Wire stripping tool: all about cable strippers

A professional electrician must have a wire stripping tool in his arsenal, which is necessary for stripping wires when connecting sockets, switches, cutting wiring, etc.Such a device will also be useful for a home handyman who has started renovations in an apartment or house.

Let's figure out what tools exist for removing sheathing from wires, what are the specifics of their use, and outline what you should pay attention to when purchasing such devices.

The content of the article:

The need to use special tools

To connect one socket or switch in an apartment, it is not necessary to buy professional equipment. You can strip a piece of wire with a regular kitchen knife. However, if there is a large-scale repair with a complete update of the electrical wiring system, then it is impossible to do without specialized devices.

The number of contacts that must be cleaned when repairing a house with an area of 100 square meters. m can reach thousands. Carrying out such work without specialized devices is an unreasonable waste of time and effort.

In addition, stripping insulation without professional wire stripping tools is fraught with negative consequences:

- there is a high risk of cable damage, which reduces the safety of electrical wiring;

- cutting the conductor leads to a decrease in the cross-section of the wire, resulting in a break or burning at the junction;

- if cut carelessly, the damaged wire may break when bent.

In high-frequency systems with alternating current, the situation is complicated by the appearance of the skin effect - the current is distributed unevenly, but mainly in the surface layer of the conductor. In such wires, any minor defect in the core can damage the equipment.

When it comes to significant volumes of work, it is better not to take risks and use special devices. Damage to the conductor can cause a fire, cause equipment failure, or cause electric shock.

Types of electrical installation devices

The variety of instruments can be classified according to the following criteria:

- method of removing insulation;

- volumes of work performed;

- process automation.

The insulating shell can be removed in two ways: thermal and mechanical.

The first option is only valid for thin, low-power conductors used in communication devices, audio equipment and electronics operating at a voltage of about 5 volts.

Professional methods are exclusively mechanical stripping. The operation of the tools is based on one of the principles of removing the protective coating:

- Cutting. The tip cuts through the insulating layer in a circle, leaving the current-carrying conductors without damage.Afterwards, part of the cut covering is removed from the wire.

- Gap. The insulation is clamped and, with force, literally torn off the conductor.

Based on the expected volume of work performed, all tools can be divided into two groups:

- household;

- professional.

Some people include an electrician's knife in the first category. However, such a tool is invariably present in the arsenal of a professional. The knife is often used in everyday life due to its affordability and ease of use.

The most popular among electrical installers are strippers. Professional tools for quick cable stripping come in three types: manual, semi-automatic and automatic.

In addition to the general classification, devices may differ in purpose. If universal tools or devices used exclusively for internet wires or electrical cables. The diameter of the stripped wire may also differ; the range of values is about 4-40 mm.

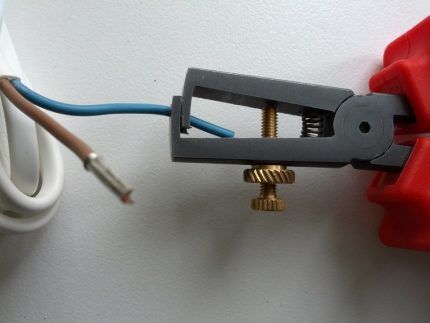

Nippers or pliers: nuances of use

A proven tool that works to break. The working principle of the cutters is simple. Using a screw, select the desired diameter of the wire, then grab the cable, twist it a little in a circle and tighten the insulating coating.

Expensive models of tongs are made with insulated handles made of high-quality steel. Some pliers strip even the thinnest wires without breaking.

Additional advantages of wire cutters include:

- reliability;

- durability;

- ability to work in hard-to-reach areas;

- stripping live wires.

Disadvantages of wire cutters: the inability to choose the length of removal of the insulating layer, the need to constantly reconfigure the screw when stripping wires of different diameters.

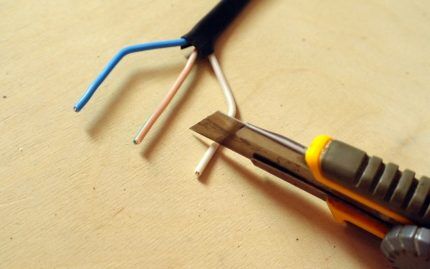

Electrician's knife - a traditional tool

A knife with a curved blade simplifies the work and speeds up the stripping process. There are several types of such devices.

