How to replace a geyser membrane: reasons + instructions for repairs

Domestic water heaters - gas water heaters are used in old high-rise buildings and private houses to prepare sanitary water. Their parts and components tend to wear out just like any other equipment. Most often, the membrane of the water reducer fails, which you can change yourself.

We will tell you how to replace the membrane of a geyser. The article we have proposed describes in detail the steps to prepare for replacing the membrane and provides recommendations for its selection. Taking into account our advice, you will be able to monitor the operation of the gas heater or restore the functionality of the water heater yourself.

The content of the article:

About the reducer and the location of the membrane

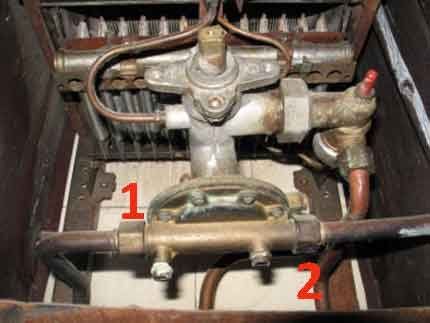

A device called a water reducer is part of almost any design of gas heat exchangers.

This part may have different configurations depending on the model of the water heating apparatus, but the principle of operation of such devices remains unchanged.

A water reducer installed on a gas water heater serves to stablely maintain water pressure directly in the water heater heat exchanger system.Due to the uniformity of pressure, a uniform flow is ensured, which means the same uniform heating of the liquid.

A part of the gearbox that facilitates smooth pressure regulation is a rubber membrane. This gear component, made in the form of a gasket, usually based on technical rubber, has the shape of a circle. It is installed inside the gearbox housing.

Due to the long-term operation of water heating equipment, being constantly in motion, the membrane gradually wears out. Wear of technical rubber in some places leads to tears in the material. Accordingly, the function of regulating water pressure stops operating according to the specified algorithm.

In such cases, it becomes inevitable to replace the rubber membrane of the reducer in the gas water heater, because the water heater does not work properly.

The quality of sanitary water heating decreases sharply, and in other cases the column simply cannot be put into operation. Comfort for the user is lost.

Reducer Diaphragm Replacement Steps

If we proceed from the rules for servicing gas equipment and strictly follow these rules, performing any installation, plumbing work, as well as work related to power supply is the prerogative of gas service providers, in particular, the local gas service company.

What do you need to know before starting work?

In other words, owners of gas water heaters are prohibited from carrying out work on gas equipment themselves.And even taking into account that the water reducer is theoretically not related to the gas system, disassembling this structural part and changing the membrane with your own hands is also prohibited.

Sometimes the desire to do everything yourself, without having practical experience in performing this kind of work, can result in disastrous consequences. As evidenced by the numerous accidents associated with household gas equipment.

However, premature wear of the membrane and other components of the water heater under pressure can be prevented by promptly carrying out equipment cleaning with your own hands or by a representative of the gas service.

There are often craftsmen who are ready to independently change the gearbox membrane on a gas water heater. Moreover, it is, in fact, not at all difficult to perform such an operation if you have plumbing skills.

Do this easy job as follows:

- Using documentation or by opening the column housing and examining the internal contents, determine the brand (model) of the installed gearbox.

- Based on the technical information obtained, they purchase a new membrane on the market.

- If the equipment is imported, you may have to purchase the membrane only to order.

- If there is a membrane, shut off the gas supply to the equipment and close the cold water supply tap from the central heating system.

- Drain the contents of the heat exchanger gas heater, using the service drain valve, the location of which is determined according to the documentation.

After these operations, you can begin dismantling the gearbox. However, there is no need to rush here. You need to work carefully and carefully so as not to damage other nearby parts of the gas water heater.

Gearbox removal and disassembly

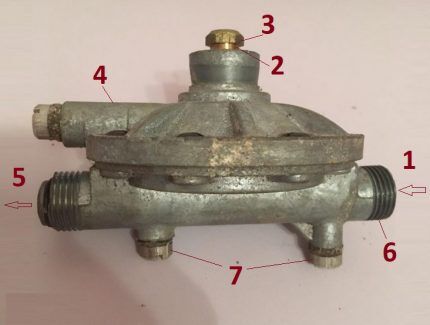

The water pressure reducer has inlet and outlet pipes. Actually, thanks to threaded union connections, the device is mounted inside the gas system, directly on the water flow line.

Therefore, in order to dismantle the device, it is necessary to unscrew the two union brass nuts securing it to the pipeline. But before doing this work, it is recommended to unscrew one or both plugs on the gearbox drain outlets, which are located under the disc housing.

The nuts should be unscrewed smoothly, while simultaneously holding the device from possible rotation. The mechanism of the device has a regulator rod that is in contact with another part of the gas water heater. On some models, the rod head is secured with a screw. This point should be taken into account and, if necessary, loosen this screw.

Dismantling may be accompanied by residual water leakage.It is recommended to stock up on convenient, capacious containers for collection.

Brief instructions on replacing the membrane

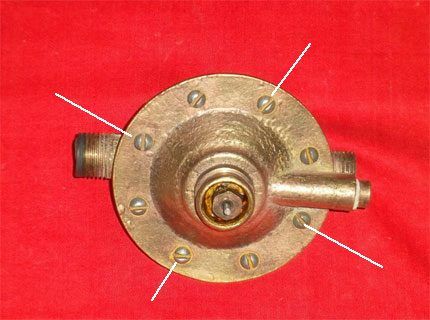

The removed pressure regulator will need to be disassembled to get to the rubber (silicone) membrane. The disassembled part looks roughly like a plate.

