Septic tanks Greenlos

The lack of central sewerage is a serious problem for owners of country houses and dachas. Someone is installing an outdoor toilet or installing an outdoor shower on the site. And someone does not want to put up with the lack of benefits of civilization.Installing a Greenlos septic tank is the most rational and economical way to install an independent sewer system in an individual home. Thanks to the presence of several series and a wide range of models, selecting a suitable water treatment plant is not difficult for any operating conditions.

The content of the article:

- Types of treatment facilities Greenlos

- Autonomous sewage system Greenlos "Aqua"

- Septic tanks Greenlos "Accumulator"

- Autonomous sewage system Greenlos "Aero"

- Marking

- Advantages of Greenlos treatment facilities

- Installation and connection of Greenlos septic tanks

- Methods for draining water

- Operation and maintenance of Greenlos stations

- Conservation of Greenlos stations

- How to choose the right treatment facility

- Video

Types of treatment facilities Greenlos

Three series of septic tanks are produced:

- "Aqua";

- "Storage device";

- "Aero".

Wastewater treatment plants differ in design and operating principle. Let's consider each type of Greenlos stations in detail.

Autonomous sewage system Greenlos "Aqua"

The Greenlos “Aqua” series includes 10 models of installations. After passing through all stages of purification, the water complies with SanPiN 2.1.5.980-00 standards for sanitary and chemical parameters.

Purpose

Cleaning systems from the Greenlos “Aqua” line are available in two modifications – with gravity and forced water drainage. They are used for biological treatment of domestic and utility wastewater coming from a residential building or group of houses.

Characteristics

Greenlos series "Aqua" have the following characteristics:

- The number of users served is from 3 to 25 people.

- Performance. The volume of treated wastewater depends on the model and ranges from 0.6 to 4 m3/day

- The salvo discharge volume is from 150 to 1200 liters.

- The depth of the inlet pipe is from 0.6 to 1.2 m.

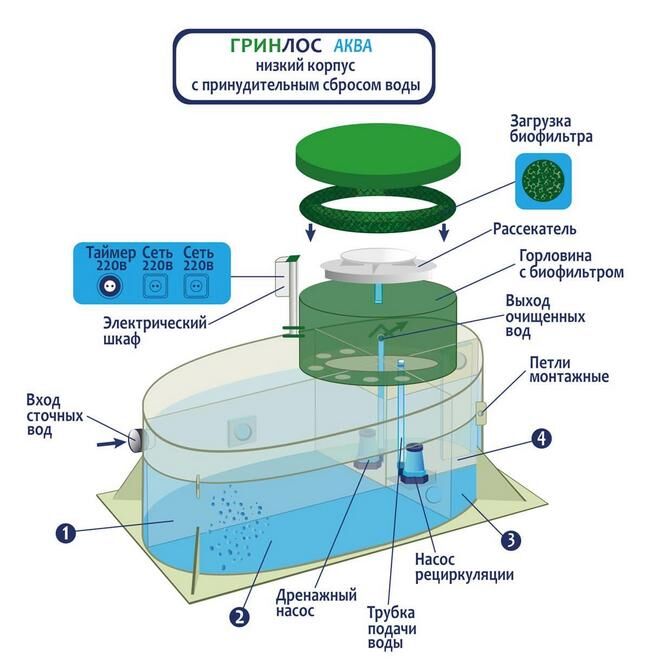

- Execution option - with a low body or standard height.

- Weight - from 115 to 300 kg.

- Energy consumption - from 1.8 to 2.2 kW/day.

- Type of discharge - forced or gravity.

In gravity discharge, treated wastewater is removed from the station through a gravity pipeline towards the final dispersion point. The movement of liquid occurs due to the laying of the pipe at a slope towards the field side. The implementation of this method of disposal is possible if there are nearby places where water does not stagnate, but goes into the soil. It can be:

- filter fields;

- natural ravines;

- drainage wells.

