Insert into a concrete septic tank: how to waterproof using a plastic insert

The massiveness and external reliability of concrete rings attracts homeowners.Concrete structures immersed in the ground easily resist soil pressure and are not threatened by corrosion. Concrete stone is strong, waterproof and durable.

Septic tanks made from reinforced concrete rings are built quickly, but after 10-20 years they begin to leak... This problem can be corrected by inserting into a concrete septic tank or externally sealing the walls of the well. Which solution is better? Let's try to understand this material.

The content of the article:

Causes of concrete septic tank leaks

To build a well, monoblock and prefabricated structures are used, made strictly from high-quality concrete - not lower than B-15. Moreover, the waterproof grade must be at least W8. Otherwise, the walls of the septic tank will allow water to pass in both directions, regardless of the quality of the sealing of the joints.

Errors in the alignment of rings lowered on the slings of a truck crane cause not only curvature of the seam line between prefabricated elements. When assembling an underground tank from reinforced concrete rings there is a high risk of them hitting each other.

It is almost impossible to set the rings the first time; you have to raise and lower them two or three times. Each reinforced concrete ring weighs about half a ton. Impacts of the upper prefabricated element on the lower segment do not go unnoticed - cracks and chips form.

Soil heaving is often underestimated by homeowners. As a result of heaving, the rings of the precast concrete tank shift. Groundwater and flood water enter the septic tank through the cracks, significantly increasing the level of wastewater in the treatment plant.

When a sewer structure is flooded, there is a high probability of untreated sewage escaping through leaky sections of the trunk. As a result, contamination of the surrounding soils and the waters they contain will occur.

High groundwater levels are characteristic of the territories of the central zone of the Russian Federation during flooding. It is especially high (less than 500 mm) in areas removed from the swampy state by reclamation measures. It is almost impossible to achieve waterproofing of the body of a precast concrete septic tank in conditions of proximity to groundwater.

If the upper part of an underground concrete tank is insulated insufficiently or ineffectively, its protruding part will be destroyed in about 10 years. Critical defects will be caused by alternating freezing and thawing cycles. Moisture penetrating into the pores of concrete freezes and expands, forming abundant microcracks. The result is the same - rain and flood water will flow into the septic tank.

To eliminate leaks, it is necessary to waterproof the concrete septic tank from the outside or inside.The use of waterproofing compounds to repair an operating tank is only permissible from the outside, since most waterproofing compounds are destroyed by contact with sewage.

The only solution for internal waterproofing is an insert into a concrete septic tank, which allows minimizing the amount of work inside the well. To give an idea of the nature of the work, we will now consider both types.

Alternative to plastic insert

The area to be repaired must be emptied first. storage tank or a septic tank, having pumped out the contents with the involvement of a team of vacuum cleaners. The service of pumping out a septic tank and removing its contents is provided by utility services and private companies. It is cheaper to negotiate directly with the municipal services sewer man.

Sewage transport will need an access area to the work site. Moreover, the shorter the transport arm of the vehicle, the shorter the access distance will be. Its permissible length is up to 180 meters and even more - up to 500 m, if it is a high-pressure polyethylene hose.

Pumping out a septic tank should be carried out by trained specialists; amateurs will not be able to do it. Work on cleaning the septic tank is carried out with a special pump - sewer (fecal).

Waterproofing concrete septic tank joints

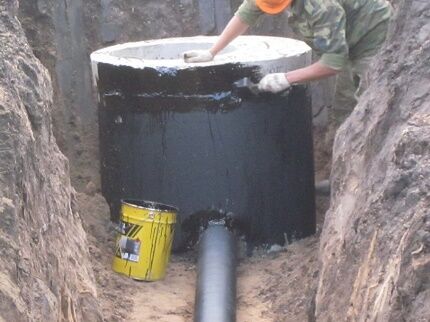

To seal the gaps between the concrete rings of the well, you need to reach them from outside the structure. It is necessary to dig a ditch around the septic tank to a depth that allows you to work with the joints between the reinforced concrete sections.

