How to make a gas generator with your own hands: features of making a homemade device

A gas generator is a device for producing gas from coal, firewood, wood waste and other materials.The generated fuel can replace traditional hydrocarbon fuels - natural gas for home heating and gasoline for cars.

The main idea of using such a unit is to save on fuel costs. The constant rise in price of gasoline, propane and methane forces home craftsmen to look for alternative ways to obtain fuel.

To make a gas generator with your own hands, you need to understand its structure and operating principle.

We will explain how solid fuel is converted into flammable gas, outline the design features of the unit and give examples of self-assembly of simple devices. For better assimilation of information, we have supplemented the article with visual diagrams, photographs and videos.

The content of the article:

Gas generator: device and principle of operation

A gas generator is a device that converts liquid or solid fuel into a gaseous state for further combustion to produce heat.

Generator Fuel Options

Units running on fuel oil or waste have a more complex design than models using various types of coal or firewood.

Therefore, solid fuel gas generators are most often found - fortunately, fuel for them is available and cheap.

The following is used as solid fuel in a gas generator:

- charcoal, brown and hard coal;

- fuel pellets from wood waste;

- straw, sawdust and firewood;

- peat briquettes, coke;

- husk of seeds.

Particularly thrifty owners prepare their own sawdust briquettes.

Gas generation is possible from all these types of fuel. Energy release depends on calorific value of different types of fuel.

Moreover, more heat is obtained from burning raw materials in a gas generator than from using solid fuel in boilers. If the efficiency of conventional wood boiler varies between 60–70%, then for a gas generator complex the figure reaches 95%.

But here one nuance must be taken into account. The boiler burns fuel to heat water, and the gas generator only produces fuel. Without a heater, stove or internal combustion engine, a homemade gas generator will be of zero use.

The resulting gas must be used immediately—it is not economically profitable to accumulate it in any container.To do this, you will have to install additional equipment that depends on the power supply.

What happens inside the gas generator

The operation of the gas generator is based on the pyrolysis of solid fuel, which occurs at high temperatures and low oxygen content in the furnace. Several chemical reactions occur simultaneously inside the gas-generating device.

Technologically, the process of generating flammable gas is divided into three sequential stages:

- Thermal decomposition of fuel. The process takes place under conditions of oxygen deficiency, which is supplied to the reactor only a third of what is required for normal combustion.

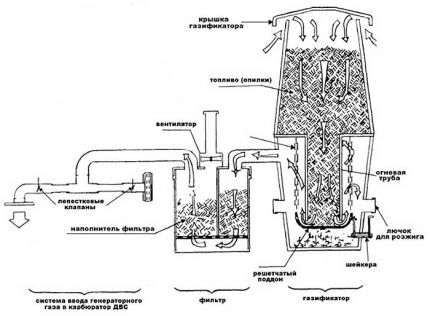

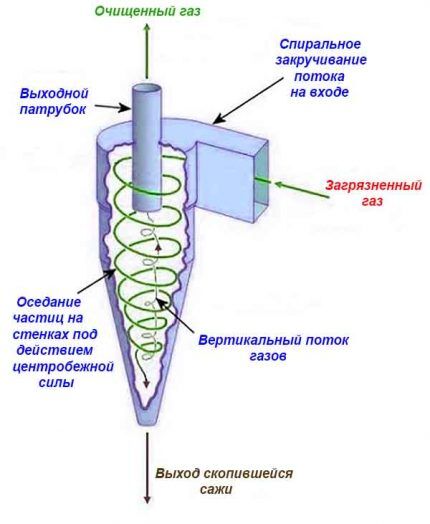

- Purification of the resulting gas. The cyclone (dry vortex filter) filters the gas cloud from volatile ash particles.

- Cooling. The resulting gas mixture is cooled and subjected to additional purification from impurities.

In fact, it is precisely the first process that occurs in the gas generator block itself - pyrolysis. Everything else is preparation of the gas mixture for further combustion.

