor air. The higher its value, the greater the heat loss.

- Air exchange through leaks. To reduce energy costs, it is necessary to eliminate the uncontrolled flow of cold air.

The wide variety of private greenhouse designs and the quality of their installation seriously complicate temperature regime modeling. Therefore, it is possible to accurately determine the amount of energy required to heat a particular object only experimentally.

Autonomous heating based on fuel combustion

Using the combustion process as a heat source is the most commonly used method for heating small greenhouses. Such heating has some specifics, since it is necessary to take into account the increased tightness of the room, the desirability of heating the soil and the need to maintain humidity.

Stoves and solid fuel boilers

One of the simplest devices used to heat greenhouses during cold periods is a stove. The popularity of using such a device is due to the low cost of fuel. It can be uncalibrated firewood, dry grass, coal and coal dust, garbage and flammable liquids.

When heating with stoves, it is necessary to ensure stable draft, since ventilating the greenhouse if combustion products get inside will lead to its cooling.

When using a metal stove, heating occurs quickly and energy is transferred to the surrounding air. It is also the cheapest and easiest to use heating method. You can build such a unit yourself.

On our website there is a selection of articles on the manufacture of different types of metal stoves that can be used to heat a greenhouse:

- How to make a Buleryan oven with your own hands: step-by-step instructions for making

- Do-it-yourself potbelly stove from a gas cylinder: diagrams, drawings + step-by-step guide

- Stove using waste oil from a pipe: how to make an effective stove using waste oil from scrap materials

A stone stove heats up more slowly and retains heat longer. This is more suitable for heating small spaces with a medium or narrow temperature range. However, such a stove must be folded and, if necessary, cannot be moved, like its metal counterpart.

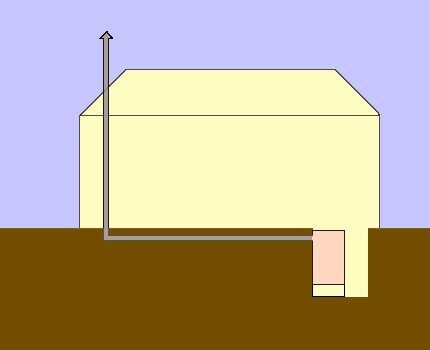

There is an idea of heating space in a greenhouse using hot combustion products. To do this, it is proposed to place the stove in a pit, and lay the chimney horizontally below ground level with its subsequent exit to the surface.

This option will really increase the heating efficiency.

However, during practical implementation the following difficulties will arise:

- Requirements for chimney assembly material. The air temperature leaving the furnace is very high. Therefore, the chimney should not have good heat transfer, otherwise the soil around it will burn out.Asbestos pipes can be used as a material for removing combustion products.

- Compliance with the rules for placement of chimneys. It will be necessary to provide inspection windows in the chimney to clean it from soot. Therefore, you need to lay the pipe between the beds.

- The need for power supply. A long horizontal section does not contribute to the creation of normal draft, so it will be necessary to install a smoke exhauster. This means the need to supply electricity to the greenhouse or periodically recharge the battery.

Therefore, the idea of underground chimney placement has not found wide application in practice.

Instead of a standard stove, you can use solid fuel long burning boilers. They burn fuel more efficiently and do not allow rapid heat release, which eliminates the possibility of damage to plants from high temperatures. Such factory-made boilers are easy to use and maintain, and are also compact.

Gas boilers and convectors

For greenhouses, a good alternative to stove heating is the use of gas liquefied gas boiler or convector. For small private buildings, equipment operating on the basis of gas cylinders is usually used.

It is better to place the gas cylinder outside the greenhouse. But in this case, it is necessary to solve the issue of preventing freezing of the gearbox during a long period with negative temperatures.

Connecting a greenhouse to the gas network is a rather complicated bureaucratic procedure. In addition, during the annual mandatory inspection by a gas service specialist, comments will be made.

In any case, the presence of a combination of gas supply and the use of open fire in a confined space requires increased safety measures. The best solution is to have a gas analyzer, as well as an automatic flame extinguishing system that is triggered when the maximum permissible concentration of a flammable substance in the air is exceeded.

From the standpoint of comparing the financial costs of installing and using stoves and gas equipment, it is impossible to draw an unambiguous conclusion. A simple gas convector costs about 12-14 thousand rubles.

This is more expensive than metal devices running on solid fuel:

- the cost of metal and consumables for self-manufacturing a potbelly stove is about 3 thousand rubles;

- A small-sized factory solid fuel installation, for example, the NVU-50 Tulinka model, costs about 6.6 thousand rubles.

- a long-burning installation model NV-100 “Klondike” costs about 9 thousand rubles.

A stone stove will be more expensive than a gas convector due to the cost of building the foundation and laying it.

The cost of liquefied or natural gas spent on heating any room will be cheaper than purchased firewood and coal. However, greenhouses are heated, as a rule, with free or cheap combustible waste, which is always sufficient in rural and dacha areas.

