Voltage stabilizer for a gas heating boiler: types, selection criteria + review of popular models

When installing a heating system, a voltage stabilizer for a gas boiler (CH) must be installed.It prevents damage to the electronic board due to instability in the electrical network. To choose this device correctly, you need to understand not only the characteristics, but also the principles of operation. Do you agree?

You will learn everything about the types of stabilizers, their design and operation by reading the article we have proposed. We pointed out the guidelines necessary for making the right choice and gave a rating of the best models. Taking into account our advice, you will correctly equip your gas boiler with the device necessary for operation.

The content of the article:

Relevance of voltage parameters on boilers

Even an inexpensive gas boiler has 15-25 sensors, information about which is processed around the clock by a built-in electronic board. Both the heating of the house and the safety of residents in the event of failure of individual elements of equipment depend on its operation.

The cost of a new original electronic board for gas boiler is approximately 40-50% of its value, so the safety of this element should be monitored with special attention.For normal operation of the gas equipment board, service centers strongly recommend using a voltage stabilizer.

Without a stabilizer, there will be no free warranty service. This is especially true for country houses, where the voltage can drop to 170-180 V in the evenings or briefly exceed 250 V if the wires break.

In addition to the electronic board, the water pump can also burn out due to changes in power supply parameters, replacing which will also cost a lot. Therefore, it is better to purchase a CH immediately when purchasing a gas boiler in order to avoid problems in the future.

The principle of operation of stabilizers

The fundamental internal structure of a voltage stabilizer is similar for all types.

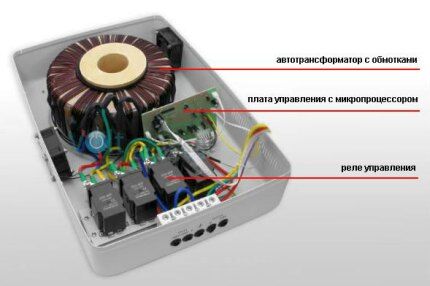

The following components are usually hidden under the body:

- An autotransformer with several windings, responsible for matching the output voltage to the established parameters.

- A control device that detects changes in input voltage.

- Circuit breakers. They turn off the stabilizer when the power supply parameters go beyond the operating range.

- Control automation, which changes the current path through the windings of the transformer, depending on the difference between the input and output voltages.

Additionally, the MV can be equipped with rechargeable batteries, which allow powering connected devices after a power failure.

The principle of operation of the stabilizer is simple.If the input voltage deviates from the norm, the automation changes the current path through the windings of the transformer so that the output produces a constant 220 V. Technically, the stabilization effect is achieved in several ways, depending on the type of device.

Types of household models

Not all types of SV are recommended for domestic gas boilers. Some categories of these devices are intended for industrial purposes and their use at home is impractical.

Therefore, further we will consider only types of stabilizers, suitable for furnishing a country house. We suggest that you familiarize yourself with the models that are suitable for heating equipment and are sold in most specialized stores.

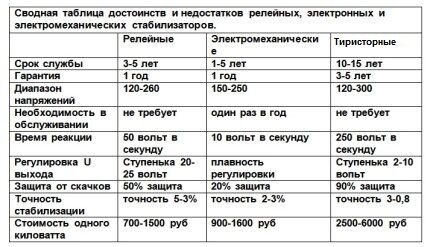

Servo or electromechanical

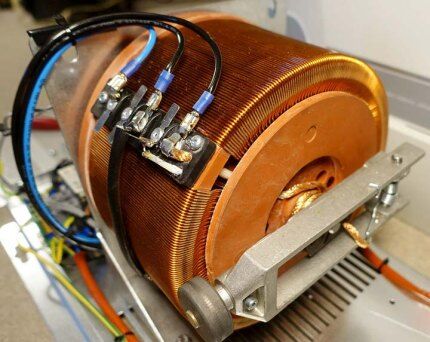

The operating principle of voltage stabilizers for servo-type heating boilers is to move the current collector along the transformer windings using an electric drive. The movement is controlled automatically.

Voltage regulation by the stabilizer is achieved by changing the number of turns of the secondary winding of the autotransformer, which are involved in power transmission. This principle allows the device to increase or decrease the output voltage of the network, depending on its input value.

Advantages of servo-driven MV:

- Overload resistance.

- The accuracy and smoothness of setting the output voltage values is 3-5%.

- Long service life with regular maintenance.

