Paving slabs Old Town - choosing the best of the best

“Old Town” is a common paving slab used to cover pavements and street paths.Buyers rated it based on many characteristics. Among them are a beautiful appearance, a variety of shades and shapes, and the ability to lay out various patterns. Each element imitates real cobblestone and has rounded edges. With its help, a unique picture is formed on the site.

The content of the article:

Configuration, colors and sizes

The “Old Town” paving material has become popular due to a number of characteristics:

- unusual design;

- wide range of possible uses;

- variety of colors;

- wear resistance and reliability.

The majority of users positively assessed the advantages of paving material in the implementation of the exterior and landscape design of the local area.

Paving slabs “Old Town” belong to the group of medium format mosaics. It is produced in a rectangular shape. Elements are manufactured in the following sizes (mm):

- 120x60;

- 120×90;

- 120×120;

- 120x180.

In addition to rectangular ones, they are available curly paving materials. They are used for sculptural pumping and necessary support. Manufacturers produce trapezoidal specimens for laying out patterns.

Dimensions with a width of 82 mm:

- 53x63;

- 63x73;

- 73x83;

- 83x93.

Thickness of paving slabs (mm):

- 40 - ideal for arranging garden paths, sidewalks with low traffic intensity, where large loads on the surface are not planned;

- 60 – used for pedestrian paths with increased traffic, for equipping parking spaces inside private courtyards;

- 80 – very durable, suitable for use in parking and traffic areas, including on the roadway.

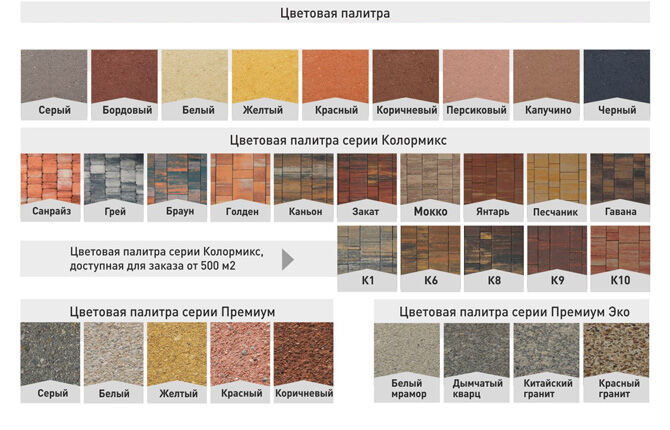

Paving slabs are produced in any color options.

Specifications

“Old Town” is produced using semi-dry volumetric vibrocompression. During the process, natural-based dyes are added to the mixture.

Thanks to this production method, paving material has the following features:

- maximum compressive strength of at least 0.5 kg/cm²;

- abrasion resistance;

- reduced water absorption;

- high resistance to low temperatures;

- weight from 94 to 189 kg/m² (depending on size).

When producing individual fragments of the “Old City”, special solutions of organosilicon compounds are introduced. This substance is necessary to impart elasticity during processing and operation. As a result, the coating does not require protective surface treatment for a long time.

Advantages of the option

Paving stone "Old Town" is available in a variety of shades. Thanks to this, the possibilities of its use in design landscape projects are expanded.

An important advantage of this paving slab is that it does not emit volatile petroleum products and other harmful chemicals when exposed to high temperatures. “Old Town” does not soften when heated. It has a high level of environmental safety. This is facilitated by manufacturing from environmentally friendly materials.

With proper installation, the formation of puddles on the coating is eliminated - all moisture flows into the recesses.

Due to the nature of production, the “Old Town” paving stone has a rough surface. This creates an anti-slip effect. For this reason, it is suitable for covering sidewalks, bus stops, and gas stations.

“Old Town” tiles are significantly superior to concrete and asphalt coatings in terms of price and quality ratio. These types of stones are easy to clean. If damage occurs, it is enough to replace the damaged “Old City” cell without disassembling the entire structure.

In the production of supporting paving surfaces, a minimum amount of raw materials is used.

Several advantages of the material should be noted:

- does not deteriorate from exposure to water;

- does not deform at low temperatures;

- allows you to implement a variety of design projects;

- does not freeze and is absolutely safe due to the existing anti-slip effect;

- has good value for money;

- provides for the replacement of damaged elements without disassembling the entire track.

Laying such tiles is an easy job. You can do it yourself in a short time.

