How and with what to cut polycarbonate at home: methods, tools, recommendations from a master

Polycarbonate is a thermoplastic polymer that has firmly occupied its niche in the building materials market.Among the positive qualities is that the work does not require highly qualified workers. In order to cut the material correctly, you need to know how and with what to cut polycarbonate.

The content of the article:

Choosing a tool for cutting polycarbonate

To cut, process and use a polymer, you need to know its properties. Sheet polycarbonate is a type of plastic that differs significantly from similar materials such as polyethylene, PVC, LDPE, including glass. It has high strength, combined with extraordinary lightness and toughness. Weather resistant.

Its production is carried out using extrusion and injection molding lines according to specified dimensions, structure and density. The softened mass is pressed through a flat-slit device. The result is a polymer slab of equal thickness at all points. The performance characteristics of the finished sheet depend on the variety of raw materials and auxiliary additives used.

The disadvantages include the likelihood of destruction from exposure to UV radiation, high reflectivity, and excessive transparency. Low abrasion resistance polymer. Has a significant thermal gap.

There are three types of polycarbonate for a certain type of work: monolithic, cellular, profiled. Sold in sheets. It has a wide range of applications: apartments, private houses, personal plots.

The product is quite innovative, so many people do not have enough information on how to cut polycarbonate. The choice is determined by the properties of the material and the thickness of the slab. Various types of tools are used for this:

- Bulgarian;

- jigsaw;

- hacksaws for wood and metal, scissors;

- construction knife.

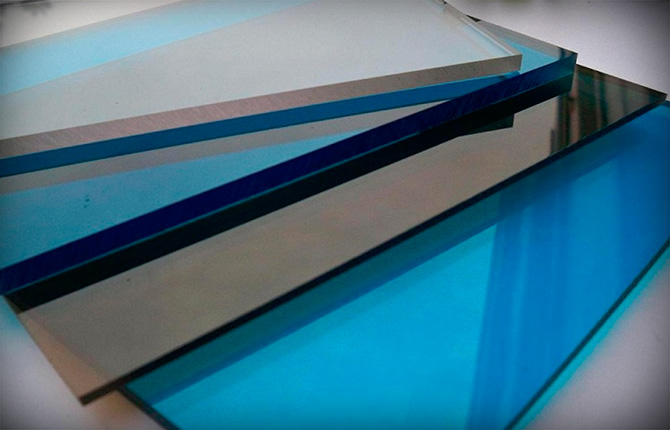

To cut polycarbonate, you need to know some properties of polymers. Monolithic polycarbonate is a thermoplastic substance without voids. It is obtained by condensation of acetone and phenol. The wide range differs in relief, color, density and light-conducting properties.

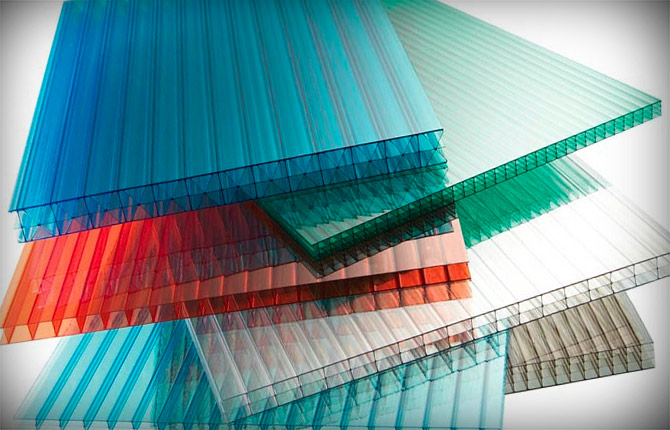

Cellular polycarbonate consists of two thin sheets with spaced longitudinal partitions. There is air in the molded channels. Thanks to this, the insulating qualities are increased, but the weight is reduced.

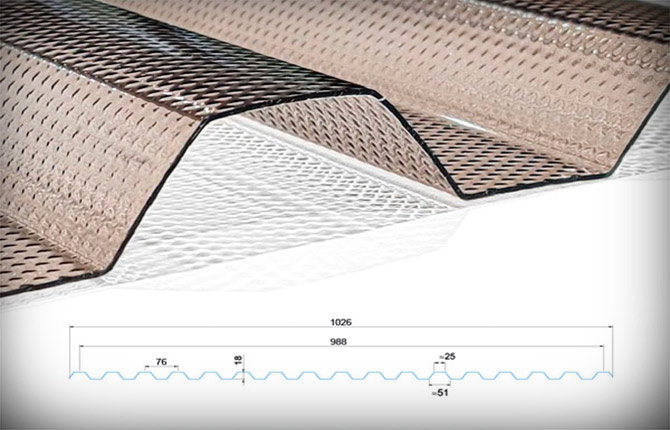

Profiled or corrugated sheets have high light transmission and a wide range of temperature fluctuations. Most often used for glazing roofs and covering greenhouses. They are used as corrosion-resistant cladding of buildings and coating of structures.

