How to check a gas meter without removing it, taking into account the service life

Although gas meters appeared in homes many years ago, not everyone knows the details of their maintenance.In order for the owners and the gas supply service to have confidence in the accuracy of the measurements, the device must be tested periodically. You can carry out verification without dismantling the device. But you need to know how to do it. Do you agree?

You will find detailed information on how to check a gas meter without removing it in the article we presented. We have described in detail the types of flow meters, their operating principles and the frequency of maintenance. We have detailed the sequence of actions required to carry out verification without dismantling.

The content of the article:

- Classification of modern gasometers

- Period of use of measuring instruments

- Purpose of performing a gas meter test

- Frequency of gas meter inspections

- How is verification carried out without removal?

- Actions upon completion of verification

- Timing and cost of verification work

- Conclusions and useful video on the topic

Classification of modern gasometers

Gas controllers are convenient devices that allow you to monitor natural gas consumption.

There are many models of such devices, which according to their operating principle can be divided into categories:

- membrane;

- rotary (rotary);

- turbine;

- vortex.

Let's look at each type in more detail.

Type #1 – membrane devices

Such devices (they are also called chamber or diaphragm) have a low throughput (about 12 m3/h).The work is based on the principle of dividing the gas flow using membrane components into volume fractions and then summing them up.

Controllers of this type are most often used in everyday life. They are easy to operate, have good measurement accuracy, and are resistant to magnetic fields. Membrane gasometers are also affordable due to the fact that their internal parts and components are made of plastic.

At the same time, such devices are quite durable: their covers are made of cast aluminum or stamped steel coated with an anti-corrosion compound, and the polymers from which the mechanism is made are resistant to aggressive substances contained in natural gas.

Type #2 – rotary devices

Although such devices are small in size, they are characterized by high throughput (10-1000 m³/h) and a wide measurement range.

The operating principle of rotary controllers is similar to chamber ones, but the converting element is made in the form of an eight-shaped rotor, which rotates under the influence of a gas pressure difference. To reduce friction, which wears out the operating part, constant oil lubrication is required.

This type of gasometer is characterized by such qualities as durability and the ability to control the pressure drop in the meters using readings.Due to this, such devices are widely used in housing and communal services institutions, especially in heating boiler houses. Small rotary units can also be used in homes and apartments.

Type #3 – turbine options

The operating element of such gasometers is a turbine wheel that rotates under the influence of gas flow, and the number of revolutions directly depends on the volume of the flowing flow of volatile fuel.

The counter mechanism installed in the device counts the number of rotations, showing the volume of substance that passed through the counter during its operation.

There are various models of turbine gasometers, which differ both in size and in the level of automation used to carry out measurements and process the results. However, due to the ability of such devices to withstand large volumes of gas flow, it is most advisable to use them at large industrial enterprises with fuel consumption up to 10,000 m³/h.

Type #4 – vortex devices

The operation of vortex gasometers, designed to process 50-12,000 m³/h of blue fuel, is based on the dependence of the purity of pressure fluctuations on gas flow. Such devices are most often used in large enterprises.

The advantages of devices in this category include:

- no rapidly wearing moving parts;

- ability to work in a significant measurement range;

- correct operation even in difficult conditions, regardless of pressure drops in the pipe and temperature effects.

The disadvantages of vortex devices include the inability to work with gas flows moving at low speeds; the difficulty of measuring gas flow in contaminated aggressive environments; the need to use electric current.

With criteria and guidelines gas meter selection The following article will introduce you in detail.

Period of use of measuring instruments

For each category of gas meters, a certain service life is provided: for example, for the popular membrane model NPM G4, the service life is determined to be 20 years.

In practice, devices usually fail much earlier.

Among the reasons causing a decrease in the period of actual use compared to the planned one are:

- excessive moisture content in gas;

- reduced device throughput;

- absence of a dust filter or insufficient size of its cells;

- violations committed during installation of the device.

To avoid failure of the gas meter, you should periodically check the condition of the device and replace it if unsuitable. Since only licensed specialists have the right to carry out such manipulations, you should contact specialized companies for this.

Purpose of performing a gas meter test

A mandatory procedure for all users of gas meters is a check, the purpose of which is to determine whether the device meets metrological requirements.Article 13, paragraph 1 “On ensuring the uniformity of measurements” of the Federal legislation informs that the gas meter must undergo primary control before using the device or immediately after its repair.

According to the regulations, during operation of the device it is also necessary to carry out regular checks of the device. The “Rules for the supply of gas for municipal and domestic needs” (clause 21) states that citizens are required to present meters for control within the prescribed time limits, and they are responsible for delivery costs.

