Why does a gas boiler often turn on and off: causes of malfunctions and ways to eliminate them

As cold weather approaches, people become dependent on heating systems. After all, heat, or rather, its absence, significantly affects the comfort of living and even the state of health. And when, instead of enjoying the comfort, you have to deal with why the gas boiler often turns off and on, this causes a lot of negativity. Isn't that right?

But it is possible to solve the problem that has arisen quickly and without significant financial costs. And in some situations, the user himself will be able to restore the equipment to working capacity.

The content of the article:

What to do when a malfunction occurs?

Gas consumers should understand that they do not have the right, but the obligation, to repair their home or apartment equipment. Moreover, in a timely manner and with high quality.

And since frequent shutdown of the boiler is potentially a malfunction, this legal requirement cannot be ignored. Because for this, according to Art. 9.23 Code of Administrative Offenses faces a fine.

The size is 1-2 thousand rubles.And, if suddenly the situation, through the fault of the user, becomes dangerous to the life and health of people or an accident occurs, then you will have to part with 10-30 thousand rubles (Article 9.23 of the Administrative Code).

It is easier and more reliable to contact the gas company with which the contract has been signed. And all the risks will fall on their shoulders. As well as responsibility for the timeliness and quality of repairs. And for violations the company will be held liable in accordance with Art. 9.23 Code of Administrative Offences. Where is it said that penalties can reach an impressive 200 thousand rubles

You should also remember that you should not take responsibility for yourself by trying to eliminate the cause of switching on/off yourself. Especially against the backdrop of the fact that problems with equipment inoperability must be solved by specialists from companies with which the gas consumer agreement signed. And for ignoring such a rule, additional sanctions in the amount of 1-2 thousand rubles are threatened - this is also stated in Art. 9.23 Code of Administrative Offences.

Any repeated violation of the above norms will be the reason for punishment in the form of a fine, the amount of which will be 2-5 thousand. The basis for this is the corresponding norm in the above article of the Code of Administrative Offenses.

Reasons for frequent boiler switching on/off

If a gas boiler is unstable, there must be a reason for this. And repairs must always begin with its identification. To do this you need to call a specialist.

But in some cases, you will be able to identify the cause yourself, since there is nothing fantastic in identifying a malfunction. Most of them have external manifestations, which means that it is possible to identify the problem visually. That is, all you need to do is inspect the gas boiler and the equipment working with it.

You should understand that there are quite a few types of gas boiler breakdowns, but they are all divided into just a few categories. Which greatly simplifies the task.

Types of failure include:

- clocking;

- failures, breakdowns of automation;

- low gas pressure;

- incorrect operation of ventilation and smoke removal systems;

- unstable operation of the electrical network.

And then we will go into detail about how the listed reasons are identified and eliminated.

Reason #1 - clocking

Frequent switching on of a gas boiler is a classic sign of its excessive power, the reserve of which is much higher than necessary. And the more overkill, the more often startup/shutdown cycles occur.

Reasons that lead to clocking:

- incorrect settings of the boiler electronics;

- improper installation and operation of radiators. For example, malfunctions are caused by narrowing of channels, their clogging, kinks, distortions, which lead to a decrease in efficiency. The negative consequences of shortcomings can only be mitigated by eliminating them;

- error when determining the power of a gas boiler upon purchase.

If a frequent on/off sequence is detected. The first thing to do is to make adjustments to the boiler operating mode. You can do this yourself in a matter of minutes, since all you need to do is go to the service menu of the unit and reduce its power.

This is possible because modern boilers have a minimum and maximum specified value, as well as an operating range.

But it should be understood that the described adjustment of the power of gas heating equipment is mostly fine tuning. Therefore, it can change the specified characteristic by only a few percent (usually within 3-8%). And such figures indicate that when exceeding boiler power values a higher value will make the setting useless.

The cause of this problem is the wrong choice of equipment. This happens when unprepared buyers pay attention to anything, including the power of a gas boiler, which is considered the main indicator, but forget to compare it with the total thermal power of the radiators.

And when there is a significant difference between the two indicated indicators, significant problems begin.

Which can be solved:

- Boiler replacement.

- Increasing the thermal power of radiators. For example, by increasing their number.

An important feature of clocking due to a significant difference in power indicators occurs only immediately after purchasing and starting a gas unit or replacing radiators.

If such procedures have not been carried out, then you should look for another cause of the malfunction.

