Rules for verification of gas cylinder reducers: deadlines, requirements and verification methods

Owners of housing not connected to a natural gas pipeline often use gas tanks or propane-butane cylinders as a fuel source. The leveling of performance indicators is carried out using special fittings - gas propane reducers, which, if necessary, reduce the pressure in the cylinder and maintain it at a given level.

To ensure that the equipment is in good working order, you should know the rules for calibrating gas cylinder reducers, as well as comply with the requirements for the installation and operation of the devices. Let's consider issues related to the use of propane devices, as well as control over them.

The content of the article:

The need to use gas reducers

Without installing a special device – gearbox – the pressure in the autonomous gas network loses stability and changes depending on the filling of the cylinder and the composition of the fuel. To prevent this from happening, they install a device with a flow meter-pressure gauge, based on the readings of which one can judge the operating pressure.

Regulating equipment requires maintenance and from time to time undergoes verification, which is carried out by representatives of the service organization - the Gorgaz or Oblgaz service.

Homeowners are not allowed to check gas reducers, but can control the actions of workers, so we will analyze all the important points in order - from the design of the device to the frequency of calling gas workers.

Device, principle of operation and types

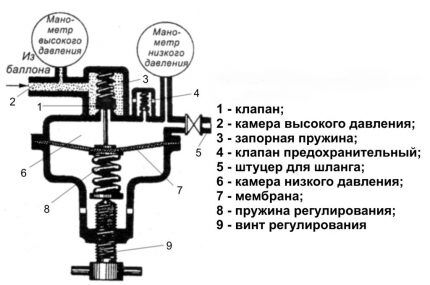

The design of the gearbox is simple, but its production is based on high precision manufacturing of all elements.

Devices from different manufacturers may differ, but the main parts of the design remain the same.

Propane device details:

- metal or polymer body;

- connecting pipe with union nut;

- working pipe with thread;

- filter unit;

- two chambers with a membrane between them;

- valve with seat on stem;

- two springs – supply and return;

- pressure gauge.

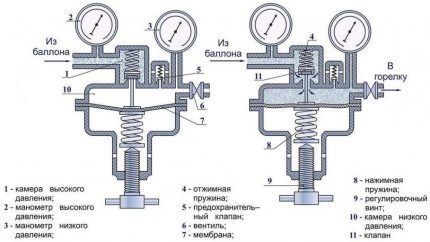

There are two types of propane gearboxes: 1-stage and 2-stage. The difference lies in the method of reducing the pressure: in a single-stage process, the process occurs in one stage, in a two-stage process - in two. The structural difference of the second is the presence of a high-pressure chamber and an additional valve.

It is advisable to use a two-stage device for cylinders that have high inlet pressure, but in everyday life single-stage models are more often used.

To distinguish a propane device from oxygen or others, it is marked in red, but there are also “metallic” devices.

The operating principle is to regulate pressure. Entering the high-pressure chamber through the pipe, the gas presses on the membrane. The valve opens by means of a spring and allows fuel to flow into the next compartment - the low pressure chamber.

There, the gas acts on the membrane from the other side, as a result of which the pressure acquires operating parameters. Once this happens, the valve closes. The process is repeated as the parameters change.

The connection to the gas pipeline leading to the gas stove is made through the inlet pipe. For household cylinders, devices with a nipple outlet with a typical diameter of 6.3 mm are produced. They are cheaper than gearboxes for welding equipment.

Rules for safe operation

According to the instructions for the safe operation of reducers for gas cylinders, a number of rules must be followed. Before using the device, you need to make sure that it is in good working order and be sure to check the date of verification. If more than a year has passed since the last verification, the equipment cannot be used - you must contact the technical service and call a specialist.

The adapter must only be inserted with a working pressure gauge (or pressure gauges). Open for inspection cylinder valve and follow the arrows on the instruments. The operating pressure is set based on the readings of the low pressure gauge. To adjust, turn the screw slowly.

When the valve is closed, operating parameters cannot be set. The high pressure gauge readings come in handy when you want to know the presence of propane in your tanks.

