Rating of the best bench and machine vices: characteristics, pros, cons, price

Any master would like to have, if not the best, then at least a very good vice in his home workshop.This type of locksmith equipment is often forgotten when buying the first thing that comes to hand. The accuracy of manual processing of parts with a tool depends on the model, material and quality of work of the vice.

The content of the article:

What to look for when choosing a vice?

Despite the external similarity of the models, there are differences in design, and quite serious ones. Which vice is better? — The question is complex, each master selects a tool independently. They may differ in size, shape of the locking jaws, material from which the base, slider (moving part) and drive are made.

When choosing, you need to pay attention to:

- The maximum distance over which the jaws diverge. The largest size of the part that can be secured in a vice depends on this.

- The depth of the neck or the distance between the top edge and the screw. Often this size is more important than the maximum opening that the slide and base are capable of opening.

- The presence of a rotary table, the base can be rotated in the horizontal plane at an angle of up to 90O.

- Material: steel or cast iron. Pressing jaws can be additionally equipped with rubber pads for working with plastic or wood.

- In addition to the material, you need to pay attention to the design of the screw drive. This can be a regular screw with a metric thread or a reinforced version with a powerful trapezoidal profile.

Accordingly, in the first case, the drive may consist of a pair: a screw and a mating part — thread cut inside the bore of the slide body. Second option — the supporting heel is made in the form of a bushing pressed inside the massive body.

At first glance, the difference is small, but such a screw drive with a bushing allows you to more accurately adjust the operation of the screw-bushing pair, and at the same time avoid the situation with the slider being misaligned. Moreover, if the drive breaks down, it can be easily repaired by replacing the pair with a repair one.

Comparison of steel and cast iron

There are many reasons for choosing a vice made of steel or cast iron. Steel tooling is recommended for heavy metal work in situations where the part has to be struck hammer or even a sledgehammer. Steel is much stronger than cast iron, so the dimensions are smaller, even with the same clamping force.

The steel base and slide better withstand alternating and vibrating loads.

Cast iron is always in the ranking of the best vices; they are more massive and heavier, which is their main advantage. Cast iron holds its shape well. Therefore, cast iron vices are used for metalworking work that requires greater precision and stability.

The cast iron base and slide do not “diverge” and do not float under load, especially if the part needs to be held and processed with different tools for a long time. Machine models are also made from cast iron, but they are of no interest to the average user.

Rating of the best

Requirements for equipment can vary significantly depending on the planned type of work. Usually, for simple plumbing and carpentry work, a universal model is sufficient, but in many cases it is more appropriate to use specialized models.

To select the right tool for a specific type of work, you must consider:

- resistance of the material to shock and vibration loads;

- the size of the clamping jaws and the reach of the slider;

- strength and rigidity of guide planes.

For repairing small metal parts at home, a massive universal vice with a neck depth and jaw opening of up to 100 mm is best suited. If most of the work involves massive but relatively light pieces of wood or plastic with complex shapes, then you will need to use a vice with specially shaped jaws.

Universal vice

Fourth place: Rothenberger 70705X

Small, even compact vice weighing only 8.7 kg. Belong to the class of professional equipment. Made of alloy steel, attached to the base with bolts. A characteristic feature of the design is the high strength of the housing and a reinforced lead screw with trapezoidal thread. That is, despite its compact size and low weight, the drive can develop a force of up to 1200 kg.

This model has a special jaw shape — with a longitudinal corner groove, which allows you to securely fix steel pipes and workpieces up to 100 mm in diameter. Jaw width — 140 mm, the slide moves away from the thrust plane by 125 mm.

The vice is used for manual work with metal blanks, straightening, pressing riveted joints, you can even chop metal with a chisel. The design is made in Germany, so the service life of the vice, even under intense loads, is very long, up to 20 years of operation.

Price — 42 thousand rubles.

