How to make a heat pump with your own hands from an old refrigerator: drawings, instructions and assembly tips

In recent decades, home owners have had a fairly large selection of heating systems.It is no longer necessary to connect to centralized networks and use traditional sources. You can choose equipment that runs on alternative energy, but its main disadvantage is its high cost. Do you agree?

However, if you build a heat pump with your own hands from an old refrigerator, the system can be significantly cheaper. And we will tell you how to do it.

In the article, we selected the simplest solutions and provided them with detailed drawings and diagrams. Therefore, it will not be difficult for a home craftsman to understand them. In addition, here you will find step-by-step instructions for making heating equipment. And the videos posted will tell you about the design features of the heat pump and the features of its connection.

The content of the article:

How profitable is using a heat pump?

Theoretically, any person has a large choice of energy sources. In addition to natural gas, electricity, coal, it is also wind, sun, temperature difference between land and air, land and water.

In practice, the choice is limited, because it all depends on the cost of the equipment and its maintenance, as well as the stability of operation and the payback period of the installations.

Each energy source has both advantages and serious disadvantages that limit its use.

Installing a heating system with a heat pump is beneficial from the point of view of ease of use. During operation of the equipment there is no noise, no foreign odors, no installation of chimneys or other auxiliary structures is required.

The system is energy dependent, but the heat pump requires a minimal amount of electricity to operate.

Thermal installations themselves are extremely economical and require little maintenance, but their initial cost is very high.

Not every home or cottage owner can afford to purchase such expensive equipment. If you assemble it yourself and use parts from an old refrigerator, you can save a lot.

Homemade installations cost literally pennies, and their use allows you to save significantly.

The only caveat: the productivity of homemade products is low, and they cannot be a full replacement for traditional heating systems. Therefore, they are often used as additional or alternative heating options.

5 main benefits for plant owners

The advantages of heating systems with heat pumps include the following:

- Economic efficiency. By spending 1 kW of electrical energy, you can get 3-4 kW of heat. These are average indicators, because... The heat conversion coefficient depends on the type of equipment and design features.

- Environmental Safety. When the thermal unit operates, combustion products or other potentially hazardous substances do not enter the environment. The equipment is ozone safe. Its use allows you to obtain heat without the slightest harm to the environment.

- Versatility of use. When installing heating systems powered by traditional energy sources, the home owner becomes dependent on monopolists. Solar panels and wind generators not always profitable.But heat pumps can be installed anywhere. The main thing is to choose the right type of system.

- Multifunctionality. In the cold season, the installations heat the house, and in the summer heat they can operate in air conditioning mode. The equipment is used in hot water supply systems and is connected to underfloor heating circuits.

- Operational safety. Heat pumps do not require fuel, their operation does not emit toxic substances, and the maximum temperature of equipment components does not exceed 90 degrees. These heating systems are no more dangerous than refrigerators.

There are no ideal devices. Heat pumps are reliable, durable and safe, but their cost directly depends on their power.

High-quality equipment for complete heating and hot water supply to a house of 80 sq. m. will cost approximately 8000-10000 euros. Homemade products are low-power, they can be used for heating individual rooms or utility rooms.

Heat pumps can last 30 years or more. Their use is especially cost-effective for hot water supply, as well as in combined heating systems that include heated floors.

The equipment is reliable and rarely breaks down. If it is homemade, then it is important to choose a high-quality compressor, preferably from a refrigerator or air conditioner of a trusted brand.