The procedure for carrying out control activities

The performance of the device is assessed in accordance with regulatory documents.

Russian Government Decree No. 549 dated July 21, 2008 defines the timing and procedure for diagnosis:

- Carrying out control measures must be agreed upon with the owner of the apartment. To do this, the specialists who are entrusted with the responsibility of the examination must report it no later than a week before the planned date of diagnosis, and they must receive confirmation of the delivery of the information letter.

- The inspection can only be carried out by employees/representatives of a specialized company that has entered into an agreement with residents on the maintenance of in-house/in-apartment natural gas equipment.

- Specialists conducting gas meter diagnostics are required to present the owner of the apartment with official documents, and, upon request, an identification document.

All results of control activities are recorded in the gasometer inspection report.

This document should reflect the following information:

- date and place of diagnosis;

- information (full name, passport details) about the owner of the gas controller being tested;

- information about the persons who were present during the inspection, including their passport details;

- device readings at the time of diagnosis;

- description of the technical condition of the seals on the device and at the place of its connection to the gas pipeline;

- information about violations, which indicates the specific clause of the agreement in which a defect was made, or a record of the absence of malfunctions.

If at least one of the above rules has been violated, the meter check may be considered illegal.

Possibility of recalculating gas fees

The verification procedure for gas controllers is important. Recently, such devices have become widespread, since they help not only to reduce the consumption of non-renewable natural resources, but also reduce gas payments.

At the same time, effective consumption of fuel resources is possible only if the meters are fully operational, which cannot be achieved without an established system for checking them. In addition to the initial assessment of the condition of the device, users are prescribed to carry out scheduled and urgent checks.

Correct operation of gasometers provides the following advantages:

- Significant savings in money.

- Developing consumer discipline when using gas.

- Establishing a scheme for the rational use of blue fuel in everyday life with careful control of its costs.

Thus, the controllers allow economical use of natural fuel reserves, and also serve as an incentive to maintain intra-house/apartment gas communications in good condition.

According to the regulations, installation of equipment must be carried out by specialized specialists. This procedure, which takes a minimum of time, is convenient, safe and comfortable.

Extraordinary check of gas meters

In addition to scheduled inspections of the condition of the device, there are a number of reasons why an extraordinary (urgent) procedure for assessing the condition of the gas meter may be required.

Such situations include:

- Violation of the integrity of the seal or verification mark. The seal and imprint are considered broken if the printed information cannot be read without the use of special means.

- Changing the position of the seal, allowing access to internal elements and making payment corrections.

- Mechanical damage to the device (impact, heavy impact, depressurization) or suspicion of it. In this case, it is necessary to carry out an urgent check of the gasometer in order to determine its ability for further operation, which is confirmed by the issuance of a new permit.

- Re-preservation.A similar procedure is necessary for gasometers that have been idle for more than one calibration interval.

- Suspicions of unreliable information shown by the meter.

Consumers must report problems to gas supply authorities themselves and call specialists for an unscheduled inspection. In some cases, the initiative for additional verification may come from the relevant organization.

Frequency of gas meter inspections

In addition to the initial check, there is also a specially developed diagnostic schedule, which outlines the timing of periodic checks of gas meters.

The interval between such events must be specified in the technical data sheet of the device. It also indicates the period during which the full functionality of the gas metering device is guaranteed.

The documents indicate the time of completion of the diagnostic procedure and put a stamp certifying the gasometer’s suitability for use.

Do not neglect the specified date of the planned inspection. If the device does not pass the inspection within the scheduled period, it is considered unfit for use, and the data taken from it may be invalidated.

In this case, the fee will be charged according to the average meter readings for the previous period or according to the standards specified in the contract. It is also possible to recalculate the payment for blue fuel already paid upward.

For each brand of gas meter, a certain verification interval is prescribed, implying a maximum period of operation of the device before it is checked. Thus, the SG-SGK-1.6 model is designed for 8 years of operation, while SGMB-1.6, Grand-1.6, SGBM-1.6 “Betar” - for 12 years.

It should also be taken into account that the service life of the gasometer is calculated not from the date of sale, but from the date of its manufacture (PR 50.2.006-94 “GSI. Procedure for verification of measuring instruments”, Ministry of Justice of the Russian Federation No. 640 07.21.94).

In the absence of a technical passport (for example, if it is lost), gas service specialists can independently determine the calibration interval of any meter using technical documentation and reference literature.

How is verification carried out without removal?

Gas services offer two options for control measures.

