Malfunctions of the Junkers gas boiler: fault codes and troubleshooting methods

A boiler breakdown at the height of the heating season is a nightmare for every owner of this equipment, isn’t it? Has it ever happened to you that the boiler stopped working, the house is cold, and the repairman can only arrive in a few days? Such malfunctions of the Junkers gas boiler can cause despair.

Don’t rush to panic, because many breakdowns of gas boilers can be fixed on your own, without experience or special tools, and we will teach you how to do this.

In this article, we will not only decipher the error codes that the boiler produces, but also link them to the current state of the unit. We will also tell you how to troubleshoot some problems and in which cases you cannot do without the help of a specialist.

The content of the article:

Gas boiler does not turn on

When the boiler does not work and not a single light is on, does not react in any way to the power button, the owner is overcome by the most terrible suspicions: the unit is hopelessly broken, serious repairs or installation of new equipment will be required.

The boiler self-diagnosis function is powerless here and the device will not display an error code.

Often the reason is simple: the plug is pulled out of the socket, or the machine is turned off.The plug could be pulled out by a child while playing, and the machine could turn off to protect against a network failure. In addition, there may be no power supply in the entire house - during the day you can easily not notice this.

If everything is fine with the power supply, but the boiler is still silent, unplug it and remove the front cover. The control panel in wall-mounted models is usually secured with two bolts, and the main compartment cover is screwed on at the corners - a Phillips screwdriver is enough to remove them.

The problem may be a blown fuse on the control board, while the boilers of the series EuroStar can issue error E9. Find it and inspect it, if possible, check with an ammeter. If a fuse needs to be replaced, look for a spare one on the inside of the lid or other parts of the boiler body. As a rule, the Junkers company makes such a reserve for the user.

After checking the markings, replace the fuse and try to start the boiler without directly assembling it. If everything works, you can breathe a sigh of relief, but if there is no response or the new fuse immediately burns out, you need to call a specialist.

Inspect the inside of the device for signs of short circuits, leaks, broken or pulled wires.

A varistor on the board may be blown or damaged - this indicates that there has been a power surge. The repair is not too complicated or expensive, but it requires soldering the board, and we strongly do not recommend doing this yourself. Entrust the work to a specialist, and purchase a voltage stabilizer yourself.

It happens that the boiler does not start working even when the house is cold.The display or indicators may show standby mode, and on EuroStar models - SS error. This indicates a lack of communication with the room temperature sensor or boiler thermostat. Check the integrity of the wires and connections, tighten the contacts tightly. If everything is intact, turn the knob on the mechanical sensor, and replace the battery on the electronic one.

If a boiler with piezo ignition tries to light a burner, gives a spark, but does not ignite - most likely there is no gas supply or it is faulty gas valve.

After several unsuccessful attempts to start the line model Ceraclass And Eurostar highlight EA error “The flame is not detected”, the “reset” button and the temperature indicator 60 are flashing on the Euroline.

In such a situation, you can only try to light the kitchen stove or unscrew the gas hose of the boiler (with the tap closed and the boiler turned off) and try to briefly open the gas. If there is a hissing sound or the stove turns on, the problem is in the boiler, you need to call specialists from the service department with which you have contracted maintenance agreement gas equipment.

If there is no hissing, then the gas supply to the house is turned off, wait until the gas supply is restored. In any case, the unscrewed gas hose must be connected back to the boiler without losing the gasket.

The boiler keeps switching off

One of the most common problems: the boiler starts to work, the burner lights up, and then turns off. At the same time it can issue error E9, CE, EA or the lamp flashes at 45 or 75 degrees - “no ionization current.”

This problem can occur every time when igniting or occasionally, unpredictably, instantly or after a short period of time - because the reasons for this behavior of the boiler can be different. We will talk about possible problems and their solutions further.

Reason #1 - the filter is clogged

This is a common problem double-circuit boilers, which is rarely indicated by self-diagnosis, because the water supply filter is usually located outside and is not connected to the sensor.

A shutdown occurs when you try to switch to DHW, because water does not flow into the coil or flows with weak pressure and the boiler overheats.

To clean the filter, turn off the boiler and find an area in the shape of an inverted “U” on the water supply pipe to the boiler.

