How to make a damper for a chimney with your own hands: instructions for making a damper

The movement of air flows in smoke exhaust channels is subject to the laws of physics, however, with the help of some devices, the draft force can be adjusted.One of such devices is a gate valve - a mandatory attribute of a home or sauna stove.

Let's find out what types of valves there are and whether it is possible to build a damper for a chimney with your own hands if you don't have a factory analogue at hand. The chimney element has a very simple design, but its manufacture requires at least minimal metal processing skills.

The content of the article:

What is a gate valve

The German word Schieber in Russian has not changed either its pronunciation or meaning. If we talk specifically about stove heating, then a damper, as well as a damper, is a shut-off device that blocks the chimney channel.

At arrangement of a chimney duct the valve is installed in the upper part of the base, which is located in the room, so that, if necessary, it is possible to manually regulate the movement of gases, and at the same time the quality of traction.

A damper on the chimney duct is required for traditional brick kiln version. By retracting it partially or completely, you can reduce the draft or block the movement of heated gases.

The damper is fully retracted when the stove is heated and gases harmful to health stop flowing into the channel.There are known cases of deaths of people who were burned by a stove that was “closed” early.

If you are late in closing the damper, the heat from the heated bricks will go into the pipe, and the temperature in the room will quickly drop. A timely retracted damper is a guarantee that the house will be warm for at least a day. As you know, in village houses during the cold season the stove has to be lit every morning.

There is an opinion that dampers, which are mandatory for brick stoves, are absolutely not needed for steel stoves (although they are offered by manufacturers), as well as for models with installed deflector.

The argument against their use is the fact that the chimney quickly becomes clogged with soot when the damper is closed. Its upper part is cooled by cold air entering the pipe, which, when in contact with a hot steel pipe, forms a large amount of condensate. This situation requires more frequent chimney cleaning.

Differences between retractable and rotary gates

So far we have been talking about the retractable type of damper on a stove chimney, although there is another type - a rotary one. Let's look at how they differ.

The purpose of both types is the same - to partially or completely block the flow of flue/heated gases. The differences relate to the design.

A retractable model is a metal plate that is fixed in a frame and moves along guides in a horizontal position. There are no strict requirements for the dimensions of the device, since they must correspond to the cross-section of the chimney and depend entirely on its parameters.

Thus, the valve consists of two main parts:

- frames, which is fixed in the smoke exhaust duct and is motionless;

- platesmoving inside the frame.

Typically, both parts are made from the same material to maintain performance when heated or cooled.

The design of the rotary (throttle) gate does not extend, but rotates along an axis, as the name suggests.

A round or rectangular plate (depending on the cross-section of the chimney) is fixed on a metal rod, the free end of which extends beyond the channel and serves as an adjustment tool.

Gate valves are considered more reliable and wear-resistant devices. The weak point of the rotary devices is the connection between the rod and the plate, which becomes loose over time and renders the valve unusable.

Which material is stronger

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used.It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

When choosing a material, you need to focus on characteristics of the chimney pipe and interior features.

For country heating stove A modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.

How to make a gate valve with your own hands

Let's look at how to make both types of chimney valves - retractable and rotary. Each of them has its own manufacturing and installation nuances. Let's start with the retractable view.

Preparation of materials and tools

To create the simplest model of a retractable gate, galvanized steel is suitable.It is lightweight, thanks to its smooth surface it is easy to clean from soot, and if necessary, the moving part can be easily replaced.

The main tools are a welding machine, electrodes, a grinder, metal scissors (choose depending on the thickness of the sheet), a drill with a grinding disc, metal drills, and a file.

It is better to carry out work on a workbench with a vice. Among other things, you will need a sheet of paper for a template, a tape measure, and a marker.

Drawing up a diagram (drawing)

Removing dimensions must be taken seriously, since even a few millimeters can cause the chimney to malfunction. To find out the dimensions of the frame, you should use a tape measure to measure the cross-section of the smoke exhaust duct - it will coincide with the dimensions of the inside of the frame.

To this value you should add 20-30 mm on three sides and calculate the outer side of the frame.

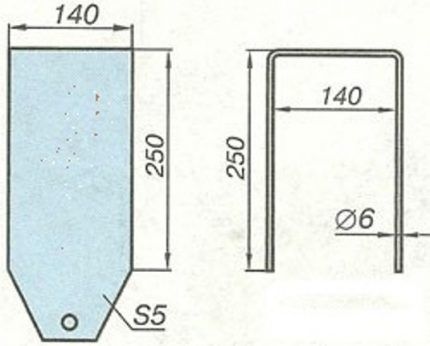

In order for the latch to slide out easily, without effort, its width should be slightly narrower than the width of the frame (taking into account the outer sides). To simplify the calculations, it is necessary to draw a design diagram and indicate all possible dimensions, so that in the future, when working with metal, you can navigate by them.

For metal pipes, a flat damper design is usually combined with a chimney fragment located perpendicularly.

For brick chimneys, a flat frame made of wire or profile with a moving valve along guides on two parallel sides is sufficient.

Marking and cutting out parts

Having determined the exact dimensions, we cut out the frame for the gate. If the chimney is small, for example, in a bathhouse or in a summer kitchen, you can use thick wire, bending it in the shape of the letter P.

A more comprehensive frame is a durable corner profile. To make it, we cut out a strip from sheet steel and bend it lengthwise at an angle of 90º. To give the profile the desired shape, in the places where the corners are marked, we cut one of the planes. When folded, we get a frame. We weld the bends.