The problem of air leaks and humidity

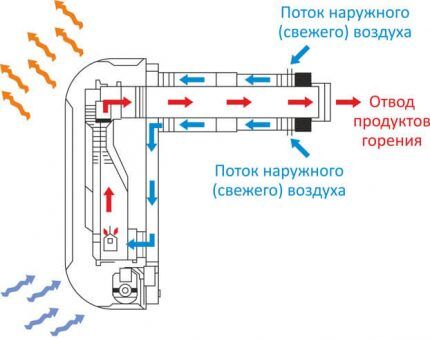

The use of heating devices in which open combustion of fuel occurs leads to the need to remove combustion products through the chimney. In this case, compensation for the volume of exhaust air is necessary.

In buildings, it is possible through uncontrolled inflow (infiltration) which occurs due to the presence of cracks and holes in the walls and ceiling.

The design of modern greenhouses, such as polycarbonate, creates an airtight space. In this case, the problem of air intake is solved by the presence of vents and the installation of a special supply opening.

It should be placed in such a way as to avoid a concentrated flow of cold air onto the plants. It is also possible to use several small holes to organize a distributed inflow.

Exhaust systems for closed-type gas convectors are already equipped with a pipe for the flow of outside air into the combustion chamber.

Often after operation of furnaces and boilers, the effect of air drying is observed. This is due to the lower absolute humidity of the incoming cold flow (especially frosty) in relation to the warm air leaving the greenhouse through the chimney.

To maintain accurate air humidity parameters, a humidifier with a hygrometer is used, which can be powered by a local energy source. If there is no such need, you can place an open container of water in the greenhouse. Then, in the event of strong drying of the air, the process of evaporation will naturally occur.

Ways to distribute heat evenly

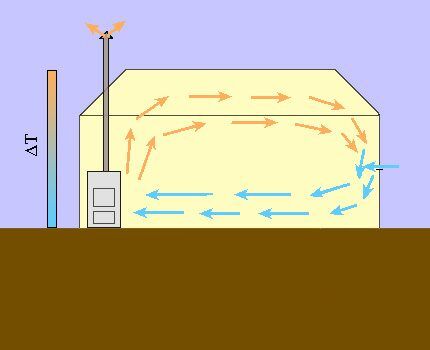

For small greenhouses, placing one heating source is sufficient. Air circulation in the room will be ensured due to the vertical temperature difference and, thus, warm air will be distributed.

In rooms of large area or complex geometry, it is possible to form zones with different microclimate parameters. This is sometimes done on purpose in industrial greenhouses, but in most cases this phenomenon is undesirable.

To distribute heat evenly, two methods are used:

- Creation of artificial air circulation. Blade fans are usually used. Sometimes an air duct system with integrated pumps is constructed so that air is taken in at one end of the room and exhausted at the other.

- Heat transfer due to intermediate coolant. As a rule, an ordinary water system with forced circulation is used. Pipes can be laid both around the perimeter of the greenhouse and under the soil layer.

Forced heat distribution is also necessary to prevent the formation of a high temperature zone near the heater. Otherwise, plants located near the stove or boiler may suffer thermal damage.

Popular heating methods without open fire

The use of open fire has some limitations, since combustion waste is released, and fire safety measures must be observed. Therefore, other methods are often used to release heat into the greenhouse room.

Application of electrical appliances

Using electricity to heat a greenhouse in winter is the most expensive method. However, it is also the simplest, since the installation of such heating only includes electrical wiring and installation of devices.

The use of simple automation systems frees people from the need to participate in constant microclimate monitoring.

Electric heating of a greenhouse can be done using the following devices:

- Heater. The simplest and cheapest device that you can make yourself.

- Convector. The presence of a fan allows, in addition to heating the air, to distribute it evenly throughout the greenhouse.

- Heat pump. A powerful device for heating air in large-volume greenhouses, which is often used in conjunction with an air duct system to distribute heat. To heat a compact room you can make a heat pump on one's own.

- Infrared lamps. The specificity of the operation of such devices is to heat the surface on which the radiation hits. Thus, it is possible to level out the vertical temperature gradient in the room without using air circulation.

- Heating cable. It is used to heat local areas in a greenhouse.

In the case of small premises, the use of electric heating is justified due to its simplicity and safety. In large and industrial greenhouses it is advisable to use other methods.

Biochemical heat release

One of the interesting methods of heating is to add unrotted organic fertilizer to the soil - animal manure or bird droppings.As a result of the biochemical reaction, a large amount of energy is released, which increases the temperature of the fertile layer and the air inside the room.

When manure rots, carbon dioxide, methane, as well as small amounts of hydrogen and hydrogen sulfide are released. Manure also has a specific odor. All this imposes certain restrictions on its use related to the need to ventilate the room.

In winter, as well as during prolonged cold spells in spring and autumn, intensive air exchange is undesirable. In this case, restoring the thermal balance after ventilation may require a significantly larger amount of energy than was released as a result of the process of rotting manure.

The use of such a “biological” method of heating the earth and air is justified in late spring, when ventilation occurs at positive daytime temperatures.

Systems with external heat source

Heating of the greenhouse is possible due to the close location of the house or other heated building. This simplifies the entire procedure, since there is no need to install an autonomous heat source. Using wired or wi-fi relays, you can remotely receive information about the temperature in the greenhouse and regulate its microclimate from home.