Accordingly, the more rings there are in the tank structure, the deeper the ditch will have to be dug. The width of the ditch is at least a meter. It will be difficult to work in a narrow ditch.

Having dug up the walls of the septic tank, you need to dry them. Back to top waterproofing works There should be no dark spots on concrete walls. The seams must be cleared of accumulated debris and soil, exposing a cavity at least 70 mm deep.

If rain is expected, the well and the ditch dug around it should be covered with moisture-proof material (plastic film, tarpaulin, etc.).

To fill the seams, you need well-punched clay and a plaster float. The clay should be kneaded with your feet in a basin or other similar container. Packing joints between concrete rings with unpressed clay is ineffective - its structure will be uneven and include voids that allow water to pass through.

The external seams between the concrete sections of the septic tank can be sealed with a cement-sand mortar mixed with liquid glass. Composition of the mixture: liquid glass, cement and sifted fine sand in a ratio of 1:1:3.

The mixture should be prepared in small portions - when liquid glass is added, the solution quickly hardens. The seams are filled with this solution using a spatula.

The joint mortar is also prepared from a mixture of cement and PVA construction adhesive. Proportion: 5 parts cement to 1 part PVA. After filling the joints with mortar, two or three layers of liquid glass can be applied on top. This will enhance waterproofing.

Before filling the joints with cement mortar, it is necessary to treat them with a primer. Technical priming materials are used for septic tanks. For example, this is one part bitumen to three parts gasoline.

There are pores in the structure of the concrete stone, so septic tanks assembled from reinforced concrete rings allow water to pass through, albeit in small quantities. When freezing, the water in the pores will crystallize, increase in volume and ultimately destroy the monolithic compound.

Installation of roll waterproofing

Having completed the work on the seams of the concrete rings, we begin to form the surface layer to protect the tank from moisture. If clay was used for the joints, then roll materials cannot be applied over them - the clay plaster will be broken when the adhesive mastic hardens.

The outer surface of the concrete well must be completely covered with a primer, for example, bitumen-gasoline. This will improve the bonding of rolled waterproofing with concrete rings. Then the walls are coated with heated tar mastic, and the rolled bitumen material is glued in two or three layers.

Note that bitumen mastic is not suitable for waterproofing the walls of a septic tank with rolled materials - it cracks when it cools.

To reduce or eliminate the likelihood of soil heaving around a concrete shaft, sand and crushed stone backfill is used (40% sand, 60% crushed stone). It fills a ditch previously dug around an underground reservoir to repair the seams between well rings.

If there is sand without clay inclusions, gravel or crushed stone deposits under the soil layer on the site, then backfilling can be done with soil from a dump formed during the development of a pit around the septic tank.

Plastic insert for waterproofing a septic tank

Regardless of the depth of the well and the known or unknown leakage zones, a plastic cylinder inserted into the septic tank can close them at once. To begin installation of the insert, it is necessary to empty the sewer tank by calling a vacuum cleaner.Then you need to rinse the walls and bottom of the well with a stream of water from a hose supplied under pressure.

Manufacturers of modular rings and full tanks made of plastic produce them ready-made, of various diameters and wall heights. It is possible to order non-standard containers and rings if the diameter of the septic tank being repaired does not match the parameters of serial plastic rings (too large or small). It is optimal if there is a gap of 50-100 mm, no more, between the walls of the insert and the septic tank.

To restore the tightness of a concrete septic tank, plastic rings with a wall thickness of 5 mm are required. There is no need for thicker walls - the main concrete walls of the old well will provide ideal protection. Reinforcement ribs made along the perimeter of the plastic rings will maintain the rigidity of the well insert when sewage flows in.