Before and after it, turn off the taps, unscrew the nut - tip. Remove and thoroughly rinse the mesh and rinse the body. If the cartridge is damaged - bent or burst, then buy a new one. Put everything back together and open both taps.

Reason #2 - pump jammed

In most models of Junkers gas boilers, the pump is built-in and controlled by the system; its malfunction is indicated by a flashing 45 degree diode, error E9, depending on the model.

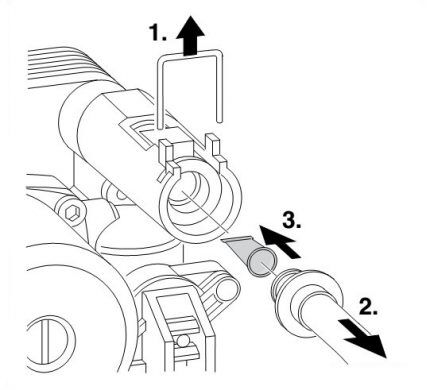

To find out if the pump rotor is jammed, you need to disassemble it.

To do this, do the following:

- turn off the boiler;

- find the pump in the lower right part of the boiler;

- place a small container under it;

- to remove the cover, unscrew the screw with a large shiny head using a flat-head screwdriver;

- a little water will drain from the pump - make sure that it does not get on the printed circuit board or other electronics;

- Try turning the rotor slightly inside the pump with the tip of a screwdriver. If it goes easily, we assemble and look for the fault further; if not, we repair or replace the pump;

- put everything back together in reverse order.

A riskier, but also more accurate way to check is to turn on the boiler with the pump disassembled and the water turned off and carefully push the screwdriver deep into it until you hear a characteristic sound when touching the rotating rotor.

If the pump is clogged with air trapped in the heating system, a special valve will help drain it.

Depending on the design, it can be unscrewed or lifted. When the coolant supply tap is open, the air will come out with a hiss, and the boiler will work as before.

Reason #3 - sensor is faulty

It happens that the main burner manages to ignite, but immediately goes out and the boiler produces EA error or the 60 degree diode is flashing. This means it is not working correctly flame control sensor – a thermocouple or ionizer diode and the protection switches off erroneously, turning off the burner to prevent gas leakage without combustion.

To correct such a malfunction, you do not always need to change the sensor; sometimes it is enough to unplug the boiler from the socket and insert it upside down. This manipulation helps because many Junkers boilers are phase-dependent; if the phase and zero of the boiler and the outlet do not match, the ionization current is not generated and the sensor does not work.

Another reason for such a breakdown is a short circuit between zero and ground in any part of the electrical wiring in the house.Remember, have you recently driven nails or connected new electrical equipment? All equipment works with such a short circuit, only the grounding is incorrect.

If a similar problem is found, fix it and restart the boiler.

In all the cases described above, the boiler turned off immediately and could not enter operating mode even for a short time.

If the device as a whole works, but sometimes, at different intervals, usually from several hours or days, the EA error “flame is not detected” occurs, then the culprit is most likely low-quality and unstable voltage in the network.

This situation is not only annoying, but also threatens to break the board. To prevent this, purchase a voltage stabilizer.

Low coolant pressure

On the front panel of each boiler there is a pressure gauge indicating heating system pressure. It has red zones for readings that are too low and too high. A pressure of 1.5 bar is considered normal for a cold boiler: at 1 bar the arrow is already in the red zone, and at 0.5 bar the boiler will turn off CE error or CF until pressure is restored.

If the boiler was installed recently - a few weeks ago, this situation is common, you just need to add clean water through a special tap. But do not rush to add water to a system that has been in operation for several years.

When water heats up, it expands and the pressure rises - this is the norm. However, if it immediately jumps by 0.7 - 1.5 bar, this indicates a lack of air in the expansion tank.

If in such a situation you add water, heating up, it will increase the pressure too much and the safety valve will operate, releasing excess coolant.

To pump up the tank, you first need to relieve the pressure on the switched off boiler by draining some water. Then connect the pump or compressor to the fitting at the top back of the tank and pump it up to 1.3 - 1.4 bar. After turning off the pump, add water, bringing the pressure in the cold system to 1.5 - 1.6.

If even when the boiler heats up, low pressure in the heating circuit remains, then it is really necessary to add water. Where to find the tube intended for this is indicated in the instructions for the device model, but we will only remind you of the need to fill this tube with water before opening the tap so that air does not get into the pump and batteries.

