Maintenance of Navien gas boilers: instructions on installation, connection and configuration

The South Korean manufacturer Kyung Dong Navien offers Russian consumers a wide range of boilers of different capacities and design variations.The equipment is adapted to the specifics of domestic communication networks and local weather conditions. Reliable and functional units are rightfully in demand.

People buy from us mainly wall-mounted models, which are attractive due to their compactness and economical consumption of gaseous fuel. The equipment presented for sale is Russified, thanks to which setting up a Navien gas boiler can be done without any problems. Moreover, it works “perfectly” in various modes.

We will talk about how to install a home heater to prepare coolant and hot water. We'll show you how to set it up depending on the period of the year. Here you will find valuable recommendations, following which you can significantly extend the operating life of the boiler and prevent operational failures.

The content of the article:

It is not without reason that boilers made in South Korea with the Navien logo are leaders in ratings compiled based on the opinions of service technicians. They work flawlessly, comply with Russian standards, and have an impressive list of qualities that ensure comfortable operation.

The benefits that owners of gas heating units can take advantage of include:

- Frost protection. A stable operating system that eliminates the formation of ice plugs in pipes and the unit.When the ambient temperature drops below +10º, the circulation pump is automatically activated; when it drops from +6º, the burner starts.

- Protection against power surges. The safety and continuous operation of the unit is ensured by a device that eliminates failures and stops. The SMPS chip (an abbreviation for Switchet Mode Power Supply) built into the microprocessor is triggered by fluctuations in the power supply.

- Protection against low pressure in the gas pipeline. The units can withstand pressure drops in blue fuel supply systems without disruption. They do not stop working even if the pressure is only 4 mbar.

- Use when water pressure drops. Boilers from the South Korean manufacturer work efficiently if the cold water pressure at the inlet to the units drops to 0.1 bar.

- Unique heating technology. The equipment is supplied with a remote control panel equipped with a temperature sensor. The readings it takes are instantly transmitted to the boiler, which turns on and off in accordance with changes in the temperature background within the object being processed.

In addition, Navien brand boilers are equipped with excellent automation and a wide range of safety systems that interrupt the heating of coolant and sanitary water in the event of a threatening situation brewing or arising.

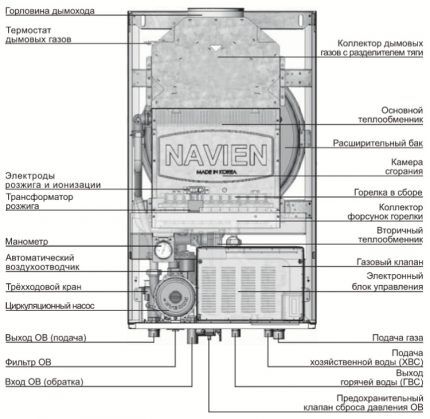

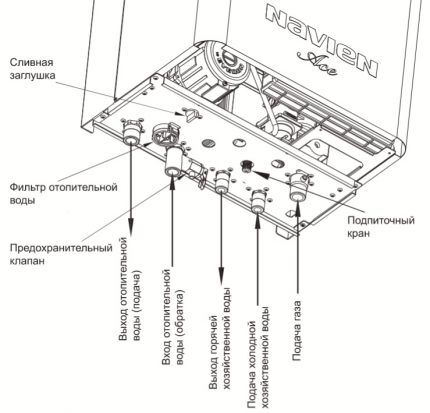

To control the water pressure within the boiler, it is equipped with a pressure gauge. There is a safety valve that allows you to reduce the pressure if it is higher than the norm regulated by the manufacturer.To prevent overheating, filters are installed for heating, water supply, and gas.

Installation and connection procedure

Let us immediately note that the installation and connection of any model of Navien gas boiler, as well as its first start-up, must be carried out by a specialist from an authorized service structure.

Otherwise, the manufacturer will not fulfill warranty obligations. However, the owner should know how the process is carried out in order to control the work of the hired contractor.

Providing conditions for installation

South Korean equipment for heating coolant and hot water can process both main gas and liquefied gas mixtures. The blue fuel options available for use are indicated on the plate. It is attached to the right side of the body.

