How to easily bend an aluminum pipe at home - simple methods

Bend the aluminum pipe as metal-plastic, at home you can either use a pipe bender or using improvised means. To get the best result, you need to know the intricacies of the process in advance.

The content of the article:

Features of production, properties of aluminum pipes

Aluminum pipe profiles are divided into three groups according to production method:

- cold-worked;

- pressed;

- welded

Rolled aluminum pipes are produced in different ways

The first position is aluminum pipes with a diameter of 6-150 mm. They are for general industrial purposes and are produced according to GOST under the number 18475-87.

The essence of the technology is that an aluminum blank is taken and a through hole is drilled along the axis. Then the workpiece is rolled between rollers, forming a cross-section of the finished product.

The second position is aluminum pipes with a diameter of 6-220 mm, manufactured according to GOST 18482-79. The technology is based on the method of pressing a heated workpiece on a special mill. The workpiece is placed on the matrix and pressed until the required shape is formed. Next, the semi-finished product is rolled on a mill through rollers.

The third position is aluminum pipes, made either from sheets or from tape, also known as strips, by twisting and welding along the seam on the inside and outside. The final step is necessarily hot tempering of the finished product. The reason is the relief of internal stresses in the welding areas.

Aluminum pipes can be divided into two further categories based on wall thickness:

- up to 5 mm – thin-walled;

- more than 5 mm – thick-walled.

During the production process, additional operations are often used that improve technical and operational characteristics. It's all about the metal itself. At temperatures below +20°C, deformation may cause the structure to break. Therefore, either heat treatment is used, for example, annealing or hardening, or mechanical processing - cold hardening, another name is cold hardening.

Both improvement options make it possible to make hard and durable metal out of ductile and soft metal. It is these profiles that are used in different designs.

And yet, high ductility is the main advantage of aluminum pipes. That is, it is not difficult to deform or bend the product, but it does not lose its qualities and properties.

Where are aluminum products used?

The scope of use is wide. Reasons for popularity:

- Aluminum products do not require special maintenance;

- ease of the resulting structures;

- ease of transportation and installation, including if the product needs to be bent.

Main areas of application:

- Agriculture. Drainage and watering systems are constructed from aluminum pipes, and fences for small animals and plants are assembled.

- Oil production. Aluminum pipes are inert to petroleum products and do not change their characteristics under their influence.

- Ventilation systems. Aluminum products are easy to deform, cut and drill; they can simply be bent, which simplifies the process of installing ventilation air ducts and shafts.

- Construction. Frames for gazebos, hangars and canopies are made from aluminum pipes. They make railings, canopies, fences.Today, they are increasingly using curtained facades in the construction.

- Furniture – chairs, armchairs, tables, etc.

- Advertising – billboards, stands, frames for display cases.

Useful: How to make a gazebo from a profile pipe with your own hands.

Bending process

It is possible to bend an aluminum pipe at home, but this compromises the density of the metal. On the outer side of the bend it decreases, on the inner side it increases. As a result, there is often a rupture on the outside and compression on the inside. This profile can only be used in non-loaded structures.

Difficulties

When bending a pipe at home, you can encounter several obstacles that reduce quality:

- It is practically impossible to bend anode-type aluminum profiles. They are durable and hard, so there is a possibility of the product breaking (cracks).

- In pipes made by pressing using hot extrusion, large internal stresses arise at the bend points.

- Duralumin, as well as alloys in which manganese is added, have increased hardness. They are also not easy to work with.

If the rolled pipe was purchased without a certificate, then it is not difficult to determine what alloy it is made of. For example, duralumin does not leave paint on your hands. You can tap the pipe with a hammer. The ringing sound indicates that it is made of hard alloy. Another way to check is to sharpen the edge with a file. If a metal deposit has formed on it, then the alloy is soft.

Manufacturers must mark the surface of pipe profiles. You can check it in a reference book and determine the alloy.

Related article: How it is produced metal pipe bending.

Bending methods

Before you bend an aluminum pipe with your own hands at home, you need to understand the bending methods. But at the beginning it is necessary to indicate that pipes can be bent cold or hot. When choosing an option, you need to consider the following factors:

- wall thickness;

- alloy grade;

- product length;

- complexity of the final product configuration.

There are basic, also commonly used, configurations:

- bend - the pipe is bent in one plane at an angle of 45°-135°;

- weft – two bends of 135° each;

- kalach is a semicircle;

- bracket - the pipe is bent three times (two extreme bends are 135° each, the middle one is 90°).

To correctly bend an aluminum pipe at home, you need to take into account some recommendations:

- If a suture product is bent, the seam should not be located in the plane of the external or internal bends.

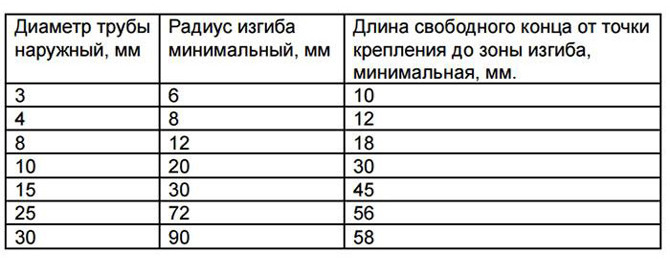

- If products with a diameter of no more than 20 mm are bent, then the radius should not exceed two pipe diameters.

