How to choose and install a door closer on a kitchen cabinet: step-by-step instructions, mistakes

Furnishing a kitchen wall is an art.Doors on cabinets and drawers are designed so that the doors can be easily opened and closed without slamming or falling. Therefore, installing kitchen closers is as important as choosing the configuration of kitchen furniture.

The content of the article:

Types of closers for the kitchen

Quite a lot of various devices for smooth braking of doors or drawers have been invented. Not all of them turned out to be easy to use. For example, classic spring closers have not caught on in the kitchen, although they are still used in wardrobes.

The main reason for installing a closer is the desire to make the process of closing a vertical cabinet door smoother. The doors of the cabinets on the top row of the furniture wall in the kitchen were usually located at a decent height - 200-230 cm above floor level. Therefore, the door is always made with a top-mounted canopy. Installing a door closer helps to avoid impact, the sash closes softly and silently.

Similarly, installing a closing mechanism on a drawer simplifies its opening and ensures shock-free closing. Since doors, doors and drawers in the kitchen are opened much more often than on any other furniture in the house, installing door closers makes the process more comfortable, protects the furniture from sharp impacts and extends its service life.

Types by mechanism of action

Main function closer - compensate (dissipate) excess energy of a moving cabinet door or drawer. The dispersion mechanism in the closer is selected depending on the weight of the door (frame):

- Mechanical closer. Used only on light vertical doors of wall cabinets. When the door is closed, the hinge eccentric rotates and for a moment rests against the metal spring-loaded “heel,” thereby slowing down the movement of the door just before it closes.

- Oil compensators. Installation is recommended for the kitchen on all solid door leaves, as well as on kitchen drawers. A rod attached to the door pushes the piston, as a result, oil flows inside the closer through a small calibrated hole and absorbs excess energy.

- Gas mechanisms. The principle is the same as that of oil, but gas is used instead of hydraulic fluid. Recommended for installation on all hinged cabinet doors weighing up to 3 kg. Service life is up to 5 years for Chinese devices, 10-12 years for mechanisms manufactured in the European Union.

Gas closers are best suited for the kitchen; they are easy to install and do not require additional maintenance or configuration. In addition, failure of the appliance does not threaten oil stains all over the furniture façade of the kitchen. Almost all models are disposable and cannot be repaired well or cannot be repaired at all. You need to think carefully before installing furniture closers with a gas chamber.

When installing mechanical closers, they require certain qualifications to set up the work. Branded devices can last 10-15 years.

Most often, the mechanism does not break, but wears out or, in conditions of poor ventilation in the kitchen, becomes overgrown with a greasy coating.Repair is not provided, it is easier to replace with a new one.

Oil closers in a kitchen work for 10-12 years. Installation is simple; only some models can be repaired. The main advantage of the hydraulic mechanism is that the device does not fail at once, like gas or mechanical ones. It’s just that the smoothness of the ride begins to decrease over time.

But there may be other reasons for poor performance. For example, a broken fastener. Most often this applies to retractable closers or any other furniture in the kitchen with hidden installation of the device.

Types by type of fastening

Installation of most door closer models is carried out using an overhead method. Moreover, in a kitchen environment, it is recommended to use protected models or install them inside a cabinet (drawer) so that the mechanism is less exposed to fatty deposits.

For example, a gas lift is installed inside a cabinet, a bracket with a movable rod is attached with self-tapping screws to the inner surface of the door, and a gas compensator is installed inside to the side wall of the cabinet.

Oil closers, as a rule, are also mounted in a hidden way on the inner wall. Most manufacturing companies require that the mechanism be placed inside the furniture, not necessarily embedded in the wall of the cabinet or door. In some cases, a special pencil case is installed for the door closer to operate. For example, a drawer device is mounted above the guide rails in a special holder.