To connect the boiler, you will need to connect a power supply line to the location. The device cannot be connected to the electrical network through adapters or extension cords.

Requirements for the electrical line for the boiler:

- The power supply source for operating a boiler of this brand must have the following parameters: 220V, 50Hz. Deviations from these standards may result in either fire or loss of performance.

- It is prohibited to connect any electrical equipment parallel to the boiler to the source. Failure to comply may result in a short circuit.

- The socket should be located 30 cm from the heater body.

- The unit must be located at least 60 cm away from electrical appliances of all types.

- Boiler body should be grounded without fail.

In the room intended for the location of gas equipment, a flawlessly functioning exhaust and supply ventilation system must be organized.

The window should have a transom that can be easily opened for ventilation. The door should have a ventilation gap or grille at the bottom.

It is not allowed to locate gas equipment in rooms with a characteristic high level of humidity: in bathrooms, in swimming pools, in showers and bathhouses. Dampness and insufficient air flow interfere with the normal operation of the boiler. In addition, its operational life is reduced.

Boilers cannot be installed in open areas.They are not intended for contact with atmospheric negativity. It is prohibited to place where explosive and flammable substances, as well as bulk building materials, are stored.

Choosing a location

In most cases, wall-mounted gas boilers are located in kitchens or hallways that have a window or only a vent for ventilation.

For installation of floor models install boiler rooms separated from residential and functional spaces in the house. In any case, sufficient space should be provided for convenient maintenance and repair of the unit.

Let's consider the rules for choosing a location for a wall-mounted gas appliance as the most common solution for our compatriots:

- Hanging is allowed on a wall made of non-flammable building material.If the wall material is capable of igniting and sustaining combustion, the surface must be lined with a non-combustible finish.

- The unit must not be located near emergency exits or staircases.

- There must be at least 0.6 m between the opposite wall and the front panel of the gas equipment. A similar distance must be maintained between the boiler and any electrical appliances.

- Between the side panel of the case and the nearest structure or piece of furniture you need to leave 0.2 m.

- There should be 0.8 - 1.1 m between the floor plane and the lower edge of the unit hung on the wall.

For fastening wall model It is advisable to find a place on a load-bearing wall. If the strength of the wall is in doubt, it should be strengthened. The boiler is fixed with anchor bolts.

If there is a suspicion that the heater will make excessive noise during operation, it is recommended to use buffer substrates on the wall made of non-flammable material.

Connecting the speaker to communications

To operate a gas heater coolant and sanitary water, a dual-circuit heating device must be connected to communications. We have already talked about laying a separate power line. Everything must be done in accordance with the PUE regulations.

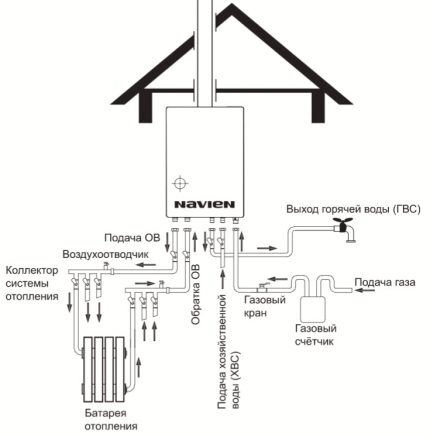

Now you need to connect branches from cold water supply systems, gas supply and heating return pipes to the boiler. And you have to remove from it the heated coolant supply line, the hot water supply pipe to the mixers and the chimney.

All stages of connecting a Navien brand gas boiler must be performed according to a diagram drawn up in advance by the gas service with which the contract was concluded and by the plumbers servicing the house. It takes into account the technical features of a particular room and the recommendations of the equipment manufacturer.

After installation, all connections of pipes transporting water must be checked for leaks. Both heating and water supply lines need to be tested. Gas pipelines also require inspections, which are simply covered with a soap solution at the connection points to detect leaks.

It is recommended to insulate pipes that are not involved in the heating process. These are partially heating routes and all water supply branches. As thermal insulation, it is better to use foam insulation that follows the shape of the pipe.