Disadvantages of electromechanical devices:

- Sensitivity to negative temperatures, at which the operation of the device is disrupted.

- With active use, the current collection brush requires replacement every 3-4 years.

- Low rate of voltage change - 10-40 V/sec.

- Servo drive noise.

- The occurrence of sparks when the current collector moves, which eliminates the installation of MV in rooms with a high probability of gas leakage.

The cost of servo drive devices is 3 times more expensive than relay devices and 2 times cheaper than thyristor devices. It is not recommended to include such MVs in the same branch as the refrigerator, because constant voltage drops when the compressor is turned on will quickly lead to wear of the current-collecting brush.

Thyristor or triac

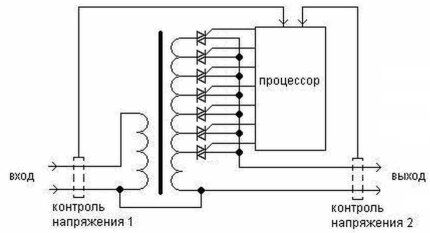

MVs with thyristors are most preferable for gas boilers. The principle of their operation is to form multiple electrical taps from the secondary winding of the transformer.

The operation scheme of electronic SVs is somewhat similar to servo-drive models. Only here, it is not the electric drive with a current collector that is responsible for regulating the number of turns on the secondary winding, but separate outputs, the activation of which is regulated using thyristor devices and a processor.

When the voltage drops, the outputs of some thyristors are turned off and the outputs of others are turned on, which ensure coverage of a larger number of turns of the winding.

The number of electrical taps from the transformer directly affects the smoothness and accuracy of voltage regulation. Their number can reach 20-25 pieces. Sometimes two-level stabilizers are used to provide even greater accuracy of the output voltage.

The described principle of operation of thyristor MVs leads to a number of advantages of such equipment:

- Service life 10-15 years.

- High response speed – 10-20 ms.

- The output voltage setting accuracy is from 1-3%.

- Operational resistance to frequent voltage changes.

- Ability to work at sub-zero temperatures.

- Resistance to electrical interference.

- Quiet due to no moving parts.

- Safety of the boiler board even with an interwinding short circuit in the transformer.

- Smooth sine wave when switching.

Disadvantages of thyristor MVs:

- High price. The cost of thyristor stabilizers is 2-3 times higher than servo drive ones, and 6-8 times higher than relay ones.

- Possibility of burnout of an expensive control board or failure of one of the thyristors due to overload.

- The need for active cooling at high loads.

Most thyristor MVs have a power of 5 kW or more and are designed to regulate voltage throughout the entire house or apartment. But about 10% of models have an operating power of up to 1.5 kW, which is enough to connect almost any household heating boiler.

Electronic or relay

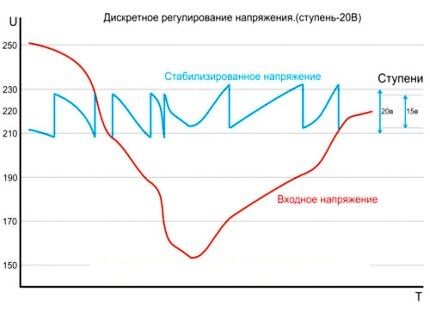

Relay-type MVs are the cheapest devices for voltage regulation. Their working “core” is from 4 to 20 inductors with different windings.

Depending on the existing voltage difference between the input and output of the device, the automation connects certain elements. As a result, a rough stepwise adjustment of the output parameters of the electrical network occurs.

The switching between coils is regulated using relays, which emit characteristic clicks.

The advantages of relay MVs are:

- Compact and light weight.

- Low price.

- Response speed within 0.1 sec.

- Operational resistance to frequent triggering.

Disadvantages of relay devices:

- Flashing light when switching coils.

- Lack of sine wave synchronization.

- Loud clicking sound when the relay is activated.

- Low tuning accuracy for most models is 5-8%.

Cheap relay devices are unlikely to be recommended in a store for a gas boiler. But if you don’t have money for more advanced models, this type of equipment is also suitable.

Double conversion models

This type of SV is symbiotic with an uninterruptible power supply. Its operation scheme consists of a two-stage conversion of incoming electricity.

First, equalized direct current with reduced voltage is supplied to the battery. Then electricity is removed from the terminals of the same battery, the voltage increases to 220V, the current is inverted into alternating current, and the converted energy is supplied to the outputs of the stabilizer.