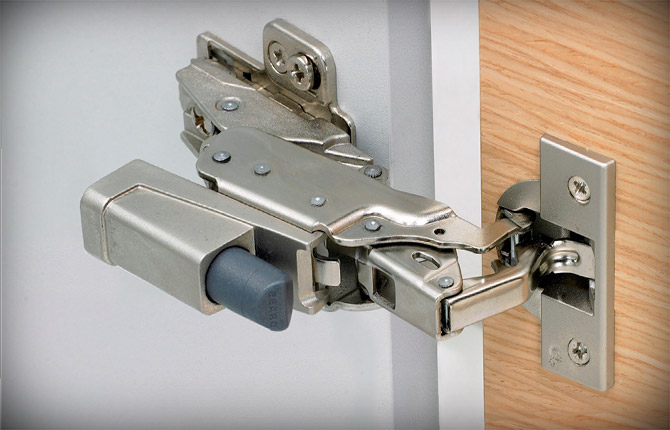

The only exceptions are hinges with a built-in closer. The mechanism with a compensator is mounted inside the cabinet on the side wall, and the counter part cuts into the sash, like a regular canopy.

Important! Some mechanisms only work for slamming.These are also door closers, but their use in the kitchen is quite limited. According to the installation diagram, the housing completely crashes into the cabinet wall and blocks the impact load if the sash is slammed too hard.

Such structures are difficult to maintain, and the working rod in a kitchen quickly becomes contaminated with fatty deposits. If you do not maintain it, the device may jam after only a year of use in the kitchen.

Types by type of lift

Most of the simplest closers, installed on hinges or embedded in the cabinet wall, serve only to softly close the door. This is often necessary due to operating conditions. For example, if you choose a cabinet with glass doors for the kitchen.

All case models of door closers are used as a service mechanism. That is, the device not only gently guides the door, but often its design allows you to fix the door in the open position, and some models allow you to fix it even in an intermediate position. Opening the door a crack can be very useful if the kitchen is undergoing general cleaning and you want to dry out the cabinet by leaving it open overnight.

Scheme for lifting the door with a closer:

- Traditional swing option. Usually this is a gas lift or eccentric mechanism. Most kitchen wall cabinets are equipped with hinged doors with a door closer and lock in the upper position. It is clear that some furniture in the kitchen is made with lower hinges. In this case, the closer rod serves as a limiter.

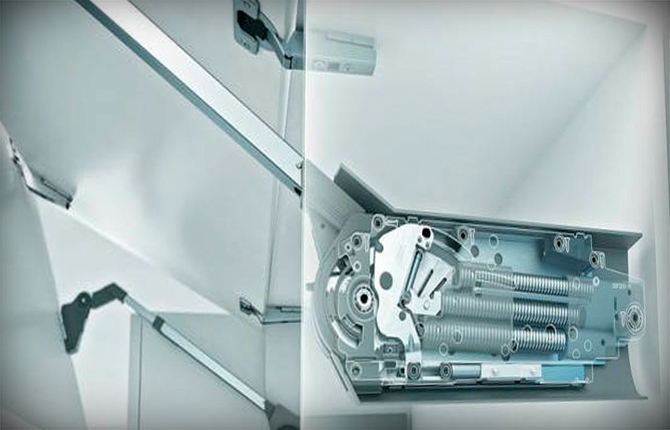

- Installation of door closers instead of traditional hinges. In this case, the sash moves away from the plane of the wall cabinet and rises upward, simultaneously making a turn.A convenient scheme in cases where there is a ventilation duct in the kitchen above the wall cabinets or a niche with lamps is installed.

- Installation on a double door closer. Complex case models are used. It is used in cases where wall cabinets in the kitchen are made in the format of closed shelves. Instead of the traditional hinged design, the doors open vertically, like blinds. In this case, the closing mechanisms perform the functions of additional loops and guides at the same time.

This scheme is becoming more and more popular, since open doors do not take up free space in the kitchen. In addition, according to the installation conditions, the lower shelves remain free from any mechanisms, which is often a serious problem when arranging a dish dryer or simply storing large utensils.

