What to do if the gas valve on a gas water heater does not work: diagnostic and repair features

In case of any breakdown, most owners of a gas water heater call a specialized service technician. However, services usually come with financial costs, right?

Why not solve a seemingly insignificant problem yourself using the skills of a mechanic? You can try to cope with a situation where the gas valve on a gas water heater does not work on your own. But what is needed for this and where to start?

In this material we will talk about the design features of the gas valve. Let's look at the main breakdowns that lead to the inoperability of the column. For a better understanding of the diagnostic and disassembly process, we will provide the presented material with visual photographs and a video.

The content of the article:

Gas water heater valve device

In order to make it easier for home craftsmen to restore the functionality of a gas boiler, in particular when there is a malfunction of the gas valve, we will consider the design of the unit and the technical nuances of diagnostics and repair.

But, if you do not have experience in disassembling geysers and relevant knowledge on the topic, then for repair and maintenance It is preferable to invite a master.

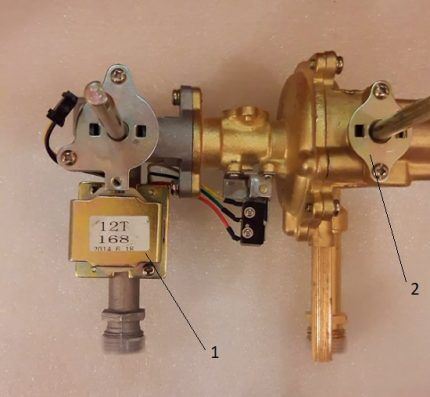

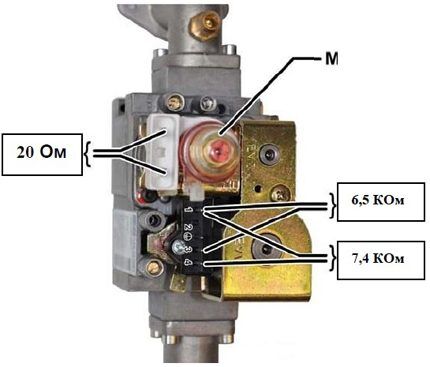

A device called a gas solenoid valve performs an important function of a gas water heater - controlling the flow of the fuel component (natural gas). The picture below shows a common version of the design of the control unit, which includes the valve.

In fact, the control unit is a two-stage mechanism, the first stage of which is the gas solenoid valve (1). The second stage is a mechanical device that provides adjustment via a manual control rod (2).

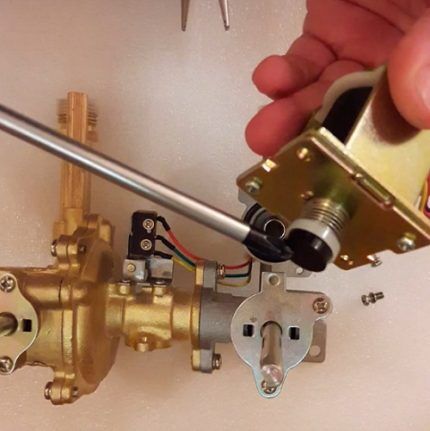

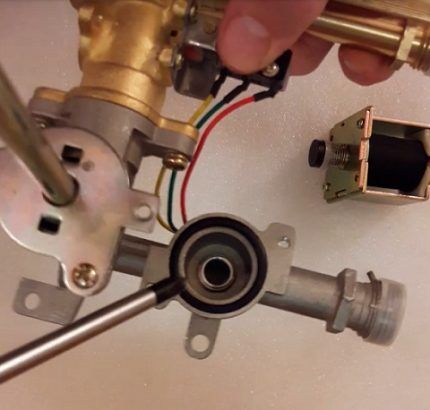

The design of the gas valve is quite simple - it is made on the principle of an electromagnetic traction device, which are used as part of a wide variety of devices and devices. If you dismantle this component from the control unit diagram, for which it is enough to unscrew a couple of screws, the valve part, which is attached to a spring-loaded metal rod, will appear before the eyes of the master.

As you can see from the picture, the design consists of body-skirts, where the valve part goes - membrane And electromagnetic module. The valve part is fixed to a metal stock, spring-loaded for the return stroke to the “closed” position.