All pipelines connected to the boiler must be equipped with taps to shut off the device in the event of a threat or breakdown. The boiler should be connected to a source of liquefied gas through a reducer, and to a group of cylinders - through a gas manifold.

Upon completion of the installation operations, the boiler is started for the first time, which must be performed by a representative of the organization supplying you with gas. Then adjustments are made according to your personal preferences and requirements for the indoor microclimate, as well as in accordance with the time of year.

Features of the first launch

The first start-up and adjustment operations are carried out by representatives of the service center, who installed the boiler and connected it to communications. All actions are documented.

The owner of the equipment needs to keep these papers, because they constitute written confirmation for the subsequent fulfillment of warranty obligations.

For the first launch you need:

- Fill the boiler and the circuits connected to it with water. This is done through a make-up unit located on the bottom of the boiler, equipped with its own tap. They are also used if for some reason the pressure in the gas boiler drops during operation.

- Monitor the pressure during filling. When the pressure gauge shows 2 atm, the tap should be turned off.

- Manually remove air pockets. Next, excess air will be removed from the unit automatically, but for the first time after filling the heating circuit with coolant, they must be eliminated using a Mayevsky tap from each device, starting from the furthest one.

- Top up the water in the heating circuitso that the coolant occupies the space that was previously occupied by non-removed air.

- Bleed air from the circulation pump, built into the boiler.

After the above steps, you need to start the equipment by pressing the “Power” button. Then you need to start setting the priority temperature regime for the owners.

Specifics of the setup

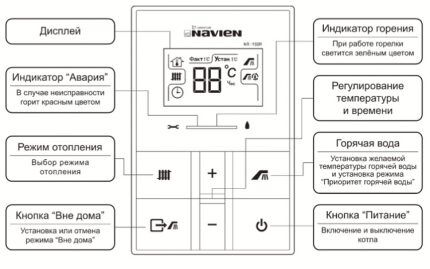

Navien boilers come with a remote control panel. It is with its help that the settings are made. All commands and modes on the panel are written in Russian, buttons for all functions are accompanied by extremely clear graphic icons.

In the lower right corner of the remote panel there is a button that is used to turn the unit on/off. One press activates the boiler in the mode set by the owner. Pressing again will stop the heater.

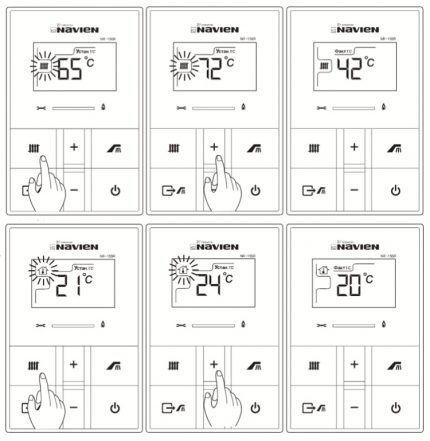

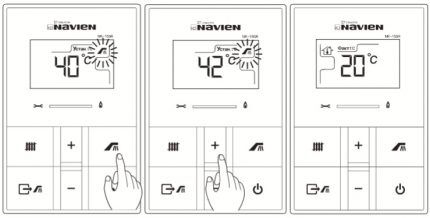

You can turn on the heating with temperature control of the coolant as follows:

- We find a button on the panel with an icon resembling a battery. Press until a similar symbol appears on the display.

- We select our priority temperature using the buttons with the “+” and “-” icons located in the center of the bottom of the panel. We increase and decrease from 40º to 80ºС in the most familiar way.

- We similarly designate the period during which the coolant will heat up.

Everything is extremely simple. If the “battery” icon on the display is pulsating, then it shows the parameters that we have just set. If it stops blinking, it means it displays the actual temperature at the moment.

To set the mode according to which the boiler will start/shut down, focusing on the temperature background in the room, perform the following steps:

- We find a button on the panel with an icon resembling a battery. However, now we wait until an exaggerated image of a house with a “thermometer” inside appears.

- We return again to the “+” and “-” buttons to select our priority temperature background in the room. It varies in the range from 10º to 40ºС.

- A flashing house will show us the selected temperature, a non-blinking house will show us the actual temperature parameter at that moment.

