Malfunctions of the Conord gas boiler: common breakdowns and how to fix them

The quality of heating of the entire house depends on the serviceability of the gas boiler, which is especially important in the cold season.Even the slightest breakdown can cause the equipment owner to have a panic attack, since repairing it can be too expensive. Agree, it is not always necessary to call a specialist, because you can independently figure out the reasons for the malfunction of the Conord gas boiler and repair the equipment yourself.

Despite the already established tendency to always blame the manufacturer, often gas boiler breakdowns have absolutely nothing to do with production features. They often arise due to a malfunction in the equipment settings, unstable pressure or voltage in the network.

Further in the article we will tell you what breakdowns of the Conord boiler occur most often, and how to independently restore its operation after another failure. In some cases, repairs may not be necessary because all you need to do to fix the problem is simply set the correct settings.

The content of the article:

Causes of gas equipment failure

Despite the high quality of products from the domestic manufacturer Conord, such gas boilers can fail over time.

The problem is not always the natural wear of parts, and, as a rule, this occurs only after at least 5 years after the start of operation.

If the equipment breaks down almost immediately after installation, this may occur as a result of a simple failure in the settings or a voltage drop.

Gas boiler malfunctions often occur for the following reasons:

- Voltage fluctuations in the network. Sudden surges in voltage can lead to a short circuit and, accordingly, a blown fuse that will need to be replaced with a working part. In this case, it is recommended to purchase high-quality stabilizer, which will allow you to no longer worry about voltage failures in the network.

- Poor quality water. In progress double-circuit boilers, which are also responsible for heating the water, malfunctions may occur. Heating low-quality water renders the flow-through heat exchanger unusable, so the only way out in this situation is to install a full-fledged water purification system.

- Incorrect installation. The installation of gas heating equipment should be carried out by a qualified specialist, since even the slightest mistake can lead to serious consequences. For example, incorrectly performed piping of a cast-iron gas boiler can lead to its body simply cracking at low temperatures.

In addition, the proper operation of gas equipment can be disrupted by weather conditions, which can cause the boiler to become unusable.

Since in frosty weather many users turn on the heating at full power, the pressure in the gas pipeline system decreases, which means that the boiler simply will not be able to produce the promised heat.

If you have a conventional Conord gas boiler (without heating hot water), it is recommended to install a good stabilizer, but it is better not to save on the purchase. So, you don’t have to change the fuse after every power failure, and even more so, spend a lot of money on purchasing a replacement for a burnt-out pump.

Typical problems with Conord gas boilers

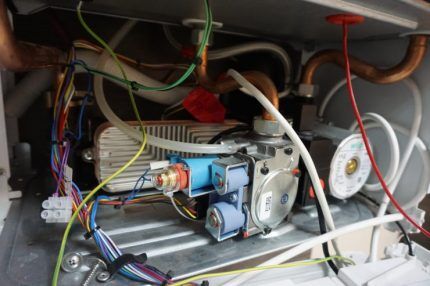

A gas heating boiler is a complex and potentially dangerous system, unqualified intervention in which can cause a large-scale explosion. All boiler systems associated with gas supply and combustion must only be serviced by qualified gas service personnel.

Despite this, there are several individual cases in which the user can independently repair a gas boiler. This applies to visible damage and all kinds of contamination that damage the pipe, chimney and other parts of the boiler.

The burner does not light or goes out

The first thing you need to do after an unsuccessful attempt to light a Conord gas boiler is to check the draft, since often its absence becomes the main obstacle.

Hold a lit match to the viewing window and observe the direction of the flame. If it deviates towards the window, then everything is in order with the thrust, and at least one problem can be excluded.

To ensure the necessary draft, it is recommended to open the window to the boiler room. If even after this the draft does not appear, you should check the remaining parts of the boiler for contamination. Thus, the presence of draft in the chimney pipe indicates contamination of the boiler itself, which will need to be disassembled and thoroughly cleaned. If the chimney becomes dirty, you will have to clean it yourself.

If, even with good draft, the boiler does not ignite, it means that a breakdown has occurred in one of the main systems of the device. For example, due to voltage fluctuations in the network, the operation of the fan that circulates air throughout the system may be disrupted. As already mentioned, the best option is to install a voltage stabilizer.