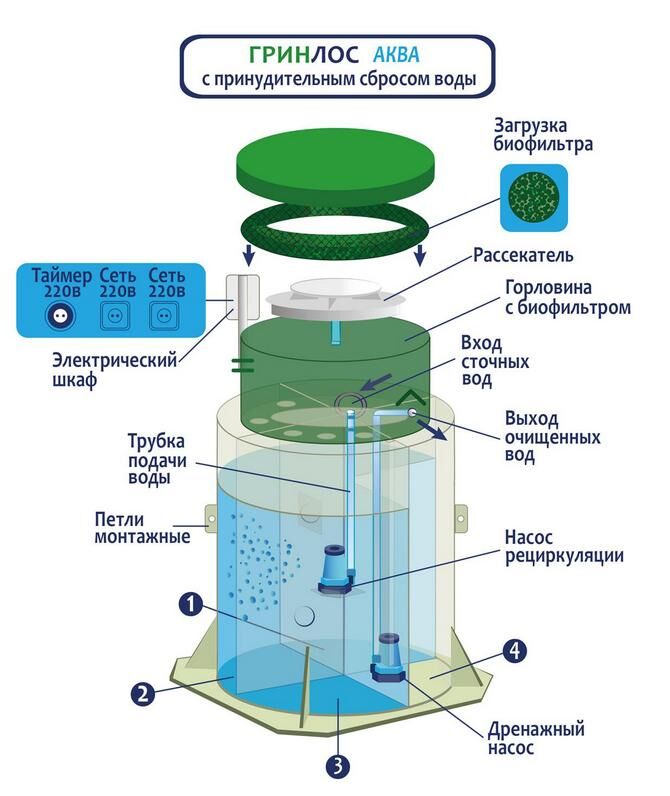

For forced discharge, a pump is placed in a separate compartment to pump out treated water from the septic tank. The process is fully automated and does not require control from the owner. Discharge is carried out into a drainage well or ditch.

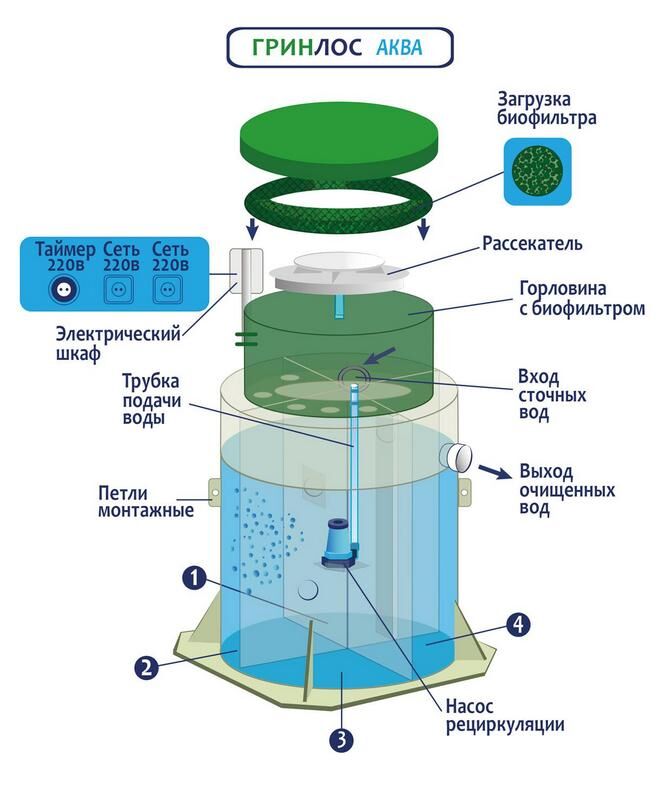

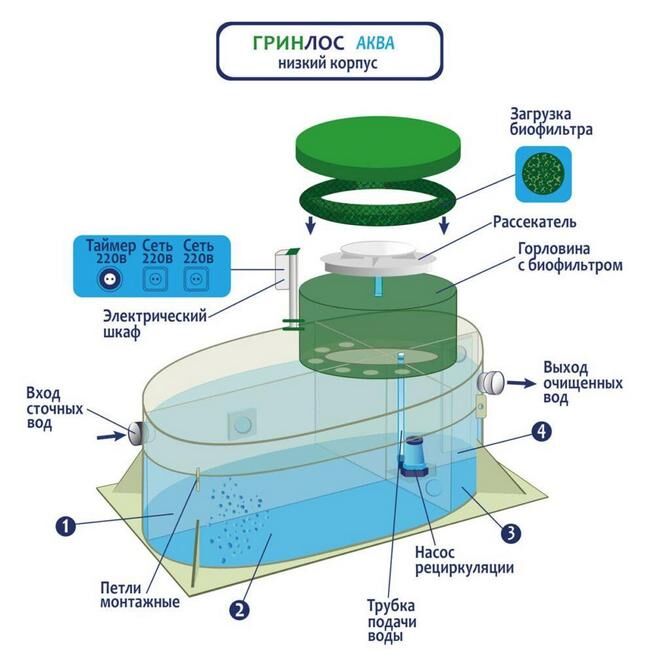

Design and principle of operation

The Greenlos Aqua station is a cylindrical structure with a neck, made of high-strength polypropylene.

