How to make a bed with your own hands: a selection of ideas + instructions on how to build a homemade one

The bed is where we spend a third of our lives sleeping. That is why you need to approach its choice responsibly.Of course, you can purchase a bed at any furniture center. But, you see, it’s much more interesting to make the bed yourself.

Therefore, next we will tell you how to make a bed with your own hands and figure out what tools and materials you will need for this.

The content of the article:

Materials for building a bed

In large construction hypermarkets and specialized furniture stores you can find everything you need to build a bed.

To make the frame, wood, plywood, and laminate are usually used. We try to make those structural elements that will be visible from MDF the color and texture you like. The painted one looks especially attractive MDF.

Very often the headboard is equipped with foam rubber and covered with fabric/leather/eco-leather. This element is decorated in the style capitone or carriage tie.

Basic materials for assembling the bed: wood or sheets MDF a thickness of at least 2 cm, a contrasting edge or to match the main color of the canvas, a thickness of 1-2 mm, a wooden beam 50x50 mm, at least 4 m long. It is better if the beam is made of pine or beech.

You will also need solid boards, at least 2 meters long, and, depending on the chosen design, sheets of plywood may be useful.

To make a bed from boxes, it is advisable to buy chipboard. This material is much cheaper MDF. The only thing is that chipboard sheets are not suitable for forming flooring because they are very thin.

In order to end up with a durable and strong stock, you need to choose the right mount. When calculating the number of fasteners, take into account the bed drawing.

Also, do not forget about purchasing glue, without which it is impossible to connect the structural elements.

In addition to glue you will need: screws, 3-7 cm long, nails, 6-7 cm long, metal corners.

When choosing metal corners, pay attention to the stiffeners and bend. The stiffening ribs should be rounded and wide. The bending surface must be smooth.

The presence of burrs indicates that burnt, low-quality metal was used to produce the corners. Such connecting elements are characterized by fragility - they quickly crack and break.

Read the article - DIY metal bed.

Assembly Instructions

There are many types of beds. They differ in the materials from which they are made, in appearance, in the way parts are connected, and in size. The bed can stand on legs or be placed directly on the floor.

Which option is best is up to you to decide. Focus on your taste and available materials. If you plan to place the bed on a concrete floor in a room with high humidity, take care about treating the wood with special antifungal agents.

Option number 1 - wooden bed

The first step is to build a frame that will serve as the basis for our entire structure. The standard height of the frame is 15-20 cm. When assembling a bunk bed, you will need to prepare two frames of the same size.

If the product rests not on the legs, but on the side walls, it is advisable to provide drawers. Such parts of the structure are intended for storing bedding and other things.

Bed assembly steps:

- Assembling the frame. The connection in the corners is carried out using a “lock” type fastening and metal corners.

- In the center, bars are installed on which the central jumper is placed.

- The legs are attached using self-tapping screws and bolts and place them, as a rule, along the ends of the bed and the central beam.

- Next, transverse boards are cut and secured with screws to the support strips with a pitch of 35-40 mm.

- When everything is ready, all ends are sanded, the product is covered with stain and varnished.

We considered the option of the simplest bed that does not have a headboard. But modern interior solutions use more sophisticated types of beds.

A design feature of such beds is the presence of a headboard or footboard.

Remember, the length of the sleeping place is selected taking into account the height of the person, 20-30 cm is added to it. The standard length is 190-210 cm. The width of the sleeping place is determined by the number of people sleeping. There are single beds - 100-150 cm, one-and-a-half beds - 120-160 cm, double beds - 140-160 cm and children's beds - 90-100 cm.

The height of the bed can be in the range from 20 to 90 cm, but the standard is considered to be a height of 40-60 cm. As a rule, high beds are placed in small rooms, andsingle bed The area is used for storing things.

Instead of drawers, the entire space of the bed can be used. The flooring with the mattress, in this case, is raised using a gas lift mechanism.

Option No. 2 - bed-podium

For those who want to assemble a podium bed with their own hands, first of all, you will need to decide on the type of structure, since the sleeping place can be located inside the frame or extend out, and the area where it will be placed.