- If rolled products with a diameter of more than 25 mm are bent, then the bending radius should be three times the diameter.

Necessary equipment

The easiest and most reliable way to bend a pipe at home is to use a pipe bender. This equipment is presented on the market in two modifications - manual and mechanical.

Since the task is to independently bend aluminum pipes at home, we need to consider manual options. They are presented in three models:

- Lever, aka Volnova machine. The design of the machine includes a special mold of a certain diameter. The pipe is placed in it. Then, under the action of a lever, it bends. The process is carried out without heating the workpiece.

- Crossbow.Here everything is the other way around, the pipe does not bend around the mold, but is pressed into it.

- Spring-loaded. To create the shape, a spring is placed in the pipe. Then the product is subjected to heating and subsequent bending. The operation with small profile diameters can be carried out “cold”. After finishing, the spring is pulled out.

Pipe benders are often equipped with drives that improve the quality of the process. Drives can be electromechanical or pneumatic. Using such equipment, you can use different technologies for bending aluminum profiles:

- Pushing. This method is used when processing pipes with a diameter of no more than 100 mm. In this case, the minimum bending radius is equal to six diameters. The process itself is carried out by pushing the pipe between the rollers of a pipe bender. One of the rollers is at an angle, which creates a bend.

- Rental The aluminum pipe is passed through three rollers (rollers) located at an angle to each other. In this way, you can bend the profile into a ring, a spiral or an arc. To achieve high quality and precise shape, the process is carried out several times. This is how not only round rolled products are bent, but also profiled ones.

- Running in. The pipe bender has a so-called rolling head, consisting of a ball and a mold. The ball creates pressure on the pipe section, and where the pressure is low, the product bends in the opposite direction. The process is carried out without heating.

- Bend under pressure. The first option is to pour oil or water under pressure inside. The pipe is first installed in the mold. It is the pressure created inside the cavity that leads to bending. The second method is to use a press or stamp that presses on the bend area.

How to bend a pipe at home

It is necessary to immediately make a reservation that if the operation of bending aluminum products will be carried out at home constantly or with enviable frequency, then it is better to buy a pipe bender. If you need to bend an aluminum pipe without a pipe bender, there are several ways.

The first option involves sand. It is dried and sifted. One end of the profile is plugged; you can use a wooden peg (chopik). Prepared sand is poured on the opposite side. To ensure that it fits tightly inside the product, tap the surface with a hammer. After which the end is also muffled.

Next, the aluminum profile is installed in the bracket and bent to the required angle. Instead of a bracket, you can use two adjacent trees, poles and other structures sticking up, such as pegs or reinforcement driven into the ground.

Option number two is the same previous method, only the profile is bent with additional heating. This is usually done if the alloy has given the product increased strength and hardness. The most important thing here is to avoid heating the same area multiple times.

The third way to bend an aluminum pipe at home is to make a template from wood. This is a round flat blank and a board. Both elements are of the same thickness, equal to the diameter of the product being bent. They are easily attached to a table or workbench with clamps or bolts. The rolled product is inserted between wooden elements and bent around the blank. The board serves as a stop.

The fourth method is to fill the profile with sand, lay the ends on two stops, and form a deflection with a mallet.

The fifth method is used when it is necessary to bend a large diameter aluminum pipe made of a durable alloy.To do this you will need a grinder and welding machine:

- Determine the location of the bend. Its length is indicated with chalk.

- A grinder is used to make cuts along the outer surface.

- Bend to the desired angle. The slots are on the outside.

- The cuts are welded using electric welding.

The video shows one of the simple and original ways to bend an aluminum pipe at home.

Basic mistakes when working

The biggest mistake made when trying to bend aluminum profiles is incorrectly identifying the alloy. If it is hard and durable, then the pipe cannot be bent without heating. If you manage to make a bend, the quality will be low. There is a high probability that cracks will appear at the bend.

The second mistake is an incorrectly selected bending radius. As mentioned above, this parameter is selected taking into account the diameter of the profile. And the larger this size, the larger the radius should be. For example, it is impossible to bend a rolled aluminum pipe with a diameter of 50 mm into a product with a bend radius of 100 mm so that the surface is not covered with a network of cracks. Even heating won't help.

The heating of the pipe must be carried out correctly. And this is the third mistake. To do this, use a gas torch or a regular blowtorch. To check whether the aluminum is heated to the required state or not, you need to bring paper to the heated area. If it starts to smoke, it means the temperature is sufficient to begin the bending process.

Not all of the methods described above allow achieving high accuracy of the configuration of the bending profile. For example, if you need to bend a piece of small diameter, then it is better to do this at the end of the pipe, and not in the middle.

To achieve the smallest area with a corrugated part, it is better to bend the product using the cold method, followed by stretching.

If high strength of the profile walls is required, it is better to use the hydraulic bending method. It consists of pouring water or oil under pressure inside.

You can bend an aluminum pipe using different methods, even without specialized equipment. The main thing is to choose a method taking into account the profile parameters and comply with the requirements for the radius of curvature.

I would like to hear comments on different ways to bend aluminum pipes with your own hands. Share the article on social networks, save it in bookmarks.

Bending a pipe manually without a pipe bender in the video.

The material in the article is clear and useful to me. However, I have a question: is it possible to bend an aluminum tube Ø16 mm so that the distance between the ends of the tubes is 20 mm. or min. only 30 mm?