Next, we cut out the damper itself. It should be approximately 5-10 mm narrower than the width of the frame. We adjust the length so that when closed, only a small fragment of the valve peeks out. It can be decorated in different ways: in the form of an ear with a hole or simply a folded edge.

We clean the edges of the cut gate with a disc so that the closing/opening process is easy and silent. Parts cannot be painted.

Gate valve installation steps

The photo shows the stages of installing a factory-made gate. A homemade device is mounted using the same principle.

The installation height of the damper largely depends on the design of the stove; in sauna stoves it is lower, in home heating stoves it is higher. The minimum height is 0.9-1 m from the floor, the maximum is about 2 m.

Instructions for making a rotary gate

Let's consider the option of manufacturing a gate valve for a metal pipe. This modification can be installed both in a new chimney and in an already finished and functioning stove.

It is a round plane with a welded metal rod - a kind of rotating mechanism and holder in one.

Manufacturing material – stainless steel sheet with a thickness of 2-2.5 mm; metal rod 6-7 mm (hollow tube); a pair of 8 mm bolts, a piece of metal reinforcement or a nail.

To cut and weld parts you will need:

- grinder with a set of discs - abrasive and cutting;

- marking tool - marker, construction tape, compass;

- welding tools – welding machine, electrodes for steel, core;

- vice, pliers, wire cutters, hammer.

Also, during welding work, you will need protective clothing - gloves, goggles, overalls made of thick dense fabric.

Progress:

All that remains is to make a clamp for the handle from a steel sheet. The finished gate must be cleaned of soot from time to time, and the strength of the welding points must be monitored.

Conclusions and useful video on the topic

With the help of videos, you will expand your horizons, learn more about stove valves and how to install them in a chimney.

How to make a damper in 5 hours:

Scheme for installing a damper on a brick kiln:

Option for installing a fireplace damper:

It is advisable to make your own gate valve if you have skills in working with metal, know how to use welding, a grinder and a drill - then the production process will bring benefits and positive emotions.

If knowledge and skills are not enough, it is better to purchase a ready-made valve, having first taken the dimensions from the chimney.

If you have anything to add or have questions on the topic, you can leave comments on the publication. The contact form is located in the lower block. If you made a chimney damper yourself and want to share ideas with readers, please add a photo of the product.

I remember my aunt had a damper like this in her house back in Soviet times: a gas stove with nozzles, made of brick, and under the ceiling was this same damper. And so she used it in a rather unique way: when she turned on the stove, she always opened the damper (and always responsibly - she thought that if she didn’t open it, the stove would explode). And she always closed it when she turned it off, so as not to “cool the stove.” I never even tried to regulate the draft with these same gates. The draft was regulated by a tap on the gas nozzle.

You only need refractory brick in the firebox, the stove brick will collapse!

Hello. Nothing will be destroyed there. Refractory bricks generally appeared only in 1822 (if I am not mistaken with the accuracy of the date). And in England. Many people in our villages didn’t even know about it until the 2000s. Heel brick stoves can still be found in old buildings, and they are still functioning.

We got a bathhouse from the previous owner of the site.Everything is well done inside, but the stove itself with the pipe is made according to a simplified version, and there is no damper on the pipe. I understand that without it it is impossible to regulate the combustion process in the stove and maintain heat in the steam room. But how to integrate this device into a finished metal pipe, which has a rather large wall thickness?

In fact, there are several options for making an adjustable damper in a metal pipe of any thickness.

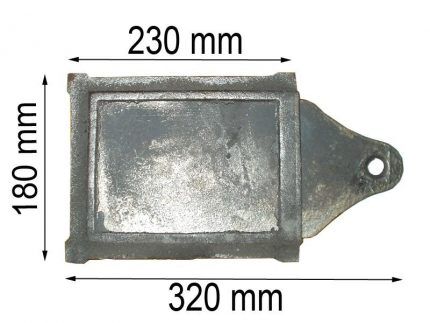

Option No. 1 - weld a special adapter. I’m attaching a photo, it’s immediately clear, it’s easier than describing what’s what. If this solution is not suitable, then you can consider another.

Option number 2 - make a gate valve. I have also attached a photo, here the work involved is much less, the regulating mechanism is different. To implement this option, it is not necessary to dismantle the pipe and then put it back in place and cook it. You can embed the valve into the pipe right away.

Everything is fine, but without welding there was not a single piece of advice for a sauna stove - it seems that in our country welding machines are found more often than microwaves and all welding masters... In short - for those who do not have welding and a non-brick stove, the article is absolutely useless...

Hello. It’s not clear what “not a brick oven” has to do with it. You can invite a welder to do this type of work, but in general, you can just rent the machine and weld it yourself, there’s nothing complicated about it.

The article deals not only with a damper that is suitable for metal chimneys, but there are also examples for brick chimneys.Naturally, the damper for stoves with a stone chimney is installed at the construction stage, otherwise it would be impractical to do so! It is clear that not every person has a welding machine, but you can always borrow this equipment from friends or invite one of your friends to help. If there are none, then hire a specialist; I don’t see any problems in this.

Well, no one is stopping you from buying a ready-made gate valve if you don’t want to make it yourself. As the author of the article noted, “It is advisable to make your own gate valve if YOU HAVE SKILLS in working with metal, know how to use welding, a grinder and a drill - then the production process will bring benefits and positive emotions.” In another case, it is advisable to purchase a FINISHED product. If you do not have the necessary tools, this does not mean that the article is bad and it gives impractical advice.

Hello. According to many, it is categorically impossible to install a damper on modern gas boilers. Your opinion, taking into account Snips. Thank you