Types of heat pumps for home heating

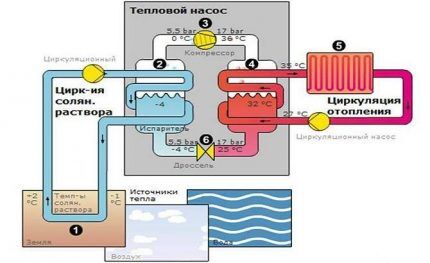

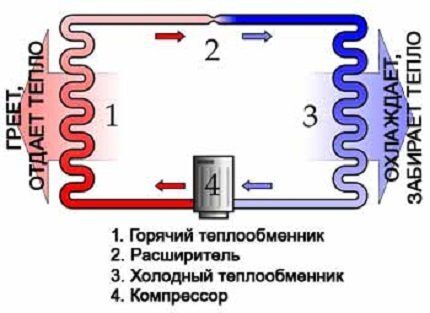

There are compression and absorption heat pumps. Installations of the first type are the most common, and this is the type of heat pump that can be assembled from a refrigerator or an old air conditioner using a ready-made compressor.

You will also need an expander, evaporator, and condenser. For the operation of absorption units, an absorbent refrigerant is required.

Depending on the type of heat source, installations can be air, geothermal, as well as using secondary heat (for example, waste water, etc.).

One or two different coolants are used in the input and output circuits, and depending on this, the following types of equipment are distinguished:

- air-to-air;

- water-water;

- water-air;

- air-water;

- soil-water;

- ice-water.

A system can only be efficient if it consumes less energy than it produces. This difference is called the conversion factor. It depends on many factors, but the most significant is the temperature of the coolant in the input and output circuits. The greater the difference, the better the system works.

There are no reliable formulas for calculating the performance of heat pumps, because... their work depends on many factors.

When you assemble a heating system yourself, you cannot expect it to be as efficient as industrially produced equipment, but it is quite enough to create an economical additional heating system.

Step-by-step instructions for making equipment

Before you figure out how to make a heat pump from a refrigerator, you should decide on the heat source and how the device operates. In addition to the refrigerator compressor, other components will be required. You will also have to purchase or rent some tools.

Even if you have to buy a compressor and other components, a homemade installation will cost much less than ready-made industrial equipment.

Stage #1.Preparation of diagrams and drawings

The energy source must be located underground. To install a heat pump, you will have to drill a well or at least dig a trench to a depth where the ground temperature does not drop below 5 degrees. You can also use reservoirs of natural or artificial origin.

Regardless of the heat source, heat pump designs are similar, so almost any design that can be found on the Internet will do.

After selecting it, you should prepare detailed drawings, which will indicate the exact dimensions, distances and connection points of the installation units.

Although calculating the power of the installation is difficult, you can focus on averages. So, for a house with increased thermal efficiency, a heating system with a capacity of 25 W/m2 is needed. This is an ideal option if heat loss is minimal.

For a well-insulated house this figure is 45 W/sq.m., and for a building with relatively large heat losses - 70 W/sq.m.

Stage #2. Selection of necessary parts

The compressor can be removed from the old refrigerator. If it is defective, it is better to buy a new one. You should not repair it: it is unprofitable, and the performance of the homemade product will be in question.

To assemble the structure, you will also need a thermostatic valve. It is desirable that all components come from the same system and are easily combined.

To install the heat pump, you will need 30 cm L-shaped brackets.

You will also have to purchase some parts:

- high-quality sealed stainless steel container with a volume of 120 l;

- large plastic tank with a volume of 90 l;

- 3 copper pipes of various diameters;

- polymer (preferably metal-plastic) pipes.

To assemble the system, you will need a standard set of tools, and to cut and join metal parts, you will need a grinder and a welding machine.

Stage #3. Installation of system components

The compressor is installed on the wall using brackets, after which they begin to manufacture the condenser. To do this, cut the metal tank in half with a grinder. A copper coil is installed in one part, after which the container is welded and threaded holes are prepared in it.

To make a heat exchanger, a long copper pipe is wound onto a 120-liter steel tank, securing the ends of the turns with slats. Plumbing transitions are connected to the terminals.

A coil is also attached to a plastic tank and used as an evaporator. It does not overheat, so there is no need to use a metal container. The finished evaporator is attached to the wall using brackets.