Such a circuit, even with a minimum battery capacity, ensures complete autonomy of the output voltage parameters.

The advantages of double conversion SV are:

- Independence of output voltage parameters from the intra-house electrical network.

- Complete protection of the heating boiler from sudden voltage surges and short circuits.

- No switching elements or delays.

- Always the correct sine wave.

- Noise immunity.

- Duration of work more than 10 years.

- Possibility of autonomous operation of a gas boiler without external electricity.

Disadvantages of double conversion voltage stabilizers:

- High price. The price of devices with a power of 1 kW starts from $200.

- Low efficiency (90%) due to the operation of the cooling system fan.

Stabilizers with double conversion of electricity are ideal for equipment in equipped boiler room of a private house. But their price can reach half the cost of a heating system. Therefore, the final choice of a voltage stabilizer for a gas boiler often depends on the amount of money allocated for it.

TOP 15 voltage stabilizers for gas boilers

Inverter and electronic stabilizers

RESANTA ACH-600/1-I

Inverter stabilizer - fast response and minimal output voltage error

A Chinese-assembled stabilizer with a relatively low price tag demonstrates good performance parameters. The ACH-600/1-I inverter type model is designed to connect household electrical appliances with a total power of up to 600 W.

In addition to a gas boiler, the device is suitable for protecting computer equipment, televisions, refrigerators, lighting systems and low-power electric motors from power surges.

Characteristics of ACH-600/1-I:

- type – inverter with double conversion;

- active power – 600 W;

- input voltage – 90-310 V;

- output voltage – 218-222 V;

- stabilization error – 1%;

- response time – 1 ms;

- sockets – 2;

- temperature range – +5°С…+40°С;

- degree of protection – IP20;

- protective functions - short circuit, overheating warning, barrier against interference and over/under voltage.

When adjusting parameters, the ACH-600/1-I device operates silently, since it does not have a relay, and cooling is carried out naturally. The user is informed about the activation of the operating mode by light indicators located on the stabilizer body.

The level of protection allows the stabilizer to be used only in dry rooms heated in winter. The device must be installed so as to ensure free air exchange around the device.

- Performance - response time 1 ms

- Comprehensive protection system

- Quiet operation - no relay clicks

- Output voltage stability

- Light indicator system

- Relatively low load power

- No display

Calm IS1500

Good ratio of active power, functionality and price tag

The domestically assembled stabilizer of the InStab series, popular among buyers, attracts the attention of users with its high active power indicator and the presence of several levels of protection.

The Shtil IS1500 model operates on a transformerless double conversion circuit; the device is equipped with a high-performance microprocessor that guarantees the delivery of high-precision sinusoidal voltage. The stabilizer has a bypass mode to provide power bypassing the stabilizer.

Characteristics of Stihl IS1500:

- type – inverter with double conversion;

- total/active power – 1500 V*A/1120 W;

- input voltage – 110-290 V;

- output voltage – 216-224 V;

- stabilization error – 2%;

- response time – instantaneous;

- sockets – 2;

- temperature range – +5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, high-frequency interference and overload, overheating prevention, over/under voltage protection, built-in lightning protection.

The stabilizer is cooled by a built-in fan with adaptive power. The unit has compact dimensions and light weight; floor or wall installation is acceptable.

- High active power

- Instant response to voltage changes

- Informative display

- Comprehensive protection system

- Availability of bypass mode

- Complaints about noisy work

Lider PS1200W-30

Thyristor stabilizer with a wide operating temperature range

The thyristor stabilizer of the Russian manufacturer is designed for connecting single-phase consumers whose power does not exceed 960 W.

The unit consists of three parts (autotransformer, electronic switch, microprocessor control circuit) placed in a white metal case. On the front side there is an ON/OFF button and a three-color LED - each color indicates a specific operating mode. Natural cooling occurs through perforations in the housing.

Characteristics of Lider PS1200W-30:

- type – electronic thyristor;

- total/active power – 1200 V*A/960 W;

- input voltage – 150-265 V;

- output voltage – 210-230 V;

- stabilization error – 4.5%;

- response time – 40 ms;

- sockets – 2;

- temperature range – -40°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, interference and overload.

There are lugs on the back of the case that allow you to hang the unit on a wall or stand. Legs are provided for floor installation.