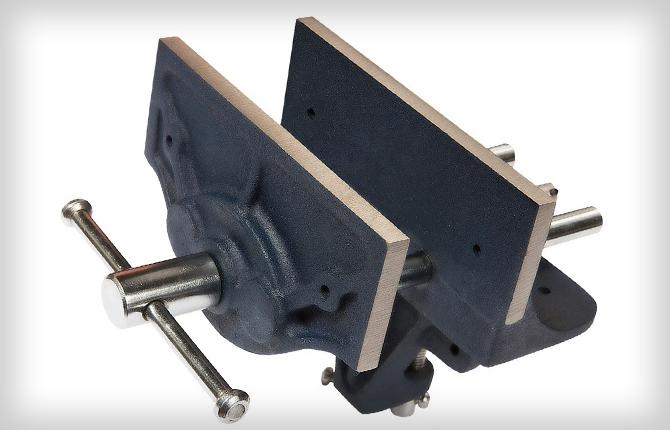

Third place: station wagon GRIFF 200 (G164012)

Often used in repair shops of all types, from car service centers to washing machine repairs. They can be found on sale in the plumbing category, but experts classify the model as a universal professional-grade vice.

The neck is often used for a variety of operations: gluing, welding, crimping and seating a bearing. The popularity of GRIFF 200 is explained by the successful design of the clamping jaws and fairly accurate screw feed.

Characteristics:

- weight — 17 kg;

- body material — cast iron, jaws and feed screw made of tool steel;

- jaw width — 200 mm;

- maximum slide stroke — 185 mm.

In the upper part there is an anvil 90x90 mm, but this is a straightening surface. Despite the fact that the body and slider are quite heavy and massive, hitting the surface is not recommended due to the cast iron base. Only slight straightening with a light hammer is allowed.

A special feature of the vice is its rather narrow frame body — only 90 mm wide. At the same time, the sponges — 200 mm, that is, the clamp overhang on one side is up to 40 mm. This makes the equipment more versatile and functional than most locksmith models.

Average price of Vulture 200 — 9000-9500 rub.

Second place: TopTul DJC01103 station wagon

The model is inferior in size and grip capabilities to most professional-level models. This vise is a universal design designed for working at a small table. Jaw width — 75 mm, distance from edge to screw (depth) — 51 mm. Lightweight, although made of steel. Weight — 8.5 kg.

A special feature of the model is the low force on the screw. You can secure the part by rotating the screw handle, as they say, with one finger. But this does not mean that the fastening is unreliable. The clamping force reliably holds a part of any shape thanks to the corrugated surface of the jaws.

The TopTul DJC01103 vice is purchased for small jobs that do not require long or heavy machining. In fact, this is an intermediate option, between a benchtop model vice and heavy metalworking equipment.

Another plus — low price, only 12 thousand rubles.

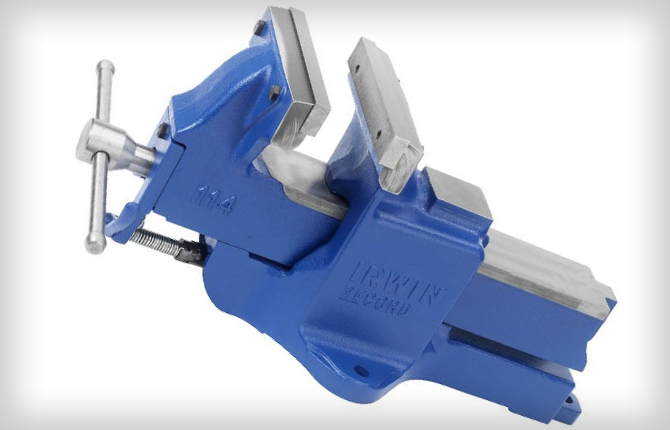

First place: IRWIN 114ZR

The first line in the rating of a short review of the best universal vices is occupied by the classic model IRWIN-114ZR. The design of the vice was developed by a well-known American manufacturer of hand tools, but they are produced in China under license.

The tool is a universal type, adapted for performing any repair, mechanical, assembly plumbing work in a home workshop.

Characteristics of the IRWIN 114ZR model:

- jaw width — 205 mm;

- opening of sponges — 114 mm;

- body material — cast iron;

- there is an anvil 90x100 mm;

- weight — 40 kg;

- Mounting to the table is flanged using M14 bolts.

Despite the enormous weight and relatively small stroke of the slide, the vice belongs to the universal class. The design uses a high-precision screw pair (screw-threaded bushing) made of hardened steel. Thanks to this, the vice is controlled much more accurately than any professional-type metalworking vice. Therefore, they are often used not only as equipment for fixing workpieces, but also for joining parts by pressing.

