Types of gas cylinders: full classification + analysis of markings

Gas cylinders are widely in demand both in industry and in medicine, the aviation, space industries, and in everyday life, as an autonomous source of energy.They can be used for heating, lighting and cooking.

To eliminate any troubles associated with operation, you need to choose the right type of equipment. Let's together try to understand the types of gas cylinders, the features of their design and connection.

The content of the article:

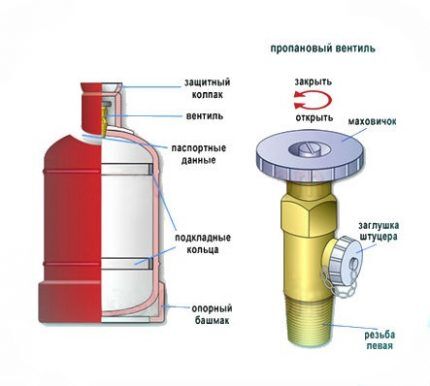

Gas cylinder device

For both storage and transportation of compressed and liquefied gas, gas cylinders have been created - special vessels in which these substances are under high pressure. The first type of gas remains in a gaseous state under any pressure, and the second, with an increase in this parameter, passes into the liquid phase.

Nitrogen, fluorine, oxygen, methane, hydrogen, as well as chlorine, carbon dioxide, and ammonia are transported and stored in a compressed and liquefied state.

The container itself is an all-welded structure with walls at least 2 mm thick and cylindrical geometry. It is made of steel or polymer.

Its components:

- shell;

- neck;

- bottom.

The neck of the cylinder has a conical thread for shut-off valve, hermetically closing the outlet. If, for some reason, the gas expands, the valve will break under the influence of pressure, and the pressure inside the vessel will return to normal.

The gas inside such a vessel is under a pressure of a maximum of 15 MPa.The cylinder body or shell has a single welded seam.

In order for the gas inside the vessel to exert equal pressure on its walls, each cylinder has a convex bottom - upper and lower. For greater stability, the cylinder is equipped with a ring support - a shoe. In addition, the gas tank is equipped with a metal or plastic cap that protects the valve during operation and transportation.

The cap is screwed onto the neck ring. Sometimes the balloon is supplied gearboxdesigned to balance pressure. The valve is a unit that includes a steel body in the form of a tee, a flywheel, and a shut-off element.

The assembly consisting of a bypass valve and a rod is called a shut-off element. Each of the assembly parts performs its own function.

The valve is necessary to regulate the gas supply through the body, and the rod is necessary to interact the flywheel with the valve through torque. By turning the flywheel, you can close or open the gas flow.

Types of gas cylinders

Gas vessels are classified according to many criteria: body material, volume, purpose, name of the filler, connection method.Both metal and composite materials are used to make the case. Both have their pros and cons. You should familiarize yourself with them to make the right choice.

Classification by body material

Alloy or low-carbon steel is used to make the body of a metal cylinder. The capacity of metal vessels is from 5 to 50 liters. Cylinders with a capacity of less than 50 liters are allowed to be installed inside the house, and 50 liters - only outside.

The latter need protection from direct rays of the sun. To do this, they are placed in a locked metal cabinet with markings applied to it corresponding to the type of gas. An empty metal cylinder weighs from 4 to 22 kg.

The vessel is filled with gas to a maximum of 85%. Depending on the volume, from 2 to 22 kg of gas are filled into the cylinder. This gas equipment is explosive and fire hazardous. Temperatures above 50⁰ are contraindicated for him. In case of sudden changes in temperature and in the event of a fire, a powerful explosion occurs. Such a cylinder cannot be turned over sharply, because... this causes an increase in pressure.

The composite gas cylinder is a newer option. Its main advantage is complete explosion safety, even if a gas leak occurs. Liquefied gases are transported and stored in such containers. When exposed to an open flame, the gas escapes through the housing gradually and simply burns.

They are lightweight - 70% lighter than their metal counterparts, and have a stylish design. Thanks to the transparent body, you can always monitor the gas level. Unlike metal, composite material is not subject to corrosion, therefore, it is more durable.

The polymer has excellent dielectric properties, 100% eliminating sparking.The operating temperature range is within -40 - 50⁰. Cylinders are recommended to be used for up to 30 years. They must be recertified every 10 years. The weight of the cylinder is 8 kg maximum.

Composite gas cylinders come in two types: those made using blowing technology and those made by winding fiberglass onto a mandrel. In the first case, the flask is made of polyethylene terephthalate. Next, manufacturers coat the vessel, made from fiberglass strands, with epoxy resin. The container is placed in a polymer casing.

In the production of cylinders of the second type, a special mandrel is used. Fiberglass is wound onto it, then the workpiece is impregnated with resins. First, two halves of the vessel are obtained. After curing, they are glued together and placed in a dense polyethylene casing.

Due to the presence of overpressure valve and fusible rate, composite cylinders have increased safety. In the event of a fire, the fuse link is activated. Melting, it gradually releases gas, with complete control over the process. Once the insert has been activated, the cylinder cannot be used for further use.