Features of using the device

An electrician's knife is more suitable for stripping flat cables. Experienced craftsmen will easily remove the insulation from round wires, but the ease of use will be less.

Removing the protective shell using a knife must be done with gloves to avoid injury. This is especially true when stripping cables manufactured in accordance with GOST. The insulation thickness of such a conductor is much greater than that of a wire according to specifications, and it fits more tightly to the cores, which complicates the work.

The braid is removed with light movements, cutting the insulation away from you.

The main advantages of using knives:

- affordable price;

- availability of models with an insulated handle;

- practicality - the knife is suitable for wires of different diameters.

The main disadvantage is the duration of work. Stripping large cross-section cables is quite labor-intensive. In addition, with little experience there is a risk of damage to the cores.

Variety of electrician knives

There are three options for electrician knives.They differ from each other in the shape of the blade and the type of tip.

Knife with heel. A device with a short wedge concave inward. A “heel” is soldered perpendicular to the blade, limiting the depth of the cut.

It is better to use a plow tool for wires with hard conductors; a knife removes the soft encircling sheath worse.

Knife with beak. A tool with a rounded blade. This knife has a very smooth bend, unlike the “heel”. The specific shape of the wedge complicates the work; the device is more often used by experienced craftsmen.

Knife with hook. This tool is capable of transverse cutting and longitudinal cutting of cables. The wire is fixed at the top with a bracket, and a sharp fang cuts through the insulation.

This model is universal and suitable for processing most types of cables. The device is popular among professional electricians.

Evaluation of instrument quality parameters

When choosing a knife for stripping the insulating layer, you must follow a number of rules.

Primary requirements:

- It is better to use a knife with a small blade. The tool will be convenient to use in a limited space (cabinet, panel).

- The blade should be made of durable steel - such metal retains its sharpness longer.

- It is better to choose a straight edge - this will simplify the cutting of double-insulated wires.

You need to pay attention to the sharpening of the blade. It should not be too sharp, otherwise it is easy to get hurt when working.

Some tools have an insulated handle. The maximum voltage that the knife can withstand is indicated on the device itself.

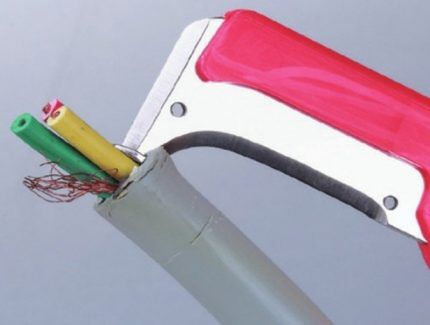

Stripper - ease of use

The best and most popular wire stripper that makes your work process as easy as possible. The instruments are presented in a wide range of models.

How different models work

The mechanism of action is based on processing the cable with two movable knives having a semicircular shape. The cut gauge is adjusted to the wire cross-section, ensuring the accuracy of the notch and the absence of damage to the metal core.

Depending on the automation of the process, there are three types of strippers:

- mechanical;

- semi-automatic;

- auto.

Manual stripper. The insulation stripper has a simple design and is used for stripping individual wires.

Working with a manual stripper is not difficult. General scheme for removing insulation:

- Determine the diameter of the wire.

- Select the appropriate hole on the lips of the device.

- Bite the cable by pressing the handles.

- Remove the braid from the wire by moving the stripper in a circle.

If you choose a socket with a smaller diameter than the wire cross-section, there is a risk of damaging the wire. If a larger hole is used, the braid will not be removed.

Pros of a manual stripper:

- compact size and light weight;

- possibility of crimping the tip;

- the presence of several gaps for wires - usually up to seven with a range of values 0.25-2.5 mm.

Semi-automatic stripper. This option is more convenient for large volumes of work. The semi-automatic unit is equipped with a mechanism that does not require turning the stripper around the wire.