The Lider PS1200W-30 model can be used indoors; the stabilizer can operate at sub-zero temperatures. The unit must be stored in more gentle conditions – at a temperature above +5°C and a humidity of no more than 80%.

- Delay start option

- Possibility of operation at sub-zero temperatures

- Quiet operation

- Floor or wall mounted installation

- Operating mode indication

- High price

- No bypass

- Response time - 40 ms

- No display

PROGRESS 1000T

Thyristor single-phase stabilizer with voltmeter and informative display

A practical, reliable and highly efficient household stabilizer with an efficiency level of 96%. The model provides power supply to equipment with highly stabilized power (220 V +/-5%) with significant fluctuations in input voltage - 150-260 V.

The stabilizer has a simple design and a long service life. The device operates using thyristor switches and a step autotransformer. The PROGRESS 1000T stabilizer is equipped with a voltmeter and displays the input/output voltage on a digital display.

Characteristics of PROGRESS 1000T:

- type – electronic thyristor;

- total/active power – 1000 V*A/700 W;

- input voltage – 150-260 V;

- output voltage – 209-231 V;

- stabilization error – 5%;

- response time – 10 ms;

- sockets – 2;

- temperature range – +5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, interference and overload.

The metal body of the unit has a dielectric coating, which protects against electric shock and prevents the possibility of a short circuit.Cooling of PROGRESS 1000T is carried out through ventilation louvers located on the side walls of the case.

- Digital display

- Low noise level

- High efficiency - 96%

- High quality build

- Warranty - 3 years

- High price

- No surge protection due to lightning strike

- Only for heated rooms

Calm R 1200SPT

Triac stabilizer with terminal connection

The model operates on triac switches, has high stabilization accuracy and a good active power indicator. The stabilizer is designed for a stationary connection - there are no sockets in the unit, but a terminal connection to the electrical network is provided.

The R 1200SPT unit is cooled passively, that is, by air circulation through the provided ventilation openings. Thanks to this solution, the device has compact dimensions and operates almost silently.

Characteristics of Shtil R 1200SPT:

- type – electronic triac;

- total/active power – 1200 V*A/960 W;

- input voltage – 170-250 V;

- output voltage – 212-228 V;

- stabilization error – 3.5%;

- response time – 40 ms;

- sockets – no, terminal connectors;

- temperature range – +1°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, high frequency interference, overheating, over/over voltage and overload.

The terminal block is located on the side wall of the housing under a removable cover. On the front side there is an automatic power switch and an indication board.

At the output, the stabilizer produces a sinusoid without distortion. A distinctive feature is that the R 1200SPT operates at the declared power even at the maximum input voltage range (150-265 V).

- High active power - 960 W

- LED indicator system

- Pure sine wave output

- Natural cooling and quiet operation

- Easy to install - there is a mounting bracket

- Voltmeter missing

- No bypass mode

- Response time - 40 ms

- No sockets - terminal connection

Relay stabilizers

Energy APC 1000

Excellent performance at an affordable price

The APC 1000 relay stabilizer from Energia demonstrates high output power, stabilization accuracy and a wide input voltage range.

The compact model has an attractive design - the 7 cm thick rectangular body does not take up much space on the wall. The unit is equipped with a display showing input/output voltage. Two sockets and a start button are located at the bottom of the case; on the back there are eyes for hanging a stabilizer.

Characteristics Energy APC 1000:

- type – relay;

- total/active power – 1000 VA/1000 W;

- input voltage – 85-270 V;

- output voltage – 211-229 V;

- stabilization error – 4%;

- response time – 10 ms;

- sockets – 2;

- temperature range – -5°С…+40°С;

- degree of protection – IP20;

- protective functions - against high-frequency interference, overheating, interference and overvoltage.

The APC 1000 has a short start-up delay (6 seconds). This function is relevant for some equipment (pump motors, refrigerators, etc.) that do not respond well to being turned on immediately after being turned off.

The stabilizer operates almost silently, so it can be used in studio apartments, placed near gas boilers in the kitchen.

- Wide input voltage range

- Voltage display

- Start delay

- Quiet operation

- Automatic fuse

- No bypass mode

- French sockets - type E with grounding

- Bright indication on the display

Energy Voltron 1000

Practicality of operation: low temperature tolerance, high efficiency and digital display

Another representative of a Russian electrical equipment manufacturer. The Voltron 1000 relay model will protect household appliances from network anomalies. The device is designed with a high-speed relay with tungsten contacts.