Sometimes troubles happen in which you should urgently call an emergency gas service, but some measures can be carried out independently. If the gearbox freezes, it is heated with steam or hot water, having previously closed and insulated the cylinder.

If you leave home for a long time, you need to turn off the gas - turn the shut-off valve installed inside the house, and be sure to tighten the cylinder valve.

The following actions cannot be performed:

- perform welding work near operating gas equipment;

- check the tightness with an open flame - a lighter or a match;

- warm frozen fittings with an open fire;

- install reducers for other purposes - for example, for oxygen or acetylene cylinders;

- use pressure gauges with inappropriate technical characteristics;

- use unverified and faulty pressure gauges.

If devices or connections have visible mechanical damage, we do not recommend using an autonomous network - you should call a specialist who will check the suitability of the equipment and issue a positive conclusion.

Rules for the safe operation of gas appliances can be found in PB 03-576-03.

Checking pressure gauges on gas cylinders

When they talk about checking gearboxes, they actually mean checking pressure gauges household gas cylinders. Let's reveal a secret: gearboxes are not listed in the state register of measuring instruments of the Russian Federation, but pressure gauges are present. And when specialists arrive, they check the operation of the flow meters - exactly the same way as they produce verification of gas meters.

But it is also necessary to monitor the functioning of the gearbox, since these two devices work in conjunction. A malfunction of one of the elements will immediately affect the operation of the entire system.

Design and purpose of the flow meter

Pressure gauges that meet the requirements are installed on household gearboxes GOST 2405-88. The main purpose of the devices is to control the pressure in the gas system. To accurately set operating parameters, two devices are used - at the input and at the output.

The design of flow meters consists of the following elements:

- durable metal case, covered with glass on one side;

- scale with units of measurement – Pa, MPa, kgf/cm²;

- arrow painted in bright color;

- a sensitive element located inside the housing and driving the pointer.

The element responsible for rotating the arrow may differ. For low-pressure environments, membrane devices are used, but for gas networks spring models are more often used - the arrow moves due to the contraction or straightening of the spring.

[adinserter name=»mobile: insert in text – 6]To make it easier for the user to navigate and adjust the parameters as needed, a red line is placed on the scale - just opposite the working pressure marks.

Some installation and operation rules:

By color marking, household pressure gauges for gas reducers differ from similar equipment for other types of gas. If oxygen fittings are painted blue, ammonia fittings – yellow, acetylene fittings – white, then devices for propane-butane cylinders – only red.

Frequency and procedure of verification

Any gas equipment is subject to regular verification, even if it is not used or is used seasonally, in the summer.

Only organizations that have accreditation or a license can carry out verification. In our country, these are most often companies connected in one way or another with Gazprom, the main gas supplier. It is the responsibility of the owner of the property in which gas cylinders are installed to issue a call in a timely manner and monitor the visit of a specialist.

Based on the verification results, a sign is placed or a certificate is issued, which must be kept until the next procedure.A special mark is usually applied to the body of the device, and if this is not possible, then it is placed directly on the certificate.

The requirements for the sign or documentation, as well as the verification procedure, are determined by the federal executive body.

It is very important not to violate the deadlines: calibration of pressure gauges and installation of a seal (stamp) is carried out once every 12 months.

If there is no mark or seal on the pressure gauge, you forgot to call a representative of the service organization in time, the “behavior” of the needle does not correspond to the real situation, or obvious mechanical damage is visible - the gas stove cannot be used!

The requirements for equipment used for hot work are much stricter. For example, gas reducers for propane tanks are checked once a quarter, and hoses are checked every 3 months.

Conclusions and useful video on the topic

What to watch out for when buying cylinders:

Recommendations for self-repair:

Only serviceable gas equipment can ensure the comfort and safety of home owners. Regular inspections are another way to protect citizens from an accidental accident, so the requirements of the gas service must be treated with attention and responsibility.

In the case of gas reducers, once a year, invite a specialist to check the pressure gauges, and, if necessary, replace or repair the equipment.

You can participate in the discussion, leave comments on the material, share your experience or ask our specialists questions - the contact block is located under the article.