Types of gas burners for heating furnaces: device options and methods of installation in the furnace

Converting a brick or metal stove to gas processing is a difficult process that requires a serious analysis of all components.It is imperative to find out which types of gas burners are ideal for furnaces and which ones should not be installed. After all, the result must meet exactly your requirements.

It would seem that the choice of model can be entrusted to gas workers; they can also be entrusted with reworking the burner block and installing the burner itself. But where is the guarantee that the equipment that you will be offered to install will have the necessary operating parameters and desired functionality?

In this article we will tell you how to independently understand the types of gas burners, the basic rules for their installation and operation, so that you can consciously choose which device to install in your heating stove.

The content of the article:

Pros and cons of using a burner for heating

A gas burner is a device that, by mixing air with natural or liquefied gas and supplying the mixture to the outlet, forms a torch and distributes the flame. It ensures efficient combustion of fuel and regulation of the combustion process.

Advantages of using gas burners for heating stoves:

- Ease of use. Gas burners greatly simplify the process of heating furnaces, eliminating the need to prepare solid fuel and constantly maintain combustion.

- Controllability of the heating process. Simple models, without automation, need to be turned off independently as soon as the temperature reaches the required level, leaving only the wick lit. Burners with a control panel make life much easier by more accurately setting the temperature.

- Security. Automatic nozzles have overheating protection functions and turn off the gas supply in case of poor draft or lack of flame.

- Minimal contamination of the chimney duct. A scheduled inspection of the chimney is carried out once a year, mainly for prevention - little soot is formed from the combustion of gases.

The transition from solid fuel equipment to heating with gas burners greatly simplifies life, freeing up a lot of time for more interesting and useful activities.

The main disadvantage of converting a stove by installing a gas block is that the energy efficiency is not very high. High fuel consumption is especially noticeable if gas heating system in a country house is designed by an amateur.

In addition, it is not always possible to obtain permission to install a gas burner - if the stove is outdated, the chimney is of incorrect design, or the room parameters do not meet fire safety standards.

Selecting a gas burner: types and characteristics

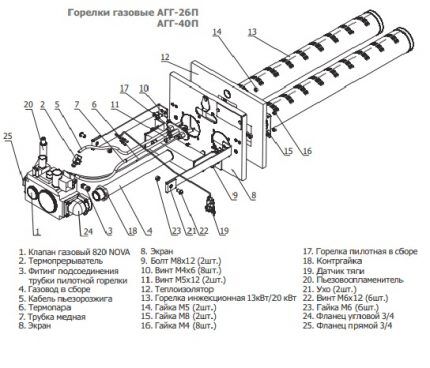

The main elements of a gas burner are a mixer and a burner nozzle with a device that stabilizes the flame. Depending on the purpose, the models differ in design.

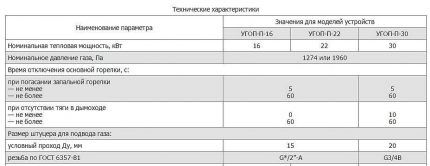

When choosing a gas burner for installation in a furnace, pay attention to the following characteristics:

- coefficient of performance (efficiency);

- heating device power;

- energy efficiency;

- flame length;

- safety;

- optionality.

The operating parameters of the gas burner must take into account the chemical composition of the fuel, the purpose and characteristics of the room, the conditions of use - home or bathhouse, industrial oven or homemade wood-burning, for constant or periodic heating, etc. The technical data sheet for the burner indicates the scope of application of the device.