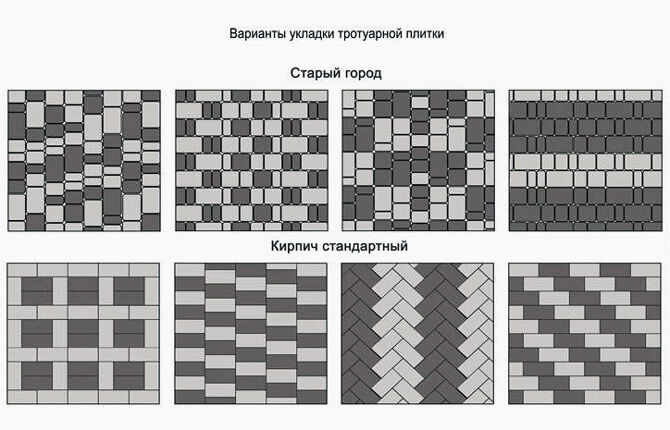

Laying methods

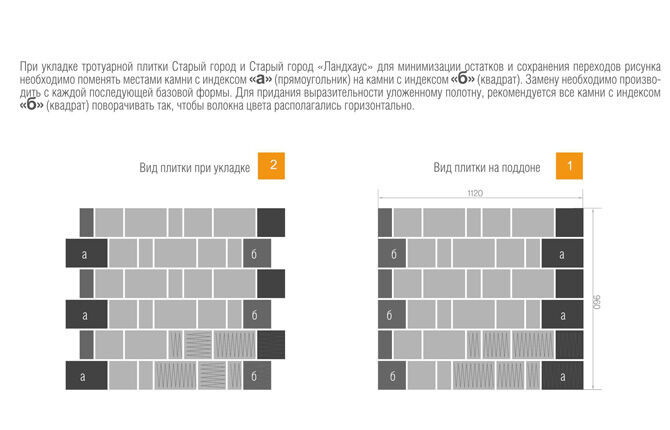

Construction stores sell different versions of Old Town paving slabs. The width of the elements is the same, but the length varies.

Segmented trapezoidal stones are positioned so that the pavement layout is maintained when turning. This does not affect the width of the passage. Thanks to this, it is easy to maintain the ratio of seams when laying. This is often used on straight sections of the track.

The most complex layout scheme is considered chaotic. It matches the seams of adjacent courses, and the tiles are laid in a unique color and pattern. This method is often used for paving individual zones and areas, leading to them with paths with the correct geometric pattern.

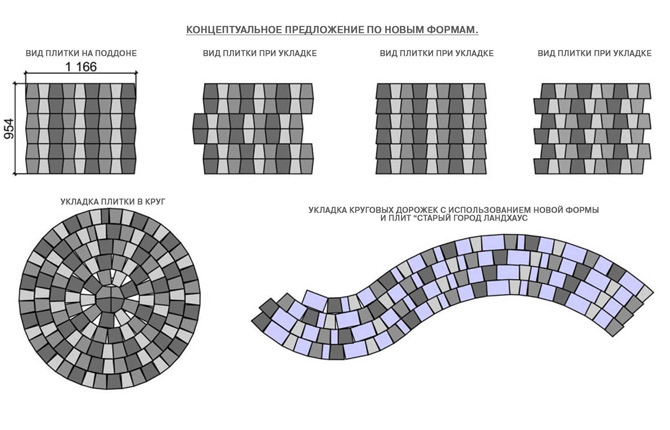

To arrange coils and construct circular sections, trapezoidal products are used, choosing the size depending on the radius of rotation. In this case masonry starts from the center of the circle and ends at the outer diameter.

Before you get started, you need to make a fragment of the track. It is made separately in size of one square meter, then the orientation is made on the manufactured sample.

Laying on a primer without a base

Before installation paving slabs, it is necessary to prepare the surface. To do this, level the soil. When creating the contours of the planned path, do not forget about the curbs. It is recommended to use twine for marking.

When installing curbs, take into account the selected primer height and the thickness of the paving stones.

The ratio of sand and cement should be 3:1. Pour primer along the length of the fragment and lay out a sample of the coating. It is recommended to distribute the material so that the center is slightly higher than the edges.

Next, all the components of the track are laid out according to the selected template. It is recommended to adjust the height of the stones with a rubber hammer. Minor slopes towards the curbs are made using a level. During rain or thaw, water will flow down them.

At the end of the paving installation, it is necessary to cover the gaps between the stones over the entire surface with a primer. Excess composition is removed.

Laying on a primer with a base

In this case, before laying the elements of the “Old Town”, you need to prepare a special foundation layer. The soil is covered with crushed stone or concrete. This prevents the tiles from sagging or coming apart.

When laying stones on a concrete base, the primer layer can be made thinner. Its task is to fix the tiles on the prepared surface.

Nuances that you should pay attention to when paving with the “Old Town”:

- Work is carried out only on dry days. Laying tiles during rainfall is unacceptable.

- For some time after installation, refrain from washing the coating.

- The remaining cement is removed carefully. Otherwise, the tile will absorb it. This will cause fading.

Since the Old Town paving stone has a rough surface, it needs to be cleaned from time to time. This prevents the tiles from changing color. It needs protection from active chemical components, since it can absorb both dry and liquid substances.

It is not recommended to clear the snow cover with metal tools. It is also not advisable to break the ice on the surface of the path with a crowbar. Otherwise it may be damaged.

Apart from these nuances, paving slabs do not require careful maintenance. It is suitable for designing garden paths, sidewalks, and parking lots as one of the successful options.

Have you used Old Town paving slabs? Save the page to bookmarks and share it on social networks.

Recommended videos on the topic of the article.

Laying tiles in the old city for screening.

Paving slabs “Old Town”.

Sources:

- https://stellard.ru/articles/10-variantov-ukladki-staryiy-gorod

- https://tvoya-plitka.dp.ua/publikacii/trotuarnaja-plitka-staryj-gorod-opisanie-i-tehnicheskie-harakteristiki

- https://protrotuarnujuplitku.ru/trotuarnaya-plitka/staryj-gorod-varianty-ukladki.html