Traditional diagnostic option

Regular verification takes place in two stages. After calling specialists and agreeing on the time of their arrival, company employees visit the apartment, where they remove the meter from gas supply system, which is taken to the laboratory. A temporary jumper is installed in place of the device.

After completing the procedures, workers return to the house, where the device is installed, followed by sealing, after which the controller is considered to be put into operation.

The activity may include the installation of a new power supply, as well as complete maintenance of the device, which is disassembled and cleaned, thereby significantly increasing its service life.

Checking the gas meter at home

There is also a modern technology for testing devices, which is suitable for most models of gas meters SGB, NPM, SGMN, BK. It involves procedures for assessing their performance without removing them at the installation site, while seals and stickers remain intact.

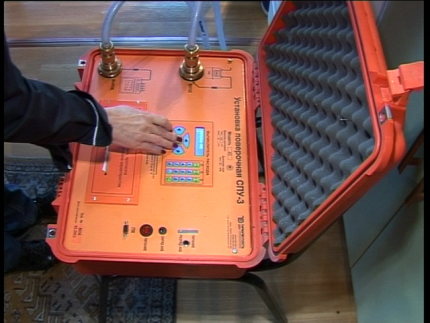

Gas meters are checked without removal using special equipment that is connected to the gas network, which makes it possible to check the readings of gas controllers.

Such an examination costs slightly more than a traditional one, but it can significantly shorten the procedure for determining the operability of the device. In addition, in this case, noise, pollution and other troubles associated with dismantling equipment are eliminated.

To carry out the procedure for checking the device without removing it at home, the user must ensure:

- Visual accessibility of the counter. If the device is hidden behind a kitchen unit or hanging cabinet, it is necessary to remove or move away the interior items so that the specialist can see the window with fuel consumption indicators.

- Free passage to the tap. Workers must be able to turn on and off the faucet that is installed on the pipe connected to the gas stove.

- Access to an electrical outlet. Near the junction of the gas meter with the pipe there should be a source of electric current, which will be needed to turn on the special device.

However, such a survey also has a number of disadvantages.This method allows you to diagnose only the general condition of the meter, while malfunction or damage to its individual parts may go unnoticed. In addition, this option is not suitable for all gasometer models.

Regardless of the verification method, upon completion, the user is given a report on the results of the procedure performed and a receipt for payment.

Actions upon completion of verification

Having carried out the verification procedure with or without removal, the specialist makes a conclusion about the possibility of using the gasometer during another verification interval.

After this, a representative of the organization that conducted the examination issues an authorization certificate, and the device is sealed with a verification stamp. Comprehensive information is entered into the technical passport of the meter, certified by a signature and a seal image.

If deviations are detected between the device readings and the actual data on consumed resources, the device is considered faulty, and the owner is issued a “Notice of Unsuitability.” In this case, it is necessary to repair the gasometer or, preferably, purchase a new device.

Specialists draw up an act of checking and sealing the gasometer in two copies: one remains with the service provider, the second with the owner of the device.After applying the seal, gas payments are calculated according to the meter readings

Timing and cost of verification work

Device checks are carried out within the time period established by the laws and regulations of the Russian Federation.

If the removal of the meter and other measures are carried out by an organization that has entered into an agreement with the owner of the apartment for the maintenance of in-house devices and networks, then the laboratory test may take 15-30 days.

If the test without removal is carried out by a specialized company using high-tech equipment, the research is carried out much faster (within an hour), although at a higher cost.

According to legislative norms, control of gas meters is carried out at the expense of subscribers, who are also responsible for the good condition and correct operation of the devices. Based on this, the services of the company conducting the gas consumption inspection of the device must be paid for by the apartment owners.

The specific cost of the work varies depending on the region, the distance of the recipient and the type of device. Before calling a specialist, it is advisable to call the company and ask the manager or dispatcher about the prices for the service.

Without dismantling and transportation to a verification organization, you can test not only the gas flow meter. How verification is carried out water consumption monitoring devices, you will find out by reading the article we recommend.

Conclusions and useful video on the topic

The video below shows how you can check a household gas meter not at home, but near the house:

Checking a gas meter without removing it at home is a fairly simple procedure, but its implementation requires high-tech equipment, as well as qualified personnel. To carry out such an operation, you need to contact a specialized company.

Please write comments in the block below. Tell us about how you checked the gas meter without dismantling it and transporting it to the service that supervises the device. Ask questions and leave photos related to the topic of the article.