Types of stove gas burners for home or bathhouse

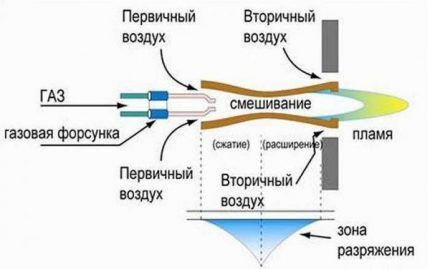

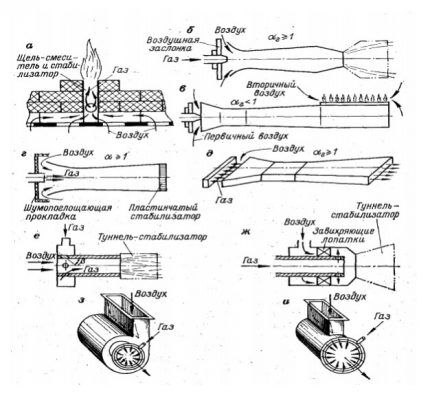

The design and operating principle of gas burners for household heating stoves should be studied more carefully, separately considering the two main types of equipment - atmospheric and forced-air options. They are distinguished by the method and speed of mixing gas with air.

Atmospheric gas burners

The design of the atmospheric burner is simple and consists of one or more hollow tubes into which gas is supplied under pressure. The gas, mixing with air coming directly from the room, forms a fuel-air mixture and is ignited using piezo ignition or electric lighters.

For normal operation of an atmospheric gas burner, it is necessary to ensure good draft and an effective ventilation system. The main disadvantage of the device is that any change in air movement leads to changes in the proportion of the gas-air mixture, and therefore to an uneven combustion process.

If there is a lack of oxygen, the burner does not completely burn the gas, which leads to the release of a significant part of the unused fuel into the atmosphere through chimney channelservicing the heating unit.

Pressurized gas burners

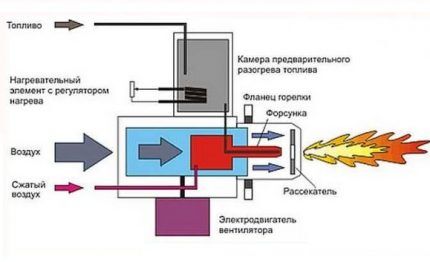

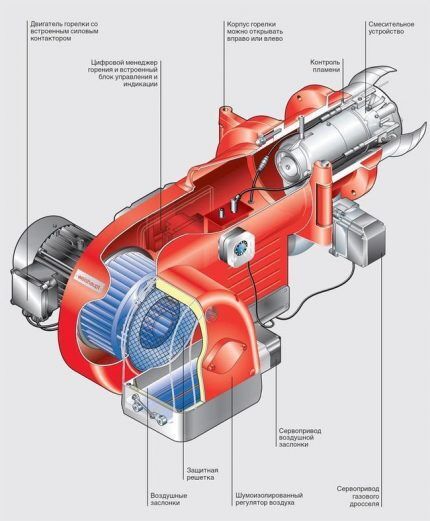

Pressurized gas burners, or, as they are also called, blower, fan, air blower, are devices where gas is mixed with air using a fan, the gas-air mixture enters a closed chamber and burns there.

The operation of the nozzles of a gas burner installed in a closed combustion chamber depends little on the state of the atmosphere in the room. The air supply intensity is adjusted by changing the fan rotation speed.

High-quality air supply and mixing with gas ensures more complete combustion of fuel.Pressurized burners are on average two times more efficient than atmospheric type equipment - their efficiency is 95-98%. The equipment operates stably even at low gas pressure and does not require the installation of a bulky chimney.

Instead of a standard chimney system, it works in tandem with a blower burner coaxial chimney, which can be taken outside through the wall located next to the stove.

The main disadvantage of the device is its dependence on the energy source, high noise level, and higher price than atmospheric burners. But short-flame models of fan gas burners can be installed in wood-burning stoves. The main condition for use, in this case, is that the flame should not rest against the walls of the firebox.

In fact, there are many more ways to supply air and gas to burners. There is no need to study everything for installation in a home oven, since only a few of them are used in the production of small household appliances.

Having decided on the type of gas burner, you can continue to study the features of individual models and their functionality.

Differences in the way power is controlled

The ability to adjust the thermal power of the burner plays an important role when organizing the process of heating a room. This is especially true for those houses where permanent residence is planned.