Reason No. 2 - automation breakdowns

In this case, human factor or wear and tear of individual elements leads to problems. Often these problems arise due to poor quality commissioning work. For example, this is exactly what happens when the installation of a circulation pump into the system. As a result, the circulation of the coolant becomes unstable, as a result of which the liquid in the heat exchanger will overheat.

This will become a signal for the automation to turn off the boiler, which can be repeated with varying frequencies. At the same time, most of the coolant remains insufficiently warm.

In this case, you most likely cannot do without a master. But initially, if normal ignition occurs followed by a quick shutdown, but the water in the system is not warm enough, then you can try to start the pump yourself, since it may not work correctly not only due to breakdown, but also if air locks occur, and simply due to jamming.

To do this, arm yourself with a screwdriver and unscrew the special screw on the unit body. As a result, the system will de-air itself. If this does not help, then use the same screwdriver to carefully turn the blades. If the outcome is positive, the pump’s functionality will be restored.

If the above procedures do not help, then you should definitely call a specialist.

Often the reason for the unnaturally frequent switching on of a gas boiler is a breakdown or absence of an external temperature sensor. As a result, the boiler automation is guided by a similar coolant indicator, which can make the operation of the entire system less stable and more costly.

U turbocharged boilers Fan problems often occur. Which is associated with wear and tear of rubbing structural elements, their breakdowns, and clogging of air channels. As a result, there is a lack of oxygen for gas combustion, which leads to flame extinction. After this, the automation turns off the boiler, but since it remains conditionally serviceable, starts will be repeated, as well as shutdowns.

Reason #3 - low gas pressure

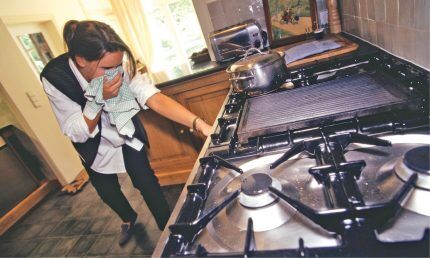

Perhaps this is the most dangerous reason for the unstable operation of a gas boiler. Its essence is that low gas pressure not only provokes frequent boiler shutdowns, but is often accompanied by a leak of this fuel, which can cause an explosion or fire.

You can verify that the cause of low pressure is a leak by a specific and unpleasant odor.

In this case, the operation of all gas equipment should be suspended until the problem is resolved, which should be done by a specialist.

You can identify the location of the leak yourself by using soap suds. The soap solution should be applied to the joints. Where the seal is broken, the soap solution will form bubbles.

In some cases, a decrease in gas pressure can occur without leakage. A similar thing happens when the meter breaks down or the filter gets clogged.

A reason such as a breakdown of the meter is usually easily identified, since hissing and extraneous sounds are emitted from its body, and the readings change jerkily.

However, carry out meter replacement you don't need to do it yourself. This can lead to unpleasant consequences, which may include a fine for unauthorized connection to gas pipelines (Art. 7.19 Code of Administrative Offenses). As a result, you will have to pay a fine, the amount of which can reach about 30 thousand rubles.

Reason No. 4 - incorrect ventilation operation

In this situation, problems with the operating mode of the gas boiler occur due to reasons such as chemical or mechanical underburning.

So, in the first case, not enough air is supplied to the boiler burner. It is not enough to burn gas. The situation is aggravated by the fact that a significant amount of soot is formed as a result of ineffective gas oxidation. Which covers all internal surfaces of the boiler.

In advanced cases, this leads to burner nozzles and pipe channels becoming clogged, resulting in attenuation.

In many cases, routine cleaning of surfaces from combustion products will help restore the boiler to working capacity. It is better to do this before the start of each heating season, or even several times throughout it.

At the same time, too much traction leads to mechanical underburning. The main sign of which is that the gas simply does not have time to burn. This causes the flame to die out and the locking system to activate.

Reducing the area of the chimney will allow combustion to return to stability, which is done using a device such as gate. It is a damper installed in the outlet channel of the smoke removal system.

If the specified device is not provided or is faulty, then such a deficiency should be eliminated. And this is when using modern sandwich chimneys It's not difficult to do.

In difficult cases, it will be necessary to change the design of ventilation and smoke removal systems.

Difficult climatic conditions often lead to problems with gas combustion, and, consequently, with stability.

Which can be:

- strong wind;

- negative temperatures;

- precipitation.