Modular rings are connected to each other by groove insertion, welding or screwing. The weight of one section of the plastic insert (height 1500 mm, outer diameter 950 mm) is about 25-30 kg. To assemble the insert correctly, its modules should be assembled outside the well. The fully assembled insert is inserted into the septic tank manually (if the length is no more than three meters) or with a truck crane.

Installation of prefabricated insert

When assembling plastic composite ring sections, a standard rubber seal is placed in the tray of the lower ring, and the upper section is exposed. To align the lower and upper rings of the insert, you need to lay the board across and in the center, then press it on both sides.

An important detail: the insert segments to be connected must be placed strictly horizontally before pressing with the board. Otherwise, complete insertion of the fasteners of the upper section into the tray of the lower section cannot be achieved.

The ring modules, which are assembled by screwing, are combined into an insert of the required height inside or outside the well. The first option is suitable if the septic tank is shallow. Although it is more convenient to screw on the sections on the site, and then lower the assembled insert into the sewer tank.

Regardless of the method of combining the plastic rings, the groove between them is additionally treated with silicone mastic. It is applied on both sides - external and internal. Of course, over the years of operation of the septic tank, the grooves in the insert will fill with silt on their own and will only increase their waterproofing properties.

However, in the first months and years of operation of the repaired septic tank, siltation will occur slowly. Therefore, the use of silicone for seams between sections is a necessary solution.

The lower module is the base of the entire insert; it is absolutely necessary to seal the septic tank. Before installing it in a concrete well (or placing a fully assembled tank), you should make sure that the bottom of the septic tank is strong. The required concrete thickness at the bottom of the sewer well is 150 mm.

When lowering the assembled plastic insert into a concrete tank, it should not be allowed to bend significantly - the fastenings of the modules may be damaged. Installation of an insert with more than three modules into a well is best done by hanging it on the slings of a truck crane.

Judge for yourself: the approximate length of a three-section well insert is 4.5 m; weight – about 100 kg. It will be difficult to lower a plastic structure of such length and weight into a septic tank by hand.

The final stage of assembling a modular structure

If the protrusions of the pipes in the septic tank being repaired are too long and will interfere with the installation of the plastic insert, they need to be cut off. The drain pipes are inserted into the cavity of the insert through its walls through sealing collars and rings, with the joints treated with silicone.

In the plastic ring modules of some manufacturers, sectors (trays) for input are indicated sewer pipes. Regardless of whether there are such designations or not, to insert a pipe you need to cut a hole in a certain section using a jigsaw.

There is a gap left between the walls of the plastic tank and the old concrete septic tank - it needs to be filled. A cement-sand mixture is prepared in a ratio of 1:5. It is poured into the wall in dry form.

From approximately the middle of the depth of the tank, you need to start lightly compacting the cement-sand filling, using a long wooden pole. The pole must be kept strictly horizontal so as not to touch the walls of the plastic well.

To be completely sure that the insertion channel will not move during the filling and compacting process, you can pour water into it - at first no more than a third of the container. As the opening between the walls of the septic tank fills, water must be added to the well. It should be poured so that the level is 200 mm above the current filling level.

Installing a plastic headband

The upper section of the plastic insert for the septic tank is called the neck. In principle, its installation on a restored sewer well in a private courtyard is not necessary. But only if the flat ring of the concrete head from the old septic tank is not damaged - there are no cracks or crumbling areas exposing the reinforcement.

If there is no need to install a neck, then the upper edge of the plastic well insert needs to be brought out 120 mm above ground level, no more. The height of the reinforced concrete slab made for the head of the well in accordance with GOST is 200 mm.

The top edge of the plastic insert should not protrude beyond it.It is necessary to place a sealant - a heel (tarred rope) - in the gap between the outer edges of the insert and the upper concrete slab.

Installing the neck module will allow you to do without laying a concrete ring-headband. On the site of a private house, this is permissible if the septic tank is not located under a pedestrian path or car area. It will be enough to close the neck plastic hatch the manufacturer that produced this set of modules for well repair.

