What is a VVG cable: explanation, characteristics + subtleties of choosing a cable

Building a home electrical network is accessible to anyone who has mastered a school physics course.Agree, the services of an electrician will not be cheap, but independent experience will always come in handy.

But amateur craftsmen usually face a problem regarding the choice of cable. What type of wiring is the most reliable and safe? The answer is simple - standard VVG cable, designed for assembling AC circuits.

If you decide to do your own home wiring, we suggest you familiarize yourself with useful information. We will analyze what a VVG cable is: decoding the letter symbols and reviewing the characteristics will help you choose the optimal modification.

The content of the article:

Purpose and application features

The VVG cable is designed for transmission and distribution of electricity in stationary installations with a frequency of 50 Hz and operating voltage from 660 to 1000 V.

It is used for the purpose of installation, repair or complete replacing wiring in residential and industrial buildings. Reinforced types are suitable for installation in fire hazardous, damp, underground areas.

In addition to popular types designed for a frequency of 50 Hz, there are modifications for use at 100 Hz.If necessary, you can select wires for a 1-phase or 3-phase circuit, for installation inside and outside buildings.

If the wire is pulled outside the house, it needs additional protection - a durable metal sleeve cable channel, special tray or corrugated pipe.

For wiring in the ground, shaft, or collector, protection must be maximum, since the product has no armor at all. Especially for difficult installation conditions, there is another option - armored cable VBBShV.

Electrical wiring device wooden house also requires protection in the form of a metal hose, non-flammable channel or metal pipe.

Decoding of letter designations and types of VVG

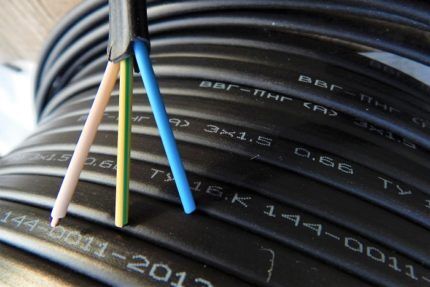

The type of cable is easy to determine, even if it is packaged in a coil: the appropriate marking is applied to the surface of the outer insulation. Among the many alphanumeric characters and the type of cable. What do these generally accepted letter combinations mean?

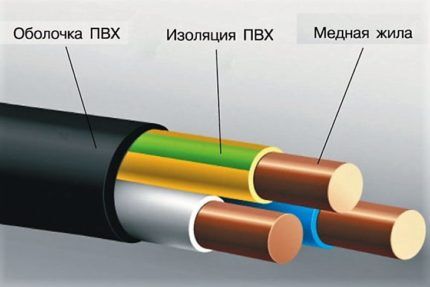

VVG – a copper cable, each core of which is protected by a polyvinyl chloride sheath, and the outer insulation is also made of PVC. “G” - lack of armor or other durable shell for use in aggressive conditions.

Literally it stands for this:

- “B” – vinyl;

- “B” – vinyl;

- "G" - naked.

Both the cores and the sheaths are made of various materials with special technical characteristics. Based on this, various types of VVG cable are distinguished.

Accordingly, copper products are ideal for home use.

The most popular types of power wires.

VVGng – non-flammable/low flammability.Fire resistance is due to the addition of non-flammable ingredients to the plastic. If a fire occurs, the wiring will not burn itself or be ignited by adjacent cables.

VVGng LS – a type of non-flammable cable with low gas and smoke emission. LS stands for Low Smoke.

VVGng LSLTx – LTx – Low Toxic (low level of toxicity) is added to the above qualities. When ignited, no hazardous substances are released from the shell. The most secure cable of this type is in demand in preschool and educational institutions, clinics and hospitals.

VVGng HF – the shell does not contain halogen substances, such as chlorine, etc. HF – Halogen Free (without halogens).

VVGng FRLS – cable for group installation, its feature is maximum fire resistance. FRLS – Fire Resistance (fire resistant). Even within 3 hours the cable will not ignite or smoke thanks to the mica shell.

VVG-Png – flat wire with 2-3 cores, non-flammable. Sometimes it is more convenient to connect a flat cable with other wires or place it in baseboards or boxes.

To install home electrical circuits, you do not need to purchase expensive types with additional protection.

Usually they use budget cable VVG, which is most suitable for interior work, or VVGng if group installation is planned.

Number and shape of conductors

All cables can be divided into two categories - single-core and multi-core.

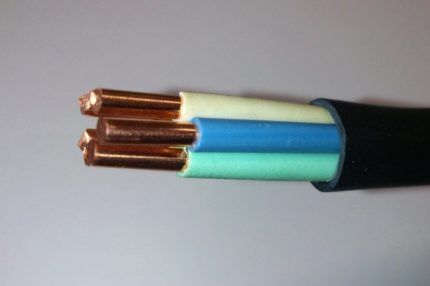

The number of conductors under the outer sheath of the cable is from 2 to 6, while the cross-section of the cores can be any - from 1.5 to 250 mm².

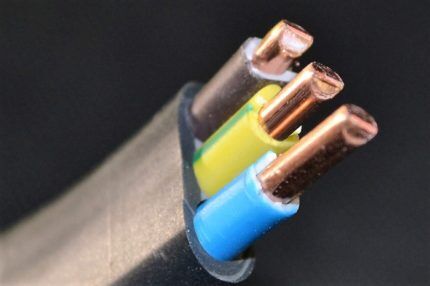

For home electrical networks, products with neutral and grounding conductors are more often used. The insulation of the first is painted blue, the second is yellow-green.

In addition to the round shape, there are also segmented conductor shapes on the market. It is advisable to use it in the manufacture of large-diameter cables for compactness, so that there are no voids between the individual cores.

In VVG products of small diameter - up to 25 mm - internal filling may not be used.