Natural processing and decomposition of organic pollutants found in wastewater is carried out due to the vital activity of a special type of bacteria - aerobic. This process in Greenlos Aqua septic tanks is improved thanks to aeration and the presence of a biological filter (an element on which a biofilm of bacteria is formed).

In order to create a favorable environment for the development of microorganisms, the internal space is divided by partitions into separate chambers. They are connected by pipes and technological holes in the walls. The height of the connecting elements is determined by the physical principles of liquid separation.

Through the inlet, sewage is fed into compartment 1, where the initial settling and averaging of organic particles is performed. Most of them sink to the bottom, and some rise to the surface. Also in the primary settling tank, settled insoluble substances are broken down. Activated sludge washed from the biofilter is used as a catalyst for decomposition.

The clarified wastewater is directed to the second compartment (2). It continues the physical decomposition of substances when saturated with oxygen and coming into contact with activated sludge.

The treated wastewater enters chamber 3, in which nitrification and denitrification are performed. By means of a recirculation pump, liquid is periodically pumped out to the upper compartment of the treatment plant, as well as to the jet sprinkler. Uniform distribution of water over the entire area of the loaded biomaterial is ensured by a divider.

During irrigation, water is saturated with oxygen directed from the air intake. The submersible pump operates cyclically - 15 minutes in operating mode followed by a 45-minute shutdown. The duration of operation/shutdown modes is adjusted using a timer.

Inside the biological filter, the wastewater comes into contact with the anaerobic bacteria of the biofilm covering the bioload. Having passed through it, the water is saturated with air, which promotes the decomposition of organic matter that has not dissolved in the primary compartment.

After passing through several stages of purification, the water is considered conditionally pure and technical. From the third compartment, through the overflow-stabilizer, the liquid enters chamber No. 4. From it it is discharged outside (storm drainage, into drainage, onto the ground).

At Greenlos "Aqua" there are two possible ways to discharge treated wastewater:

- gravity (spout from the outlet pipe);

- pressure (if a drainage pump is installed).

In the first case, water is removed by gravity without the influence of pressure. In the second - by means of a float-type drainage pump, which is activated when the last chamber is filled with water.

Septic tanks Greenlos "Accumulator"

The Greenlos "Accumulator" line of septic tanks is represented by 7 gravity-flow models of varying performance. A pump for pressure removal of purified liquid is installed optionally at the customer’s request.

Purpose

Greenlos "Accumulator" septic tanks are flow-type water treatment systems. The energy independence of the installations allows them to be used in seasonal homes.They are used for biological purification of domestic water coming from a residential building or cottage.

The devices are among the most effective and economical methods of wastewater treatment in the absence of a connection to a central sewer system.

Characteristics

Greenlos “Accumulator” septic tank models have the following characteristics:

- The number of users is from 3 to 25 people.

- Performance. The daily volume of treated wastewater, depending on the modification, ranges from 0.6 to 5 m3/day

- The volume of the salvo release is from 180 to 1260 liters.

- Case diameter – 1250-1450 mm.

- Neck height - from 1000 to 2000 mm.

- Neck diameter - 115, 120, 130 mm.

Device and principle of operation

The body of Greenlos “Storage” is made of high-strength polypropylene foam. The material does not rust, does not rot, and tolerates temperature fluctuations over a wide range. The thickness of the internal walls is 8 mm, external - 10 mm. The container is reinforced with special stiffening ribs to transfer constant soil pressure to the walls.

Due to the lightweight design, the use of special lifting equipment during loading/unloading and installation is not required.

The container is divided into four chambers, in each of which a separate sewage treatment process takes place:

- In the first compartment, wastewater settles, impurities of large fractions settle at the bottom.

- In the second chamber, anaerobic bacteria in the biological load come into play. In the process of their life activity, wastewater is biotreated.

- In the third compartment, the liquid is clarified. The degree of purification of wastewater at its outlet allows it to be discharged to the ground for further treatment.

- Purified water flows into the last, fourth chamber for subsequent discharge by gravity or pressure mode.

At the exit from the Greenlos “Accumulator” septic tank, the level of wastewater treatment is 75-80%. To comply with the sanitary and hygienic parameters standardized by SanPiN 2.1.5.980-00, additional filtration of clarified water is required. Effluent must be directed to an aeration field, a filtration trench, or to a drainage element for soil purification.