Another plus — The screw design is quick-release, which means that it takes much less time to retract the slide than with a conventional vice.

Price IRWIN 114ZR — 51 thousand rubles.

Specialized vices

Many craftsmen and DIY enthusiasts prefer to have several types of special-purpose tools in their own workshop.Usually it's a vice — clamps of different calibers or equipment for fixing parts of non-standard shape.

Fourth place: Rockforce RF-32936 vice-clamp

The clamp is made of cast iron and steel and belongs to the class of professional equipment. This is something between a full-fledged vice and a classic screw clamp. A vice-clamp can be attached to a workbench using several bolts, but most often they are used as a clamp for parts on complex welded rolled structures.

Characteristics:

- weight — 3.1 kg;

- the width and height of the jaws are 150 mm and 51 mm, respectively;

- working stroke of the slider — 115 mm.

The design of the vice does not have a rotary joint, since the main requirement for fixed parts — absence of shearing and rotational movements. For carpentry parts, vices are practically not used due to the small width of the supporting surface.

Average price per tool — 2500 rub.

Third place: model vice TOPEX 07A310

Very light, made of hardened aluminum alloy. A clamp-type clamp is used for fastening to the supporting surface, so the vice can be installed directly on the workbench.

Design Features:

- all parts are made of VT95, except for the clamps and screw pair, these two parts are made of hardened steel;

- jaws 100 mm wide are covered with a rubber pad;

- working space — 100x95 mm, depth — 50 mm.

- the drive is quite soft, so it is almost impossible to crush the part in a vice when clamped.

A vice is often used as an auxiliary tool, for example, in cases where a part needs to be mounted on two support points during processing.TOPEX 07A310 are optimally suited for fixing thin-walled tubes and structures made of thin sheet metal.

Second place: WILTON WWV P-6 portable vice

The design was developed for the American market, but has been produced by companies in India for a long time. Belongs to the class of carpentry clamps for household use. The amount of force developed on the screw drive does not exceed 100 kg. Pressing surface size — 140x65 mm, maximum opening of the slide relative to the base — 120 mm, so the Wilton vice can be used for gluing packages of several parts.

Wilton advantages include:

- very durable construction, nodular cast iron is used;

- precise drive, the screw pair is manufactured with high precision, operates with virtually no backlash;

- light weight — 2.9 kg.

The maximum width and height of the vice are 160 mm and 190 mm respectively. The tool turned out to be quite compact and lightweight. Therefore, you can take it to the dacha along with other tools for carpentry work and home repairs.

average price — 4000 rub.

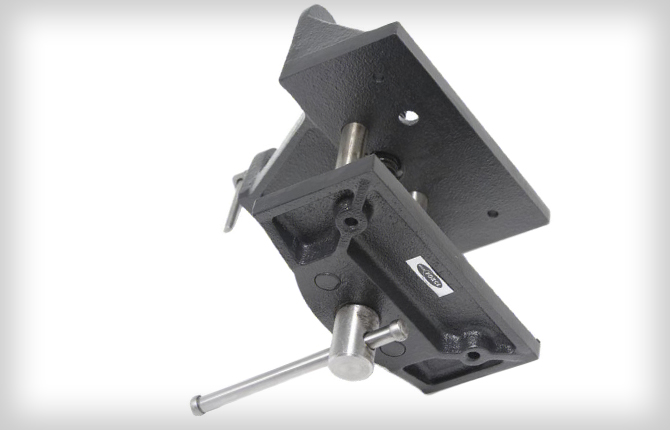

First place: multi-position vice STANLEY183069

In this design, the fixing jaws are attached to the base using an adapter hinge. This makes it possible to set the slider-base pair in almost any position relative to the table. The main purpose — processing of wood and plastic parts.

The model was developed in the USA, but produced in China.

The structure is completely made of alloy steel, the base is attached to the table using a clamp. All screws, including the main drive, have undergone heat treatment and hardening, so the vice, after clamping, maintains its position even under a load of several tens of kilograms.