Separation according to installation location and purpose

All existing gas cylinders, depending on where they are installed and what they are intended for, are divided into the following types:

- Household. They are used for heating, stoves, boilers.

- Automotive. They are used on cars whose engines run on gaseous fuel.

- Tourist. Suitable for mobile devices such as blowtorches, burners, kebabs, heaters.

- Industrial. This category includes containers in which gases are stored. Such cylinders are used in metallurgy, the chemical industry, and pharmaceutical plants.

- Medical. They are filled with breathing mixtures and carried in ambulances, used in hospital wards for intensive care and where oxygen cocktails are prepared. Such cylinders are also used by rescuers and firefighters.

There are also universal cylinders that are used in many industries. For mobile gas appliances, disposable cartridges are produced that hold 100 - 450 g of gas. Visually they resemble aerosol sprays.

Features of classification by filler

Based on the composition of the mixture, cylinders are called propane, butane, hydrogen, nitrogen, acetylene, carbon dioxide, argon, oxygen, helium, etc. Each composition has its own temperature regime.

For standard conditions, the difference between them is small. When a cylinder is needed for use in high mountain areas or in very low temperature conditions, this parameter plays a decisive role.

Butane isomer is a mixture of isobutane and propane, well suited for low temperatures. It is safe for the ozone layer. Both propane and butane are very dangerous for humans. If they are inhaled, serious consequences for the body are inevitable. Direct contact with liquid butane causes the body to cool down to -20⁰.

Butane is used to charge lighters and is sometimes used as a refrigerant in air conditioners and refrigeration units. Propane is necessary in the production of solvents. Metal work involving welding and cutting requires acetylene.It is also used in the production of explosives, acetic acid, rubber, all kinds of plastics, and for rocket engines.

Nitrogen is used by the electronics industry, chemical, oil and gas, pharmaceuticals, and metallurgy. Hydrogen is needed by the food and chemical industries. It is also used as fuel for rockets and for welding.

Bicycle wheels and fire extinguishers are pumped with carbon monoxide or carbon dioxide. In the food industry, carbonated drinks are produced using it. In the form of dry ice, carbon monoxide is used as a refrigerant.

In the metallurgical and metalworking industries, in processes where interaction of the molten flow with oxygen is unacceptable, argon is used. It is also used in medicine for anesthesia, and it is used to purify the air. Helium cylinders are necessary not only for filling balloons, but also for cutting, welding, and melting metal.

This gas is part of the breathing mixtures used in diving; it can be a coolant in scientific experiments. Ammonia is a strong solvent. Since it is very poisonous, cylinders with it must be transported and stored very carefully. The same applies to containers with chlorine.

Oxygen containers can be found near welding machines, where explosives and acids are produced, and where oxygen cocktails are prepared. Compressed air, transported in cylinders, is most often used in the operation of pneumatic devices.

Liquefied natural gas methane is used as a sleeping pill in medicine, for the production of fertilizers, and in the form of fuel.This gas is safe for humans.

Types of cylinders by connection method

Different models of gas cylinders are connected to devices using four connection standards. The most popular is threaded standard that meets all safety requirements. The products have a 7/16″ thread. A hose or burner is attached to such cylinders by screwing it on.

The following cylinder standard is collet. This type of connection is also called push or clamp. A cylinder with this type of connection is considered the cheapest. Here, the role of a clamp when connecting is performed by a cylindrical part. The collet cylinder can be connected to threaded equipment, but this will require an adapter.

The pierced type of cylinders is the most common all over the world. These disposable cylinders have the disadvantage that the container cannot be removed until all the gas has been used. The latest models of pierced cylinders with the SGS system do not have this drawback.

Here it is possible to block gas leakage when disconnecting from the burner and turn off a container that is not completely emptied. They are used for soldering lamps, lighting lamps, and portable stoves.

Valve connection is the type that is used mainly in Europe. The connection is simple and reliable with a high degree of leakage protection.

Explanation of cylinder markings

By reading the label correctly, you can get complete information about the gas cylinder. If it is a propane cylinder, then its passport is in the valve area, on a metal mug.

The passport of the propane cylinder indicates: operating pressure in MPa, test pressure in the same units, actual volume of the container in l, serial number, date of manufacture in the form “MM.YY.AA”, where the first characters indicate the month, the second - the year , third - the year of the upcoming certification.

This is followed by the weight of the empty cylinder in kg, and the mass of the filled cylinder. The last line is the letter designation “R-AA”. “R” is the mark of the recertification site or plant. The combination of characters “AA” reveals information about the year until which this certification will be valid.

The oxygen cylinder marking has its own order and consists of four lines. The first contains information about the manufacturer, as well as the container number. The second contains the release date and recommended testing date. In the third - hydraulic and working pressure. In the fourth - the volume of gas and the mass of the cylinder without valve and cap.

When buying a cylinder, you should pay attention to how the information is printed on it. It is not applied to the body with paint, but is knocked out and then coated with a special colorless varnish to protect it from corrosion. Often the last line contains the manufacturer's mark.

