The valve structure on a gas cylinder and how to replace it if necessary

Cylinders are universal equipment for storing and transporting gaseous substances for domestic and industrial purposes.The shut-off valves in them do not last forever, so over time the valve on the gas cylinder needs to be replaced. You can do it yourself, following a number of safety rules.

We will tell you how to choose the right valve for equipping a gas cylinder. For independent craftsmen, we provide detailed instructions on how to change a worn-out device. Here you will learn what safety measures must be observed when installing a shut-off device on a gas tank.

The content of the article:

Components of a gas cylinder

Requirements for production processes and technical characteristics of gas cylinders are regulated by rather old GOSTs 949-73 and 15860-84.

The maximum operating pressure in the devices ranges from 1.6 MPa to 19.6 MPa, and the wall thickness can vary from 1.5 to 8.9 mm.

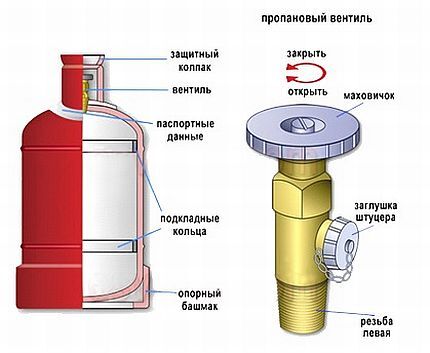

A standard gas cylinder assembly consists of the following elements:

- Cylinder body.

- Valve with shut-off valves.

- Valve closing cap.

- Backing rings for fixation and transportation.

- Support shoe.

An important element of the cylinder is also the technical information stamped on it.

The bottom of the cylinders is shaped like a hemisphere for uniform distribution of internal pressure. For better stability of the body, a shoe is welded on the outside, on the lower edges of which there are often holes for attaching the cylinder to horizontal surfaces.

With types of gas cylinders and features of their markings read the article, which we recommend viewing and reading.

Types and design of valves

The threads of valves for gas cylinders are standardized, but they themselves can have a variety of designs. The choice of valve model is influenced by the type of chemical substance being stored, production features of operation and the amount of money.

Before purchasing new equipment, you should familiarize yourself with the design options and the internal structure of the valves.

Classification of shut-off valves for cylinders

The design features of gas cylinder valves are determined not by the whims of engineers, but by safety considerations.

Depending on the material used, shut-off valves are divided into brass and steel. The choice of metal for the manufacture of the valve body is determined by the type of gases contained in the cylinder.

There are the following types of shut-off valves, depending on the type of chemicals stored:

- Acetylene. The body of such cylinders is painted white. Special valves are used in cylinders containing acetylene, chlorine, ammonia and other aggressive substances.

- Oxygen. The cylinders are painted blue and are intended for storing oxygen, argon, hydrogen, nitrogen, carbon dioxide and other inert gases.

- Propane-butane. They are painted red and are intended for storing substances corresponding to the name and other gaseous hydrocarbons. The most common valve type model for such a cylinder is VB-2.

Valves for acetylene cylinders are not made of brass because the substances they contain may react chemically with copper. Typically, carbon or alloy steel is used to manufacture shut-off valves of this type.

Gas valve device

A standard gas valve has the form of a tee, each fitting of which has an external thread. More advanced models may have an additional protrusion - a safety valve. Its purpose is to relieve excess pressure in the event of a full cylinder heating up or in case of incorrect filling.

The lower fitting of the valve is used to connect to the gas cylinder, the upper one is used to attach the flywheel, and the side one is used to connect communications for gas outlet and injection. The arrangement of the gas cylinder tap is quite simple.

Shut-off valves usually consist of the following general elements:

- Brass or steel body.

- A stuffing box valve or flywheel connected to the body with a union nut.

- Internal locking mechanism with valve and stem.

- Sealing gaskets.

- Plug for the outlet.

You can examine in detail the design of valves on gas cylinders of each type in the presented images.

Worn valves can leak small amounts of gas, which can lead to unpredictable consequences in enclosed spaces. To prevent such situations, a plug is used on the side fitting, which serves for additional sealing of the cylinder during transportation and long-term storage.

The direction of the threads on the outlet holes depends on the chemicals contained in the cylinders: the right is used for non-flammable gases (oxygen, nitrogen, argon, etc.), and the left is used for flammable gases (hydrogen, acetylene, propane, etc.)

The principle of operation of the assembled gas valve is unremarkable. To supply gas and shut it off, simply slowly turn the flywheel in the appropriate direction.

Mandatory Precautions

Before replacing the gas cylinder valve, precautions must be taken. Work must be carried out in such a way as to protect people from potential hazards and keep the equipment in working condition.

The following precautions are used when preparing to replace a gas valve:

- The remaining contents of the cylinder can only be vented in an open space. An exception can be made only for nitrogen, air and argon.

