Plaster consumption per 1 square meter: norms, how to calculate it yourself

Plastering walls is a necessary process for leveling the surface, carried out before finishing.Depending on the goals pursued by the plasterer for finishing walls, mixtures of different compositions can be used: gypsum, cement-sand or decorative.

Each has its own density, and therefore, when applied to the walls, different amounts of material are spent. Based on this, the question arises: what is the consumption of plaster per square meter of wall and what factors influence the determination of these parameters.

The content of the article:

What factors influence the consumption of plaster?

The first, most important parameter that influences the determination of the cost of the plaster mixture per 1 m2 the surface being processed is the curvature. That is, any deviation from the horizontal or vertical plane. It will increase if depressions, cracks and other defects are added to the overall curvature.

The second, no less important factor is the type of mixture used:

- Gypsum plaster has the lowest consumption. This is due to its density.

- The consumption of cement-sand plaster is slightly higher, since the size of sand grains is larger than that of gypsum. However, if the word expense refers to the financial side of the issue, then cement-based plaster is more expensive.

- Mixtures of cement-sand composition prepared independently have a higher consumption. The fact is that the plaster offered by stores is lighter.

- Decorative plaster can have different compositions (with and without the addition of coarse fraction components), and therefore it is impossible to give an exact answer.

Attention! If you purchased the finished composition in a store, pay attention to the information left by the manufacturer on the bags. As a rule, you can find the exact answer there.

The third parameter is the method of applying the plaster layer. If all the work is done manually, the consumption will be the same; when machining the walls it is reduced. When mixing on your own solution keep the proportions. Otherwise, the density of the finished mixture will change, and subsequently the consumption of plaster will change.

Consumption rate of plaster per 1 m2 - table

For all types of mixtures there is a standard that determines the consumption of material. You can see them in the table.

| Composition name | Consumption of plaster per 1 m2 |

| Cement | For each mm of layer, 1.5-1.9 kg of mixture is spent |

| Plaster | 0.8-0.9 kg |

| Venetian | The plaster is applied in several layers. For 1 m2 of each layer you need from 100 to 600 grams of the mixture. |

| Textured | Costs increase to 1.5 kg |

| Structural | Depending on the type, the composition may include grains of different fractions. This determines the consumption from 1.8 to 5 kg. |

Attention! As mentioned above, the quality of the surface determines the consumption of the plaster mixture. Therefore, you need to add another 10% to the indicated values. This way you can avoid lack of plaster during work.

Consumption of gypsum plaster

Gypsum plaster mixture is a material with the addition of a natural mineral, gypsum.There are different compositions on the market: for rough or finishing coating. The surface of walls plastered with gypsum plaster dries much faster, which means it is ready for further work earlier.

Gypsum-based compositions are recommended for use in rooms with low humidity conditions. Even after complete drying, gypsum plaster, when the air is saturated with moisture, absorbs it, changing its original structure. Adding gypsum to the plaster makes it more flexible and lighter. This in turn reduces the consumption of the composition.

The target orientation determines the internal content of gypsum plaster:

- Fine-grained. That is, fine fraction components have been added to the mixture. This type of plaster can be used as a finishing coating and is applied in a layer of 8 mm to 1.5 cm.

- Medium grain. The composition is similar to cement mortar. The thickness of the finished layer cannot be more than 5 cm.

- Coarse grain. The main purpose of application is a rough thick layer.

Attention! The production of gypsum plaster is carried out by the same companies, known to a wide range of experienced workers. The most common of them are Rotband, Knauf, Volma, Yunis and Vetonit. Gypsum plaster 30 kg is the most common type of product packaging.

All of the above parameters in one way or another determine the cost of plaster per 1 m2. However, in order to calculate the total consumption of the gypsum plaster mixture, it is necessary to know the working surface area, the number of window and door openings, the volume of the plaster mixture by weight and, of course, the consumption rate per 1 m2.

Consumption of decorative plaster

The building materials market offers a wide range of mixtures for decorative wall finishing. Thanks to special additives used in the plaster, it is possible to obtain exclusively designed coatings.

Based on the type of base substance, there are four types of decorative plaster:

- Acrylic. It arrives on the shelves in finished form. The elastic composition, resistant to moisture absorption, stretches well, which reduces the consumption of the working mixture per square meter of the treated surface.

- Mineral. Thanks to the addition of mineral components, it is possible to obtain a durable finished surface. However, components (quartz, etc.), consumption increases significantly.

- Silicate. Potassium glass, polymer resins and mineral fillers are added to the mixture. The working mixture is plastic. Consumption is average.

- Silicone. It is made mainly with the addition of polymers.

Decorative plaster can also be divided according to the type of filler:

- Textured. This category includes compositions with the addition of mineral components, which make it possible to obtain reliefs such as “Bark Beetle” or “Lamb”.

- Structural. To create a decorative layer, improvised means are used: rollers, cellophane, foil, etc. To decorate walls in this way, a large layer of the treated surface is not necessary. As a rule, before applying the working layer and starting decoration, the wall is treated with cement-sand or gypsum plaster.

- Venetian. The difference between this type of plaster is the use of coloring pigments in its composition. The finished coating imitates the color of natural stone.

Consumption of cement plaster

Since the composition of the cement-sand mixture practically does not change, an average consumption of 1.7 kg per 1 square meter is determined for it. Of course, there are manufacturers on the market who are trying to reduce the amount of material consumed for wall decoration.