At the exit from the gas generating unit, a flammable mixture of carbon monoxide, hydrogen, methane and other hydrocarbons is obtained.

Also, depending on the fuel used in pyrolysis, water in the form of steam, oxygen, carbon dioxide and nitrogen are added to them in varying quantities. According to the described principle, they also function pyrolysis heating boilers, demonstrating high efficiency.

Features of the operation of various converters

According to the design and technology of internal processes, gas generators are:

- straight;

- converted;

- horizontal.

They differ in the points of air supply and the exit of generated gas.

Direct process occurs when the air mass is pumped from below and the combustible mixture exits at the top of the structure.

Reversed version involves supplying oxygen directly to the oxidation zone. Moreover, it is the hottest in the gas-generating device.

It is quite difficult to inject it into it yourself, so this operating principle is used only in industrial installations.

IN horizontal gas generator The gas outlet pipe is located immediately above the grate in the zone where oxidation and reduction reactions combine. This design is the simplest to implement independently.

Advantages and disadvantages of gas generators

A factory-made household gas generator will cost 1.5–2 times more than a conventional solid fuel boiler. Is it worth spending money on this “miracle technology”?

Among the advantages of using gas generators are:

- complete burnout of fuel, loaded into the firebox, and the minimum volume of ash;

- relatively high efficiency when working together with an internal combustion engine or gas boiler;

- wide selection of solid fuels;

- ease of operation and no need to continuously monitor the operation of the unit;

- time interval between reboots fireboxes - up to a day on wood and up to a week on coal;

- Possibility of using unseasoned wood — wet raw materials can only be used in some models of gas generators;

- environmental friendliness of the device – this device does not have an exhaust pipe; all the generated gas goes directly into the combustion chamber of the engine or boiler.

When using wet firewood, the generator will work, but gas production will be reduced by 20–25%. The drop in productivity occurs due to the evaporation of natural moisture from the wood.

This leads to a decrease in the temperature in the firebox, which slows down the pyrolysis process. It is best to thoroughly dry the logs before loading them into the pyrolysis chamber. Industrial devices are fully automated; fuel is supplied to them by a screw from a nearby container.

A self-made gas generator does not offer such autonomy, but it is also quite easy to operate. You just need to fill it up with fuel from time to time.

The gas generator has fewer disadvantages, but they do exist:

- poor controllability of generated gas volumes – when the temperature in the furnace decreases, pyrolysis stops and instead of a flammable gas mixture, a mixture of resins is formed at the outlet;

- cumbersome installation – even a homemade gas generator with an average power of 10–15 kW takes up quite a large space;

- duration of kindling – 20–30 minutes will pass before the reactor produces the first gas.

After “warming up,” the generator stably produces a certain volume of gas mixture, which must be burned or released into the air. To make this unit with your own hands, you will need durable gas cylinders or thick steel, and this is a lot of money. But all this is paid off by the efficiency of the generator and the low cost of the original fuel.

Some gas generator models are equipped with an air blower, while others are not. The first option allows you to increase the power of the installation, but ties it to the electrical network. If you need a small generator for cooking outdoors, then you can get by with a compact unit without an air blower.

Most self-made gas generating installations operate using natural draft.

To heat a private home, you will need a more powerful and energy-dependent device. However, in this case, it is worth taking care of a backup electric generator, so that in the event of a network failure, you will not be left without both power supply and heating.

Working components of a homemade unit

To figure out how to make a solid fuel gas generator with your own hands, you need to clearly understand its design. Each of the elements has its own purpose, even the absence of one of them is unacceptable.

Inside the body of a homemade gas generator there should be:

- bunker for solid fuel at the top of the unit;

- pyrolysis chamber where the smoldering process occurs;

- air distribution device with check valve;

- grates with ash pit;

- outlet pipe for the produced gas;

- cleaning filters.

In a homemade wood-burning generator, a fairly high temperature is generated, so strict requirements are imposed on each of its elements. Strong sheet steel is used for the body, and all parts inside are selected to be as heat-resistant as possible.

