What is decorative plaster for concrete - advantages and disadvantages

Repairing and decorating the walls of an apartment often becomes a serious challenge.Now in stores there are various materials for carrying out such work. It can be difficult to choose something specific. But concrete plaster, the advantages and disadvantages of which are discussed below, is considered the most popular finish.

The content of the article:

What is decorative plaster for concrete?

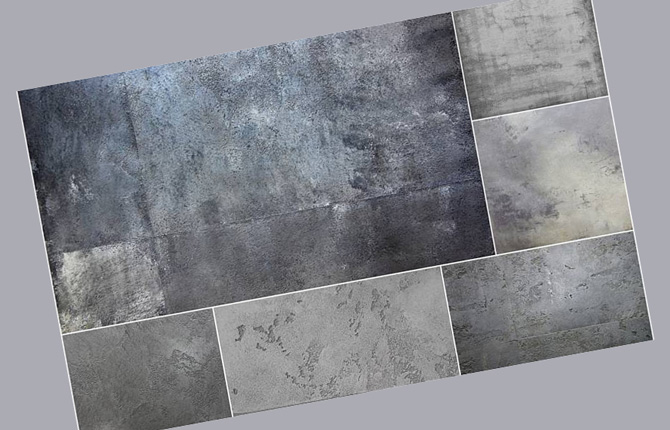

The secret of a good renovation is perfect walls. To decorate an apartment in the currently fashionable loft, grunge or military styles, decorative concrete-like plaster is ideal. These are special mixtures based on microcement or microconcrete. Using them, walls are finished quickly and efficiently, and different textures are reproduced. After renovation, the apartment looks creative and fashionable.

Decorative plaster under concrete is used to decorate various rooms:

- commercial;

- industrial;

- residential

It successfully complements the interior and combines with:

- plank floors;

- glass windows;

- wooden furniture;

- brick partitions;

- iron decorative objects - lamps, chairs and others.

Features and types of plaster

The stores offer dry, ready-made plastic mixtures for plastering. They differ in composition, advantages, and disadvantages from conventional cement. They contain various additives and additives that improve properties. The mixtures also contain sand, small pebbles or stone chips to result in a rough, heterogeneous “playing” wall.

Manufacturers produce mixtures based on microcement or microconcrete.

| Base microcement | Micro concrete base | |

| Compound | Aqua cement, microfino, polymer additives, dye, no mineral chips | Cement, modifying additives, resins, dye, quartz chips |

| Application area | Interior, bathroom, toilets, furniture | External and internal works |

| Mix structure | Very thin, homogeneous | Porous |

| Properties | Resistance to salts and chlorine, high humidity | High plasticity, adhesion, hygroscopicity |

Advantages and disadvantages

Any material has advantages and disadvantages. The advantages of concrete compositions outweigh their disadvantages.

The material is lightweight, but at the same time durable. Any walls covered with these mixtures do not become heavier.

The coating is heat resistant. Applying concrete plaster is permissible on a metal, plastic or wooden base. The composition has good adhesion to the material it is coated with. Another advantage is the fact that decorative plaster for concrete does not absorb any foreign odors (even the strongest ones).

Mixtures based on aquacement are highly resistant to moisture. Using them in rooms with constantly high humidity is an excellent solution to the problem. The advantages of plastered walls include resistance to mold, mechanical stress, and non-flammability.

The concrete composition is easy to apply and dries quickly. With its help you can create various patterns and decorative effects. Surfaces covered with this plaster are easy to clean and resistant to chemicals.

After applying the composition, there is no construction waste left. Plaster goes well with other materials used in the interior. Using mixtures, they eliminate and hide defects on the surface of the walls. The compositions also have good sound and noise-absorbing properties.

Despite the advantages, there are still disadvantages. Decorative plaster for concrete is not a cheap finishing material. In addition, when carrying out work, the mixtures have a toxic effect on the body, so follow the instructions for use and observe safety regulations.

Technology of applying plaster under concrete

At the preliminary stage, it is necessary to prepare tools and personal protective equipment. It’s easy to make a list of them based on the advice of professionals:

- Apply the composition using gloves, respiratory protection (respirator, protective mask), vision protection (glasses, transparent shield).

- Before applying plaster, the surface is cleaned of old coating. To prepare the walls, the ideal solution would be a grinding machine, spatulas, and sandpaper of various grain sizes.

- To apply the mixture, use a spatula, a trowel for layer-by-layer application, and a sponge for shading.

- To work, you will need a bucket or large container for diluting the dry mixture, an electric drill, and a mixer attachment for mixing.

The mixtures are sold both dry and ready-made, already diluted.

Before applying a new coating, prepare the surface:

- the old coating is removed;

- irregularities are removed;

- obvious defects are eliminated - cracks, chips, potholes;

- covered with primer (after this the surface must dry completely).

Then decorative mixtures are applied. If the composition is purchased in dry form, it is diluted following the manufacturer's instructions.