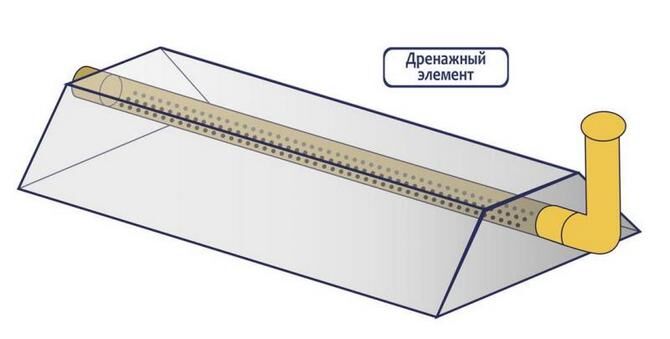

The drainage element is a special container without a bottom, placed on crushed stone fill. It has the shape of an inverted trough. A pipe runs along the entire length of the element, through which clarified water from the septic tank flows by gravity. Thanks to good ventilation, colonies of aerobic microorganisms develop on the surface of the crushed stone. Upon contact with oxygen, the nitrification process starts. Then, as the soil absorbs water, denitrification occurs.

Thus, both aerobic and anaerobic microorganisms are involved in the complete cycle. Thanks to this, waste liquids come out 80% purified.

Autonomous sewage system Greenlos "Aero"

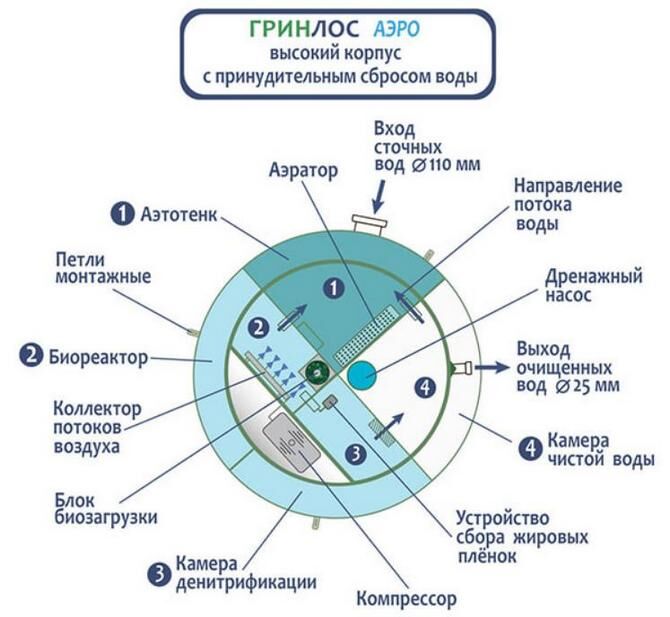

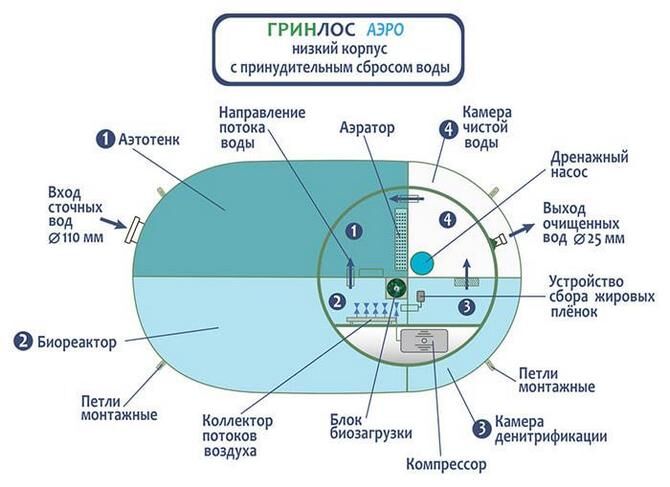

The Greenlos Aero station series consists of 10 models with forced and gravity discharge of treated wastewater. The manufacturer's catalog presents devices with both low and high casings.

Purpose

Greenlos "Aero" - aeration systems that allow you to achieve complete purification of household sewer liquids. The versatility and efficiency of the installations is due to their popularity and wide range of applications. The body is made of foamed polypropylene, which is highly durable and resistant to ground pressure.

Greenlos Aero biological treatment stations are used for residential buildings, dachas with permanent and seasonal residence. In case of a long-term break in operation, preservation is required.