Next, you need to complete the drawing and make markings on the walls and floor. When placing the podium close to the wall, you will need to remove the baseboard.

Consumables: timber with a section of 50x50 mm, plywood sheets with a minimum thickness of 12 mm for rough finishing, boards, MDF, laminate or laminated chipboard for finishing cladding, galvanized corners, glue, screws, anchors. Tools you will need: building level, screwdriver, tape measure and saw.

Stages of creating a bed-podium:

- The prepared beams are attached to the floor and walls horizontally according to the markings. Anchors are used for this.

- Vertical bars are attached to the resulting workpiece, which will serve as the legs of the structure. The distance between the logs should not exceed 40 cm.

- Determined by the location of the mattress. An additional frame is created at its location: 2 long beams on the sides and 1 along the center line.

- Stuffed lamellas at the locations of the frame beams.

- Place the head of the bed, attaching it in the right place.

- Prepared sheets of plywood or MDF They are attached to the top and sides of the frame using screws. Visible sections of panels are covered with an edge matched to the color of the frame.

Additional elements of the podium bed can be built-in drawers or steps. The decor of the product involves placing carpet, LED strip, and bedside tables.

Stylish podium beds perfectly zone the space, allow you to allocate more free space in the room, hide uneven floors, and also look very original and stylish.

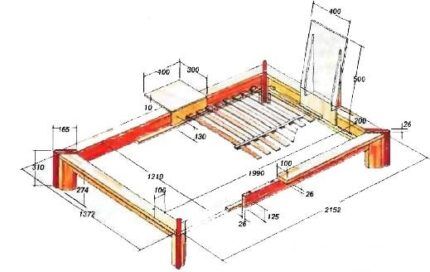

Option No. 3 - double bed with headboard

Double beds with a headboard are the perfect solution for bedrooms decorated in any style. The headboard can be soft or hard. Standard sleeping place - 200x160 cm.

Before starting work, be sure to develop a drawing. It will not only allow visualize future product, but will also help to correctly calculate the amount of consumables.

Manufacturing stages floating style beds:

- Cleaning edges using a sander. Staining wood.

- Connecting boards using metal corners.

- Forming the head of the bed. Planks are attached to the two beams, and boards are placed between the planks.

- Accession lamellas to the sides.

- The vertical beams are connected to the horizontal strip using wood glue and large bolts.

- Connecting the base of the bed with the headboard.

With such a floating bed, your abode will look stylish and unusual.

Option No. 4 - a bed of pallets

Recently, beds made from pallets have become especially popular. They are located in the country, in the back rooms of commercial real estate and in apartments.

Homeowners consider this solution as a temporary option until they purchase a suitable bed.

When assembling a bed from pallet wooden pallets are treated with protective agents that prevent the wood from being exposed to moisture and the formation of fungus. To build a standard double bed, use only 6-8 pallets or 4 Euro pallets.

Furniture is prohibited from being placed nearby fireplaces. It is also not advisable to jump on it, otherwise you can simply break the bottom.

It will take very little time to assemble the product, because pallets - these are ready-made structures that just need to be correctly connected to each other.

Stages of working with Euro pallets:

- Cleaning pallet remove dirt and dust with a grinding machine or sandpaper. Primer, opening with varnish or paint. Waiting for complete drying.

- Fastening pallets together in the chosen order. As a rule, 6 pallets are connected to each other. Metal corners, plates, and bolts are used as fastening elements.

- To assemble a bed, the design of which includes a niche for a mattress, the top layer of pallets is laid bottom down. The supports are cut in such a way as to form the letter “P”.

- A headboard made of pallets is placed on top of the knocked together frame.

The knocked together frame of the finished product is placed in the room. A mattress is placed on top and bed linen is laid.

A bed made of pallets can have side tables on which it is convenient to place lamp, mobile, magazines.

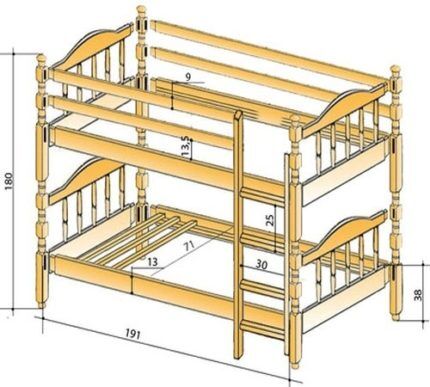

Option No. 5 - children's bunk bed

Bunk beds are relevant for families with several small children. Designs with two beds allow you to rationally organize space.

