Pyrolysis heating boilers: operating principle and types of long-burning boilers

Years go by, science and technology move forward, and solid fuels still remain in demand.Burning wood in a traditional stove or potbelly stove is not very effective, but pyrolysis heating boilers have changed the situation - the units are characterized by high efficiency and relatively simple operation.

Agree, these are quite significant arguments when arranging autonomous heating. If you are looking for an efficient boiler for your home, then you should take a closer look at pyrolysis boilers.

We will tell you how long-burning units are designed and operate, what their technical and operational features are, and also provide an overview of the most rated models from domestic and foreign manufacturers.

The content of the article:

What is pyrolysis

Firewood is perhaps the very first fuel in human history. Almost everyone knows how quickly they burn in the open air, and that not much heat is released. But the situation changes radically if different conditions are created for the combustion process.

The so-called pyrolysis combustion is carried out in closed chambers. Firewood or other solid fuel of a similar type is loaded there: pellets, sawdust, wood waste, etc.

The fuel is ignited and then the amount of air entering the chamber is reduced.

As is known, during combustion oxidative processes occur, one of the main participants of which is oxygen contained in the air. If there is little oxygen, the reaction slows down and the wood burns slowly; in fact, in such conditions it simply smolders. This releases a certain amount of thermal energy, ash and flammable gas.

The pyrolysis process does not end there.The gas obtained by burning the primary fuel mixes with air masses and also burns. As a result, it releases significantly more thermal energy than when operating standard heat generators.

Therefore, pyrolysis boilers demonstrate very decent efficiency compared to their pure solid fuel “brothers”, and also often provide an opportunity to significantly save on heating costs.

The advantage of heating equipment of this type is that the principle of its operation and design is relatively simple. The amount of air entering the combustion chambers is controlled by a conventional mechanical damper. The simple design ensures the reliability of the device; breakdowns for pyrolysis boilers are not a frequent occurrence.

Another “plus” of pyrolysis boilers is a long combustion period. Fully loading the device with fuel allows you not to interfere with the process for several hours, sometimes more than a day, i.e. there is no need to constantly add wood to the firebox, as happens with open burning.

Of course, this does not mean that the pyrolysis boiler can be left unattended. As with other heating equipment, there are strict safety regulations.

It is worth remembering that a pyrolysis boiler is not omnivorous - the fuel moisture content should be low. Otherwise, part of the precious thermal energy will be spent not on heating the coolant, but on drying the fuel.

When implementing pyrolysis combustion, the fuel burns almost completely; the device will have to be cleaned much less frequently than when operating a traditional solid fuel boiler. The fine ash obtained after cleaning is used as fertilizer. Fuel combustion in such boilers occurs from top to bottom.

Therefore, the possibilities for natural air circulation in the firebox are noticeably limited. The use of forced air injection using a fan significantly improves the efficiency of the device, but at the same time makes the boiler energy-dependent, since the fan requires electricity to operate.

Design and operation of a pyrolysis boiler

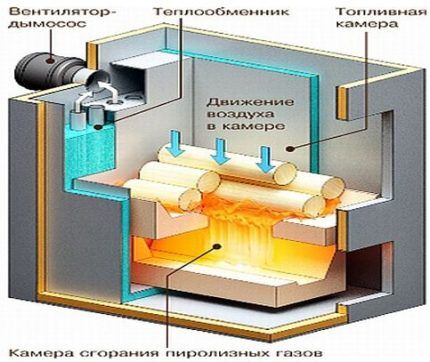

The firebox of the pyrolysis boiler is divided into two sections. In the first, firewood is burned, and in the second, secondary combustion of a mixture of pyrolysis gases and air is carried out. The first chamber is separated from the second by a grate, on which the fuel is placed.

The air is usually forced by a small fan. Although in small models sometimes a smoke exhauster is used to create draft.

The presence of forced ventilation can be considered the main difference between a pyrolysis boiler and a classic solid fuel model. The device body consists of two parts inserted into each other. The space between the walls is filled with a coolant, the role of which is traditionally played by water.

First, fuel is loaded into the first compartment of the furnace of the pyrolysis boiler, then the fan is turned on and the fuel is ignited.The resulting flammable gases move to the second compartment, mix with air and burn.

The combustion temperature can reach 1200°C. The water in the external heat exchanger is heated and circulated through the heating system of the house. Remains of combustion products are removed through the chimney.

Devices that use the pyrolysis combustion principle can be reproached with a relatively high price. A conventional solid fuel boiler costs significantly less. But in long-burning boilers, wood burns almost completely, which cannot be said about a classic boiler.