Be sure to check all the taps, connections and radiators, as well as the insides of the boiler for leaks - the water circulating in the system has gone somewhere.

No draft in the chimney

Problems with draft are also familiar to all types of boilers - both with a conventional chimney and with a coaxial one. Point out this problem errors A4, C4, C6, the diode blinks 45 degrees, sometimes alternately with 90 degrees.

When such errors occur, first of all, you need to find out whether there really is a problem, because traction sensor could have worked incorrectly, and failures C4 and C6 may also indicate problems with the pressure switch.

To check the draft, first find out where your boiler takes its combustion air from. Models with an open combustion chamber take it from the room, usually through a grate at the bottom of wall-mounted and on the side of floor-mounted versions. With the combustion chamber closed, air is taken from the street through the outer pipe of the coaxial chimney.

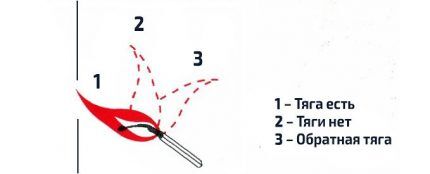

Place a sheet of paper near the air intake point when the equipment is operating or attempting to operate. If it sticks to the grate or is pulled into the pipe, then everything is fine with the draft.

If there is traction, but it is weak, it may not be enough to hold the paper. In this case, a burning match is used to check.

Open chamber boiler

Most often, when traction errors appear, there really is none. The main reason is problems with the chimney. He can be:

- clogged with soot or acid condensate;

- clogged with foreign bodies - sometimes birds can make a nest in the chimney, the remains of which will fall inside;

- incorrectly calculated - too thin or short;

- not insulated enough, an air lock has formed.

Inspect and clean the pipe, if necessary, use the services of specialists.

Turbocharged gas boiler

A fan controlled by a flue gas pressure switch - a pressure switch - is responsible for air exchange in boilers with a closed combustion chamber.

The cause of traction failure is usually a malfunction of one of these devices.

The boiler owner himself can check the integrity of the inductor with a multimeter - it must have a resistance of 50 - 80 Ohms, otherwise it must be replaced.Also, due to the accumulation of dirt and dust, the fan impeller may be unbalanced.

To detect this, remove the turbine, blow off any dust and rotate the impeller several times. If it always stops in one position, attach a weight to the top blade and check again.

In addition, the pressure switch may not start the fan due to low voltage in the network: check it with a voltmeter in the outlet, the lower threshold of the permissible value is 195 V. If this is the problem, connect the stabilizer.

To check the operation of the pressure switch, connect the fan directly and try to start the boiler. If the operational problems disappear, the pressure switch requires replacement.

Boilers with a closed chamber are supplied coaxial chimneys, which are installed horizontally and therefore are practically not subject to clogging. However, in severe frost, icing of the end of the pipe may occur, caused by freezing of condensate or improper installation of equipment.

You can get rid of this problem by insulating the chimney.

Other faults and code meanings

Most of the error codes that we have not yet mentioned indicate a distress signal from a specific sensor, caused by its breakdown, a line break, or a malfunction of the monitored equipment.

You can find out all the error options that the Junkers wall-mounted gas boiler produces and repair it in the instructions for your model.Depending on the series, indication method and boiler configuration, the list of errors may differ, and sometimes the same code in different models does not have a completely identical meaning. Therefore, we will not provide a complete list here, so as not to confuse you.

Fault #1 - noise during operation

The boiler body is not sealed and dust often settles in it. Most of it accumulates on the fan impeller, because it sucks dirty air out of the boiler.

If you have an air compressor, the problem is easy to fix. Remove the front panel of the boiler and unscrew the turbine. Blow out the entire fan with compressed air, then its seating area, and then the entire boiler. Be careful when cleaning the board - the blast of air may dislodge the contacts.

Allow the dust in the room to settle and blow out the boiler again. Do several such cycles until completely clean.

The impeller and fan housing can be wiped with soapy water - just be careful not to wet the motor and electrical contacts. If there was a lot of dust, ask a specialist from the Junkers gas boiler maintenance and repair company to also remove and wash the gas burner. You should not do this yourself - incorrect installation can result in a gas leak and explosion.