Creating a separate heating circuit

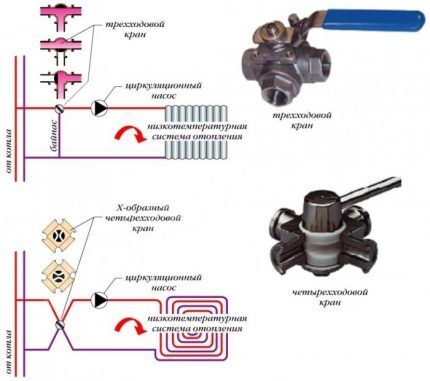

If the house uses water or steam heating, then it is possible to create a separate circuit leading to the greenhouse.It must be equipped with a separate pump, since the total horizontal length of the new segment will be large.

You also need to install an open expansion tank in the greenhouse to remove air from the system. The area of open water in the tank must be minimized to prevent intense evaporation of hot water into the room.

Radiators are rarely installed in a greenhouse, since the design of its premises plays a secondary role. If there is a lack of heat, it is better to lengthen the pipe contour, as this is cheaper and reduces the risk of leaks and breakdowns.

The outdoor segment of the circuit must be insulated to avoid heat loss and minimize the risk of freezing. The underground option for placing pipes is best suited for these purposes.

Connecting the heating segment of the greenhouse to the general circuit can be done using a three- or four-way valve.

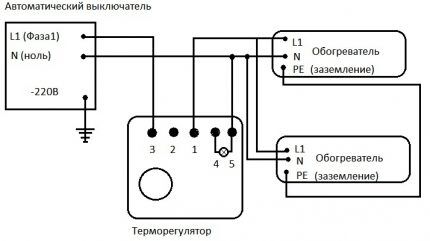

It is also possible to create an automatic temperature control system.

This can be done in the following ways:

- Changing the volume of hot water passed through depending on the readings of temperature sensors. In this case, it is necessary to purchase a pump with power control.

- Turning the greenhouse heating circuit on and off. For this purpose, automatic crane control systems are used.

Instead of manually changing the position of a three- or four-way valve, servo-based devices can be used. Its electronic control unit is adjusted to the readings located in the greenhouse temperature sensors.

If it is necessary to change the heating mode, a control signal is sent to the motor, which turns the rod, setting a different position of the valve.

Heating using extract air

Good heating can be obtained by using warm air from the exhaust ventilation of a residential building. By directing an insulated ventilation duct into the greenhouse, you can obtain a constant incoming flow with a temperature of 20-25°C.

The only condition is the absence of excess humidity and impurities in the air, which are typical for kitchens and bathrooms.

Air outflow from the greenhouse can be organized in two ways:

- Local exhaust vent to the street in the form of a tube without a fan. It must be of small cross-section to create a high flow rate. In this case, at negative street temperatures, the condensation formation zone will be located at some distance from the tube, which will prevent the formation of ice.

- Return the flow back using an additional air duct and obligatory connection to the general house hood. Otherwise, odors from the greenhouse will spread throughout all areas of the house.

This method is the most economical in terms of one-time costs for installing the system and recurring costs for fuel use. The only question remains whether the hood volume is sufficient to maintain the required temperature. It is better to check this experimentally.

If sometimes, during extreme cold snaps, the air temperature in the greenhouse drops below the permissible level, then you can build a small air heater into the air duct, or install an additional electrical device at the facility itself.

Conclusions and useful video on the topic

Homemade stove with a long chimney for heating a greenhouse:

Several options for wood stoves in a real greenhouse:

Gas burners as a heat source. Piping throughout the greenhouse:

There is no universal option for heating a greenhouse. The choice in favor of one of the methods or their combination must be made taking into account its reliability, low cost of installation and use of equipment, energy prices and battery life.

Most projects can be implemented in-house, which will reduce their cost and provide the opportunity for further independent modernization.

Do you have personal experience in designing and installing heating in a greenhouse? Do you want to share your accumulated knowledge or ask questions on the topic? Please leave comments and participate in discussions - the feedback form is located below.

Last year I heated the inside of the greenhouse using an electric heater, but it took a lot of electricity. I decided to build a stone stove: I’ll spend it once, but it will be of high quality and for a long time. I’m not going to change the location of the greenhouse yet, the materials for the stove are available, I’ll start construction, I’ll use the information from your article, everything is accessible and detailed.

Imported vegetables are inexpensive, even despite the sanctions. In addition to heating, in winter you need a lot of light to extend daylight hours.It only makes sense to install heating if you are interested in it. It is almost impossible to make money from this. Of all the proposals, only the option with stove heating can be implemented without high costs. I heat the greenhouse myself only in the spring with an old potbelly stove. It is portable and lightweight. And it’s not difficult to attach a pipe to it and bring it out through the window. Some of the smoke, however, still remains, but this is even beneficial for the plants.

Heating a greenhouse is also beneficial. You just need to know what to grow. With strawberries, for example, you can gain profit in just one season.