Features of painting gas cylinders

Compressed gas cylinders are painted differently in Russia and abroad. Moreover, each type of gas corresponds not only to a specific color of the body, but also to the color of the stripe and inscription.

The table shows the identification colors of cylinders with certain types of gases, as well as the color of the inscriptions and stripes.

| Gas | Color of the cylinder | Inscription | Band |

| Ammonia | Yellow | Black | Brown |

| Nitrogen | Black | Yellow | Brown |

| Argon is technical and pure | Black, gray respectively | Blue; green | Blue; green |

| Acetylene | White | Red | Green |

| Butylene | Red | Yellow | Black |

| Butane | Red | White | Black |

| Hydrogen | Dark green | Red | Black |

| Compressed air | Black | White | Black |

| Helium | Brown | White | Black |

| Oxygen | Blue | Black | Black |

| Hydrogen sulfide | White | Red | Red |

| Carbon dioxide | Black | Yellow | Yellow |

Nitrous oxide is pumped into a gray cylinder with a black lettering and the same stripe. A protective-colored phosgene cylinder has a yellow inscription and a yellow stripe, and a cylinder of the same color, but with a black inscription and a green stripe, contains chlorine. The aluminum color of the cylinder, the black inscription on it and two yellow stripes indicate that it is filled with freon-22.

For sulfur dioxide, a black cylinder with a white stripe and a yellow inscription is intended. Ethylene is contained in a purple container with red lettering and a green stripe. For other flammable gases, red vessels with a white inscription and a green stripe are intended. Non-flammable gases are indicated by a yellow inscription on a black background of the housing and a green stripe.

Types of cylinder malfunctions and their elimination

All existing malfunctions in gas cylinders are divided into two types: those that can be eliminated and those that cannot be eliminated.

The first type includes:

- incorrect operation of the cylinder valve and pressure gauge;

- shoe damage or displacement;

- damage to the threaded connection;

- gas leak;

- The body paint is peeling off in many places.

The second type of malfunction is a significantly damaged surface of the case in the form of dents, cracks, swelling, and lack of markings. In this case, the cylinder is rejected.The decision on the possibility or impossibility of repair is made by a specialist with appropriate qualifications.

When repairing gas cylinders, defective elements are often simply replaced. Sometimes it is necessary to flush the inside of the container and check for corrosion from the inside. Periodic inspection includes all this work, and upon completion a certificate is issued.

This should not be done at home. All you can do yourself is paint the body of the cylinder. This must be done extremely carefully so as not to paint over the inscriptions or damage the markings. All other faults can only be repaired by a specialized workshop or manufacturer.

Popular gas cylinder manufacturers

Among the many manufacturers of cylinders, the Russian brand should be highlighted "Sledopyt". They offer two types of gas cylinders with threaded and collet connections - for all-season mixture and winter. American company Jetboil supplies the market with cartridges filled with propane and isobutane that can be used in winter.

French company Campingaz produces all kinds of devices equipped with gas cylinders. Their connection type is collet, valve or pierced. Primus — produces several types of gas cartridges. All connections are threaded.

Good quality composite vessels are supplied by a Czech brand Research. The package includes special valves that protect the container from overfilling. All these cylinders are explosion-proof.

Conclusions and useful video on the topic

Video about the correct use and inspection of gas cylinders. Advice from a specialist:

About composite liquefied gas cylinders:

A gas cylinder is a useful thing in the household. To ensure that its operation does not lead to undesirable consequences, you need to thoroughly study the issue. And most importantly, adhere to basic safety rules.

After reading the material, do you have any questions? You can set them in the block below. There you can also share your experience of using gas cylinders and tell us what equipment you use.

I remember how, back at the university, during occupational safety classes, an entire lecture was devoted to this topic. I liked your section about malfunctions in cylinders and their elimination, it’s a pity that it wasn’t much. And let me add from myself: such an important aspect as safety precautions when operating gas cylinders is completely missing. Well, it wouldn’t hurt to add a little more to fill the tank.

Hello, thank you. We will inform the administrator of your wishes and hopefully a separate article on this topic will appear on the site soon.

Before we connected to the main gas pipeline, we used cylinders at the dacha. Usually the gas lasted for a long time. But cylinders have this peculiarity - the gas always runs out at the wrong time, when there is no transport or other opportunity to go and buy. We bought metal cylinders of 50 liters. Usually, two cylinders were used for the season of active use of the dacha from April to October.

Nothing about w21.8 and G5/8 connections

In what color of the cylinder can SF6 gas be filled?

Hello. This is a black steel cylinder with a working pressure of 150 MPa, with a yellow enamel inscription “ELEGAS”.

Hello! Please tell me, is it possible to fill an argon cylinder with oxygen or carbon dioxide?

Are there any regulations (GOSTs, regulations, Federal Laws, etc., etc.) that define a household gas cylinder? Tourist? A 180 ml tourist cylinder still differs from a 5-50 liter cylinder, but they are not allowed to carry it on the subway. And it says that the transportation of “household gas cylinders” is prohibited; with this approach, the transportation of deodorants can also be prohibited