To ensure the tightness of the fuel loading hatch when closed, the lid will need a seal. The cheapest material for this is asbestos. However, it is not harmless to human health; it is better to find special heat-resistant gaskets based on silicones or silicates in the store.

The body can be either cylindrical or rectangular. Often, to simplify the work, a pair of natural gas cylinders or iron barrels is taken. One of the grates at the bottom of the firebox is welded “tightly”, and the second is built in so that it can be moved. This is necessary to clean them from slag and ash.

The air distribution unit is located outside the housing. It ensures that the required volumes of oxygen enter the firebox, but at the same time, thanks to the check valve, it does not release flammable gases from it.

Gas generator manufacturing technologies

There are several ways to make a gas-generating installation yourself. The choice here depends on the availability of materials and the further use of the resulting gas.

Option #1: An example of constructing a coal-fired apparatus

Let's look at an example of making a useful homemade product from a metal bucket with a lid. First, we will prepare a unit that will process the gas obtained from the installation into electricity.

After preparing the consumer for the upcoming operation, you can start constructing the gas generator itself.

The pipe that removes gas from the installation must be equipped with a filter, because During the combustion process, coal releases a lot of fine suspended matter and dust.

Having completed the process of constructing a homemade gas generator, you need to check its functionality.

Option #2: Gas generator from two-hundred-liter barrels

For a homemade barrel gas generator you will need a pair of 200 liter containers. One of them is inserted two-thirds into the other.

The space formed at the bottom will be used as a combustion chamber, and the upper part is ideal for a bunker for firewood or pellets.

On the side, at the level of the pyrolysis section, a pipe with a cross-section of 50 mm is welded for air injection, and closer to the lid - a gas outlet pipe. A hole is cut in the bottom of the inner barrel to allow fuel to enter the combustion chamber, and a blower door is attached to the bottom of the outer barrel.

All that remains is to make filters for cleaning the gas mixture before transferring it to the hot water boiler. To do this, you will need used fire extinguishers or pieces of pipe of similar size.

They are tightly closed at the top, and a conical nozzle is welded at the bottom, at the end of which there is a fitting for removing ash.Then a pipe is cut into the side to supply the gas mixture for cleaning, and an outlet for the already filtered gas is cut into the lid.

Next, to lower the temperature of the combustible gas, a cooling radiator is made from several pipes with a diameter of 10 cm. They are connected to each other by small pipes.

For final purification of the gas, install another filter with expanded clay, small metal washers or sawdust inside. It is permissible to use the latter material only if the incoming gas has already cooled, otherwise it could lead to a fire.

You can make a “potbelly stove” from a gas cylinder. Instructions for creating a primitive stove are given in this article.

Option #3: Homemade model for internal combustion engines

For a car or motorcycle, a homemade gas generator is made according to a similar scheme. Only here it is necessary to reduce the size of the installation to a minimum. Carrying a heavy unit with you is expensive, and it doesn’t look very aesthetically pleasing.

To make your work easier, for the car version of the generator it is best to take household gas cylinders. The main thing is to make sure before welding that there is no hint of the presence of propane in the container, otherwise a small explosion may occur. To do this, you need to unscrew the bottle valve and fill the container to capacity with water.

Initially, the car gas generator produces gases that are too hot. They must be refrigerated. Otherwise, upon contact with hot engine parts, they may spontaneously ignite.In addition, heated gaseous fuel has a low density, which makes it simply difficult to ignite it in the cylinders.

A homemade gas generator for a car can be mounted in the trunk or on a trailer.

The second method is preferable due to:

- ease of repair;

- the ability to leave the gas generating unit in the garage;

- availability of free space in the trunk;

- the possibility of using the installation for other needs besides supplying fuel to the internal combustion engine.

Don't be afraid of bumps in the road. When bouncing on bumps, the solid fuel in the combustion chamber will be shaken, which will only contribute to its better mixing and combustion.