- The work area should be well ventilated, although it is advisable to carry out work outside.

- There should only be one closed gas cylinder within the workplace.

- The flywheel must be unscrewed slowly to prevent electrification.

- You can begin replacing the valve only after the pressure in the cylinder and outside has been completely equalized.

When screwing the valve into the cylinder, fum tape or special lubricants are used, which provide increased tightness and strength of the connection. When replacing a faucet, such seals greatly complicate the process of dismantling it. To solve this problem, you can heat the valve with a hairdryer.

You can heat the shut-off valves only after bleeding the gas from the cylinder and closing the tap. In this case, the procedure is safe and will not lead to unpredictable situations.

An alternative to a hairdryer is to wrap a cloth around the valve and then pour boiling water over it. With this heating method, any suitable plug should be screwed onto the outlet fitting to prevent water from entering there.

After taking all precautions and warming up the shut-off valves, you can begin to unscrew the valve, which can be a difficult task at home.

If, in addition to replacing the cylinder locking device, you also need faucet replacementinstalled on a gas pipeline, we advise you to study the procedure and rules for performing this work.

Guide to unscrewing the valve

An additional supply of tightness is never superfluous, but when replacing shut-off valves on a gas cylinder, the strength of its fastening can become a big problem. The difficulty lies in fixing the cylinder body so that it does not rotate when the valve is unscrewed with a key.

It is with this problem in mind that further step-by-step actions for replacing shut-off valves will be considered. There are many ways to secure the body of a gas cylinder; let’s look at some of them.

Method 1: Attaching the limit bar

You will need the following tools and materials: a pipe wrench, two bolts at least 20 mm long with two nuts and a metal corner profile at least a meter long. Instead of a corner, you can use any other product in which you don’t mind drilling two small holes.

Next, you need to measure the distance between the two nearest holes on the cylinder shoe and drill the corresponding holes from one edge of the metal profile. After this, screw the iron bar to the cylinder body using bolts and lay it on its side. This design will not allow the cylinder to rotate.

Then you need to place your foot on the metal profile, and using your hand, using a key, carefully unscrew the valve.

Step-by-step photo instructions for the process are presented below.

Method 2: welding the cylinder to a metal base

This method is quite dangerous and should only be used by a professional welder with extreme caution. The shoe is grabbed in two places so that after unscrewing the valve, you can easily tear the cylinder off the base.

After welding the body, the fittings are carefully unscrewed using a pipe wrench. Then the internal thread of the cylinder should be cleaned of any remaining sealant.

Methods for fixing a gas cylinder are not limited to the described options. Many alternative methods can be used to secure it. Liquid water condensation sometimes accumulates at the bottom of the container, so after removing the valve, be sure to turn the container over so that water can flow out of it.

Screwing in new shut-off valves

Before tightening the valve, all connected parts must be degreased to prevent clogging of the locking mechanism. To do this, you can use a cloth with regular detergent or moistened with white alcohol. After this, rinse the surfaces with plain water and allow them to dry.

A new valve is never screwed to a cylinder with bare threads. It is imperative to use a sealant: special thread compound or fluoroplastic fum tape. They are applied to the lower fitting and only after that the valve is tightened.

The thickness of the gas fum tape is greater than sanitary tape and is 0.1 - 0.25 mm, and its reel should be yellow. The tape is wound with tension in 3-4 layers. It is better to twist it once again when it breaks than to make the seal loose.

It is advisable to tighten the valve with a torque wrench. Steel shut-off valves are screwed with a maximum force of 480 Nm, and brass valves - 250 Nm. After clamping the valve, you can proceed to subsequent steps to test the tightness of the resulting connection.

Checking tightness and completing work

When checking the tightness of the valve connection, you will need to pump gas under pressure into the gas cylinder.

This can be done in two ways:

- Pump gas using compressor equipment or a car pump.

- Connect two cylinders with a hose, the first of which is empty (tested), and the second is filled with gas.

First, under the control of a pressure gauge, you need to fill the test cylinder with gas with a pressure of 1.5-2 atmospheres.After this, soap foam is applied to the connection and the tap is opened slightly.

If soap bubbles are not inflated anywhere, then the connection is sealed. But if even slight swelling of foam appears, you will have to re-tighten the valve.

If the cylinder is small, then you can immerse its valve in a small basin of water and see for bubbles.

After replacing the shut-off valves, the corresponding mark must be placed in the gas cylinder passport.

It should be remembered that the methods described above for replacing a used valve are applicable only to metal tanks. If you have composite gas storage cylinder, you cannot act this way because of the possibility of damaging the flask and breaking its tightness.