Characteristics

A total of 10 models of Greenlos Aero stations are produced. Their main characteristics:

- The number of users permanently residing in the house is from 3 to 25 people.

- Productivity per day - 0.6-4.0 m3/day

- Salvo discharge - from 180 to 1200 l.

- Case height: standard - 1.7 m, low - 1.2 m.

- Weight - from 70 to 245 kg.

- Volume - from 1.5 to 6 m3.

- The insertion depth of the inlet pipe is 0.6 m.

- Electricity consumption – from 1.5 to 2.5 kW/day.

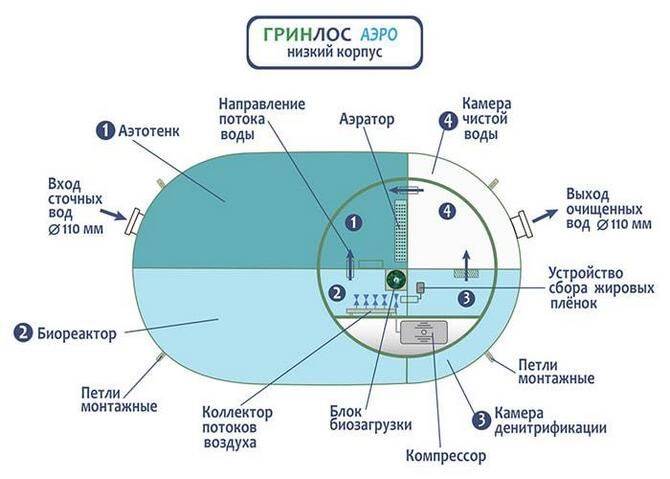

Design and principle of operation

Greenlos Aero systems are used to separate and process organic pollutants found in wastewater under the influence of aerobic and anaerobic bacteria. The decomposition process in the septic tank is improved, reduced by aeration of sewage and the installed biofilter, on the surface of which a biofilm of bacteria appears.

A high level of purification is achieved due to the use of two types of sludge - free and bound. This also extends the interval between scheduled maintenance.

Creating a favorable environment for high-quality cleaning requires separation of intermediate processes, distribution of waste liquid into isolated chambers, and their sequential flow from compartment to compartment. The design of Greenlos Aero stations is designed in such a way that all cameras are combined in one building. The processes of splitting, aeration and clarification of sewer liquid take place in them.

The body is divided into four tanks connected by technological overflows. When flowing from one compartment to another, wastewater is successively subjected to:

- averaging;

- aeration;

- I suck;

- nitri- and denitrification;

- clarification.

In the primary chamber, the sewer liquid coming from the inlet pipe is aerated using a fine-bubble aerator. Oxygen-saturated air is the main catalyst for the biopurification of domestic and industrial waters.

During aeration, large fractions of organic matter are separated into small ones. The purified liquid is saturated with oxygen, creating a favorable environment for the life of aerobic microorganisms. During aeration, activated sludge flakes are formed.

Then, oxygen-saturated water, through a hole arranged at the required height, is sent to the second compartment (bioreactor). It contains an inert load, which serves as the basis for the formation of immobile sludge, oxidation and nitrification of activated sludge particles.

Activated immobile sludge is concentrated in the bioreactor, due to which:

- the productivity of the treatment plant increases by 30%;

- the degree of purification of liquid from low-oxidation organic matter increases;

- nitrification is activated;

- resistance to salvo discharges increases.

Restoration of bioloading (removal of waste sludge) is carried out using a large-bubble aerator. The volume of air entering the second compartment is adjusted with a ball valve. The sludge washed away from the loading surface is fed into the primary chamber by means of an airlift.

In the third compartment of Greenlos “Aero”, during anaerobic processes, nitrification and denitrification of the liquid is carried out with the formation of molecular nitrogen. Using an airlift, non-degradable fat films are collected and redirected to the bioreactor.

At the end of the purification cycle, the water is considered technically clean. Through a soothing overflow it is fed into the last, fourth chamber. Depending on the modification (with pressure discharge or gravity), the liquid is sent outside (storm or drainage ditch, onto the ground, etc.). The remaining sludge that has not decomposed and settles at the bottom is redirected to the first compartment through the airlift. When discharging wastewater by pressure method, the drainage pump is placed above the airlift intake line.

Marking

Greenlos models of autonomous sewers are indicated by letter and digital markings. Its decoding looks like this:

- Greenlos “Aqua”, “Accumulator”, “Aero” is the name of the series.