The Voltron 1000 stabilizer is easy to use. The case is provided with an output socket and an informative display - the input and output operating voltage is displayed on the display.

Voltron 1000 Features:

- type – relay;

- total/active power – 1000 V*A/700-1000 W;

- input voltage – 105-265 V;

- output voltage – 209-231 V;

- stabilization error – 5%;

- response time – 10 ms;

- sockets – 1;

- temperature range – -30°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, overload, under/overvoltage.

Reviews about the work of the domestic stabilizer are mostly positive. The Voltron 1000 model is praised for its good price-functionality ratio, the ability to be placed in unheated rooms: summer houses, garages or change houses. However, users have also identified some weaknesses of the unit.

- Digital indication of input/output voltage

- Working at sub-zero temperatures

- Universal placement - floor or wall

- There is a startup delay

- Circuit breaker

- Only 1 outlet

- No bypass mode

- Warranty - 1 year only

- Complaints about incorrect voltage display

Energy ACH 1000 (2019)

Budget proposal - relay type stabilizer providing multi-stage protection

A single-phase stabilizer is designed to connect one electrical appliance with a power of up to 700 W. Thanks to the housing design, the ACH 1000 (2019) unit is able to operate uninterruptedly at a temperature of -20°C. Even under such extreme conditions, the stabilizer continues to operate over a wide input voltage range and quickly respond to voltage fluctuations.

The “core” of the device is a microprocessor unit - the element is responsible for automatically turning off electrical appliances at an unacceptable voltage level and controls the restoration of functionality when the parameters are normalized.

Characteristics of ACH 1000 (2019):

- type – relay;

- total/active power – 1000 V*A/700 W;

- input voltage – 140-260 V;

- output voltage – 202-238 V;

- stabilization error – 8%;

- response time – 10 ms;

- sockets – 1;

- temperature range – -20°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, overload, under/overvoltage, start delay.

The design of the stabilizer is made as comfortable as possible. On the front there is a large digital display and operating mode indicators, two control keys.

The stabilizer is equipped with an automatic fuse that trips in case of overload and short circuit; the cooling system is natural. The device operates economically, as evidenced by its high efficiency level of 98%.

The stabilizer is suitable for placement in a country house, private house, garage, small workshop or apartment. People present in the room will not feel discomfort from the operation of the unit - the device operates quietly.

- Convenient control interface - display and indicators

- Working at sub-zero temperatures

- Low cost

- Quiet operation

- There is a carrying handle

- No bypass function

- Only one outlet

- No terminal connectors

- Warranty - 12 months

- Stabilization error - 8%

BASTION Teplocom ST-1300 version 5

Relay stabilizer for outdoor use

The high-quality stabilizer stands out among its competitors because it can be used outdoors. The sealed plastic case is reliably protected from moisture and dust, which is confirmed by a high degree of IP – 56.

Due to its performance characteristics, the stabilizer is used to provide high-quality power supply to sewer and drainage pumps, well pumps, irrigation systems and other outdoor equipment with a total power consumption of up to 950 W.

Characteristics of Teplocom ST-1300:

- type – relay;

- total/active power – 1300 V*A/950 W;

- input voltage – 165-260 V;

- output voltage – 204-231 V;

- stabilization error – 7.5%;

- response time – 20 ms;

- sockets – no, terminal connection;

- temperature range – -40°С…+50°С;

- degree of protection – IP56;

- protective functions - against short circuit, overheating, overload, under/overvoltage.

The stabilizer can also be used for a gas boiler. When choosing a unit, it is worth considering the conditions of its placement.If the stabilizer is not subject to extreme operating conditions, then it is not advisable to overpay for a high degree of IP.

- Wide operating temperature range

- High protection class - IP56

- Safe plastic housing

- Warranty - 5 years

- High price

- Terminal connection only

- Input voltage error - 7.5%

- No voltmeter

Powercom TCA-1200

Inexpensive and compact unit - a solution for low-power equipment

The relay type model is in demand among users. Many are attracted by the low cost, the name of a popular brand and comprehensive protection. There are 4 sockets with grounding on the back of the case, and there are light indicators on the front panels that inform the user about the operating mode.

Characteristics of Powercom TCA-1200:

- type – relay;

- total/active power – 1200 V*A/600 W;

- input voltage – 176-264 V;

- output voltage – 209-231 V;

- stabilization error – 5%;

- response time - no data;

- sockets – 4;

- temperature range – 0°С…+40°С;

- degree of protection - no data;

- protective functions - against short circuit, high-frequency interference, overload, under/overvoltage.