The lower tier can be made in the form of a bed or desk, the upper one is intended for a child’s sleep.

To create a traditional bunk bed, you need to stock up on boards and self-tapping screws. Calculation of materials is carried out taking into account the drawing. The thickness of pine or beech boards varies in the range of 20-45 mm.

The first step is to start forming the end frames of the bed. The boards are attached to one another using self-tapping screws. Assemble the horizontal bars and then place them lamellas. Finally, a staircase is built. All other elements are attached according to the drawing.

Before attaching the parts, be sure to drill holes in the screw locations. After the sleeping bed is assembled, cover it with stain or colorless glossy varnish.

Option No. 6 - hanging bed

In the world of interior design, hanging beds deserve special attention. They are distinguished by their unusual, stylish appearance and the ability to easily swing - ceiling version.

Is it possible to make such a bed yourself? Of course! It is enough to be patient and strictly follow the recommendations of professional furniture makers.

There are several types of hanging beds: ceiling, wall, combined - attached to the ceiling and wall.

Furniture is made as follows. First, the location of the bed is determined. It is best to install it away from furniture, otherwise during movement it can touch and damage other objects in the room. Then the frame is knocked together. Corners are used to connect wooden elements, self-tapping screws and glue. The sides are attached with nails to the frame.

Bolts are installed along the perimeter of the bed on 4 sides, and anchors are attached parallel to the ceiling. To fix the bed in a floating position, first thread the ropes through the anchors on the ceiling, and then attach them to the frame of the swing. After this, you can put the mattress on the bed and lay down the bed linen.

Hanging beds have an extraordinary design. Children and young people simply adore these swing beds.

The only drawback of the beds is the inability to move around in the room. The difficulties of making a bed are more related to reliable fixation than to making a frame.

Making a soft headboard

Beds with upholstered headboards look like a million. You absolutely do not need to spend exorbitant amounts of money on purchasing such a bed, because you can make it yourself.

We will look at the most difficult way to make a soft headboard in the form of a carriage screed - in a different way capitone. To do this, prepare glue, foam rubber, upholstery material, buttons, silk thread and stapler with staples.

Manufacturing stages:

- Choose beautiful buttons covered with fabric. If you wish, you can cover the buttons with material yourself.

- Mark the slab. Draw parallel and perpendicular lines, mark the vertices of the diamonds. Drill through holes at the tops of the diamonds, 2-3 mm thick.

- Cut a piece of foam rubber to the desired size and use glue to attach it to the stove. If necessary, excess foam rubber is trimmed with a sharp knife.

- Make marks on the foam rubber where the buttons will be located. To do this, take the awl through the holes in the plywood or chipboard, pierce the foam rubber with it and mark a dot with a felt-tip pen at the puncture site.

- In foam rubber in the mark area cut it out small diameter holes. They should be clear and round.

- Apply a layer padding polyester to level the surface. Lock it down stapler. Using your fingers, tear through the area where the buttons will be placed.

- Place the fabric/leather on the headboard. Secure it stapler. For better tension of the material, use a strip that is nailed to the inside of the product. When working, pay special attention to the corners.

- Using an awl, pull the buttons with silk ropes inside. Tighten each rope one at a time and secure it with staples.

After these rather complex procedures, the headboard is placed above the bed. The most important thing in the work is the accuracy of the markings and the correct tension of the fabric/leather, especially in the corners.

We bring to your attention articles - DIY bed-house And How to make a bed from a profile pipe

Conclusions useful video on the topic

About, how to assemble a bed from timber watch the video with your own hands:

We hope we have answered in detail the question of how you can assemble a bed yourself. This will require: desire, minimal skills and some free time.

And if you have experience in independently building a bed from scrap materials, be sure to write to us in the feedback form located under the article. There you can ask questions about the topic of the article that interest you.