When the main components are prepared, a suitable thermostatic valve is selected, the structure is assembled and R-22 or R-422 freon is pumped into the system. If you don’t have the appropriate skills, it makes sense to invite a specialist, because... the procedure is unsafe.

Stage #4. Connection to the intake device

The type of intake device and the features of connecting the heat pump to it depend on the circuit:

- "Water-earth". The collector is installed below the soil freezing level. The system pipes must be located at the same depth.

- "Water-air". Systems of this type are relatively easy to install, because no excavation required. A convenient place near the house or on the roof is suitable for installing the collector.

- "Water-water". The collector structure is assembled from polymer pipes and then lowered into the center of the reservoir.

It is possible to install a combined (bivalent) heating system. In this case, the heat pump is connected in parallel with an electric boiler. It performs the function of additional heating.

Installing a bivalent heating system allows you to achieve the optimal temperature in the house even in severe frosts, and its energy consumption will be minimal.

Conclusions and useful video on the topic

In our country, heat pumps are not yet particularly common, but you can already find craftsmen who can share their experience in making their own similar systems. We offer a selection of useful videos.

Heat pump design, system assembly features:

Features of connection and operation of a homemade heat pump:

Video review of the operation of a homemade heating system from an air conditioner:

Heating schemes with heat pumps are not always cost-effective or convenient, so be sure to weigh the pros and cons of this type of heating.

If you come to the conclusion that such a system is suitable for your home, do not rush to spend huge sums on a ready-made installation and assemble the structure yourself. This is not so difficult, requires much less investment, and the effect can exceed all expectations.

Are you planning to assemble a heat pump yourself, but don’t know where to start? Or maybe you have already assembled a similar design and have the necessary knowledge that you can share with our readers? Please leave comments and ask questions in the block below.

Such pumps are ideal for private houses where there is no connection to central heating, and the idea itself is a good one, it will save a lot of money. But in general, to make such a pump, you need the necessary knowledge and direct hands, as well as many tools. And it’s even better to do everything with a person who understands the heating system. Undoubtedly, this is much more economical than other heat sources and will pay for itself quickly.

Egor, rather, first of all, we need a specialist in refrigeration units.

But indeed, a heat pump from an old refrigerator can be a good addition to gas heating, reducing gas consumption. A private home cannot live without such a convenient invention! It is urgent to familiarize my husband with the principle of the device; it seems to me that this idea might be of interest to any homeowner with golden hands.We just have a suitable refrigerator for experiments.

Does anyone know what the power of the refrigerator compressor is? And how long will it work continuously? Miracles don’t happen; without spending energy you won’t get anything. This design, even theoretically, can heat no more than 10 square meters, but practically 2-3. Is it worth building a garden of heat exchangers for such power? Although they also built an e-mobile, and they want to make a car with a Stirling engine, but AvtoVAZ still produces Wenkel, with a consumption of 20 l/100 km.

It’s not for nothing that a heat pump costs so much; it’s not a refrigerator, or even an air conditioner. On the basis of an air conditioner, something else can be built that will work at a positive temperature of what the heat is taken from, with an efficiency of not 3, at best 1.5, but definitely not a refrigerator, and especially not an old one - they were new in themselves not very effective, and they don’t get better with age.

The entire structure will produce effective heat a maximum of 1.5 times more than the electricity consumed, and this is until the compressor burns out or the freon evaporates. It is also worth recalling the dangers of freon - if anyone doesn’t know, it is deadly in some conditions.

There are analogues to Freon, for example, we use propylene glycol from Ukraine, which has a freezing threshold of more than 25 degrees!

Horizontal heat collection - below the freezing depth - will freeze the entire area to an abnormal depth. That is, such a system should be placed away from the house and other buildings. Well, say goodbye to the garden and vegetable garden - this block of ice will not allow trees and grass to grow even in summer.

What about combining a refrigerator with a heating system? on one side there is an ammonia freezer, on the other there is a steam room.