Upon completion of all the actions performed, there is no need to press any buttons to save; the settings we selected are automatically saved.

You need to choose the optimal temperature for preparing sanitary water as follows:

- We find the button for controlling the “Hot water” mode.Press it and wait for a pulsating image of a working shower head to appear in the upper right corner of the display.

- Again we use the “+” and “-” buttons to find the optimal temperature for us. It can be set in the range +30 – (+60)ºС.

- We are waiting for the shower to finish blinking. This means that the boiler automatically saved the set level and switched to operating mode in accordance with it.

If the unit is to be used only in the summer or was purchased for the preparation of hot water, the “Hot water priority” function comes into play. The procedure for selecting it is slightly different from the method described above. The difference is that a double symbol will appear: a shower and a circle of three arrows.

Selecting this mode will force the boiler to heat sanitary water even when it is not in use. Those. the heater activates and prepares water, and after 10 minutes it turns off if no one opened the taps during this period.

If the heated water is consumed, as indicated by an open tap and a drop in pressure, the boiler will always prepare water at the set temperature. It works to heat water only when there is a need for it. If you switch the equipment to another mode, this one automatically stops working.

You can switch the Navien boiler to a mode that only heats water by using another function. Our compatriots know it under the name “Winter-Summer”. However, it is correct to call it “Outside the Home”. The button to select it is located in the lower left corner.

There is a timer to set the period of continuous operation of the gas unit and turn it off when it is not particularly necessary. It is controlled according to the absolutely simple scheme described above. The range of capabilities of the timer device is designed for an interval from 0 to 12 hours.

Recommendations for use

To ensure that the coolant and sanitary water heater does not malfunction during operation and does not fail prematurely, you must strictly follow the operating rules. You just need to remember them and try not to violate the instructions specified by the manufacturer.

If you do not need the heating system to operate in the next two to three days, do not disconnect the equipment from the power supply. When the power supply is interrupted, the anti-icing system stops. During this time, ice must not grow in the boiler or in the pipes connected to it.

However, if an ice plug has already formed, do not despair. You probably have an effective and quite affordable means to eliminate it at your disposal. Use a hairdryer at home and warm up the pipes. And if he didn’t help, call the gas workers.

If in winter a long “downtime” of the boiler without operation is planned, all water from it and from the systems it processes needs to be drained. There is no need to create the slightest prerequisites for the circuits to freeze. Believe me, the consequences can be not only dire, but also extremely dangerous.

Before turning on, try to constantly check whether the water supply and heated coolant outlet taps are open, as well as the supply of blue fuel. Do not forget that when working to heat without the medium that the unit is required to process, it may burn out.

Never wipe the body of a running electrical appliance with a damp cloth. If you want to tidy up your Navien gas boiler, see how to turn it off. To do this, first interrupt the operation with the activation button on the remote panel, then disconnect from the power supply line.

Remember that the remote panel must not be positioned in such a way that it will inadvertently generate external heat. There is no need to install it in an intensely sunny corner or next to a heating device. This way, all temperature settings will be lost due to the fact that the sensors record an unrealistic temperature.

Clean the heating system and cold water inlet filters regularly. Their clogging will force the unit to unnecessarily increase the heating power in an attempt to maintain performance. As a result, overheating and failure of important functional systems of the equipment will occur.

If there is a need for boiler conversion Navien to use liquefied gas, invite a gas service employee. He will change the module with gas injectors and reconfigure the boiler. Please note that translation work can be completed independently if you have no doubt that you can carry it out efficiently.

Do not use it yourself and make sure that the invited specialist does not use used pipes to connect gas processing equipment.This is fraught with serious poisoning and damage to property worth a very impressive amount.

Conclusions and useful video on the topic

Detailed instructions on connecting and commissioning a wall-mounted version of a gas boiler:

Knowing the specifics of installing, connecting and configuring a gas boiler is useful both for independent home craftsmen and for owners who invite plumbers and gas workers to perform the work described above.

Possession of information will ensure the correct execution and proper control of all actions. Then the boiler will work perfectly, will not create problems and will last for an extremely long time.