The model does not have a voltmeter, bypass mode or terminal connectors - with a modest price tag, you should not count on wide functionality. The stabilizer does its job well, as evidenced by numerous user reviews.

- Low cost

- 4 output sockets

- Compact dimensions and light weight

- There is protection against high-voltage impulses

- Low active power - 600 W

- No voltmeter or display

- Complaints about loud relay clicks

- No start delay or bypass function

- Smell the plastic

Hybrid and electromechanical stabilizers

RESANTA ACH-1000/1-EM

High-precision electromechanical stabilizer with active power 1 kW

Reliable electromechanical stabilizer, designed for light load operation. The unit converts the incoming current, smoothes out sudden surges and long-term decreases/increases in voltage, producing an even 220 V. The front panel is equipped with an electronic voltmeter and a power button.

The device is cooled naturally - air circulates through the ventilation holes.

Characteristics of RESANT ACH-1000/1-EM:

- type – electromechanical;

- total/active power – 1000 VA/1000 W;

- input voltage – 140-260 V;

- output voltage – 216-224 V;

- stabilization error – 2%;

- response time – 10 ms;

- sockets – 1;

- temperature range – 0°С…+45°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, over/under voltage.

The ACH-1000/1-EM stabilizer is optimally suited for working in a network with long-term rises or falls in voltage, but without frequent fluctuations. The optimal lower limit is 190 V. When the voltage drops to 140 V, the output power can be reduced by up to 50%.

- Acceptable cost

- Stabilization error - only 2%

- Digital voltage display

- Automatic fuse

- Convenient carrying handle

- Only 1 socket

- No bypass mode

Energy Hybrid SNVT-1000/1

Hybrid unit - combining electronic and electromechanical stabilization

Hybrid version of a single-phase voltage stabilizer.The Hybrid unit SNVT-1000/1 combines an electronic stabilization method with an electromechanical one. The model produces a sinusoid without distortion, the error in stabilizing the output voltage does not exceed 3%.

At a network voltage of 144-256 V, the device operates as an electromechanical device; at a critical value (105-280 V), the model switches to electronic stabilization.

Characteristics of Hybrid SNVT-1000/1:

- type – hybrid;

- total/active power – 1000 V*A/800 W;

- input voltage – 144-256 V;

- output voltage – 213-227 V;

- stabilization error – 3%;

- regulation time – 20 V/s;

- sockets – 2 without grounding, 1 with grounding;

- temperature range – -5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, interference, over/under voltage.

The control interface is provided by an ON/OFF push-button switch and a voltmeter with a dial indicator. An analog meter is inferior to a digital meter in the accuracy of voltage display; the error can be 5-10 V. However, for everyday tasks this data is sufficient.

The Hybrid SNVT-1000/1 stabilizer is adapted to domestic operating conditions. The model is perfect for protecting a heating boiler, circulation pump, TV or refrigerator.

- Acceptable cost

- High precision stabilization

- There is a voltmeter and a start delay

- Wide input voltage range

- High level of efficiency - 98%

- Analog voltmeter - dial indicators

- No bypass circuit

- Warranty - 1 year

SUNTEK SNET-2000-EM

High-power stabilizer with a wide operating input voltage range

Electromechanical stabilizer with a high power rating and a wide range of operating input voltage. The SNET-2000-EM model is equipped with a Holtek microcontroller, which ensures accuracy, reliability and stability.

For ease of use, there is a small display on the front with an indication of the voltage value and a power button. Installation is easy. For quick commissioning, the manufacturer equipped the unit with a Euro plug for connecting to the network and a socket for connecting electrical appliances to the stabilizer.

Characteristics of SNET-2000-EM:

- type – electromechanical;

- total/active power – 2000 V*A/about 2000 W;

- input voltage – 120-285 V;

- output voltage – 213-227 V;

- stabilization error – 3%;

- regulation speed – 30 V/s;

- sockets – 1 with grounding;

- temperature range – -5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, interference, over/under voltage, protection against pulse discharges.

The SUNTEK SNET-2000-EM model is covered by an extended warranty - 3 years full, 2 years of free service. The unit begins to operate at full power at an input voltage of 140 V.

The stabilizer is suitable for gas boilers, refrigerators, low-power office and household appliances, television and video equipment and climate control equipment.