When voltage is applied to the electromagnet coil, the metal rod moves upward under magnetic influence and moves the membrane away from the passage hole of the skirt.This opens the gas passage towards the manual valve and further to the burner.

Valve troubleshooting and troubleshooting

Loss of functionality of the gas valve leads to the complete impossibility of operating the heating equipment, or to a situation where the required level of heating is not provided due to incomplete opening of the membrane.

On the other hand, there may be reasons that, on the contrary, lead to a constant flow of gas to the boiler (column) burner. That is, a situation arises when the gas valve is constantly open.

Step #1 - Simple Check of Electrical Components

It is possible to test the functionality of the gas solenoid valve on the dispenser (boiler) without dismantling the control device. However, to perform the test directly on the equipment, it is necessary to ensure that the gas supply is turned off by closing the valve on the main line. In this case, the gas water heater (boiler) remains connected to the electrical network.

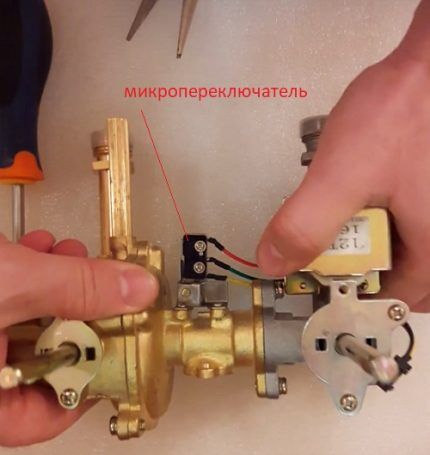

The device for regulating the gas supply to the burner, as a rule, contains an electronic component - a microswitch (see picture above), through which, when the gas water heater is turned on, power is supplied to the main technological parts.

In particular, the supply voltage is supplied via a micro-switch:

- to the ignition module;

- to the traction turbine fan;

- to the solenoid valve coil.

So, if you forcefully, for example, use a screwdriver blade, to act on the pusher plate of the microswitch, these geyser (boiler) systems will receive power.

As a result, the following components are activated:

- fan;

- electric lighter;

- solenoid valve.

That is, the inspector will hear the sound of a running fan, the characteristic clicking sounds of a gas lighter, and, of course, the characteristic click of the solenoid valve rod. This state of the equipment demonstrates the serviceability of the components, at least electrically.

Stage #2 - disassembling and testing the valve

The reason for the failure of the unit can be various defects.

Among them:

- violation of the shape of the membrane seal;

- foreign object getting inside the skirt body;

- return spring break (wedge);

- break in the electromagnet coil conductor.

The first three defects in the list are discovered after disassembling the device with a careful inspection of the structure and checking the rod for free axial movement.

The last item on the list requires a separate approach to testing – coil conductor break electromagnet. We will talk about the types of breakdowns and methods for eliminating them further.

Stage #3 - checking the electromagnet coil and repairing it

The practice of operating geysers and boilers shows that a defect in an electromagnet coil is not only a break in the winding conductor.

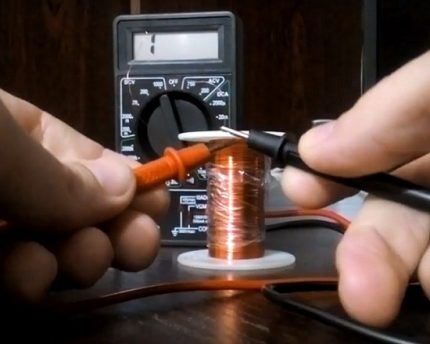

There are frequent cases turn-to-turn short circuit, which also leads to loss of node functionality.How to check the solenoid valve of a household geyser at home?

Of course, each individual geyser manufacturer (boilers) original valve designs are used. Therefore, the resistances of the inductors that make up the electromagnet differ significantly.

In general, we can note a certain range of resistances characteristic of such inductances: 1.3 - 7.5 kOhm. Essentially, the specific parameter should indicated in the documentation for the equipment.

Measuring an inductor is traditionally carried out in resistance measurement mode - by connecting the tester probes to the contacts of the inductor. If the device does not respond to connection, it is obvious that there is an open circuit.

