Simple connection of metal pipes without welding - the best methods for this

In some situations, it becomes necessary to connect metal pipes without welding.This is due to the lack of an electrical network at the workplace, the inability to deliver welding equipment, inexperience in carrying out work of this type, etc. To connect metal lines without welding, minimal technical knowledge and skills in pipeline installation will be required.

The content of the article:

Classic methods for connecting elements

Hot and cold water supply systems are installed in various ways. The connection technology is selected taking into account a number of factors, such as the availability of specialized equipment, places for its use, etc. Classic connection methods:

- Welding. Metal pipes are joined by melting their edges. The connecting seam is filled with metal. Electric or gas welding is used for joining. Installing a water pipeline in this way requires specialized education and skills in working with equipment.

- Threaded connection. On the edges of both parts cut the thread. This way it is possible to obtain a joint that can withstand heavy loads. Liquid or gas may leak between the threads. Sealing materials are used for sealing. They are wound on every part.

No specialized equipment is required to assemble the threaded connection. Use wrenches, adjustable wrenches and tools designed for cutting threads.

Read the article: Rating of the best wrenches.

Connections that do not require welding

Pipeline parts are connected without the use of a welding machine.This method allows you to install water supply systems regardless of the availability of an electrical network.

The lines are connected without welding as follows:

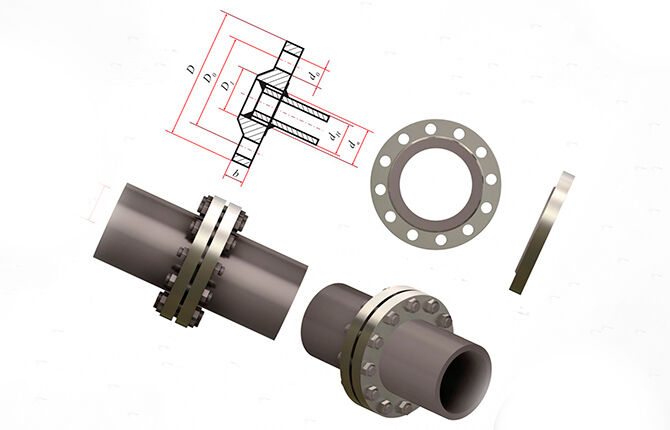

- Flanges. There are protrusions located at the edges of the part perpendicular to the surface. They have holes for mounting fasteners. Bolts and nuts are used for fastening. When joining metal pipes, the holes coincide. The bolts tightly tighten the flanges of adjacent parts. To ensure the tightness of the connection of metal pipes without welding, a seal is installed between the protrusions.

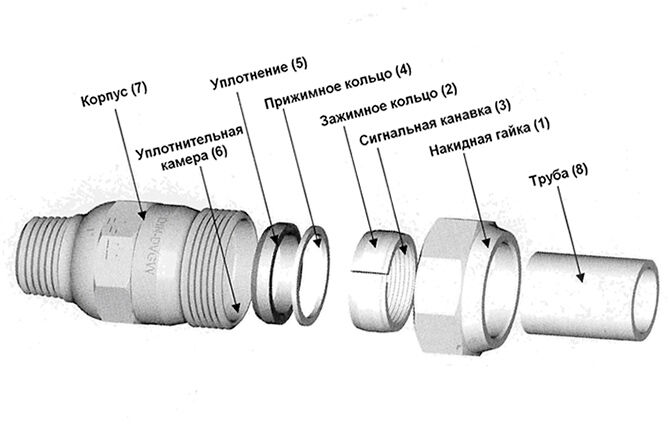

- Gebo couplings. The fitting allows you to clamp a pipe of the required diameter, regardless of the condition of its ends. Tightness is ensured by an o-ring. To connect metal pipes without welding using this method, no specialized tools are required. Enough wrenches.

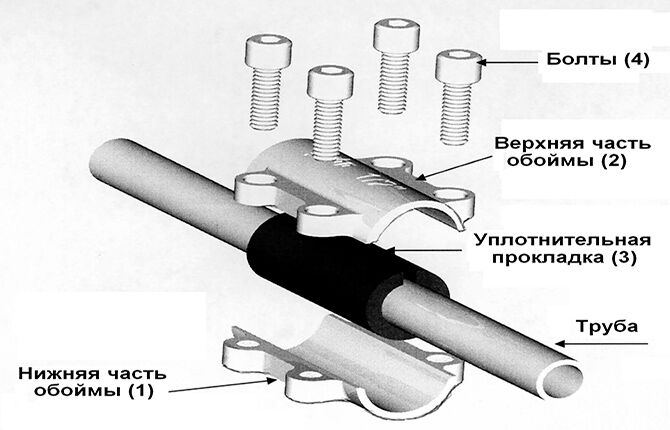

- Clamps. The method is used when a pipe breaks. The clamp is applied to the damaged area. When tightening the device, the elastic gasket is pressed to the place of the rupture.