How to choose a door closer

The most common model remains the standard gas mechanism, or gas lift in other words. It is used on 90% of all ready-made furniture facades for the kitchen. Very simple installation, you can always replace it yourself. If double horizontal doors are not used in the furniture façade of the kitchen, then all cabinets with lifting or folding doors can be equipped with gas closers.

Complex case models with a built-in fixation system at different opening levels, an oil compensator, are quite expensive, require correct adjustment. Repairing a cabinet closer is quite possible to do it yourself, but purchasing components and spare parts is often more expensive than installing a simple gas appliance.

Therefore, such schemes are used only for custom-made kitchen furniture.But even in this case, it is better to coordinate the choice of hinges and closers with the designer or technologist before starting to manufacture the furniture façade for the kitchen.

If the wall cabinets in the kitchen are made according to the classic design with doors that swing open to the sides, then there is no particular need to install gas or oil mechanisms. Moreover, the more complex the device, the more free space it takes up inside the cabinet.

When opening the doors, the owners automatically hold them with their hand. For soft closing, it is enough to install overhead spring closers. In this case, it is better to buy ready-made hinges with a built-in compensator; they are more durable. But if the furniture has already been purchased ready-made, then you can install additional expansion joints yourself.

Step-by-step instructions for installing a door closer

Simple mechanisms used on typical kitchen furniture facades do not require special preparation. To install, you just need to correctly mark the mounting location on the cabinet flap. In this case, it is better not to rush with the final tightening of the screws. The reason is that the installation of the closer almost always affects the operation of the hinges. It will be necessary to additionally adjust the lift or look for a new type of closer for the kitchen.

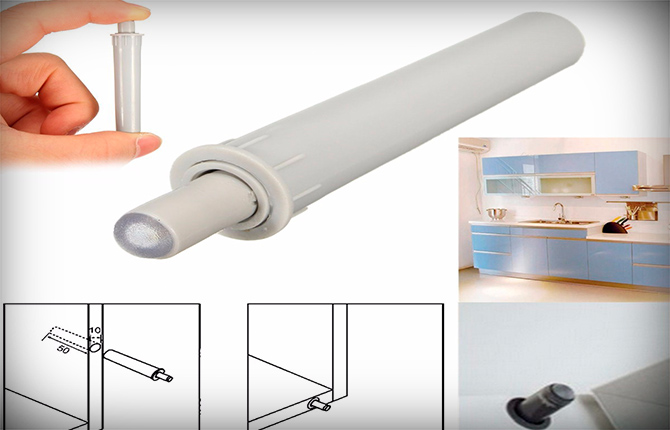

Installation of mortise devices

The simplest option is to install a mortise (push-button) shock absorber-closer. Essentially, this is an ordinary capsule with a spring and an oil chamber. The dimensions of the closer allow it to fit into the end of any wooden furniture in the kitchen.

All you need is to choose the appropriate door closer model. It is best to use products from well-known manufacturers of kitchen furniture fittings:

- HAFELE is a German brand, one of the best manufacturers of accessories;

- HETTICH is a manufacturer of door closers of all types for any furniture, including kitchens;

- Italian SIRO is one of the best manufacturing companies of mortise closers.

To install, you need to cut a hole to the depth of the housing and insert the closer; after the depth of the hole is adjusted, the closer can be sealed with transparent silicone.