Problem #2 - batteries do not heat up

If the double-circuit boiler does not switch to heating mode, even when all hot water taps in the kitchen and bathroom are closed, the flow sensor is most likely faulty or three-way valve. In this case, as a rule, the error is not displayed - it seems to the boiler that there is a constant water intake, and it works in accordance with this situation.

If you really use hot water for a long time and the batteries have cooled down, the boiler is working normally, the DHW circuit is its priority.

When such a problem occurs during the first startup after installation, design errors are possible. For example, a heated towel rail can be connected to the DHW circuit, as in high-rise buildings with a centralized hot water supply.

Water constantly circulates in it, and therefore the flow sensor does not close and does not allow the boiler to start heating.

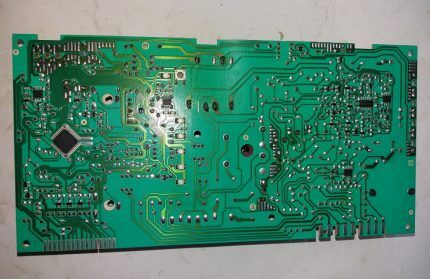

Problem #3 - board errors

The electronic control board is the most capricious and expensive part of a modern boiler, it error F0, E0 or a flashing 75 degree indicator can seriously upset the owner who looked at the instructions for a decoding.

However, everything is not always so bad: perhaps the contacts have simply come loose, and on Cerapur series boilers it also indicates an incorrect ratio of gas and air supplied to the burner. The cause of the malfunction may also be moisture on the printed circuit board. Everything will work after thorough drying.

It has been experimentally established that sometimes board errors correct themselves if you set the fan to the 5th operating mode.

In addition, sometimes the board does not work correctly, the boiler behaves strangely, but does not display an error. The reason for this may be poor quality electricity. Try disconnecting the boiler from the network for half an hour so that all capacitors are discharged, and then start it again.If it helps, that’s the problem. Resetting the settings to their original settings may also help.

A specialist can also resolder or reflash the board, restoring its functionality.

Conclusions and useful video on the topic

You can see more clearly the most common breakdowns of Junkers boilers and their self-repair in the video.

Troubleshooting the flow sensor:

Do-it-yourself Junkers boiler repair:

As a conclusion, we can note that not every error generated by the boiler self-monitoring is fatal. Do not be afraid to repair the Junkers boiler yourself: many faults can be eliminated without the help of a specialist. But we don’t recommend tampering with the gas pipeline and soldering the board yourself, it’s too risky.

Did your Junkers boiler stop by mistake? Did you manage to solve the problem yourself or did you have to resort to the help of specialists? Tell our readers about it - join the discussion in the comments.

In the summer, hot water turns on spontaneously and shows an error until you stop the Junkers boiler with a triangle

Hello, such a problem, Junker boiler with two circuits

When the heating mode is turned on, the boiler only heats up to 40 degrees, the burner barely burns and does not react in any way to increasing the temperature with a knob

Good day, I encountered the following problem: when turned on, the Junkers boiler triggers explosive combustion. I ask for your advice on what to do? Scary to use...

Good afternoon. You should contact a gas boiler specialist.

Good afternoon.You should contact a gas boiler specialist.

Good afternoon, the boner was heating up the water in the washer, and it made a noise, so you can hit the wrong button and it shows error E9

Good afternoon. You should contact a specialized organization to identify and fix the problem.

Error F7. Reset doesn't help anymore. How to fix the problem?

Good afternoon. Dear friends, please tell me what to do - when the cold water tap is turned on, the boiler lights up and then boils for an hour with the tap turned back on. or for a couple of seconds with my eyes I’m cold and wincing again. It is only during such manipulations that the vein reacts. Having translated the duct sensor, the fuckers of the prazuu without a spring, Tobto burst Chi Zreti (((ї ї deputy -іnity I do not know the yak, the izilki in the ilnerenneti videsleti izhormatsky ((finish, I will be in the back!

An explosion occurs when ignited

Boiler technicians can't figure out why

Tell me, is there anyone who can fix the problem?

Good day! The Junkers Euroline boiler is a double-circuit boiler, hot water flows from the cold water tap, when cold water is turned on the boiler does not react, with hot water everything is fine, when turned on the boiler turns on and heats up.

Good afternoon, Junkers turbo boiler, the sensor has burned out, is it possible to start without it?