- 3, 4, 5, 6, ..., 15, 25 - the maximum number of regular users.

- Pr - discharge of treated wastewater is carried out in pressure mode. The absence of this designation indicates a gravity discharge.

- Low case - installation in a case of reduced height. Used for placement in difficult geological conditions, with high groundwater levels, and the presence of quicksand.

Advantages of Greenlos treatment facilities

Foamed polypropylene is used to manufacture Greenlos stations. This is a modern high-strength material. The use of high-quality raw materials is not the only advantage of water treatment systems produced under the Greenlos brand. These also include:

- High level of purification - up to 99%.The use of innovative technologies allows us to achieve unique efficiency of septic tanks.

- Strength. Thanks to its cylindrical shape, the body is resistant to compression and does not float up, regardless of the depth of the ground water line.

- Ease and speed of installation. The modern design of septic tanks, their low weight simplifies and reduces the cost of installation. Installation, connection to the pipeline and configuration are completed within 12-24 hours. On the same day you can enjoy the benefits of civilization.

- Low operating costs. The carefully designed design of Greenlos treatment plants maximizes maintenance intervals.

- Service life - 50 years. The use of high-strength thick polypropylene allows Greenlos water treatment systems to last for several generations of owners.

- Safety, quality. Greenlos treatment plants are certified in the ISO 9001 system and have passed all the necessary examinations.

Installation and connection of Greenlos septic tanks

Thanks to the well-thought-out design of Greenlos treatment plants, installation work does not pose any particular problems. But in order to avoid possible errors during installation, each stage must be considered in detail.

Selecting a location

Greenlos septic tanks must be located in places that provide unimpeded access for sewage disposal equipment. At the same time, parking and traffic movement are not allowed within a radius of 2.5 m.

When determining the location of wastewater treatment systems, the following recommendations must be taken into account:

- protective gap (distance) to the house - at least 4 m;

- distance from the road and the boundaries of the personal plot - at least 5 m;

- distance to the nearest body of water - from 30 m;

- the protective gap to the point of drinking water intake is at least 150 m.

These distances are the minimum recommended. The exact dimensions are determined at the sewer design stage, taking into account the topography of the site and the geological conditions of the area.

Construction of trenches and pits

For the inlet and outlet pipes, trenches with a slope of 1-2° (1-2 cm/m) are equipped. A leveling sand cushion is placed at the bottom of each trench. To prevent pipes from freezing, it is necessary to provide insulation (sheet insulation, thermal cable, etc.).

The dimensions of the pit for installation of a septic tank are determined by the design features and dimensions of the model. The side walls of the pit must have slopes to prevent collapse and sliding of the soil. If necessary, they are strengthened. It is not allowed to install the container close to the walls - the gap between the body and the sides of the pit should be 25-30 cm.

Before installing Greenlos stations of any model, the bottom of the pit requires careful preparation. It is leveled manually or using machinery, and a sand cushion 10-15 cm thick is poured.

Pillow filling

The nature of the following work depends on the groundwater level at the site. When the groundwater level exceeds 2 m, it is sufficient to arrange a sandy base 30-40 cm thick.

The pillow performs two functions simultaneously:

- simplifies the precise leveling of the septic tank;

- serves as a kind of damper during seasonal ground freezing.

Sand is poured in layers - 5-10 cm. Each layer is saturated with water and compacted one by one. For greater reliability, sand concrete is added to the sand bedding in a ratio of 5:1.

If groundwater flows at a depth of less than 2 m from the ground surface, it is necessary to lay a reinforced concrete slab on top of a sand cushion or concreting the bottom. These measures help prevent the pit from flooding, floating and damaging the septic tank.

Formwork is installed along the perimeter of the bottom; for large models (from model 20), a concrete base is poured, reinforced with two-layer reinforcement. Before pouring, mounting loops are released for subsequent fastening of the Greenlos station. The surface is leveled using a cement screed. Horizontal deviations in level up to ± 3 mm are allowed.

It is possible to lay ready-made reinforced concrete slabs of standard sizes. The use of non-solid (composite) reinforced concrete products as a base slab is not permitted.

Installation of a septic tank and connection to the sewer network

The most important condition for efficient and trouble-free operation of the station is to install it strictly at level to ensure uniform distribution of liquid pressure on the walls of the container.

Installation is carried out only with closed covers. The tank is easily installed manually by 4-6 people, placed at each corner of the pit, using mounting loops or using textile slings. The use of metal chains and cables is not permitted.