When choosing a pyrolysis boiler, you should remember that inexpensive low-power models are usually designed only for firewood. Expensive modifications can work on different fuel types.

Moreover, you will have to load fuel into the device to the maximum; reducing the load leads to increased formation of ash and soot, and also negatively affects the operation of the unit as a whole.

Top combustion boilers

One of the options for a pyrolysis device is an upper combustion boiler. The operating principle of these two units is very similar.

In the same way, a large amount of low-humidity solid fuel is loaded into the firebox, air is forced in and the fuel is allowed to smolder with a reduced amount of oxygen. The valve that regulates the flow of oxygen is installed in the desired position.

But long-burning boilers have neither an ash pan nor a grate.The bottom is a blank metal plate. Such boilers are designed so that the wood burns completely, and the small amount of ash remaining in the firebox is blown out with air.

Such devices are characterized by high efficiency and also operate at temperatures above 1000°C.

The main feature of such devices is that they really provide a long service life when fully loaded. The fuel chamber in such devices is usually made in the shape of a cylinder.

Fuel is loaded into it from above, and the air necessary for combustion is pumped from above, in the center.

This ensures slow smoldering of the top layer of fuel. The fuel gradually burns, its level in the firebox decreases. At the same time, the position of the device for supplying air to the firebox changes; this element in such models is movable and it practically lies on the top layer of firewood.

The second stage of combustion takes place in the upper part of the firebox, which is separated from the lower compartment by a thick metal disk. Hot pyrolysis gases formed as a result of combustion of fuel below expand and move upward.

Here they mix with air and burn, additionally transferring a significant portion of thermal energy to the heat exchanger.

The beam holding the disk that divides the combustion chamber into two parts, like this disk itself, is constantly under the influence of high temperature during the operation of the top combustion boiler. Over time, these elements burn out and will have to be replaced periodically.

A draft regulator is usually installed at the outlet of the second part of the fuel chamber.This is an automatic device that determines the temperature of the coolant and, depending on the data received, regulates the intensity of movement of the combustible gas. It protects the device from possible overheating.

It is worth noting that the external heat exchanger in such boilers reacts to changes in the speed of liquid circulation in the heat exchanger, i.e. to temperature fluctuations. A layer of condensate immediately forms on the surface of the device, which causes corrosion, especially when it comes to steel boilers.

It is preferable to take a device made of cast iron, which resists such effects much better.

Although fuel in long-burning pyrolysis boilers should burn without residue, in practice this is not always the case. Sometimes the ash cakes, forming particles that are difficult to remove with a stream of air.

If a large amount of such residues accumulates in the firebox, a noticeable decrease in the heat output of the unit may be observed. Therefore, the top combustion boiler should still be cleaned periodically.

The peculiarity of devices of this type is that as the fuel burns, it can be reloaded without waiting for the entire fuel load to burn. This is convenient when you need to get rid of flammable household waste.

There are also varieties of top-burning boilers that run not only on wood fuel, but also on coal. There are no complex automatic control units in pyrolysis boilers of this type, so serious breakdowns are extremely rare.

The design of the top combustion boiler allows the firebox to be loaded only partially, if necessary. However, in this case, igniting the top layer of fuel may not be easy.The fuel itself must be dried; firewood from an open woodpile is not suitable for such a boiler.

Fuel of large fractions should also not be used for this type of equipment, i.e. The wood will have to be chopped into small pieces.

Features of operation of gas generator boilers

The operating efficiency of a pyrolysis boiler largely depends on the type and quality of fuel. Technically, not only wood, but also coal and even peat can be loaded into the firebox; most modern boiler models are designed to use several types of fuel.

Wood burns in about 5-6 hours, depending on the type. The harder the wood, the longer it burns.

It will take about ten hours to burn black coal, and the same amount of brown coal will smolder for eight hours. In practice, pyrolysis technology demonstrates the highest heat transfer when loaded with dry wood. Firewood with a moisture content of no more than 20% and a length of about 45-65 cm is considered optimal.

If access to such fuel is not available, you can use coal or other organic fuel: special sawdust briquettes and wood pellets, waste obtained from wood processing, peat, materials containing cellulose, etc.

Before starting to operate the boiler, you should carefully study the device manufacturer’s recommendations regarding fuel.

Too wet fuel in such devices is unacceptable.When it burns in the firebox, additional water vapor is formed, which contributes to the formation of by-products such as tar and soot.