We had a gas meter installed for 5 years. Verification was carried out regularly in accordance with the verification interval. After the expiration date, the service company replaces the gas meters. Its representatives come and check or replace it. Normal, experienced craftsmen from the gas office. They always warn you in advance by mail or by phone. The work is done quickly.

And we had a whole story with the verification of the gas meter. Representatives of the company arrived, removed the meter and connected the jumper. Then they brought it back after verification and connected it. Looks like everything has been checked. In the morning we go into the storage room where the meter is located, and it stinks of gas. They were called back. They removed and installed again, but the second time there was a leak again. I had to call them again. The third time it was connected successfully. What a hassle it was. It’s better to pay more, but let them check without removing it, it’s safer.

To check the gas meter, you need to contact a specialized company... Please write the addresses and contacts of such specialized companies! I searched all over the Internet and didn’t find a single company.

Hello. You can contact the city gas service in your locality, or there is a second option. According to the Federal Law of June 26, 2008 N 102-FZ (as amended on July 13, 2015) “On ensuring the uniformity of measurements”, Art. 13:

“Verification of measuring instruments is carried out by legal entities and individual entrepreneurs accredited in accordance with the legislation of the Russian Federation on accreditation in the national accreditation system for verification of measuring instruments.”

Unfortunately, we cannot tell you the addresses and contacts of such companies, because we do not know your geographical location. These are different companies in different cities.

In Goryachy Klyuch, Krasnodar Territory, the proper operation of the meter is checked by turning on the smallest burner of the stove. If the meter readings do not change within 45 seconds, the gas meter is considered faulty. And then the consumer incurs enormous expenses - this includes payment for months of gas consumption since the last check at the company’s tariffs (and this can amount to from 15 to 30 thousand rubles), and the purchase of another meter, and the fee for installing and sealing the meter. But the act does not reflect the persons present when checking the meter.

The specialist does not say that the meter should be sent to the laboratory for verification, he simply breaks the seal and draws up a report on the unsuitability of the meter.Hence the financial losses of the consumer, since gas consumption tariffs vary greatly in the situation if the meter is found to be faulty and if it is sent to a laboratory. In the latter case, the consumer is charged gas consumption according to his average readings for a year or six months, but not according to the organization’s monstrous tariffs.

I would like to know whether our gas workers are doing the right thing, checking the serviceability of the meter on the small burner of the stove? Are there standards that state that the normal operation of a meter is to change the reading within 45 seconds?

Hello. Article 12. Approval of the type of standard samples or the type of measuring instruments 102-FZ of June 26, 2008 “on ensuring the uniformity of measurements”:

«1. The type of standard samples or the type of measuring instruments used in the field of state regulation to ensure the uniformity of measurements is subject to mandatory approval. When approving the type of measuring instruments, accuracy indicators, the interval between verifications of measuring instruments, as well as the verification methodology for this type of measuring instruments are established.". That’s why this document standardizes 45 seconds.

GOST 8.324-2002 “GSI. Gas meters. Verification Methodology" - and this document will tell you how the verification is carried out.

You should not believe the “specialists” of Regiongaz that the meter can be rejected by looking at the numbers and the stopwatch, or by “checking” it at the minimum gas flow (when the smallest burner barely burns), or it requires verification judging by its appearance and how the numbers spin, or what they don’t like about the operation of the device (it rubs or creaks). Visually, in seconds, you can’t find out anything. Or more precisely, it is impossible to state.This is all their speculation and desire to simply push a person to replace the meter.

Even when the meter has worked for five years in ideal (comfortable for the meter) conditions, it is required to either be replaced or have it checked. They are not competent to make such conclusions! Only calibration laboratory specialists can say unambiguously whether the device is suitable or requires replacement.

And further. Verification at the installation site of a gas meter of any type is PROHIBITED by GOST. This is the main document on which VERIFICATION is carried out. What is indicated in the instructions of the device, which has the ability to check the performance of the meter (the installation is located in a compact suitcase) is contrary to GOST, contradicts it. In our country, a lot of this happens with laws, most of the laws grossly contradict the Constitution (fundamental law). Therefore, with the device from the suitcase you can only check the gas meter, but not believe it. Otherwise, during CHECKING, a Certificate of suitability for use of the device is not issued during verification. And when verified in laboratory conditions, a State Certificate is issued, with signatures and seals and holograms.

After replacing the gas meter from “Grand-4” (the display went out) to Grand-6, the consumption readings tripled! Upon my request, a gas service worker assessed the change in readings when turning on 4 burners of a gas stove in a few seconds and said that the changes in readings were normal. Question. Please provide a link to such a method for assessing the correctness of testimony or answer about the correctness of such an assessment.