Auto. The tool simplifies the work as much as possible. The user does not need to select the diameter of the wire cross-section. The device has one socket, the size of which automatically adjusts to the installed cable.

The stripper is suitable for stripping wire insulation with a cross section of 0.2-6 mm.

Most automatic strippers have advanced functionality. In addition to the direct task, they are able to perform:

- crimping of tips;

- cutting the ends of the wire;

- twisting of multi-core cables.

The automatic stripper is capable of stripping wires with single and double insulation. In one pass, the tool will remove only the top shell. To remove the lower braid, the manipulations must be repeated.

Stripper selection options

It is necessary to purchase a tool based on the specifics of the activity. Before going to the store, you must compare the following criteria:

- scope of application – professional or household;

- volumes of work – regular or periodic use;

- tool skills;

- purchase budget.

For professional electromechanics, it is definitely better to choose semi-automatic or automatic devices designed for stripping a large number of cables. The high price of the devices is justified by the speed and convenience of work.

A home craftsman can “enrich” his arsenal of tools with a hand stripper. If you do not have the skills to work with electrical wiring, then it is better to choose a semi-automatic device - the risk of cutting the cores is minimized.

Preference should be given to trusted manufacturers who guarantee the safety of materials and the durability of the tool. It is better to avoid cheap models made of low-quality alloys and with a plastic body.

You can read more about how to choose a stripper in this material.

Alternatives: side cutters and pliers

By using some tools for purposes other than their intended purpose, it is quite possible to remove the insulating wrapping. Popular alternatives to professional tools: side cutters and pliers.

Side cutters. The device is designed for cutting small-diameter wires, as well as for trimming plastic and metal elements when performing installation and repair work.

When using side cutters to clean insulation, you must control the pressing force so as not to damage the core.

For processing wires, pliers with precision holes of various diameters are suitable.A universal tool is in demand when installing wiring.

These pliers allow you to:

- grab and bend wire;

- cut medium hard wire;

- carry out crimping of contact sleeves;

- remove insulation.

The number of holes determines the functionality of the tool; usually pliers are designed for processing wires of 3-6 standard sizes.

You must work with pliers carefully. If you do not calculate the clamping force, you can easily damage the core.

Choosing a stripping method for different wires

The complexity of removing insulation is largely determined by the type of wire. When choosing a tool, you should consider the cable features:

- Coaxial wire. When removing double insulation, work is carried out in two stages. The top layer can be removed thermally, and the bottom layer can be removed using a stripper. The cores of such a cable are very fragile and thin, so they are easily damaged.

- Cable with fluoroplastic coating. Heat-resistant insulation that can only be removed mechanically. An electrician's knife or stripper will do.

- Enameled wire. If the cross-section is less than 0.2 sq. mm, then you need to resort to the thermochemical method using a soldering iron and vinyl chloride tape. The wire is placed on the tape and passed along the cable with a soldering iron - the released chlorine promotes the “removal” of the enamel sheath from the wire.

When choosing a tool, you need to take into account the diameter of the wire the device is designed for, as well as the material used to make the handle.

If it is necessary to process electrical cables, it is necessary to select strippers with a handle made of dielectric material.

The coating protects against voltages up to 1000 W.

Conclusions and useful video on the topic

A variety of tools for stripping wires and cables, comparison of strippers:

The choice of a tool should be based on the upcoming conditions of its use and the need for additional functionality. The main thing is that the device ensures compliance with two main requirements: it removes insulation without damaging the conductors and meets the declared dielectric characteristics.

If there is any doubt about the second, then all work is carried out exclusively with the voltage removed.

What tools do you use to strip wires? Please share your own experience with our site visitors. Leave your comments in the block below. There you can ask questions about the topic of the article.

No matter how many years I’ve lived, I still never cease to be amazed. There are so many different special tools that we have never heard of.

For those who do minimal work with electrical equipment (for example, only minor repairs at home or in the country), practical advice: use a dull knife to remove insulation. It will cut vinyl chloride anyway, but the chances of damaging the core are much less. This is especially true if you have old aluminum wiring in your house - the aluminum at the cut site breaks immediately.