Conclusions and useful video on the topic

The presented video materials allow you to see with your own eyes all the details and difficulties when replacing valves on gas cylinders.

Video #1. Unscrewing the valve from the gas cylinder:

Video #2. Screwing in a new valve with an original method of fixing a gas cylinder:

Video #3. How to replace the valve on a gas cylinder:

When performing work to replace a gas valve, you need to take your time and think about each subsequent action and its consequences.

Even if all precautions are taken, the described manipulations with gas equipment are quite dangerous for a beginner. It is best to entrust this work to professionals who will carry it out at a specialized stand.

If you have any questions while reading the article, you can ask them in the block below.Here you can leave comments and share useful information. Please comment on the material, we are interested in your opinion.

I came across your article and it surprised me. I didn’t think that if a gas leak was detected from the valve, it could still be repaired with your own hands. I have such a cylinder in the kitchen in my garden. Sometimes I change it if I run out of gas. When exchanging, they give you another cylinder (I don’t like this), they come across old ones. My personal opinion is that not everyone will undertake valve repair. It's easier to buy a new cylinder. But if someone needs it, then a specially trained person should do it.

The main thing is to have your hands in the right place and your brains. Any straight-armed person can repair a valve. In this matter, the main thing is to think everything over carefully, find out the diagram of your valve (find a diagram of the type of valve you are going to repair) and work, strictly observing safety regulations. Everything is real, and not only with propane. Just ATTENTION: DIAPHRAGM VALVES FILLED WITH GASES CANNOT BE REPAIRED UNDER ANY CASE! The valve will shoot into the sky.

Membranes can be repaired without problems. You need a good plug and a steel pin, and a new membrane. No matter how many repairs were made there were no problems.

When you open the valve on the gas balcony, there is no gas coming out. How to bleed gas from a cylinder?

hmm, I expected more specifics on the valves, alas, it’s a pity.

I have several old gas cylinders with valves, I want to replace them with valves, since they no longer fill with valves. The question is: what is the best way to seal the thread and are there any other nuances?

Special lubricant for threaded connections of GAS CYLINDER equipment.

After filling the cylinder, the propane poisons in the valve. Valve VT-2. What can be done?

Hello. In general, it’s strange that they didn’t check for leaks during refueling; that’s their responsibility. And the question for you is this: the answer requires clarification, are you sure that the valve is VT-2, and not VB-2?

GOST 21804-94 Shut-off devices for cylinders for liquefied hydrocarbon gases for pressures up to 1.6 MPa. General technical conditions.

Extract:

2 Main parameters and dimensions

2.1 Devices must be manufactured:

— valves of types 1 and 2 — for cylinders with a capacity of 5.0, 12.0, 27.0 l; type 3 - for cylinders with a capacity of 5.0, 12.0 l;

— valves of types 1 and 2 — for cylinders with a capacity of 5.0, 12.0, 27.0, 50.0 l.

Example of device symbols:

valve (K) cylinder (B) type 2: KB-2 GOST 21804-94

valve (B) cylinder (B) type 1: VB-1 GOST 21804-94

Check the VALVE or replace it with a new one in accordance with all SAFETY rules,

Hello. When you open the valve on a fully filled gas cylinder No. 1 (to supply gas to the gas stove), no gas flows. I put in cylinder No. 2 and the gas started flowing. That is, the problem is in cylinder No. 1. In what way? cause? In the valve? If yes, what type of fault is preventing gas from flowing from the cylinder when the valve is in the open position?

But in my cylinder there’s a bucket’s worth of liquid “swaying”! I unscrew the valve, tighten it - NO SENSE!!! THE GAS IS NOT COMING OUT! NO SMELL AT ALL!

What to do? I completely unscrewed the top nut and the thread under the valve stem - nothing happened. I looked inside: some debris. It looks like a fragile axle box.He picked it out piece by piece. one remained “bitten” between the square of the lower rod and the body.

I think this is the reason for the “freezing” of the exhaust valve. What can you guys tell me about this problem? I will cut the balloon for other purposes!

To empty a 50-liter CYLINDER, you need to tip it over and pour out the contents, every drop. If necessary, replace the VALVE. CAREFULLY study the VALVE design.

Hello! Tell! I lightly close the knob on a large gas cylinder, and after some time it opens with difficulty, as if it was tightened with a key

It is necessary to use special lubricant, look at the VALVE diagram.

Where can you replace the balloon reducer (in the photo) with one so that you can use the balloon?

At stations like PROMCRYOGEN they change old CYLINDERS for old ones and charge refillers for e

that SERVICE A certain amount of REAL cash, they don’t give a guarantee. They repair it BADLY! In the store, a new cylinder costs from 3 to 4 thousand!

I have an old Soviet 5L cylinder! Which faucet is suitable for replacement so that a modern tourist burner fits it?