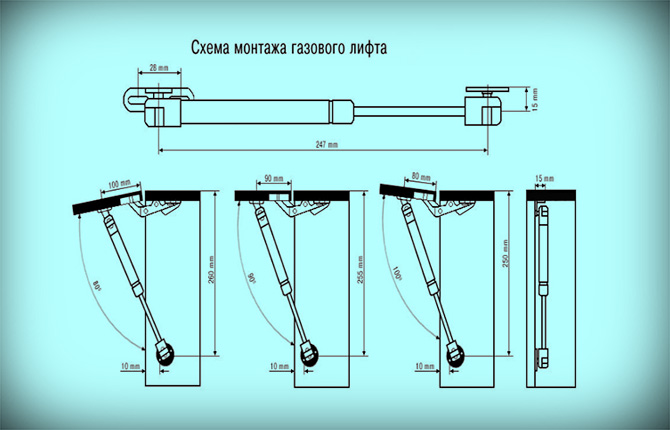

Gas lift installation

First of all, you need to choose the right door closer model. There are a number of gas elevator models designed for specific weights and loads. You cannot buy a dozen gas closers and install them on all the doors of the furniture façade of the kitchen. For example, the 100N marking means that the gas lift is designed for heavy sashes. Installation on a lightweight door will lead to premature failure of the hinges.

Most manufacturing companies complete door closers with everything necessary that may be required to install the device. First of all, you will need a screwdriver, a pencil and a template.

The sheet with the contours of the fastenings is laid out on the inner wall so that the cut of the template coincides with the front edge of the board. This is the way to mark any drawers with hinged doors in the kitchen. Using a bit inserted into a screwdriver, holes are made for future self-tapping screws. All that remains is to drill and secure the bracket connected to the closer body.

Next you need to determine the height of the sash. It is chosen based on the height of the kitchen ceilings, the location of the drawer, or personal preferences. The open position of the sash depends on the distance selected for the bracket during installation.

The smaller the distance, the higher the rise of the sash. After installing a gas elevator, it is necessary to check and adjust the operation of the hinges.If this is not done, the gas closer will not last long in the kitchen. On average, the service life of an elevator is half that of a furniture hinge.

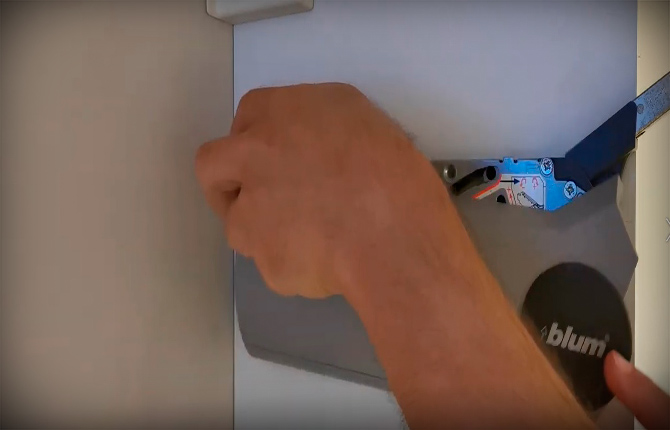

Installation of a cabinet closer

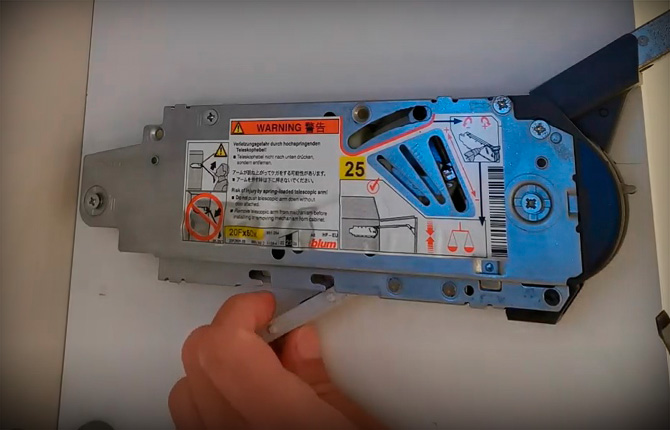

If possible, then for kitchen furniture it is better to use BLUM AVENTOS universal cabinet hinges, version HK-S. This model is much more convenient and reliable to use, especially in the kitchen. Installing a door closer on a kitchen cabinet is not difficult, but you will need to carefully follow all the instructions.

One cabinet in the kitchen will require two lifting mechanisms. Installation is carried out strictly according to size, from the inside of the sidewalls. When purchasing, you need to pay attention to the drive force. There will be Latin letters on the case or in the instructions. You need to install the option that suits the weight of the sash.