In addition, the boiler may not work due to a malfunction traction sensor. If, after the first ignition of the Conord gas boiler, the flame goes out, and a second attempt is also unsuccessful, it is worth checking the sensor and shorting the terminals together. And only if this does not help, it may be necessary to replace the traction sensor.

The boiler is smoking - what to do?

This malfunction can occur in both wall-mounted and floor-standing models. If immediately after turning on the ignition unit soot begins to appear, this means that the air in the fuel is in insufficient concentration and needs to be adjusted.

There is only one way to eliminate the problem of soot emission - by adjusting the air on the burner.To do this, you will need to find the adjustment washer and adjust the air supply in the desired direction without turning off the burner. It is the burner flame that will help you determine in which direction the washer needs to be turned.

If there is an excess of air, there is a noticeable hum and separation of the flame from the burner, and if there is a lack of air, the red fire will be “diluted” with yellow inclusions. The normal ratio of air and gas is determined by an even blue flame without any impurities.

Burner flame separation

If, when starting a gas boiler, the flame is unstable and periodically comes off the nozzles, then the problem most likely lies in the draft supply. Any changes in the flame dynamics lead to the sensor triggering and, accordingly, the system shutting down. In this case, it is recommended to check the chimney for contamination and, if necessary, clean it.

Also, the problem of flame separation may arise due to deformation of the nozzles, which could occur during the cleaning process. It is because of the deformation of the holes that the gas flows unevenly. To restore the operation of the injectors and normalize the flame, you will need to replace damaged parts.

The flame may come off the burner due to elementary gas valve malfunction, pressure sensor or diode bridge. In this case, immediately after identifying the cause of the breakdown, you need to purchase a new part and replace the broken element yourself.

The coolant does not heat up

If the gas boiler does not heat the water, then the first thing to do is check and adjust the settings. If there are no subsequent changes in the operation of the boiler, it is necessary to check the heat exchanger for the presence of scale deposited on the walls of the channels. A thick layer of plaque significantly reduces the heat transfer of the device, while the amount of fuel consumed only increases.

There is no need to buy a new heat exchanger, because accumulated scale can be removed using special reagents. In this case, a solution of citric acid is ideal, because unlike other means, it does not affect the metal structure of the heat exchanger, so it does not damage the part. This solution is used for cleaning copper, brass and stainless steel appliances.

Read more about how to properly clean the heat exchanger of a gas boiler. this material.

Also, the problem may lie in the operation of temperature sensors that have failed due to a malfunction of the automation. Having identified a breakdown, you can repair the Conord gas boiler yourself.

To restore the operation of the entire system, it is enough to replace the broken parts. If the boiler does not heat water due to a blocked pump, then in this case you can unblock it yourself by setting the necessary boiler settings.

The boiler is loud

Over time, noise and crackling noise may occur in the operation of gas equipment, caused by a large accumulation of salts on the walls of the radiator.It is for this reason that the water overheats and boils, so the accompanying noise often resembles the sound of a boiling kettle.

Loud noise emanating from a Conord gas boiler may occur due to “migrating” pieces of scale, which break off and hit the walls of the device during the heating of water. This process can lead to clogging of the pipes, and, consequently, to water obstruction.

To avoid serious consequences, it is recommended to clean the heat exchanger in a timely manner so as not to spend money on purchasing a new part.

During operation of the boiler, a noticeable whistle may be observed emanating from the nozzles, which is due to the accumulation of air in the line. To eliminate the problem, it is enough to release excess air from the line, and the noise will stop.

Conclusions and useful video on the topic

You can find out why there is a bang when you turn on the Conord boiler from the following video:

This video explains in detail why the wick of the Conord boiler does not light, and how to fix this problem yourself:

Like any other equipment, gas boilers can break down from time to time, thereby depriving the residents of the house of heat, which is so necessary during the cold season. To restore the operation of a gas boiler, it is enough to correctly determine the type of breakdown, after which you can carry out the repair yourself without resorting to the help of a specialist.The article revealed the most common malfunctions of Conord boilers, as well as ways to eliminate them - replacing broken parts and cleaning contaminated systems.

If you have already repaired a Conord gas boiler yourself, then please share your experience with our readers. Tell us what problem you encountered and whether you were able to repair the boiler without the help of specialists. You can leave your comment in the special field immediately after the article.