Disassembly/assembly sequence:

- Unscrew the fastening screws on the top of the plate;

- carefully use a flat-head screwdriver to bifurcate the plate;

- remove the defective membrane;

- install a new one;

- articulate the halves of the plate;

- secure the joint with screws in a circle.

The correct location of the membrane on the gear plate is determined by a special “key” recess or pin, which, in turn, is located on the radial edge in the same row as the holes for the mounting bolts.

You need to align the membrane “key” with this notch before connecting the plate halves and screwing in the screws.

The moment of screwing in the mounting screws is a traditional action. However, you should keep in mind the uniformity of tightening of the gearbox parts. Technically competent tightening is performed using the “crosswise” method. That is, first, four screws located one opposite the other are tightened sequentially, and only then all the others are tightened.

The assembled gearbox, equipped with a new membrane, is installed in place in the reverse order.Carefully insert the rod inside the tube of the control device, align the device to the level of the water pipes. The nuts are then manually screwed onto adjacent sections of the pipe.

As a rule, pipe connections require the presence of sealing gaskets and their correct installation. This point must be taken into account when installing the gearbox at the installation site. Next, all that remains is to tighten the fastening nuts, applying a little force and do not forget to tighten the drain plugs under the plate.

Membrane shapes and materials

The design of geysers is varied. Accordingly, a change in the design of the pressure reducer cannot be ruled out. Therefore, the existence of reducing membranes of various shapes also seems to be an obvious phenomenon.

If a round-shaped product, which can often be found when disassembling the valves of domestic geysers, is considered standard, imported devices are often equipped with “exotic” ones.

One such example is the geysers of a well-known foreign company that produces household appliances under the Electrolux brand. Many models of equipment from this brand are equipped with figured membranes in the form of a “figure eight”.

The devices of the foreign company Vaillant are somewhat less popular compared to Electrolux, but they also stand out from the entire range of household geysers due to the non-standard production of gear membranes. When disassembling their valve, there is a chance of colliding with the flag membrane.

For the sake of objectivity, it should be noted: products of non-standard shape show finer regulation of flow pressure, however, in terms of long-term performance, they are often inferior to standard ones. Often the degree of durability is determined by the quality of the material.

In practice, it has been noted that silicone membranes last longer than rubber ones. However, for silicone, an important criterion is careful filtration of network water. Even a small amount of sand or rust that gets into the area where a silicone product is located will dramatically reduce the service life of the material.

Technical rubber is less sensitive to the effects of suspended particles, but for the most part “suffers” from insufficient chemical resistance. That is, if the composition of the water has an aggressive component to some extent, under these conditions, products made from technical rubber usually do not last long.

Repair of geyser membranes

The desire to save on everything forces some users to resort to such a virtual replacement technique as repairing a defective membrane with their own hands.

It should be noted right away: this activity may be interesting for a home handyman, but, from a service point of view, it is absolutely irrational and pointless.

They try to repair geyser membranes in different ways:

- by puttingty with silicone sealant;

- using various types of adhesives;

- application of pentelast;

- installation of miniature patches;

- and even masking tape.

The activity of such a “repaired” part lasts, as a rule, no more than 1-2 days. After which the problems begin again, and often worsen.

Repairing membrane plates of geysers, especially with your own hands, ends in failure in any case. Tested in practice more than once. So, it is not recommended to change the “awl for soap”, unless there is a purely research interest in this matter.

If it is not possible to restore the functionality of the wall-mounted water heater, you will have to buy a new gas water heater. Will familiarize you with guidelines for choosing equipment next article, which examines this topical topic in detail.

Conclusions and useful video on the topic

The video demonstrates the personal experience of one of the heater owners - that is, do-it-yourself repair of the water pressure regulator. In particular, all repairs come down to replacing the membrane. We remind viewers once again: independent repair of gas systems is unacceptable!

It’s easier to find and buy a new membrane for a geyser, replace this accessory according to the instructions described above and sleep peacefully. Moreover, replacement, in most cases, does not require significant financial costs. On average, 200-300 rubles are enough to purchase a complete accessory.

Please leave comments, post photos related to the topic of the article and ask questions in the block below. Tell us about how you selected and changed the membrane in a gas water heater. Share useful information and technological nuances that will be useful to site visitors.

After five years of operation, the gas water heater suddenly stopped working. It took me a long time to figure out what the reason was, then I realized that the membrane was to blame. We barely managed to buy a new one to replace it. Imported column, I was very afraid to change it myself, I read a lot of instructions. But still, after much torment, I managed to do everything myself, but it only took a very long time to assemble and put everything in place.

The column began to work somehow strangely. My neighbor is a mechanic. I called him, and we began to think about what could be the reason. We came to the conclusion that the faulty membrane was to blame. We spent half a day fiddling with it. Although you described everything in the smallest detail, the lack of practice took its toll, and you didn’t have the right tool at your disposal. In the end, I called a mechanic from the gas industry, and he got it done in half an hour.

MEMBRANE 18POP PROTHERM. I barely found it in online stores. And even then it’s a question of availability. From 2000 to 3000 price

There are different membrane options. I have a Bosch term 4000, I found a membrane for it for 1700 rubles.