The easiest way is to install it on a disassembled cabinet before installing furniture in the kitchen. The mechanisms are always accompanied by instructions that describe the marking scheme.

The first step is to mark drill points under the centering pins and drill holes to a depth of 5 mm. Next, you need to insert the pins and “fit” the closer body itself onto them.

Pressing the body tightly with your hand, you need to tighten three screws with a screwdriver. Moreover, this is done into the body of the sidewall without any preliminary drilling. Only in this case the installation will be durable and accurate, and the closer will “live” in the kitchen for at least 15 years.

A similar method is used to install the second device on the left (or right) side.

Next, according to the diagram in the instructions, you need to attach two support brackets to the cabinet door.Plastic stops are inserted into each of the devices, and you can attach (snap) the door to a wall cabinet for the kitchen.

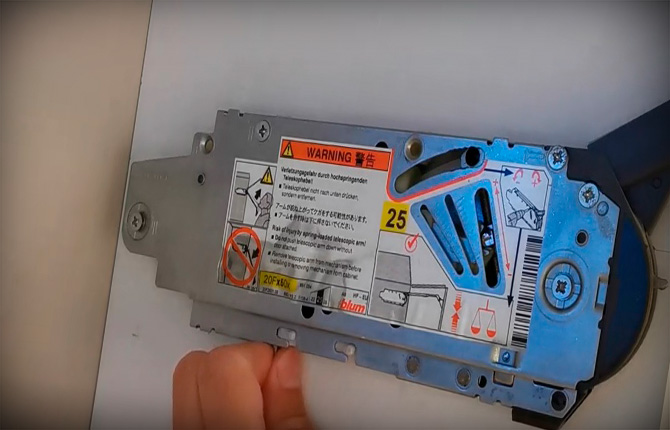

But first, the operation of the mechanism needs to be adjusted.

It is necessary to set the backpressure value of the closer. Its value determines with what force the sash will have to be closed. We find a screw with a scale placed on the side surface of the case, and use a screwdriver to unscrew it to “-” or “+”.

When installing, you cannot make the lowering force very large; you could rip the cabinet off the kitchen wall. If it is low, the sash will lower on its own. You will have to experiment with different cabinets in your kitchen to determine the best back pressure option.

Also, after installation, you will need to align the position of the sash along the top edge line. But this will need to be done only after all the wall cabinets have been mounted on the furniture façade of the kitchen. There is no point in doing this before; the line will still turn out uneven, even if you stretch a thread or paint cord between the kitchen walls.

How to fix a door closer

Branded devices work for quite a long time. If everything is in order in the kitchen with ventilation and exhaust hood, then the mechanism does not even need to be washed to remove accumulated dust and grease. The only part that wears out over time is the oil compensator capsule inside the closer.

The fact of a malfunction can be determined by the weak back pressure of the device when closing the sash. You can even compare how the mechanisms on other kitchen cabinets work. Oil stains may also appear on the bottom of the housing. There is no leakage of hydraulic fluid, but there is a leak, so at the bottom of the cabinet wall you can see a greasy spot covered with dust.

The first step is to remove the decorative cover from the closer.

The compensator is located at the bottom of the closer. Using a slotted screwdriver, you need to press and push the capsule forward so that the compensator disengages from the closer body.

You need to wear gloves when working, remove all the contents of the cabinet and cover the floor. If the capsule leaks, then when pressed, hydraulic fluid may appear, drops of which will scatter to the sides, some of which may fall on the kitchen floor. The oil is non-toxic but adheres firmly to any surface. If it gets on the floor or kitchen furniture, it will leave dark stains.

The damaged oil capsule is disposed of. Before installing a new shock absorber, you will need to remove dirt and stains. But the main thing is to try to establish why the shock absorber leaked. If due to natural wear and tear, then it will be necessary to install new capsules on closers throughout the kitchen.