The container is installed on a sand, sand-cement pad or on a concrete slab. The septic tank is secured through mounting eyes in the body and hinges in the slab using bandage belts or synthetic slings. If there are no eyes, slings or belts are thrown over the container and fixed.

To ensure stable ventilation, a vent riser is equipped.

Formation and installation of septic tank stiffeners

On the outside, on the vertical walls of some Greenlos models, stiffening ribs are structurally provided in the form of hollow columns with holes. Reinforcement is passed into these holes immediately before concreting or backfilling in the horizontal and vertical directions. At the intersection points it is tied with knitting wire, the columns are filled with concrete.

The formation of stiffeners is required when:

- deepening the septic tank using extension necks;

- high groundwater level;

- presence of quicksand;

- installation of equipment in rocky soils.

Concreting or backfilling of the septic tank is carried out only after the concrete has hardened in the columns.

Columns can be left empty when the container is deepened without the use of additional necks, in places with a low groundwater level, in homogeneous soils.

Backfilling of the station

Backfilling is done with sifted clean sand mixed with cement in a ratio of 5:1. The use of soil removed from the pit is not permitted.

Before backfilling, it is necessary to close the lids and fill the tank with water to a quarter of its volume. The amount of liquid in the container is gradually increased according to the level of the poured mixture. Backfilling is carried out in layers, with alternating compaction of layers every 30 cm and watering.

When using extension necks with a height of more than 25 cm, high groundwater level, and the presence of quicksand, instead of sand-cement backfill, the sinuses are filled with concrete.

The top of the container is filled with sand to a height of 15-30 cm with a small margin for shrinkage. The hatches should rise 15 cm above the ground surface.

For thermal insulation of a septic tank, it is desirable to use sheet material (EPS, isofol, etc.). The use of polystyrene foam is not recommended - under soil pressure it compresses and loses its heat-insulating properties. It is also undesirable to lay short-lived and hygroscopic mineral wool.

Volatile models of Greenlos stations require the installation and connection of a sealed electrical panel from which the electrical equipment is powered. The shield is carried above ground level.

Methods for draining water

There are several ways to discharge treated sewage water from septic tanks. The possibility of implementing one or another option depends on the installation model and discharge mode, groundwater level, and geological conditions of the area. Let's look at all the methods in detail.

Greenlos models with gravity discharge

Installation of a station with gravity discharge of clean liquid into a drainage ditch is carried out for low groundwater level and soils with normal water absorption (loamy loam, sand). To implement this method, a device for the free flow of outgoing water from the outlet pipeline is required to prevent flooding of the outlet pipe.

In other cases, during the warm season, the septic tank becomes clogged and silted - there is a high risk of flooding with discharged water. In autumn-winter time, both the pipes and the discharge point freeze. When operating a septic tank under these conditions, accidents are possible.

Installing a septic tank with clean water discharged into drainage allows you to reduce the occupied area of your personal plot. But the drainage element when implementing this method is subject to flooding during the seasonal rise of groundwater.

Installation of a septic tank with the discharge of treated wastewater into a filtration well is selected if there are water-absorbing soils on the site and if the groundwater level is low. It is possible to construct a well from standard reinforced concrete rings or install a ready-made plastic tank with corrugated walls and a base.

A check valve must be installed on the outlet pipe. It is necessary to protect the Greenlos septic tank from flooding during prolonged rains and active snow melting.

It is advisable to install an emergency pump under the outlet of the outlet pipe from the station to protect the equipment from flooding from the absorption well.

Greenlos models with forced reset

If it is impossible to organize the discharge of treated wastewater by gravity, water disposal is carried out in a forced mode. Such cases include:

- the occurrence of groundwater close to the surface;

- lack of nearby stormwater systems and drainage ditches;

- low water absorption of soils.

For weakly absorbent soils (clay, loam), installing a septic tank with water discharge into a drainage ditch is suitable.

Installation of a system with pressure discharge of water into a filtration well is used when laying a supply pipeline at a depth exceeding 1.1 m.

Operation and maintenance of Greenlos stations

The operation of a septic tank is based on the activity of living aerobic and anaerobic bacteria. The main participant in cleaning is the active biofilm. If unfavorable conditions arise for the development and nutrition of colonies of microorganisms, the quality of cleaning decreases.To prevent such a situation from arising, it is necessary to observe the culture of using the sewer system and bathrooms.