It is important to remember that concrete plaster sets instantly, in about 30-40 minutes.Work quickly or do not dilute too much dry mixture at once. At the end of the process, the surface is covered with 3 layers of protective varnish to prevent destruction.

Apply layer-by-layer plaster under the concrete:

- Base layer. Its thickness is determined by the size of the granular inclusions present in the composition. The layer must dry completely, then it is sanded with sandpaper (grit up to 130).

- The main (or intermediate) layer. It is left raw, since here a texture (pattern) is formed on the surface. Using a sponge, broom or corner of a spatula, create streaks, scratches, and strokes. Next, the layer should dry. After this, it can be adjusted using sandpaper.

- Special impregnation against moisture (if necessary).

- Ironing and polishing. Rub the surface with wax. The easiest way to do this is with a sanding machine with a soft felt or wool attachment.

A simple and quick way to apply decorative plaster under concrete - video tutorial.

Consumption of plaster for concrete

At the manufacturing plant, the approximate consumption of the mixture per 1 m2 of surface is indicated on the packaging. In fact, generally more plaster will be used for concrete (this is taken into account in the calculations). It all depends on:

- planned design;

- surface condition before starting repairs.

Famous manufacturers

The leaders of the Russian market are firmly held by five compounds recognized by builders:

- Knauf (Germany). Products are high quality and inexpensive. Plasters for concrete are produced on the basis of Knauf Diamond cement. There are 4 varieties sold in stores to create different surface options: rough, granular structure (coat), grooved (bark beetle), with different fractions of inclusions. Base color is white.But after plastering, painting in any other shade is acceptable. Suitable for external and internal work. After application, plastered surfaces are resistant to moisture and light mechanical stress. Easily tolerate high humidity. Not bad for insulation, sound insulation.

- San Marco (Italy). With the help of these mixtures, durable cement patterns are created in the interior. Concrete plaster is durable, breathable, and harmless to humans. Consists of cement with acrylic-siloxane copolymers. Using plaster, you can easily achieve the effect of aged concrete or formwork. Price segment – premium. There are 30 types on the market. The advantage is economical consumption of material. On average it is 0.8-1.3 kg/m2.

- Spiver (Italy). So-called Venetian plasters. Used for external and internal work. Many types are sold, creating coatings with different effects: imitation marble, natural stone, shimmering crystals, velvet, craquelure (crack effect) with inclusions. Consumption of plaster mixture depends on the chosen composition.

- VGT (Russia). There are 16 types of concrete plaster on sale with various texture effects, including bark beetle and Venetian. Suitable for external and internal work. Basically, these are textured mixtures with dolomite inclusions. Craftsmen achieve the effect of natural stone or concrete when decorating walls. The compositions are suitable for interiors with rough textured surfaces in loft and military styles.

- Lakra (Russia). Available in 3 versions. There is plaster for concrete with the effect of fur coat, bark beetle, graininess. Suitable for external and internal work. It is used for plastering walls and ceilings. Base color is white. They add color to the composition or paint surfaces already covered with plaster.High resistance to moisture, weathering, and mechanical stress. No more than 2 kg of solution is required per 1 m2 of surface.

Using plaster in the Loft style

One of the common types of finishing is plastering. Concrete-like plaster applied to the interior makes it easy to implement bold ideas. Imitation of a rough stone or concrete surface is popular and is actively used to decorate loft-style apartments.

Fans of the style are attracted by the brutality and the impression of reliability of the walls. People feel protected. This interior, in ensemble with the minimalist decoration of the apartment, gives such a feeling.

Gray concrete has different shades and a rich range of colors. In combination with interior items in loft solutions, it looks perfect. Concrete and stone with a feeling of cold emphasize the warmth of natural materials, which are additionally used in furnishing an apartment or house.

Let's sum it up

Loft, military, grunge are styles that are ideal for extraordinary conceptual individuals. Plastering to look like concrete allows you to demonstrate at a high level the possibilities of decorating a home in this style. The compositions are easy to apply, moisture resistant, with good characteristics of strength, noise absorption, etc.

Considering all the features of concrete-look plaster, this finishing option has earned the love of finishing craftsmen and designers. Therefore, now the material is often used to implement ideas in the interior of apartments and houses.

Do you like this finish? Write in the comments. Bookmark the article and share the link on social networks.

We recommend this video: How to apply decorative concrete to walls.

Sources:

- https://kvartirnyj-remont.com/shtukaturka-pod-beton.html

- https://kladembeton.ru/montazh/materiali/dekorativnaya-shtukaturka-pod-beton.html

- https://pobetony.expert/stroitelstvo/shtukaturka-pod-beton

I always use Italian San Marco. It’s very easy to work with, it dries quickly and doesn’t take long, I just have time to level everything out and then apply the relief.

And I fell in love with Knauf from the very beginning, when it first appeared on our market. I think this option has an ideal price/quality ratio.