- Repair clips. The device consists of two parts connected by threaded fasteners. Tightness is achieved by installing an elastic seal.

- Fittings. You can clamp a water supply system pipe regardless of the condition of its ends.

The installation method is selected separately for each case. For proper assembly, you must strictly follow the technology for installing parts.

Fitting method

You can connect metal pipes without welding fittings. The element is fixed on the pipeline with a specialized ring. The degree of clamping is adjusted with a nut.

Manufacturers produce fittings designed for the installation of metal pipes. The method allows you to obtain a reliable joint that prevents leakage.Fittings are installed when assembling pressure systems. The selection of an element is carried out taking into account the scope of its application.

According to their design, fittings are divided into several groups:

- Straight-through with a constant internal diameter. The pipeline capacity does not change.

- Knees. When installing such a fitting, the water supply turns at an angle of 90 or 45 degrees. Used to shift the highway in a vertical or horizontal plane.

- Deaf. They have one connection side. They are used as plugs for blocking pipes.

- Triples. They have three connection connectors. Used to branch a highway.

- Cross. Used when joining 4 pipes simultaneously.

- Transitional. The diameter of the connectors of one part is different. The capacity of the highway changes.

- Fittings. Serve for joining metal pipes with hoses.

The type of fitting is selected taking into account the location of its installation. Using clamping structures, you can connect metal pipes without welding.

Coupling method

The product is a coupling whose diameter is larger than the outer size of the workpiece being fixed. The part is placed on the end of the pipeline and secured with a nut. The joint is sealed with an elastic ring. It is made in the shape of a cone. When tightening the nut, the ring is pressed into the space between the inner wall of the coupling and the pipe.

The product is easy to install. Installation does not require specialized welding equipment. The coupling can be mounted regardless of the condition of the workpiece end.

How to install the Gebo coupling

Simplicity of installation makes the coupling in demand when eliminating emergency situations.The product can be installed by a person who does not have skills in assembling water mains. Installation is carried out in the following sequence:

- The edge of the workpiece is cleaned of corrosion and contamination. This is necessary for the best seal fit. Use sandpaper for cleaning.

- A fixing nut with internal thread is installed on the workpiece. The location of the part should be taken into account. The nut is mounted with the side facing outwards.

- Install the split ring. When connecting, it plays the role of a clamp. As the nut presses on the ring, its internal surfaces are pressed against the pipe. This way the workpiece is fixed motionless.

- Install the ring necessary to press the seal.

- Install the elastic seal and assemble the coupling.

When tightened, the nuts control the force applied to the wrench. Exceeding the permissible values will lead to damage to the integrity of the components. After assembly, a sealed joint is obtained. This is how steel pipes are connected without welding.

Connection using a repair and mounting clip

The main area of application of the design is restoring the integrity of the highway after a break. Using a clip, seal the resulting hole.

The design provides for the presence of two metal parts with holes for fasteners. Compression of individual elements is carried out by bolts and nuts. There is an elastic seal between the parts of the holder.

The pipeline at the site of the rupture is cleaned with sandpaper. Remove traces of corrosion, paint coatings and dirt. Cleaning is necessary to ensure that the elastic seal fits snugly.

A clip is installed on the highway. Before this, a sealing gasket is placed on the damaged area.The parts of the holder are clamped together with bolts. To avoid distortion, the bolts are tightened one at a time.

Pressing against each other, the halves of the clip press the seal to the place of the break. This eliminates the possibility of a leak. The repair and installation clip is considered as a temporary measure to eliminate the gust. After some time, major repairs will be required.

Flange method

The method is used when constructing pipelines intended to move liquid or gas. A person with minimal technical knowledge can connect metal pipes without welding using flanges. The work is carried out in the following sequence:

- The elements are flanged to each other. In this case, pay attention to the coincidence of the holes for mounting the bolts.

- A gasket is placed between the flanges. Its configuration must match the holes on the metal parts.

- The flanges are tightened with bolts. The gasket eliminates the possibility of leakage.

This makes it possible to connect metal lines without welding. To avoid an emergency, it is necessary to regularly inspect the gasket for integrity.

You can connect two metal pipes without welding yourself. There are several assembly options. The method is selected separately for each case. Installation requires the use of specialized equipment.

Have you connected metal pipes without welding? What assembly method did you use? Leave comments, bookmark the article and share it on social networks.

We also recommend watching selected videos on our topic.

Clamp couplings. Heating installation without welding.

How to embed a bend without welding onto a metal pipe for a water heater.

GEBO threadless compression/clamp connection.