Discharge into the sewer is not allowed:

- construction waste (lime, cement, sand), household waste;

- petroleum products, fuels and lubricants, solvents, paints and other chemically active things;

- water obtained after washing swimming pools and containing disinfectants (chlorine, ozone, etc.);

- regeneration wastewater from water purification and preparation systems containing external oxidizers;

- wastewater from the regeneration of boiler or drinking water with a high concentration of salts, leading to the destruction of bacteria and biofilm;

- large volumes of wastewater with chlorine-containing products such as “Belizna”, “Persol” and others;

- medications, especially antibiotics;

- biological preparations used for cleaning pipes;

- drugs used to improve the efficiency of septic tanks and water treatment systems.

Allowed reset:

- toilet paper that easily decomposes;

- kitchen drains and water from washing machines, provided that detergents and cleaning products without chlorine are used;

- drains from the bathroom and bathhouse;

- a small amount of cleaning products for kitchen equipment, ceramic toilets, sanitaryware.

Maintenance of Greenlos water treatment systems is simplified as much as possible; it does not require the use of special tools. Monthly quality control of cleaning through visual inspection of the outlet water is sufficient.

Once every 1-2 years, it is necessary to remove the formed inactive sludge. Pumping can be done independently using a drainage pump or using the services of sewage disposal companies.

When the station operates correctly, the water after passing through all stages of purification is transparent and odorless. If the outlet liquid is cloudy, then it contains undissolved suspended particles. As a rule, this is observed when putting a septic tank into operation and occurs for the following reasons:

- an active biofilm has not yet formed in the biofilter;

- Bioremediation processes have not completely stabilized.

Also, the reason for a decrease in the level of purification may be changes in the quality parameters of incoming wastewater:

- temperature fluctuations:

- change in pH level;

- the presence of chemical pollutants that suppress the activity of bacteria;

- discrepancy between the volume of wastewater and the productivity of Greenlos installations;

- insufficient oxygen content;

- low air flow into the biofilter;

- hydraulic overload.

Conservation of Greenlos stations

Greenlos cleaning systems can be installed not only for permanent use. For the remaining time, for example, between the end and the beginning of the new summer season, the septic tank will be idle. When there is a break in operation for a period exceeding 3 months, equipment conservation is required.

The procedure includes the following steps:

- disconnecting pumps from the network;

- removal of pumping equipment, through which forced drainage is ensured;

- disconnecting pipes;

- alternately pumping out accumulated liquid from containers using a fecal pump or sewage disposal equipment;

- filling the container with clean water;

- filling the compartments with water to the level of the supply pipe tray;

- installation of temperature compensators in each compartment to prevent rupture of the housing during freezing.

How to choose the right treatment facility

Before purchasing a Greenlos treatment plant, first of all, you need to make sure that the selected model has sufficient performance. It is important that the treatment plant can handle the volume of waste generated in the home.

According to the standards established by SNiP 2.04.01.-85*, for each person living in a house, 0.2 cubic meters of water is required to be discharged as sewage. Thus, when selecting a Greenlos model for productivity, it is necessary to correctly calculate the daily volume of wastewater. To do this, a simple arithmetic operation is performed: the number of permanently residing people is multiplied by 0.2 (the consumption rate).

Thus, if the house is intended for permanent residence of a family of 3 people, then Greenlos stations with the digital marking “3” are suitable for installing an autonomous sewer system. The devices are capable of receiving and processing volumes up to 0.6 m3/day. If there are often guests in the house, or an increase in the number of residents is planned in the future, then the estimated volume must be taken with a reserve. In this case, a good solution would be the purchase and connection of Greenlos “4” or “5” systems, processing 0.8 and 1.0 m respectively3/day.

A septic tank with free-flow water drainage is selected only if there is a suitable topography and geological conditions. In other cases, preference should be given to installations with pressure discharge.

When choosing, you also need to focus on the groundwater level. If the ground level is low, the model is placed in a standard case; if the ground level is high, the model is installed in a lowered one (120 cm high).

Overflow septic tanks, storage tanks, and full-fledged biotreatment stations are produced under the Greenlos brand.A wide selection of treatment devices with different volumes, performance, and type of discharge makes it easy to select the appropriate model.

Have you successfully installed a Greenlos septic tank or another brand of installation on your property and would like to share your experience? Or are you just selecting a possible option and want to clarify some nuances? Ask questions in the comments, bookmark the article so as not to miss the answers that interest you.

Video

About the company and production Greenlos.

Installation of GREENLOS Aqua 4 Pr in winter conditions.

Installation of GREENLOS Aqua 3 in one day.