Technical characteristics of VVG cable

To correctly determine the purpose of the wire, you need to clarify its technical and operational characteristics, which relate to design features, dimensions and weight, and physical characteristics. Let's consider the main selection criteria.

#1 – design features

Considering the many modifications, you should choose the most successful one from all the options presented on the market. And to do this you need to compare the characteristics of different products.

Suppose the choice is between VVG and VVGng - which one is better suited for kitchen electrical wiring? Both are copper, three-core, “sealed” in a PVC sheath. It is impossible to tell the difference by appearance.

Considering that the kitchen is usually crammed with electrical household appliances, it is better to play it safe and choose an option with a non-flammable braid. Although for single wires with a small load a standard 3-core VVG 2-2.5 mm cable is suitable, but for group installation it is better to take a product in non-flammable insulation.

Is it possible to use other types of wires, for example, VVGng LS? Yes, but this is not always advisable. Cables with reduced smoke emission are more complex in design: they are multi-core, consist of twisted round or segment conductors, filled with plastic, one wire may have a smaller cross-section.

The option marked LS is usually used in industrial workshops or other premises where there is a real risk of accidental fire.

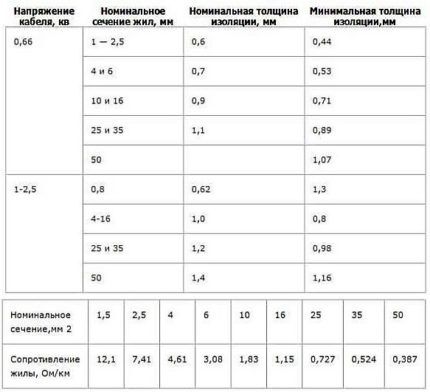

#2 – cross section

For domestic use, a cable with a cross-section of each core from 1.5 to 3.5 mm² is used, for industrial purposes - up to 250 mm². Products with a small cross-section are always on sale; modifications with parameters above 35 mm² are usually delivered to order.

If you are offered a cable with one conductor smaller in diameter, that’s okay. Most likely, this is a grounding conductor, which is usually enclosed in a yellow-green sheath.

Whether there is a core with a smaller diameter than the rest inside the outer sheath can also be determined by the markings. Usually the digital designation “+1” is assigned to the name. Example of a name: VVGng 3x2.5 mm²+1 – that is, 3 cores with a cross-section of 2.5 mm² plus one step smaller, 1.5 mm².

Both “single-gauge” products and wires with a core of unequal cross-section are classified as standard and are manufactured in accordance with GOST.

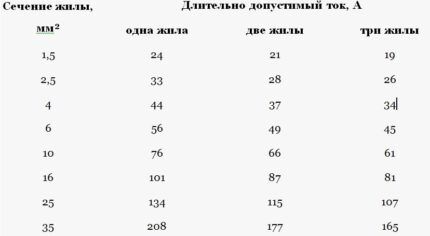

#3 – parameters of long-term permissible current

When choosing a cross-section, the main role is played not so much by the resistance of the conductors, but by the magnitude of the electric current, the maximum permissible in the circuit.

It depends on the following factors:

- installation method;

- number of cores;

- cross section of each core.

The installation method means open or closed (in grooves) installation.

We remind you that VVG wires are used for AC electrical wiring from 0.66 to 1 kW.

#4 – VVG cable weight

The cable is sold by manufacturers and intermediary companies, which are construction and electrical materials stores and specialized companies. Various modifications with a cross-section of 1.5-2.5 mm² are sold in coils and sections from 10 to 100 m.

It is clear that the weight will directly depend on both the cross-section and the footage. It is calculated that the mass of a coil of VVGng wire 1 km long, depending on the cross-section, can weigh 30, 10, or 250 kg.

A 100-meter bay of 3-core VVG cable with a cross-section of 2.5 mm² weighs a little more than 13.5 kg.

#5 – other operational and physical indicators

When purchasing a coil or a piece of cable, you can inquire about other technical characteristics, which are necessarily indicated in the accompanying documentation.

The following values are typical for VVG cable:

- operating temperature – -50°С – +50°С; max temperature – up to +70 °C (with long-term use); emergency temperature – +80 °C (during short-term overheating);

- the minimum temperature value for installation is -15 °C or higher;

- relative air humidity – 98% (at t +35 °C);

- climatic version - T/UHL (tropical or moderately cold climate, respectively);

- service life – 30 years, warranty – up to 5 years;

- bending radius - at least 7.5 outer diameters for multi-core products, 10 outer diameters for single-core products.

Coils should be stored indoors for a maximum of 10 years, outdoors (under a canopy) for no more than 5 years. The absence of a canopy reduces the shelf life to 2 years.

Recommendations for using VVGng at home:

- lighting contours – 3x1.5;

- socket groups – 3x2.5;

- connection of powerful equipment (boiler, stove, dishwasher) - 3x4.

The latest version of the cable can withstand a load of up to 8 kW - this is enough to build the most energy-intensive kitchen network.

Conclusions and useful video on the topic

About cable markings:

Which type of cable is better for sockets and why:

About choosing cable cross-section:

The best option for use in residential buildings is VVGng copper cable. Inexpensive, easy to use and assemble electrical networks, suitable for connecting electromechanical installations and household appliances.

When choosing a cross-section, be sure to take into account the approximate load; if you are in doubt about the correct conclusions, consult sellers or qualified electricians.

Remember: the life of your family and the safety of your property depend on reliable and safe material for electrical wiring!

We introduced you only to general information about the VVG cable, without touching on the technical details of production, installation and connection methods. If there are experienced electricians among you, please comment on controversial issues, share your own experience or valuable advice. Photo illustrations will be the best addition to your story.