Nuances of operation and operation of gas generators

It is important to remember that the gas produced by the installation is odorless and poisonous. If mistakes are made when welding the metal parts of the gas generator with your own hands, then trouble cannot be avoided.

For natural air flow in the combustion chamber, you can drill 5 mm holes around the circumference of the housing. All installation work and performance testing should be carried out in a well-ventilated workshop or outdoors.

After combustion, the damper is closed to limit the flow of oxygen into the combustion chamber. In order for the homemade gas-generating product to work properly, you must correctly adjust the outlet of the resulting gas mixture and the oxygen supply.

Before you start building a gas generator, you should make engineering calculations, in which you need to take into account the combustion area and type of fuel, as well as the required output power and the intended operating mode.

Conclusions and useful video on the topic

How to use a charcoal gas generator as a fuel supplier for a small car:

A simple gas generator made from propane cylinders:

Wood-burning gas generator structure:

The above methods are suitable for self-manufacturing an effective gas generator. But there are many more models of this device. Some of them are easier to do, others are more difficult.

The main thing when assembling the unit is to pay maximum attention to the quality of the welds, otherwise gas leaks and an explosion may occur. If everything is done correctly, the gas generator will serve properly for 10–15 years. And then the metal of the case will start to burn through, and you will have to do everything again.

Do you have practical assembly skills or experience using a homemade gas generator? Please share your accumulated knowledge and ask questions about the topic of the article in the comments below.

With the current cost of firewood and coal, will gas production be profitable? Let's say, how many cubic meters of gas can you get from a cubic meter of firewood? A cube of sawn and chopped firewood will cost 500 rubles. And the cost of natural gas is about 4 rubles. This means that to be profitable, the installation must produce at least 200 m3 of gas per cubic meter of wood. Plus the risk of explosion in case of leakage. There's a lot to think about.

In Siberia, our timber is conditionally free (unless you get caught logging). Therefore, the gas generator turns out to be quite profitable.I thought about buying a store-bought one, but the price tag is too high. Now I’m looking at how to build a homemade one.

Where are industrially manufactured gas generators sold?

You should not consider a gas generator, especially one assembled by yourself, which will subsequently have to be modified, as a full-fledged replacement for natural and industrial types of gas. If you have access to free firewood, coal and other materials used in the gas generator, then you can consider such a project as the main source for gas production. But this is ideal.

Also, do not forget that the gas generator is simply not capable of producing propane-butane, which is obtained as a side reaction during oil distillation. Actually, in order not to talk about the difference for a long time, I will give a table with different gases and indicators.

To make it clear, let’s compare the gas mixture produced in a gas generator with methane. If the resulting gas mixture is pumped into methane cylinders, the car will travel 6 times less distance.

Hello. I recently read an article by a craftsman who made a lightweight gas generator with his own hands. He claims that the boiler costs 100-200 dollars at cost, and 1 kg of firewood produces 2.2 m3 of gas.

I am an avid fisherman, often going out into the wilderness for a day or more. After reading the article I immediately wanted something similar. A sort of homemade, portable stove for cooking. You often sit by the lake and want something hot, be it a drink: tea, coffee or lunch. And I don’t want to be distracted by the long process of lighting a fire.It will be useful for fishermen, hunters, and those who go hiking.

Has anyone tried using asbestos, something like ceramics or, for example, graphite inside the combustion chamber? After all, as I remember, they are not afraid of temperature, and in general there is a fireplace sealant of 3800 degrees Celsius.

Come on, read the Fisher Trope process. The Germans used and made diesel fuel from coal; gasoline was cleaner than at a gas station in millions of tons. You can take CO2 from the air; in reaction with water, if everything is correct, then oil and gas are no longer required.

The planet does not belong to anyone, no one can prove that they created it, which means everything is shared, including resources. UN Law 2222. We tried everything and it worked https://www.holz-kraft.com/en

learn languages for free 50 languages, source of knowledge, from native speakers https://www.50languages.com/