Characteristics:

- weight — 1.6 kg;

- clamping plane width — 75 mm;

- clamp height — 40 mm;

- The jaws diverge to a distance of up to 70 mm.

For fastening thin-walled parts in a vice, the kit includes additional rubber pads. But, according to reviews, it is better to use regular cotton fabric.

Average price for a vice — 2200-2300 rub. According to reviews, this is one of the most successful models for amateur ship and aircraft modeling.

The best vice for a mechanic

There are usually several types of vices used in a locksmith shop. Specific models are selected in accordance with the nature of the work performed. You can buy a universal model, but this solution is more suitable for a garage or cottage. For complex work, you will need both miniature models and classic vices for working with a hammer and sledgehammer.

Fourth place: TSS4 standard

Small-sized tabletop vice for fine metalwork work, performing precise drilling, fine-tuning the diameter of holes, and lapping work. You can use a hammer and a punch, since the vice, including the screw drive, is made of tool steel. Case width — 50 mm, weight — 3.2 kg.

A special feature of the STANDARD TSS4 is the reinforced jaws with a width of 100 mm. The supporting surface is grooved, so the part can be fixed without excessive force.

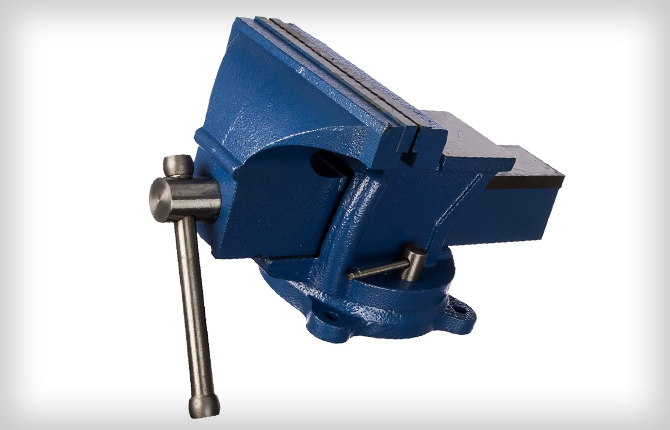

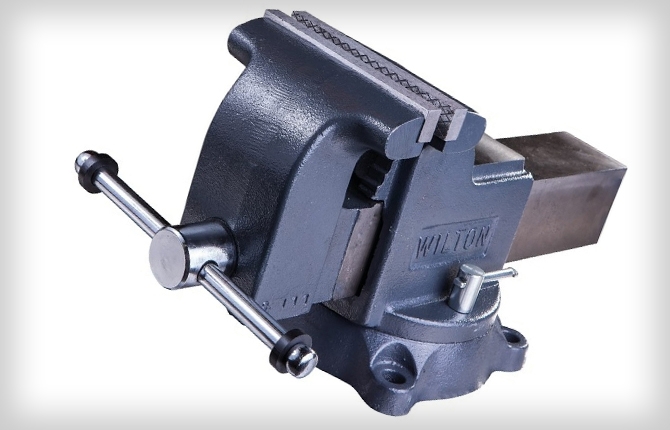

Third place: WILTON WS8 bench vice

The design provides a minimum set of functions, so the vice is most often classified not as universal, but as metalworking equipment. All parts, except the screw drive and jaws, are made of gray cast iron.

In fact, this is an excellent metalworking equipment, both for a home workshop or garage, and for industrial production.Jaw width and stroke — 200 mm. Weight — 33 kg.

The drive consists of a screw pair and a bushing, so thread wear is minimal. Handle length — 450 mm, which allows you to compress the part with a force of up to one and a half tons. The only problem — heavy weight of the rotary handle. You need to carefully release it after clamping, otherwise the thick steel rod may hit your fingers hard.

average price — 19500 rub.