- High power - 1600 W

- Digital voltmeter

- Surge lightning protection

- Good build quality - durable body

- Warranty - 3 years

- Only 1 socket

- No bypass mode

- Small display

- Heavy weight - 7.5 kg

Energy Hybrid SNVT-2000/1

Hybrid model - a symbiosis of electromechanical and relay technology

The combined type of stabilizer uses two principles in its operation: relay and electromechanical, that is, servo-driven. The combination of two technologies helps to expand the operating voltage range - at extreme values the stabilizer operates on a relay principle, at 144-256 V it functions as an electromechanical unit.

The Hybrid model SNVT-2000/1 is equipped with a smooth control unit and an electronic discrete control unit. The latter begins to work when extreme voltage surges or sags are recorded in the electrical network; the range of critical values is 105-280 V.

Characteristics of Hybrid SNVT-2000/1:

- type – hybrid;

- total/active power – 2000 VA/1400 W;

- input voltage – 144-256 V;

- output voltage – 213-227 V;

- stabilization error – 3%;

- stabilization speed – 20 V/s;

- sockets – 1 with grounding;

- temperature range – -5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, over/under voltage.

When choosing a Hybrid device SNVT-2000/1, you must take into account that there is no socket in the model. The stabilizer is connected to electrical appliances through a terminal connection. This option is convenient if the device is stationary, since reconnecting to other consumers will take time.

- Active load power - 1400 W

- There is a bypass mode

- Analog voltmeter and indicator lights

- High output accuracy - ±3%

- There is a startup delay

- Complaints about humming at high network voltage

- Dial indicators show only output voltage and current

- No sockets

IEK SNI1-0.5

A simple and inexpensive low-power electromechanical stabilizer

In fifth place is a budget version of the electromechanical stabilizer from IEK. The SNI series models have 4 levels of protection: against transformer overheating, short circuit and overload, high or low voltage.

The body of the unit is compact (19*13*17 cm), the front panel contains light indicators, a start button and a voltmeter.

Characteristics of IEK SNI1-0.5:

- type – electromechanical;

- total/active power – 500 V*A/500 W;

- input voltage – 160-250 V;

- output voltage – 213-227 V;

- stabilization error – 3%;

- response time – 5000±2 ms;

- sockets – 2;

- temperature range – -5°С…+40°С;

- degree of protection – IP20;

- protective functions - against short circuit, overheating, interference, over/under voltage.

IEK SNI1-0.5 is designed for floor installation; an ergonomic handle at the top of the case is provided for carrying. Spare fuses and autotransformer brush are included as standard.

- Low cost

- There is a startup delay

- Possibility of operation at low temperatures - down to -5°C

- Clear control interface

- High precision stabilization

- Low load power

- No bypass mode

- Response time

- Does not show output voltage value

Selection criteria when purchasing a device

Not every boiler can be connected to a cheap voltage stabilizer. When choosing voltage stabilizer it is necessary to take into account the parameters of the connected equipment, because sometimes it may not even turn on due to the operation of the built-in protective fuses.

All important technical parameters of the stabilizer will be discussed below.

Maximum load power

The instructions for the SV usually indicate the performance of the equipment in Volt-Amperes (VA). This indicator is often confused by consumers with Watts. An indicator on a device of 500 VA does not mean that this stabilizer can normally operate equipment with a power of 0.5 kW.

Domestic boilers in apartments usually consume up to 150 W in operating mode.

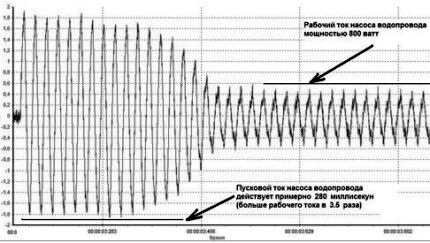

But the moment they are turned on, two processes start that sharply increase the current:

- charging electronic board capacitors;

- starting the electric motor of the heating pump.

As a result of these two phenomena, the load on the stabilizer during the first 0.1-0.4 seconds increases by 3-5 times to 450-750VA. The resulting inrush currents can be perceived by the MV as a short circuit, as a result of which the device will be turned off due to the triggered protection.

The best SN option for gas boiler there will be a model whose total power in VA will be 5 times the operating needs of the boiler.

If this recommendation is not followed, the situation can develop in two ways:

- The boiler will not turn on and you will have to exchange the stabilizer for a more powerful one.