We read: Summer shower made of polycarbonate

angle grinder

This tool is suitable for processing large slabs of monolithic polycarbonate in straight lines. You can use cutting wheels designed for working with metal, namely aluminum, since they are least susceptible to heat. You need to choose an angle grinder with a speed controller. To make any straight cut, you can even use a small machine. The grinder at low speeds does not tear the material and does not leave burrs. The optimal disc diameter is 125 mm.

An angle grinder allows you to form radius surfaces and perform not only straight, but also curved cutting, thus realizing the most interesting ideas. The main thing that is required when working is to remember that an angle grinder is a high-speed machine.

With insufficient experience, the sheet can easily be damaged. It’s better to practice on unnecessary scraps first. An angle grinder is equally practical for cutting both monolithic slabs and honeycomb structures, including complex curved configurations.

Another handy electric tool is a circular saw. A disk with a small sharp tooth is installed on it. There are special discs for working with plastic as well as metal. Sawing is carried out according to the same principle as working with an angle grinder. The tool is turned on, the speed is picked up, the base plate is pressed against the edge of the material, and the cut is made with a smooth movement “from yourself”.

The disadvantage of the circular saw method is the absence of disk speed regulators on most models. Among the advantages is variable cutting depth. This function allows you to cut not just one sheet, but several at once in a package, which is very beneficial for large volumes of work. For example, when arranging greenhouses. The safety measures are the same as when working with an angle grinder.

Jigsaw

Probably, many of the craftsmen have wondered more than once how to cut polycarbonate at home. An electric jigsaw is most suitable for cutting materials with complex configurations and cuts with rounded elements. For example, the arch of the side wall of a greenhouse. It is safer than a circular saw or grinder.The speed increases sharply and the labor intensity decreases compared to cutting with a knife.

Both monolithic and cellular polycarbonate are processed with a jigsaw. When there is a need to make a straight cut along the honeycomb sheet, marking is not required. It can be cut not only with a jigsaw, but also with a knife. In such a situation, the guide line will be the cells themselves. You can cut several sheets at once by folding them and placing plywood on them.

When choosing a file, you need to pay attention to the shape of the teeth. Set teeth are designed for working with wood. They will tear the polycarbonate cutting line, rendering the cut part unusable. You need a metal file with fine, frequent teeth, straight or wavy. More teeth mean better cutting quality. To avoid burrs, various defects and nicks, a new blade is needed. It must be sharp, correctly and securely attached to the tool.

Scissors and hacksaws for metal

It happens that in the yard, except for a hacksaw, there are no power tools. In this case, you choose the option of how to properly cut polycarbonate manually. First, you should fix the polymer to be cut. The hacksaw blade must be new and free of defects. It is installed at an angle of approximately 30 degrees. The direction of the cut being made is “towards you”.

Hacksaw for metal You can cut parts that are small in length. A long cut is made with a fine-toothed wood hacksaw. This method is good when you need to cut polycarbonate for greenhouses - straight cuts of different lengths. Curvilinear cutting with a hacksaw is impossible.

Scissors, like hacksaws, are used for cutting only monolithic sheets; cellular sheets are greatly deformed with this tool.Industrial equipment remains the most reliable and efficient. Manual cutting is much inferior to processing with laser and milling equipment. It should be noted that shaped cutting of a monolithic slab is carried out only on CNC milling machines. The laser does not cut, but melts the cast sheet due to the peculiarities of its chemical structure.

Knife

An ordinary stationery knife is suitable for cutting. A construction knife is also used; it is more convenient and ergonomic. It is used to cut sheets of small thickness, usually 3 mm. A knife can cut cellular polycarbonate up to 10 mm.

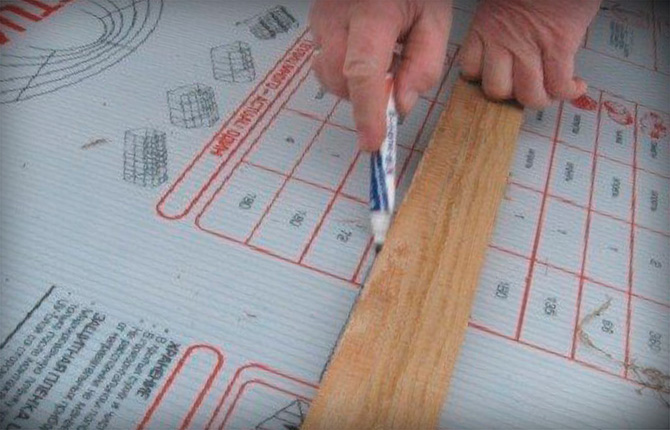

Before cutting, the sharpness of the knife is checked; if necessary, dull elements of the retractable blade are removed. The polycarbonate sheet is cut in a straight line using a rule or ruler. First, an incision is made, and then the blade is slowly and carefully drawn toward itself along the marking line. The material may not be cut at the first pass, then the method has to be repeated until the result is obtained.

Important! The sheet must not be broken or bent, as this will lead to significant deformation of the edge.

How to cut polycarbonate

Industrial equipment for this purpose uses special types of lasers and milling machines. Since a specific tool is selected for each type of material, it is important to know how to cut polycarbonate yourself. Step-by-step instruction:

- choosing the appropriate tool;

- clearing the workplace;

- arrangement of the site using even, smooth materials;

- laying the sheet on the prepared surface;

- transferring the sketch, marking with a marker;

- Next, cutting is carried out using the selected type of tool.