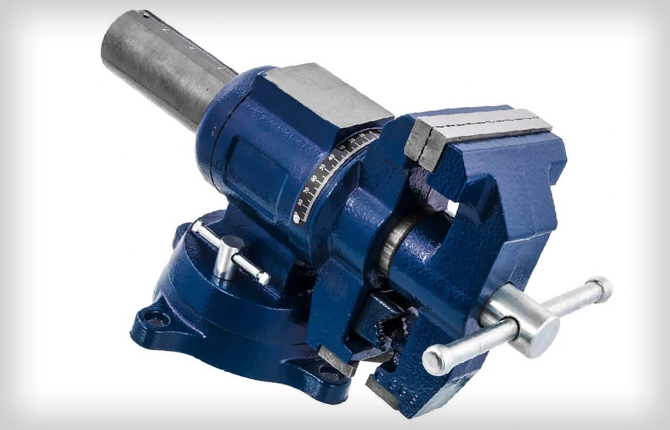

Second place: universal vice Cobalt 246-012

They are distinguished by a unique body design and a well-thought-out slider design. Instead of a rough surface with a characteristic cast texture, Cobalt looks as if it was cast from aluminum. The vice is actually made of malleable cast iron. The strength of the parts is only slightly inferior to structural steel.

Advantages of Cobalt 246:

- Sturdy base, housing is flanged and bolted to the table.

- The guide shank is made in the shape of a cylinder; this is the optimal solution if the owners use the body as a small anvil.

- Very fast screw with a short handle. After getting used to the tool, it takes a maximum of 5-7 seconds to clamp and release a part in a vice.

Often in universal models, the vise jaws are attached to the base and slider with ordinary countersunk screws. Sometimes a loose fastener causes one of the jaws to break, so in Chinese instruments this part must be regularly checked and adjusted.

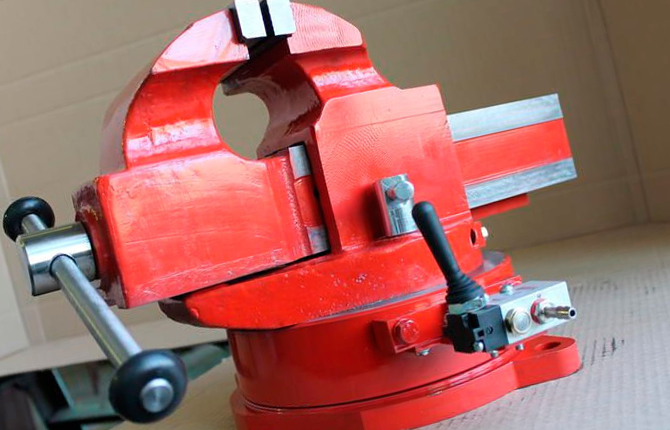

First place: WILTON Tradesman

The vice has a classic design with a massive base and a reinforced slider. The guide surface is made cylindrical. This solution is typical for all models developed by the famous company WILTON.The equipment is produced in Taiwan, so the quality of the screw drive and the main components of the plumbing equipment is quite high.

The Tradesman model features a fully enclosed screw with support sleeve. This means that plumbing equipment can be used in relatively unfavorable conditions, with high humidity or heavy dust in the atmosphere.

Tradesman Features:

- body made of impact-resistant cast iron with steel inserts;

- The design includes a rotary table, it is possible to rotate the part in the jaws 360O;

- weight — 32 kg;

- sponge size — 165x50 mm;

- maximum distance between jaws when fully open — 150 mm;

- depth — 100 mm.

The equipment has an anvil, but for straightening work it is recommended to use a hammer weighing no more than 300 g. Despite the fact that the manufacturer declares the vice to be impact-resistant, even small blows past the pad usually cause microcracks and subsequently chips.

The thread size and pitch are selected in such a way as to provide a minimum force of resistance to rotation, but at the same time the clamping surfaces move quickly enough.

To decide which vice is best to choose, you need to have at least a little experience in handling the appropriate equipment. In addition, you need to clearly understand what kind of work the equipment is needed for, whether it will be a mechanic’s workplace or just a tool for a small hobby.

Tell us which vise model you would choose for your home workshop and share the article on social networks.

At all times, we bought the heaviest vices. Steel is good for cutting something at home at a table once.And if you constantly do metalworking, then manganese cast iron, preferably cast in 50-60 years of the last century. Such vices often outlive their owners.

Yes, it’s all nonsense, for the house you need to have a small steel model in stock, for the garage you can use whatever you like. Not necessarily cast iron. I have steel ones, very old ones. They burst due to the impact, I welded everything back together and continued working. Try to brew human-thick cast iron, there are probably no masters anymore.