Some manage to reduce consumption to 1.4 kg per 1 square meter. This is provided that the thickness of the applied layer does not exceed 1 cm.

Let's try to calculate:

- the worker needs to plaster 10 square meters. m surface;

- since the walls do not need leveling, a layer thickness of cement-sand plaster of 0.5 cm will be quite sufficient;

- Let's take into account that the average consumption is 1.7 kg/sq.m;

- Having performed simple steps, we get the following: 10 x 0.5 x 1.7 = 8.5 kg.

However, it is worth understanding that if a worker prefers to work with self-prepared mixtures, then the consumption of plaster may vary significantly. Other factors may also affect the result:

- sand fraction - it may differ;

- brand of cement - the final numbers determine the consumption;

- additives used to prepare the mixture;

- Each manufacturer has its own recipe, which affects the result.

Attention! Despite the desire of some plasterers to work the old fashioned way, self-prepared mixtures are far from perfect, and it is better to avoid them.

Plaster layer thickness

It is better to start calculations after all defects have been identified and removed: cracks have been cleaned, poorly adhering elements of old plaster have been removed, and then sealed with mortar. If irregularities (bumps or dimples) are identified, measures must be taken to eliminate the deficiencies.Upon completion, carry out calculations and prepare the surface for plastering.

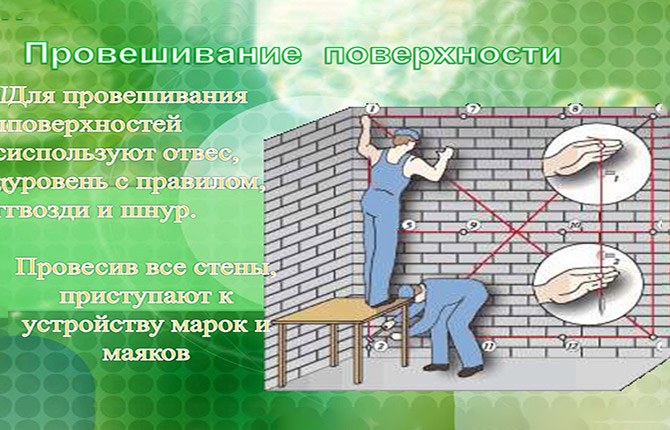

In order for the data obtained during calculations to be reliable, it is necessary to set the guides. Then, using a bubble level and a construction tape, take measurements and find points with maximum and minimum deviations from the zero plane. In order to find out the average layer thickness on the surface being treated, measure the height of the errors at several points.

For example, it was determined that at 3 points there are deviations from the plane of 15 mm, 25 mm and 50 mm. It is necessary to add up the existing indicators. We get a result of 90 mm. The sum of deviations must be divided by the number of points. In this case, the action will look like this: 90:3 = 30 mm. Therefore, the average layer thickness will be 3 cm.

How to calculate it yourself?

When making your own calculations, take into account the safety factor. For gypsum plaster it is from 1.10 to 1.5. This parameter is determined by the grain size of the composition. So for a solution from the Knauf company the coefficient will be 1.15.

Let's look at an example calculation:

- goal: to plaster 12 m2 walls;

- taking into account the average error for walls, the layer thickness is approximately 2.5 cm;

- the safety factor using the Knauf mixture as an example is 1.15;

- each manufacturer indicates the consumption rate on the packaging - for Knauf it is 8.5 kg.

From the available data, an equation is obtained with the following actions: 12 x 2.5 x 1.15 x 8.5 = 293.250 kg.

Continuing the calculations, it turns out that for 12 m2 walls with a required plaster layer thickness of 2.5 cm, you need to purchase 10 bags of gypsum plaster, packaged in 30 kg.

Attention! Based on the calculation example, you can find out what the mixture consumption is if the layer thickness is less than the specified values.

Let's take a closer look at decorative plaster. Since it is divided into three types according to the type of filling, we will define an explanation for each of them:

- Textured. Consumption is determined based on the fraction size of the component added to the mixture. For this type, from 1 to 3 mm. Accordingly, the use of a mixture with grain of a larger fraction increases the total consumption of textured plaster. So, if for a fraction of 1 mm the flow rate is 2 kg/m2, then with an increase in the fraction to 3 mm, the flow rate will also rise to 4 kg/m2.

- Structural. Here the consumption depends on the type of texture. The more highlighted the design, the lower the material costs.

- Venetian. You can determine the consumption of the Venetian mixture by looking at the back of the package. For example, it is planned to process 20 square meters. m of surface, and the consumption for this mixture indicated on the packaging is 0.5 kg. Therefore, by multiplying the values, we get the answer 10 kg. Venetian plaster has minimal errors, so it is not taken into account during calculations.

In custody

If you are still a beginner and have never tried to plaster walls yourself, then before you start studying this issue, you need to understand how to correctly calculate the required material. This will allow you not to return to the store again and save time, money and nerves.

Have you had experience in independently calculating plaster consumption or are you a beginner? Dear guests and regular subscribers of the portal, share the article on social networks and add it to your bookmarks.This way you will help promote our site!

Probably every specialist who has experience in plastering works knows that it is better not to start work without preliminary calculations. Of course, you can plaster the walls this way, but if you compare the result without calculations and with them, you will be pleasantly surprised. Savings are obvious.

Thank you for the article. This weekend I’ll go to the dacha, where work on plastering the walls will be done. Now I know. That you can save a little.