Preparing the site and tools

Immediately before cutting, you need to do preparatory work - organize a workplace. To do this, use a standard chipboard sheet, having previously cleared the area. There should be no stones or bumps on it. Bars of equal thickness are laid under the chipboard. A moving board is placed on top of the slab to be cut so as not to deform the polycarbonate.

A certain order in the workplace is necessary. The material to be cut is placed on one side. On the other hand, finished parts are stacked according to size and nomenclature, which will allow you to avoid sorting the parts again during installation.

Particular attention should be paid to electrical safety. The power supply cable must be undamaged, connected and branched in standard connectors designed for this purpose. Avoid laying cables in the movement area to avoid getting your feet caught. At the work site, it is necessary to provide for a quick shutdown of the power supply.

Apply markings

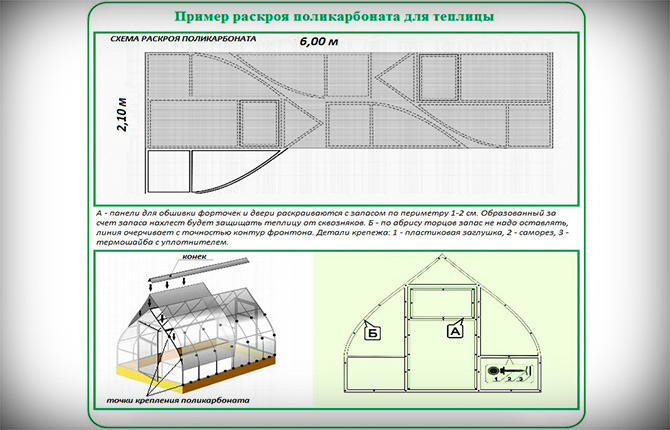

We draw up a computer cutting map or marking diagram on paper in compliance with a convenient scale. If necessary, we make curved templates.

We transfer all dimensions to the material, using the rule, a long metal ruler or tape measure. It is better to apply the markings with a black marker and then remove all lines and marks from the finished parts after cutting.

We cut sheets

After turning on the angle grinder, use the regulator to set the required disk speed. Moving the tool away from you in a smooth motion, you need to cut through the material along the previously marked lines.After finishing cutting, you should check the evenness of the cut line and remove chips and dust from the cells.

Important! When working with an angle grinder, be sure to wear safety glasses to protect your eyes from flying chips.

To cut with an electric jigsaw, the polycarbonate is laid on a strong, flat surface and firmly secured (for example, with clamps) to prevent vibration during the cutting process. The jigsaw is brought to the starting point of the cut, where a notch has been previously made with a knife. The base plate of the tool is pressed against the sheet being cut.

The jigsaw is turned on and the required saw speed is set. The tool is carefully pushed forward along the marking line. You need to cut slowly, paying special attention to curved sections. The cut fragment is cleaned of chips and dust. If necessary, unevenness is corrected with a construction knife.

It is better to cut large-area slabs, especially cellular polycarbonate, with a more high-performance tool. Still, the knife is useful for removing burrs, trimming various irregularities, and more accurately adjusting the cut parts to the given formats.

For the process to be successful, you must adhere to the following rules:

- Place the slab to be cut on a flat, vibration-free surface.

- Lay the sheets with the protective layer facing up, the same applies to mirror and laminated boards.

- Do not remove the protective film until the end of processing.

- For cellular polycarbonate it is necessary to provide a protective edge.

- To avoid damaging or deforming the sheet during work, a board of sufficient length and width of at least 100 mm is laid on its surface. You can only step on it.

- Two boards are placed parallel to the cutting line on both sides so as not to damage the polymer, and for ease of work they lift the slab in the cutting area.

- If it is necessary to move on polycarbonate, a boardwalk will be built to distribute the load.

- To cut small pieces of polymer, it is more convenient to use a workbench or large table.

Polycarbonate as a material is intensively used in the advertising and construction industries. High technological properties allow it to be used as a full-fledged alternative to traditional glass. To cut polycarbonate correctly, it’s a good idea to remember the proverb: measure seven times, cut once.

Have you ever cut polycarbonate yourself? Share your experience. Leave a comment on the article, bookmark it and repost it on social networks.

How to cut straight polycarbonate, not cellular?

You can only cut monolithic polycarbonate perfectly evenly on a cutting stand. At home, either a circular electric saw or an angle grinder with a guide mechanism. The guide mechanism prevents sudden jerks of high-speed tools, making the cut as smooth as possible.

Tell me which disc to use on the grinder, for metal or for stone?

You can use abrasive wheels for both metal and concrete. It is better not to use metal circles on concrete.

I have a plunge-cut saw with a guide bar on my farm. This is very convenient for clean cutting of chipboard.Based on what the author recommends, I can probably use my specialized tool to cut polycarbonate. Accuracy down to the millimeter. You can use, I think, a simple parquet floor, and use the mentioned rule or just a flat board as a guide.