The walls of the boiler become dirty, heat transfer decreases, and over time the boiler may even stop working and go out.

If dry fuel is placed in the firebox and the boiler is configured correctly, the pyrolysis gas produced as a result of the operation of the device will produce a yellow-white flame. Such combustion is accompanied by an insignificant release of by-products of fuel combustion.

If the color of the flame is different, it makes sense to check the quality of the fuel, as well as the settings of the device.

Unlike conventional solid fuel devices, before loading firewood into pyrolysis boilers running on solid fuel, the firebox must be preheated.

To do this, perform the following steps:

- Load small dry kindling (paper, wood chips, etc.) onto the bottom of the firebox.

- They set it on fire using a torch made of similar materials.

- Close the combustion chamber door.

- The loading chamber door is left slightly open.

- Add portions of kindling as it burns.

- The process is repeated until a layer of smoldering coals forms at the bottom.

By this moment, the firebox has already warmed up to approximately 500-800°C, creating conditions for loading the main fuel. Do not use gasoline, kerosene or any other similar liquid substances to light the kindling.Before warming up the furnace of a long-burning boiler, you should make sure that the device is ready for use.

To do this, check the presence of draft, the tightness of the doors, the serviceability of locking mechanisms and control equipment, the presence coolant in the heating system and so on.

Then you should turn on the thermostat to make sure that voltage is supplied to the device. After this, open the direct draft damper and ventilate the boiler for 5-10 minutes.

Review of popular models

It should be understood that any pyrolysis boiler is a fairly heavy unit that is not intended for hanging on the wall. Such devices can be used both for heating a small house and spacious cottages. Like other heating units, long burning boilers vary in power.

Buyers usually focus on this indicator.

Among the popular models of such equipment we should mention:

- Atmos (Ukraine) - are represented by devices that can operate on both wood and coal, power varies from 14 to 75 kilowatts.

- Attack (Slovakia) - capable of heating areas up to 950 sq. m, some models are able to continue working even during power outages.

- Bosch (Germany) - high-quality products from a well-known brand, power varies between 21-38 kilowatts.

- Buderus (Germany) represented by rulers Elektromet And Logano, the first is well known in Europe as a classic version of a pyrolysis boiler, the second is more modern versions intended for private homes.

- Gefest (Ukraine) - high-power devices with efficiency up to 95%.

- KT-2E (Russia) is specially designed for large residential premises, the power of the unit is 95 kilowatts.

- Opop (Czech Republic) - relatively inexpensive boilers, reliable and durable, power 25-45 kilowatts.

- Stropuva (made in Lithuania or Ukraine) with a power of seven kilowatts or more are quite suitable for a small home, but the model range also includes more powerful devices.

- Viessmann (Germany) - an ideal choice for private households, power starts from 12 kilowatts, the use of modern technologies allows you to save fuel.

- "Buran" (Ukraine) with a power of up to 40 kilowatts is another popular option for owners of large cottages.

- "Logics" (Poland) high-power devices of 20 kilowatts easily heat rooms up to 2 thousand square meters. m, it is more of a boiler for industrial needs: heating workshops, offices, greenhouses, etc.

When choosing a pyrolysis boiler for a private home, you should pay attention to models with two circuits, in order not only to heat the home, but also to provide it with an autonomous hot water supply.

The heat exchanger for hot water supply can be storage or flow type. For the latter option, boiler models with increased thermal power are used.

If you want to save money, you can try making a pyrolysis boiler with your own hands. Its assembly technology is described in this article.

Conclusions and useful video on the topic

This video clearly shows the operating principle of a pyrolysis boiler:

A detailed overview of the operation of a top combustion boiler can be found here:

Pyrolysis boilers are not cheap, but they are fully worth the investment in their purchase. When properly installed and maintained, such devices will provide your home with stable and inexpensive heat.

Are you looking for a pyrolysis boiler for heating your home? Or do you have experience operating such units? Please leave comments on the article and share your impressions of using pyrolysis boilers. The feedback form is located in the lower block.

A pyrolysis boiler is good when there is no connection to gas or you live surrounded by forest. In other cases it is simply not justified, in my opinion. It is too capricious to operate and maintain.

You need to constantly monitor the quality of the firewood, they must be dry, of the same size, you must constantly monitor the condition of the chimney, otherwise fumes will clog it and condensation will corrode it. Although, my friends have had “Stropuva” for 10 years: at first there were difficulties, but now I haven’t heard a single complaint from them about the boiler for a long time.