From a controllability point of view, gas stove burners can be divided into two categories:

- Single stage. Gas is supplied to the injector without the ability to influence power. If the device is automated, then when a certain temperature level is reached, the burner will turn off and then turn on again when the room becomes cooler.

- Two-stage. Two combustion modes, normal and economical, are automatically adjusted and allow you to maintain a more or less stable temperature in the room. Fewer turns on and off reduces wear on parts and extends the service life of the device.

Two-stage devices are divided into floating or modulated models. The power can vary from 10 to 100% or more, and accurately set a comfortable temperature in the house. The gas burner device can be automatic, mechanical or pneumatic.

The ability to regulate thermal power allows you not only to set the optimal temperature regime, but also to save energy. For example, fuel savings when using a modulated gas burner reaches 15-20%.

Additional design options

In order not to use lighters or wicks to ignite the stove, the design of the gas burner provides two methods of ignition:

- electric ignition - requires connection to the electrical network;

- piezo ignition - used in simpler burner models and does not require power.

Installing special sensors that monitor oxygen levels makes it possible to detect flame extinction and turn off the fuel supply. This function protects against gas leaks and emergency situations.

Some equipment models require working not only with natural and liquefied gas, but also with diesel fuel. When choosing such models, pay attention to how easy and quickly this transition is made.

Safety rules when using burners

Failure to comply with precautions when installing and using gas burners for heating premises can lead to emergency situations and accidents: fire in the house, carbon monoxide poisoning.

When operating gas equipment, you should adhere to the following rules:

- Observe the service life. The burner's service life, depending on the model, can range from 8 to 15 years. Then it must be replaced.

- Use models with a function that automatically turns off the device in the absence of draft or flame.

- A stove equipped with gas burner units must meet safety requirements.

The design, installation or repair of a gas burner must be carried out by certified gas service workers with whom contract signed for the supply of fuel and maintenance of units.

To obtain permission to install and connect to the main gas network, a number of conditions must be met:

- compliance with the rules for connecting a gas burner;

- appropriate design of the smoke channel, its high-quality insulation;

- installing a spark arrester at the top of the chimney.

This is the minimum requirement for installing forced-air gas burners.

For atmospheric there are additional requirements:

- presence of adjustable traction;

- ensuring good ventilation;

- volume of the room in which the gas burner is installed, from 12 m3.

In case of transfer of equipment to use of liquefied gas It is necessary to ensure safe storage of the gas cylinder. This can be a separate room or a metal cabinet. If you plan to store gas reserves in a gas tank, then the tank is installed underground at a distance of no closer than 5 m from the building.

Installation of a gas burner in a heating furnace

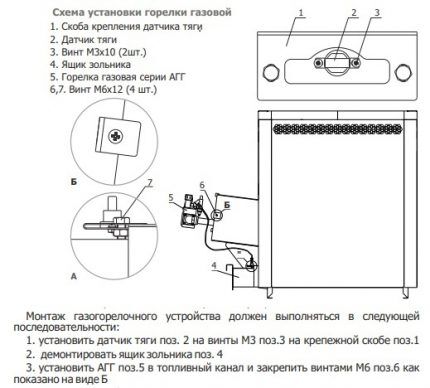

We remind you that it is prohibited to install gas equipment yourself. However, it won’t hurt to familiarize yourself with the nuances of installing a gas burner in a stove.

So, installation of a gas burner is permissible in furnaces in which the length, shape, nature and temperature of the flame can be adapted to the nature of the material of the combustion chamber. The flame should not touch the walls, but should be freely located in the combustion space. If it is a brick wall, then the firebox should be made of refractory bricks.

Before installation, check the walls of the stove for cracks, voids, and unsealed seams through which combustion products can enter the room. The room into which the firebox door opens must have an opening window, a ventilation duct and a gap in the door for air to enter from below.

Gas burners of any type are characterized by the creation of high temperatures - more than 1000 °C in the combustion chamber. When installing a gas burner in the oven, you must ensure that the flame does not touch the walls.