So, in a strong wind, the draft can significantly deteriorate, which will lead to underburning and possible shutdown of the gas boiler.

At subzero temperatures, ice freezes on internal surfaces smoke removal systems, which leads to instability of traction or its complete absence. In this case, the negative consequences can be eliminated by removing ice.

What can be done:

- mechanically, that is, simply chipping off the resulting ice;

- heating the chimney duct. For example, using a disposable gas cylinder.

To reduce the consequences of ice freezing, you should not use a head (umbrella).

Precipitation leads to a decrease in traction, as well as a decrease in its stability. Negative consequences in each of the listed cases eliminate themselves after the situation normalizes. But, you should remember that you can reduce the likelihood of their occurrence by changing the design of the smoke removal system. This is expensive, but will increase the safety of using gas equipment.

Often, attenuation occurs due to reverse thrust. The cause of which is improper ventilation of the room where the boiler is installed.

Namely:

- lack of special channels for air exchange at the bottom of the doors, throughout the entire building;

- tightness of the premises, which occurs thanks to the use of modern windows and doors.

And also the occurrence of reverse draft indicates excess draft in the smoke removal system.

All of the above leads to the fact that the resulting air flow simply extinguishes the flame, after which the automation turns off the boiler. After subsequent switching on, the situation may repeat due to the subsequent formation of reverse draft.

In this case, negative consequences can be eliminated by creating proper ventilation in the building, as well as by installing a deflector on the chimney.

Reason No. 5 - instability of the electrical network

Often the reason for the boiler turning off/on is a voltage drop in the electric current in the system. Since when the set critical values are reached, the electronics will shut down the unit.

And when the voltage returns to normal, the automation will independently generate a command signal to resume heating. This is convenient, but can create additional problems.

The reason is that in many cases, users may not even realize that there is a breakdown for a long time. Or ignore it, since from the outside everything usually looks not as problematic as it really is.

After all, if there is an unstable voltage, the electronics may fail at any time. The repair is expensive, and in some cases it will not be possible to carry it out promptly due to the fact that you will have to wait for the delivery of the spare part.

In addition, all other electrical equipment located in the room is at risk of breakdown. And the most important thing is that such a malfunction as voltage surges is a direct threat to the life and health of users.

Therefore, the performance of the gas boiler must be monitored regularly. And if a problem is identified, immediately begin to fix it, and not talk about how often the gas boiler in use should be turned off. In this case, repairs must be carried out by a specialist.

It will help to avoid breakdown of the gas boiler due to voltage instability Voltage regulator.

It must be of adequate power and reliable. That is, you should not purchase a device that costs a penny, especially from an unknown manufacturer.

Conclusion and useful video on the topic

The video explains what clocking is, how such a negative phenomenon occurs, and also outlines ways to combat it:

The following video describes the situation with boiler attenuation in strong winds:

Frequent repetition of off/on cycles of any modern gas boiler directly indicates its unstable operation.And therefore, there is a malfunction or incorrect setting, which causes accelerated wear of the equipment. Therefore, having identified a problem, you should immediately begin to eliminate it.

Have you ever encountered interruptions in the operation of your gas boiler? What exactly was the problem you faced and how did you manage to overcome your situation? Please share your experience with our readers in the comments section.

During operation, the boiler turns on frequently→

When the nozzle is operating, the heating boiler often turns on and off until it reaches the set temperature. And then it just turns off altogether. There is no such thing that it will catch fire and burn until it reaches the temperature of the water in the system. It twitches constantly until the temperature rises. What could be the reason for this behavior?

The reason for the extinguishing of the column flame is insufficient draft with a small gap under the door, insufficient for a full flow of air. Trim the door from the bottom or install (cut) transfer air duct grilles at the bottom of the door.

Frequent switching on/off of the gas boiler.

We changed the board and the same thing happened.

There is traction indoors. The sensors were all cleaned, the boiler was cleaned.

This switching on/off can happen at any time and continue for some time, then the boiler works normally again. The times of normal and abnormal operation are different and are not repeated. There is a voltage stabilizer. The reason is not clear.

During abnormal operation, try turning on the boiler without a stabilizer.

Hello.Tell me, by what percentage should the boiler power be reduced to avoid frequent switching on/off?

After the boiler is turned off, it quickly turns on within 3-4 seconds. How to extend a period of time. Katel »

castela"