- The CV will regularly operate in overload mode, which will lead to its early breakdown.

Therefore buy Voltage regulator for a heating system it should be with a power reserve of 3-5 times.Considering the electrical consumption of most boilers, this will not be an expensive investment, but it will save you from many problems.

Voltage stabilization speed

In stabilizers, voltage equalization does not occur immediately. The main thing is that the delay time does not negatively affect the operation of the boiler, because a short-term impulse with a value of 260-270V can already lead to burnout of the electronics.

Servo-drive voltages have the lowest speed (10-40V/sec), so they cannot reliably protect the electronic board from critical voltage drops.

Relay stabilizers are faster and equalize the voltage in 0.1-0.2 seconds. This time is quite enough to protect the boiler from problems.

Thyristor MVs provide a voltage correction speed of 10-20 ms. The electronics will not even notice such an interruption. These are the best stabilizers.

Operating voltage range

Most even budget stabilizers have an operating range from 140-160 to 250-260 Volts. If the voltage in the network is even lower, then this is a reason to contact the organization that services the electrical networks. If the input parameters deviate beyond the specified ranges, the protection is triggered and the MV is simply turned off.

In the evening, the voltage can drop in the private sector to 170-180 V, so buy stabilizers for heating systems country houses with operating parameters below those specified are not recommended.

Ambient temperature

Servo-drive stabilizers do not tolerate sub-zero temperatures very well. This is due to icing of the transformer windings along which the current collector moves. As a result, high currents can occur under load, which can melt the copper wire and cause a short circuit.

When installing the CH in cold weather, be sure to check the instructions for the temperature range at which the equipment can be operated. Some stabilizers even have an insulated or waterproof housing.

Other non-critical parameters

When purchasing a voltage stabilizer, it is advisable to take into account other non-critical characteristics of the equipment:

- voltage stabilization accuracy:

- possibility of mounting the MV on the wall;

- presence of grounding;

- number of built-in protection systems.

Even the worst voltage stabilization accuracy of 10% will not be an obstacle to the stable operation of a gas boiler. In addition, its electronic boards have their own low-power circuits.

For other equipment, 200 or 240 V is sufficient for stable operation. But the optimal value is still 220 V with minimal deviations.

The device can always be mounted on the wall by building a small shelf, but specialized mounts are better suited.Therefore, if it is necessary to place the SV on the wall, it is better to purchase appropriate models for this.

In addition to being protected from surges, the connected equipment must be protected from the hazards of the stabilizer itself.

Therefore, HF must have protective mechanisms against such factors:

- overheat;

- overload;

- deviation of the output voltage beyond the permissible values;

- short circuit.

The more protection the design provides, the less likely it is to damage the connected equipment. The last characteristic worthy of attention is the price of the device, but this parameter depends on many factors.

Manufacturers of voltage stabilizers

Only a few manufacturers produce voltage stabilizers of all types at once. Companies generally focus on making products for a specific niche. In recent years, domestic manufacturers have launched the production of their own SVs no worse than their foreign counterparts.

Thus, the best manufacturers of household relay MVs are:

- Resanta;

- Leader;

- Luxeon;

- Energy;

- SVEN

Good electromechanical devices are produced by:

- LogicPower;

- Luxeon;

- RUCELF;

- Resanta;

- Solby.

The following companies are engaged in the production of thyristor stabilizers:

- Walter;

- Luxeon;

- Leader;

- Calm;

- Progress.

There are dozens of other voltage stabilizer manufacturers that are also worthy of consideration. Their products can also be purchased in the store if there are no suitable models from the above companies.

Conclusions and useful video on the topic

The presented videos will help you decide on the choice of a good SV for a gas boiler.

Video #1. Choosing a voltage stabilizer for boiler equipment - useful tips:

Video #2. Operation and internal structure of the stabilizer:

Video #3. Testing five different voltage stabilizers:

For buyers of voltage stabilizers, the main selection criterion remains the cost of the device. But for the same price you can purchase both a SV, which is not suitable for a gas boiler at all, and a device that will reliably protect the connected equipment for years.

In order not to regret the money spent, when purchasing a stabilizer, you should definitely take into account all the above-described equipment parameters.

Please write comments in the block form below. Tell us about how you selected a stabilizer for your own gas boiler. Share useful information that will be useful to site visitors, ask questions, post photographs related to the topic of the article.