Classic plastic waterproofing

If it is possible to install a monolithic cylindrical polyethylene insert into the trunk of a sewer well, then it is better to use this method. Work on installing waterproofing will be carried out much faster and with minimal labor costs.

In the manufacture of inserts of this type, polyethylene is used - a material that is absolutely impervious to the direct effects of an aggressive environment. The thickness of the case walls is 8 mm, which eliminates accidental damage to the structure during transportation and installation.

Before immersing the insert into the trunk of a concrete septic tank, holes are drilled in the walls of the housing for the entrance and exit of sewer pipes exactly along the outline of the connected communication branches. The passages are sealed or scalded around the perimeter. The gap between the insert and the concrete walls of the septic tank is filled with concrete mortar.

Choosing a waterproofing method

Classic solutions for isolating a sewer well built from concrete rings from leaks are quite effective. However, sealing joints, treating tank walls with bitumen mastic and similar measures are only suitable for septic tanks under construction. Those. for new underground tanks not yet put into operation.

One-sided waterproofing of external walls, acceptable for septic tanks with many years of operation, will reduce the degree of seepage of sewage into the ground. The strength of waterproofing coatings on the external walls of a concrete well will remain for more than 10 years, but only if repair work is carried out professionally and high-quality materials are used.

Plastic ring modules are produced at the enterprise, i.e. in a workshop environment. They are intended specifically for repairing wells and building new buried tanks. The plastic insert placed in the concrete well is not connected to its structure.

Therefore, its tightness does not depend on the degree of wear of the septic tank being repaired; it will only be a protective case for the plastic tank.

The inherent performance qualities of a plastic container designed for waterproofing a septic tank are quite high:

- light weight (compared to reinforced concrete);

- complete tightness;

- low thermal conductivity;

- resistance to abrasion and aggressive environments;

- long service (more than 40 years);

- high impact strength, resistance to mechanical loads;

- immunity to ultraviolet radiation;

- frost resistance;

- simple installation (except for the welded principle of assembling sections).

Therefore, the choice in favor of a polyethylene insert is most justified.Getting rid of problems with a leaking sewer well in a suburban area for decades is an excellent option! We also recommend reading our other article about waterproofing methods concrete septic tanks.

Conclusions and useful video on the topic

In this video you can examine the plastic modules from all sides and even touch them:

Video about assembling a well from plastic elements at the installation site:

A plastic well insert will completely solve three problems: leaks through joints, through cracks and through the walls of concrete rings. However, the price of such repairs will not be cheap. The cost of a one and a half meter insert segment, with a diameter of 950 mm and a wall thickness of 5 mm, is approximately 15,000 rubles. However, decades without sewer “surprises” are worth it.

Are you planning to install a plastic insert into a concrete septic tank, but don’t know where to start? Or do you have experience in carrying out such work? Please share your accumulated knowledge with our readers - leave comments in the block below.

Hello, tell me if you know I need 2 plastic inserts with a bottom for reinforced concrete rings 950* 1500 price

Good evening.

The price depends on the insert height, diameter and wall thickness. That is, the more plastic was used, the higher the cost of the product. Some models have additional parts, which also increases the price.

Here are the average prices depending on geometric parameters.

Insert height (mm) Insert diameter, mm Wall thickness, mm Price, rub

1500 950 5 17300

2000 950 5 24500

2500 950 5 26600

3000 950 5 252800

3500 950 5 36000

4000 950 5 38000

4500 950 5 40000

5000 950 5 47000

5500 950 5 49600

6000 950 5 51800

1500 1450 6 33000

2000 1450 6 45000

2500 1450 6 49700

3500 1450 6 66300

4000 1450 6 70500

4500 1450 6 74700

5000 1450 6 87000

5500 1450 6 91000

6000 1450 6 95500

1500 1950 8 56000