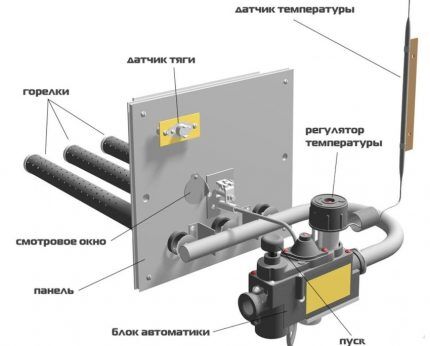

The installation process itself is not complicated and is carried out in the following sequence:

- Remove the firebox door.

- A burner is placed in the combustion chamber.

- The shield is secured in the door frame.

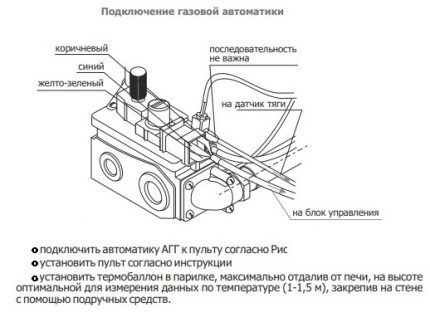

- Connect the automation according to the manufacturer's instructions.

At the end of installation, connect the burner to a hose, the other end of which is connected to a gas source.

The system is started by a master from the gas service, he checks the operation of the injectors and the system automatic adjustment and safety, configures and tests the response of sensors.

Another step is to check the tightness of all connections and the presence of traction. After successful startup of the system, the gas installer must issue a completed control certificate for the installation of the burner.

When starting the heating, you should first select the minimum thermal power, heating the stove continuously and little by little or, if there is no power adjustment, cyclically, turning the burner on and off. This is especially important for a brick kiln - strong continuous heating of a cooled brick can lead to cracking.

General rules for installing a chimney for a stove

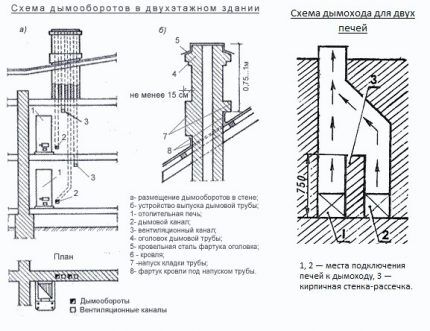

Another condition for the normal operation of a gas stove is the installation of a chimney. For gas-fired stoves, smoke channels must be vertical, without ledges. The design of the chimney of a wood-burning stove is often not suitable for the removal of gas combustion products.

You can refurbish an old chimney by lining it. Upgrade options:

- Installation of a stainless steel pipe in the chimney duct. In this case, the diameter and height of the pipe should be selected according to the characteristics of the chimney duct. The gap between the walls of the chimney and the pipe is filled with non-flammable heat-insulating material such as expanded clay or foam glass.

- Application of FuranFlex technology. The method involves placing an elastic polymer tube inside the channel, which, under pressure, takes its shape and hardens. The protective layer serves to insulate, seal and internally protect the chimney.

If none of the chimney modification options work, you will have to install a new one. Depending on the location of the stove, two options for installing a chimney are possible: an external attached one or an internal one.

The influence of the characteristics of the chimney on the safety of heating is such that it will necessarily be checked by the Fire Inspection authorities with the subsequent issuance of a written certificate, without which the equipment will not be connected to gas networks.

Conclusions and useful video on the topic

Installing an automatic gas burner in a furnace:

General information about the operation of gas burners:

When studying the variety of models and functions of gas burners for furnaces, you need to pay special attention to safety.

Any actions related to design and installation must be coordinated with the gas supply organization, and the installation must be entrusted to an experienced technician. Before purchasing a gas burner, it is also better to consult with gas specialists.

Please share your own experience in converting solid fuel units to gas consumption. It is possible that your recommendations will be very useful to site visitors. Please leave comments in the block form below, post photos related to the topic of the article, and ask questions.