If the measured resistance parameter differs from that indicated in the documentation, most likely there is an interturn short circuit. In both cases, the coil should be replaced.

In practice, replacing a coil as a separate element of a gas boiler valve is rare. As a rule, if a fault is detected specifically in the inductance winding, the technicians replace the entire solenoid valve assembly.

This replacement is due to the difficulty of finding a specific component.And the procedure for replacing an individual element itself is more complicated than replacing a gas solenoid valve assembly.

Stage #4 - finding and eliminating mechanical defects

As noted above, a magnetic valve for a household geyser may lose its functionality for purely mechanical reasons. For example, the accidental appearance of a foreign element inside the valve threatens the loss of tightness of the membrane seal.

To detect the cause of the breakdown, the technician will have to perform a number of actions:

- removing the gas valve;

- its subsequent disassembly;

- careful check.

These manipulations make it possible to detect and eliminate malfunctions associated with foreign objects entering the working chamber.

Among mechanical defects, a fairly common point is elastic membrane defectwhen there is a violation of the shape or partial destruction of the landing site. Here, in principle, you can get by by installing a new membrane on the rod, but traditionally craftsmen in such cases resort to completely replacing the solenoid valve.

The situation is similar with device repair when it comes to broken return spring or loss of necessary pressure force this element. To replace the spring you have to disassemble the entire structure.

However, some valve models are assembled using joints without screws - rivet method or metal fasteners. Therefore, it is much easier to replace the structure completely than to engage in restoration.

Stage #5 - valve assembly and leak testing

If troubleshooting a gas solenoid valve involved disassembling the mechanical structure, reassembly must involve careful leak test. Definitely worth checking gasket integrityinstalled on the upper rim of the skirt, if necessary, replace the gasket.

The assembled unit is checked in the standard (traditional) way with the gas supply turned on. Take a suitable container, add a little water and add soap powder. Created thick soap suds, which is applied to the skirt body in the place where the gasket is installed. If the formation of bubbles is not visually observed, then the tightness is within normal limits.

Have you figured out the valve, but are you faced with attenuation of the gas water heater or other problems? We recommend that you read our other articles, in which we examined the most common breakdowns and how to fix them:

- Why the geyser goes out: typical reasons and a guide to eliminating them

- Gas boiler draft sensor: how it works and works + subtleties of checking functionality

- How to replace a geyser membrane: reasons + instructions for repairs

Conclusions and useful video on the topic

Testing the device in a simple way, filmed on video, clearly demonstrates how this process is carried out. Of course, this technique is not suitable for all geysers without exception, but for most models the material is quite relevant:

You can perform a test for the operability and suitability of an electromagnetic gas valve yourself or contact a specialist. However, it is worth remembering that gas equipment belongs to equipment with a high level of danger and when handling it you should adhere to certain rules and regulations. The slightest shortcomings, omissions, or ignorance when performing installation (repair) work can lead to serious consequences.

At the same time, turning to specialists eliminates the risk component. Therefore, without experience in performing repairs and relevant knowledge, it is not recommended to compare monetary costs and personal safety in such matters. It’s easier and safer to call a specialist from a specialized service with whom you have contract signed.

Would you like to supplement the above material with useful tips for troubleshooting failures of the solenoid valve of gas equipment? Or are you engaged in self-diagnosis and disassembly of the unit and want to clarify a couple of nuances? Ask your questions, add unique photos containing a clear example, write recommendations in the feedback block located below the article.

Column Oasis. The solenoid valve is activated if the water is not turned on (we turn on the microswitch ourselves). After it clicks, we turn on the water - the column lights up (this means gas is supplied and the valve is working). Simply by turning on the water, the microswitch is activated, because... a spark appears, but the solenoid valve does not click and there is no gas supply. please tell me what is the reason and how turning on the water can affect the valve so that it does not open?

THIS IS THE OPERATION OF THE RETRACTING RELAY. BY RETRACTING THE ROD, THE GAS COURSE OPENS AND THE COLUMN LIGHTS ON.

idiotic article, it’s a no brainer. What kind of sensor gives the signal to turn on?

In Column Neva.