First, let's check the operation of the lever without a compensator. If the mechanism creaks and jams, it will require cleaning and lubrication. It’s even worse if the device jams under load. This means it's time to install a new door closer.

After checking, you need to install a new shock absorber. To do this, squeeze the rod with your fingers and, in a compressed state, insert it into the lower part of the body. After replacement, you will need to check the operation of the closer and make sure that the problem was in the faulty shock absorber.

This is the only option DIY repairs. In all other cases, the mechanism is simply replaced. For an average kitchen, the service life of the appliance is 15 years.

Main mistakes during installation

Most apartment owners spend a long time and meticulously choosing a door closer model.But when it comes to installing the mechanism on the cabinet, the rush begins. As a result, the closer is installed, but somehow it doesn’t work very well.

Everything is written in the instructions

The biggest problem when installing BLUM AVENTOS door closers is considered to be incorrect markings on the sides of the shelf. First, you need to read the instructions carefully. Secondly, the installation scheme was thought out to the smallest detail by German engineers. Any attempt to make changes only worsens the quality of installation, makes it difficult to adjust the closer, and often leads to damage to the appearance of the furniture in the kitchen.

What you need to pay attention to:

- The instructions do not contain markings for drilling holes for self-tapping screws. The diagram and dimensions in the instructions are required for installing the pins. You cannot screw in self-tapping screws without pins. This is a mistake; the cabinet will be installed skewed, and a sash hanging askew will ruin the interior of the kitchen.

- Holes for the pins must be made with a drill with a depth limiter of 5 mm. Otherwise, you can easily pierce the cabinet wall; you will have to move the furniture to the corner of the kitchen to hide the hole.

- They often make a similar mistake due to the wrong choice of screw. The standard is 35 mm fasteners. Shorter ones will not hold the body, and longer ones can pierce a 20 mm thick wall.

In addition, it is important to consider the material from which the kitchen furniture façade is made. If it is chipboard, then before installing the screws it is necessary to perform preliminary drilling. Otherwise, the wrapped screw may peel off the “bump” on the outside of the sash. The kitchen façade can only be restored by replacing the lid.

Markup errors

The problem may arise if the installation diagram is not read correctly.You need to pay attention to how the dimensions are indicated on the drawing. Typically, the vertical dimension (indentation) for drilling for the pin is set aside from the outer plane of the top shelf, laid on top of the sidewalls.

This means that after closing the sash (if installed correctly), its upper edge will be flush with the horizontal shelf. For kitchen wall cabinets, this is the most common option.

Often the upper plane of the cabinet is cut between the sidewalls. For example, if the furniture in the kitchen is capital or the kitchen façade was made to order. In this case, after installing the closer, the sash will protrude above the cabinet and will completely ruin the look of the updated kitchen facade.

Adjusting the closer

After installation is completed, you need to check the operation of the mechanism. An experienced master evaluates the tension of the springs and the level of backpressure of the closer with his hand, according to his feelings.

Many owners prefer to install appliances in their kitchens on their own. The installation instructions recommend slightly increasing the tension of the springs so that the door fits snugly against the cabinet body.

It would be a mistake to immediately tighten the springs. You need to let the closer mechanism run in for a couple of weeks. During this time, the cabinet in the kitchen will be opened and closed a maximum of a hundred times. This is enough for the parts to get used to, and the tension can be increased.

Important! The screw may need to be loosened if the kitchen door slams too much.

Results

Any neat person can install the door closer on the cabinet themselves. But first you need to decide: limit yourself to gas lift or install expensive cabinet models. The choice of complex devices must be justified and installed exactly according to the instructions. Otherwise, most of the money will be wasted.

Tell us about your experience installing mechanisms, which ones do you think are best suited for a modern kitchen? Also share the article on social networks and bookmark it.

In my opinion, a gas lift is enough for a cabinet in the kitchen. You can put a couple. The German has a hydraulic closer, the load is high. It will leak before the gas lift. I can tell you from experience, the simpler the better.

The level of sensations is different. On cool door closers you just want to open and close the door.